• •

郑文杰1( ), 杨景轩1,2(

), 杨景轩1,2( ), 孙刚3, 鲍鹏飞4, 丛有祥4, 郝晓刚1,2

), 孙刚3, 鲍鹏飞4, 丛有祥4, 郝晓刚1,2

收稿日期:2025-11-13

修回日期:2025-12-26

出版日期:2026-01-21

通讯作者:

杨景轩

作者简介:郑文杰(2001—),男,硕士研究生,2317279936@qq.com

基金资助:

Wenjie ZHENG1( ), Jingxuan YANG1,2(

), Jingxuan YANG1,2( ), Gang SUN3, Pengfei BAO4, Youxiang CONG4, Xiaogang HAO1,2

), Gang SUN3, Pengfei BAO4, Youxiang CONG4, Xiaogang HAO1,2

Received:2025-11-13

Revised:2025-12-26

Online:2026-01-21

Contact:

Jingxuan YANG

摘要:

改善两相的流动和传热特性是提升造粒塔性能的关键。本文采用计算颗粒流体力学方法研究了硬脂酸在旋流式并流冷却造粒塔和常规逆流组合塔中的传热和造粒特性。结果表明:旋流塔中全部液滴降温至凝固点所需要的高度大约是常规塔的一半。颗粒在旋流塔内平均停留时间为5.3 s,常规塔的对应值为8.5 s,这意味着前者的生产效率更高。相较于常规塔,旋流式造粒塔在大部分区域内显示出更优的颗粒温度分布均匀性,这表明旋转并流工艺有助于实现更均匀的液滴凝固过程。旋流塔具有以上优势的原因在于入塔气体因旋转形成更高的流速,进而使气固湍动程度增强和对流传热系数提高。此外,气流旋转形成的离心力场促使液滴向塔壁迁移,存在黏壁风险,但迁移过程也是对流传热最强的阶段,合理调控流场可消除风险。

中图分类号:

郑文杰, 杨景轩, 孙刚, 鲍鹏飞, 丛有祥, 郝晓刚. 旋流式冷却造粒塔的优势与风险分析[J]. 化工学报, DOI: 10.11949/0438-1157.20251267.

Wenjie ZHENG, Jingxuan YANG, Gang SUN, Pengfei BAO, Youxiang CONG, Xiaogang HAO. Advantages and risks of swirling cooling granulation towers[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251267.

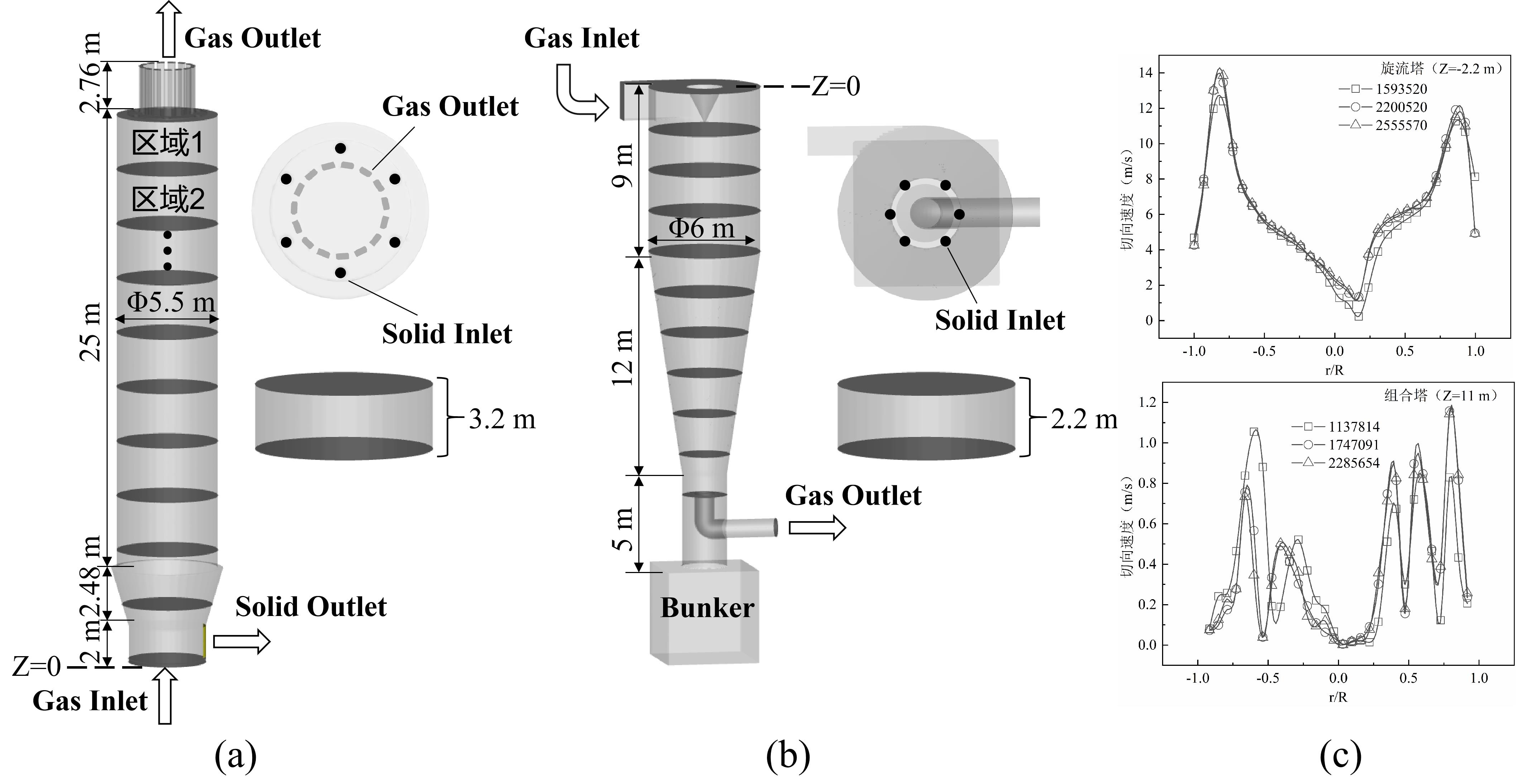

图1 造粒塔的几何模型、边界条件及切向速度径向分布:(a)组合塔,(b)旋流塔,(c)切向速度随径向位置的变化

Fig.1 Geometric model, boundary conditions, and variation of tangential velocity with radial position in the granulation tower: (a)combined tower, (b)swirling tower, (c)variation of tangential velocity with radial position

| 温度/K | 密度/(kg·m-3) | 热导率/(W·(m·K)-1) | 比热容/(kJ·(kg·K)-1) | 熔化热/(kJ·kg-1) | 粒径 /mm | 速率/(m·s-1) | 凝固点/K | 质量流量/(kg·s-1) |

|---|---|---|---|---|---|---|---|---|

| 429.86 | 880[ | 0.3[ | 1.987[ | 192.47[ | 0.55[ | 8 | 325[ | 4 |

表1 颗粒计算所用参数

Table 1 Parameters used in Particle calculation

| 温度/K | 密度/(kg·m-3) | 热导率/(W·(m·K)-1) | 比热容/(kJ·(kg·K)-1) | 熔化热/(kJ·kg-1) | 粒径 /mm | 速率/(m·s-1) | 凝固点/K | 质量流量/(kg·s-1) |

|---|---|---|---|---|---|---|---|---|

| 429.86 | 880[ | 0.3[ | 1.987[ | 192.47[ | 0.55[ | 8 | 325[ | 4 |

温度 /K | 密度 /(kg·m-3) | 黏度 /(Pa·s) | 热导率 /(W·(m·K)-1) | 比热容 /(kJ·(kg·K)-1) | 进气量 /(m3·s-1) |

|---|---|---|---|---|---|

| 300 | 1.166 | 1.84×10-5 | 0.026 | 1.005 | 40 |

表2 空气计算所用参数

Table 2 Parameters used in air calculation

温度 /K | 密度 /(kg·m-3) | 黏度 /(Pa·s) | 热导率 /(W·(m·K)-1) | 比热容 /(kJ·(kg·K)-1) | 进气量 /(m3·s-1) |

|---|---|---|---|---|---|

| 300 | 1.166 | 1.84×10-5 | 0.026 | 1.005 | 40 |

| [1] | 孔亦周. 高塔造粒技术在复合肥生产中的应用研究进展[J]. 生态产业科学与磷氟工程, 2025, 40(10): 82-87. |

| Kong Y Z. Research progress on the application of high tower granulation technology in the production of compound fertilizers[J]. Eco-industry Science & Phosphorus Fluorine Engineering, 2025, 40(10): 82-87. | |

| [2] | 沈立, 王垚森. 熔体沥青高塔造粒工艺研究[J]. 工程与建设, 2024, 38(5): 1134-1137, 1145. |

| Shen L, Wang Y S. Research on high tower granulation technology of melt asphalt[J]. Engineering and Construction, 2024, 38(5): 1134-1137, 1145. | |

| [3] | 谷长超, 周桂娟. 造粒塔内气固两相流动的数值研究[J]. 石油化工设计, 2024, 41(4): 30-34, 79. |

| Gu C C, Zhou G J. Numerical study on gas-solid two-phase flow in prill towers[J]. Petrochemical Design, 2024, 41(4): 30-34, 79. | |

| [4] | 冯留海, 赵凡, 刘美丽, 等. 喷嘴径向位置对喷雾造粒塔流动特性的影响[J]. 石油学报(石油加工), 2016, 32(5): 1013-1019. |

| Feng L H, Zhao F, Liu M L, et al. Effect of nozzle position on the flow behavior in a spray tower[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2016, 32(5): 1013-1019. | |

| [5] | 齐刚, 董瑞伟, 侯明, 等. 旋转式造粒喷头制造技术改进及应用[J]. 化工进展, 2020, 39(S1): 39-42. |

| Qi G, Dong R W, Hou M, et al. Manufacturing technology improvement and application for rotating urea prilling bucket[J]. Chemical Industry and Engineering Progress, 2020, 39(S1): 39-42. | |

| [6] | 刘孝弟, 朱余乐, 吕俊复, 等. 塔式尿素造粒粒径分析[J]. 清华大学学报(自然科学版), 2016, 56(6): 592-597. |

| Liu X D, Zhu Y L, Lü J F, et al. Drop diameters during urea prilling[J]. Journal of Tsinghua University (Science and Technology), 2016, 56(6): 592-597. | |

| [7] | 祝妍妮, 王维, 孙闫晨昊, 等. 基于单液滴蒸发的离心喷雾干燥数值模拟[J]. 化工进展, 2024, 43(4): 1700-1710. |

| Zhu Y N, Wang W, Sun Y C H, et al. Numerical simulation of centrifugal spray drying based on single-droplet evaporation[J]. Chemical Industry and Engineering Progress, 2024, 43(4): 1700-1710. | |

| [8] | 唐珂, 段虎生, 徐美萍. 一种中密度超高强度陶粒支撑剂的制备方法: CN111960807A[P]. 2020-11-20. |

| Tang K, Duan H S, Xu M P. A preparation method for medium-density ultra-high strength ceramsite proppant: CN111960807A[P]. 2020-11-20. | |

| [9] | 尹俊东, 杨建民, 杨富春. 一种熔体法复合肥造粒用塔底进风结构及造粒塔: 222969766U[P]. 2025-06-13. |

| Yin J D, Yang J M, Yang F C. A bottom-inlet air structure for melt compound fertilizer granulation and granulation tower: 222969766U[P]. 2025-06-13. | |

| [10] | Lou T, Zhao B T, Zhang Z X, et al. Separation of exhaust gas pollutants from urea prilling process with gasified biochar for slow-release fertilizer: adsorption characteristics, process improvement, and economic assessment[J]. Separations, 2025, 12(7): 173. |

| [11] | Carles H, Yohana E, Tauviqirrahman M, et al. Heat and mass transfer analysis of tea particles in low-temperature spray dryers using a combination of swirl and co-current flows[J]. Case Studies in Thermal Engineering, 2025, 71: 106116. |

| [12] | Zbiciński I, Piątkowski M. Spray drying tower experiments[J]. Drying Technology, 2004, 22(6): 1325-1349. |

| [13] | 蒋中昕. 热风分配器、喷雾干燥装置及喷雾干燥方法: 118882331A[P]. 2024-11-01. |

| Jiang Z X. Hot air distributor, spray drying apparatus, and spray drying method: 118882331A[P]. 2024-11-01. | |

| [14] | 余承焰, 李倩, 涂小进, 等 一种喷雾干燥造粒装置 : 221999797U[P]. 2024-11-15. |

| Yu C Y, Li Q, Tu X J, et al. A spray drying granulation apparatus: 221999797U[P]. 2024-11-15. | |

| [15] | 袁远, 袁诗霖. 一种喷雾干燥器: 222969186U[P]. 2025-06-13. |

| Yuan Y, Yuan S L. A spray dryer: 222969186U[P]. 2025-06-13. | |

| [16] | Zhang N, Pan X E, Yang J X, et al. Simulation of gas-solids heat transfer in cyclone pyrolyzer using CFD-DEM model[J]. Particuology, 2024, 85: 155-166. |

| [17] | Zhang N, Pan X E, Yang J X, et al. A compensation strategy to improve gas-solid heat transfer without sacrificing kinetic energy in a cyclone pyrolyzer[J]. Energy, 2025, 324: 135952. |

| [18] | 张金廷. 脂肪酸及其深加工手册[M]. 北京: 化学工业出版社, 2002: 96-101. |

| Zhang J T. Handbook of Fatty Acids and Their Deep Processing[M]. Beijing: Chemical Industry Press, 2002: 96-101. | |

| [19] | Wu Y Y, Shi X G, Liu Y C, et al. 3D CPFD simulations of gas-solids flow in a CFB downer with cluster-based drag model[J]. Powder Technology, 2020, 361: 400-413. |

| [20] | Chen Q, Hu J H, Yang H P, et al. Experiment and simulation of the pneumatic classification and drying of coking coal in a fluidized bed dryer[J]. Chemical Engineering Science, 2020, 214: 115364. |

| [21] | Loha C, Chattopadhyay H, Chatterjee P K. Three dimensional kinetic modeling of fluidized bed biomass gasification[J]. Chemical Engineering Science, 2014, 109: 53-64. |

| [22] | Snider D M, Clark S M, O'Rourke P J. Eulerian–Lagrangian method for three-dimensional thermal reacting flow with application to coal gasifiers[J]. Chemical Engineering Science, 2011, 66(6): 1285-1295. |

| [23] | Andrews M J, O'Rourke P J. The multiphase particle-in-cell (MP-PIC) method for dense particulate flows[J]. International Journal of Multiphase Flow, 1996, 22(2): 379-402. |

| [24] | Zhu L T, Chen X Z, Luo Z H. Analysis and development of homogeneous drag closure for filtered mesoscale modeling of fluidized gas-particle flows[J]. Chemical Engineering Science, 2021, 229: 116147. |

| [25] | Liu B, Li Y W. Simulation of effect of internals on particulate mixing and heat transfer in downer reactor using discrete element method[J]. Powder Technology, 2016, 297: 89-105. |

| [26] | Zheng Q, Yang J X, Lian W H, et al. Multi-fluid Eulerian simulation of binary particles mixing and gas–solids contacting in high solids-flux downer reactor equipped with a lateral particle feeding nozzle[J]. Chinese Journal of Chemical Engineering, 2021, 35: 152-162. |

| [27] | Li J, Mason D J. A computational investigation of transient heat transfer in pneumatic transport of granular particles[J]. Powder Technology, 2000, 112(3): 273-282. |

| [28] | 冯留海, 卜亿峰, 祝岩青, 等. 网格划分对喷雾造粒塔数值模拟精度的影响[J]. 石油学报(石油加工), 2019, 35(3): 502-508. |

| Feng L H, Bu Y F, Zhu Y Q, et al. Effect of grid generation on simulation accuracy of spray granulation tower[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2019, 35(3): 502-508. | |

| [29] | Okada S, Ohsaki S, Nakamura H, et al. Estimation of evaporation rate of water droplet group in spray drying process[J]. Chemical Engineering Science, 2020, 227: 115938. |

| [30] | Du J L, Zhang L J, Wu F, et al. CFD simulation of a novel downer with swirling blade nozzle: Field synergy characteristics, heat transfer contribution and structure optimization analysis[J]. Fuel, 2024, 375: 132549. |

| [31] | Zhang B P, Yang J X, Zheng Q, et al. Centrifugal force caused high-density rotating downward quasi-plug flow in cyclone reactors[J]. Chemical Engineering Science: X, 2021, 11: 100101. |

| [32] | 王喜忠, 于才渊, 周才君. 喷雾干燥[M]. 2版. 北京: 化学工业出版社, 2003: 60-72. |

| Wang X Z, Yu C Y, Zhou C J. Spray Drying[M]. 2nd ed. Beijing: Chemical Industry Press, 2003: 60-72. | |

| [33] | 周学永, 高建保. 喷雾干燥黏壁的原因与解决途径[J]. 应用化工, 2007, 36(6): 599-602. |

| Zhou X Y, Gao J B. Reasons for wall sticking during spray drying and countermeasures[J]. Applied Chemical Industry, 2007, 36(6): 599-602. |

| [1] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 基于CPFD方法的U3O8氢还原流化床反应器数值模拟[J]. 化工学报, 2024, 75(9): 3133-3151. |

| [2] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [3] | 邓爱明, 何玉荣, 唐天琪, 胡彦伟. 导流板对喷雾流化床内颗粒生长过程影响的模拟[J]. 化工学报, 2024, 75(8): 2787-2799. |

| [4] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [5] | 朱兵国, 何吉祥, 徐进良, 彭斌. 冷却条件下渐扩/渐缩管内超临界压力二氧化碳的传热特性[J]. 化工学报, 2023, 74(3): 1062-1072. |

| [6] | 李昀, 曹杰, 华夏, 吴慧英. 短程逆流式微通道内的流动沸腾传热特性实验研究[J]. 化工学报, 2023, 74(11): 4501-4514. |

| [7] | 任盼锋, 海润泽, 李奇, 李文彬, 余国琮. 流化床液固两相传质过程的模拟研究进展[J]. 化工学报, 2022, 73(1): 1-17. |

| [8] | 张瑞, 钟静, 林森, 于建国. 盐湖铝系提锂吸附剂成型条件的影响研究[J]. 化工学报, 2021, 72(12): 6291-6297. |

| [9] | 李光晓,刘塞尔,苏远海. 微尺度内液-液传质及反应过程强化的研究进展[J]. 化工学报, 2021, 72(1): 452-467. |

| [10] | 田济阳, 邹源佐, 蒲源, 王丹. 亚临界水耦合冷冻干燥法制备芹菜素纳米分散体[J]. 化工学报, 2020, 71(6): 2768-2779. |

| [11] | 曲洋, 初茉, 朱书全, 张超, 郝成亮, 徐芳. 回转窑内利用液化残渣共热褐煤以抑制其粉化的影响因素分析[J]. 化工学报, 2018, 69(5): 2166-2174. |

| [12] | 祝叶, 管宁, 李栋, 赵孝保, 刘志刚. 不同截面形状超疏水微肋阵内对流换热特性[J]. 化工学报, 2017, 68(1): 63-71. |

| [13] | 魏庆, 姚秀颖, 张永民. 竖直管气固鼓泡流化床传热机理的CPFD模拟[J]. 化工学报, 2016, 67(5): 1732-1740. |

| [14] | 车煜, 田洲, 张瑞, 高宇新, 邹恩广, 王斯晗, 刘柏平. 乙烯气相聚合流化床反应器内Geldart B类和Geldart D类颗粒流动特性的三维数值模拟[J]. 化工学报, 2016, 67(2): 519-529. |

| [15] | 吴君军, 王宏, 朱恂, 廖强, 李俊, 林林. 转盘离心粒化中丝状成粒特性[J]. 化工学报, 2015, 66(7): 2474-2480. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号