化工学报 ›› 2023, Vol. 74 ›› Issue (8): 3457-3471.DOI: 10.11949/0438-1157.20230211

收稿日期:2023-03-09

修回日期:2023-06-25

出版日期:2023-08-25

发布日期:2023-10-18

通讯作者:

陈晓东

作者简介:高燕(1998—),女,硕士研究生,3479471548@qq.com

Yan GAO1( ), Peng WU1, Chao SHANG2, Zejun HU1, Xiaodong CHEN1(

), Peng WU1, Chao SHANG2, Zejun HU1, Xiaodong CHEN1( )

)

Received:2023-03-09

Revised:2023-06-25

Online:2023-08-25

Published:2023-10-18

Contact:

Xiaodong CHEN

摘要:

针对现有磁性琼脂糖微球(MAM)制备技术工艺流程长、重复性差、难以实现规模化及连续化生产等问题,提出了一种基于双流体喷嘴雾化技术的新型磁性琼脂糖微球制备方法;探究了不同雾化条件下,液滴尺寸变化的规律;在优化后的喷雾条件下,成功制备出球形度高、粒径小、磁响应迅速的磁性琼脂糖微球;将筛分后的微球制备成DEAE阴离子交换剂(DEAE-MAM),并以牛血清白蛋白(BSA)为模型蛋白,探究了不同粒径下的DEAE-MAM的蛋白吸附性能。结果表明,在保证水相性质一致的前提下,喷雾条件通过改变气液比影响液滴尺寸,进而影响微球粒径;粒径最小的DEAE-MAM(d32 = 36 μm)离子交换容量最大(192.5 μmol/ml),饱和吸附量最高(150.0 mg/ml)。

中图分类号:

高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471.

Yan GAO, Peng WU, Chao SHANG, Zejun HU, Xiaodong CHEN. Preparation of magnetic agarose microspheres based on a two-fluid nozzle and their protein adsorption properties[J]. CIESC Journal, 2023, 74(8): 3457-3471.

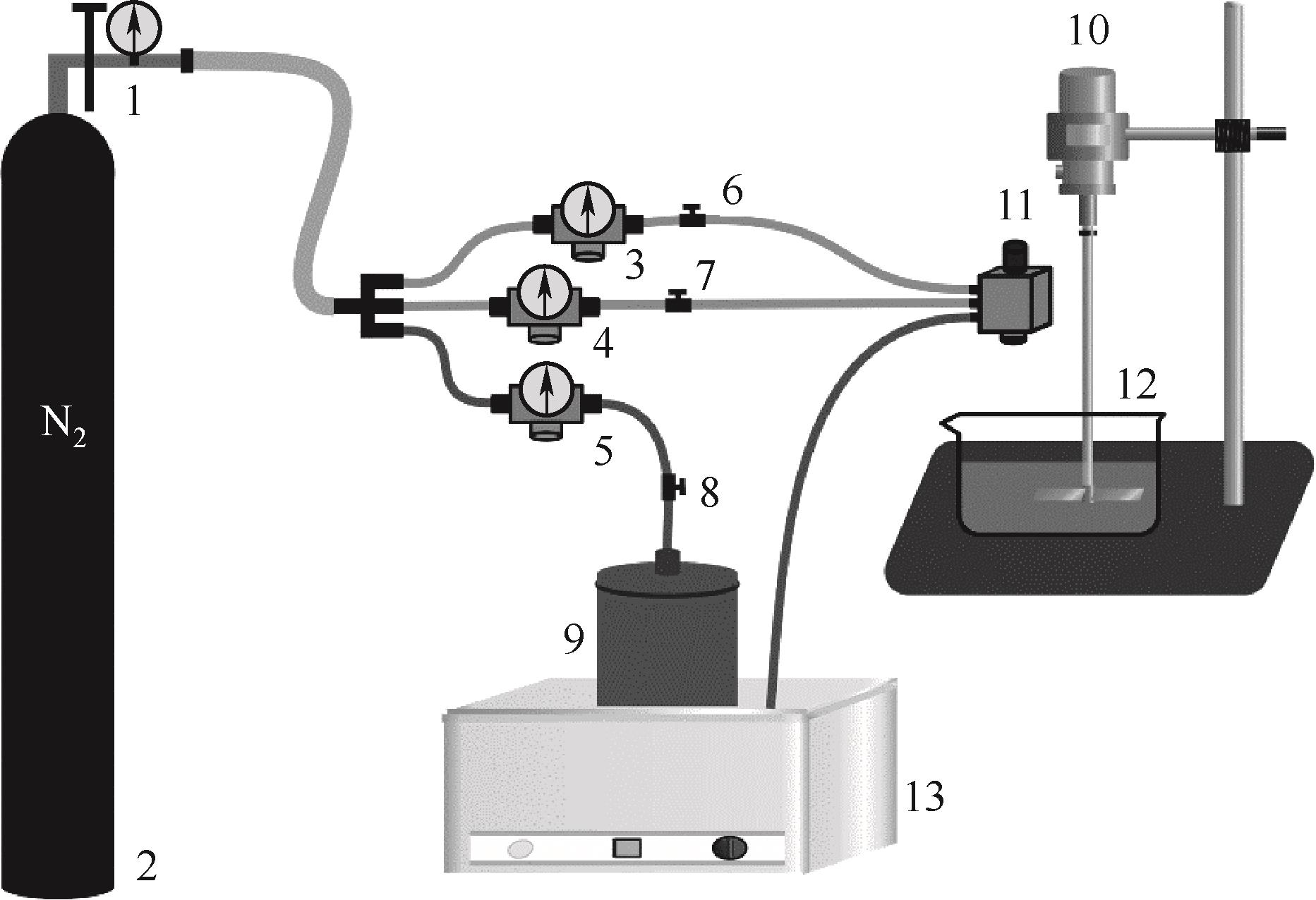

图1 用于制备MAM的喷雾装置1—钢瓶减压阀;2—N2钢瓶;3~5—气路调压阀,对应的气压分别为开枪气压(PS)、雾化气压(PZ)和水相气压(PM);6~8—气路开关;9—料液罐;10—机械搅拌装置;11—双流体喷嘴;12—承接容器(直径18 cm);13—水浴加热装置

Fig.1 Spraying device for preparing MAM1—pressure reducing valve of steel cylinder; 2—N2 cylinder; 3-5—pressure regulating valve for gas pipelines, the corresponding nitrogen pressure is opening pressure (PS), atomization pressure (PZ), and water phase pressure (PM) respectively; 6-8—switches of gas pipelines; 9—liquid tank; 10—mechanical stirring device; 11—two-fluid nozzle; 12—receiving container (diameter 18 cm); 13—water bath heating device

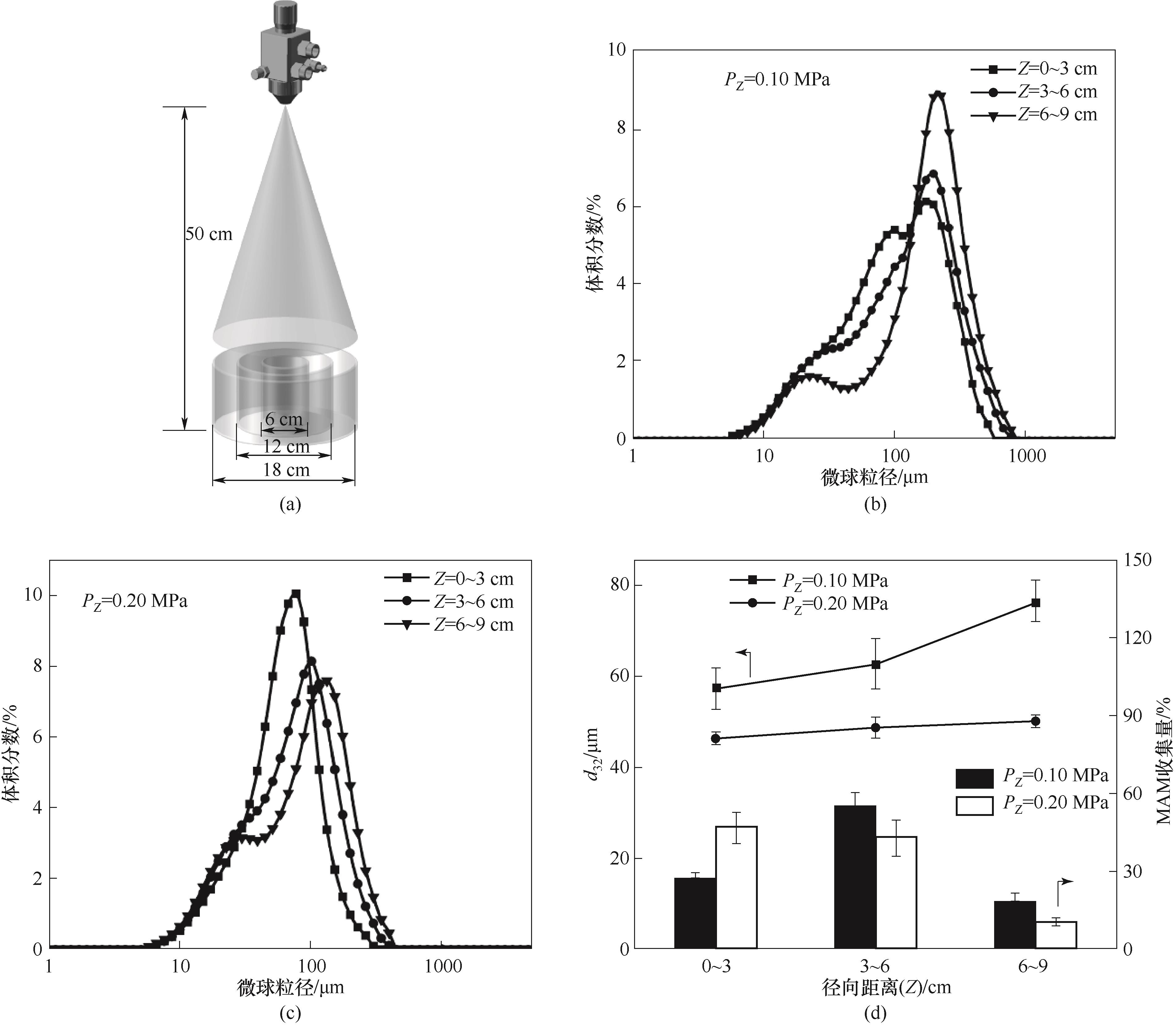

图5 雾化区域对微球粒径的影响(a) 实验示意图;(b),(c) 粒径分布曲线;(d) 不同雾化气压下d32随径向距离的变化及不同区域中MAM收集量的体积分数

Fig.5 Effect of atomization area on particle size of MAM(a) experimental schematic; (b),(c) particle size distribution curves; (d) variation of d32 with radial distanceat differentatomization pressure and volume fraction of MAM collected in different areas

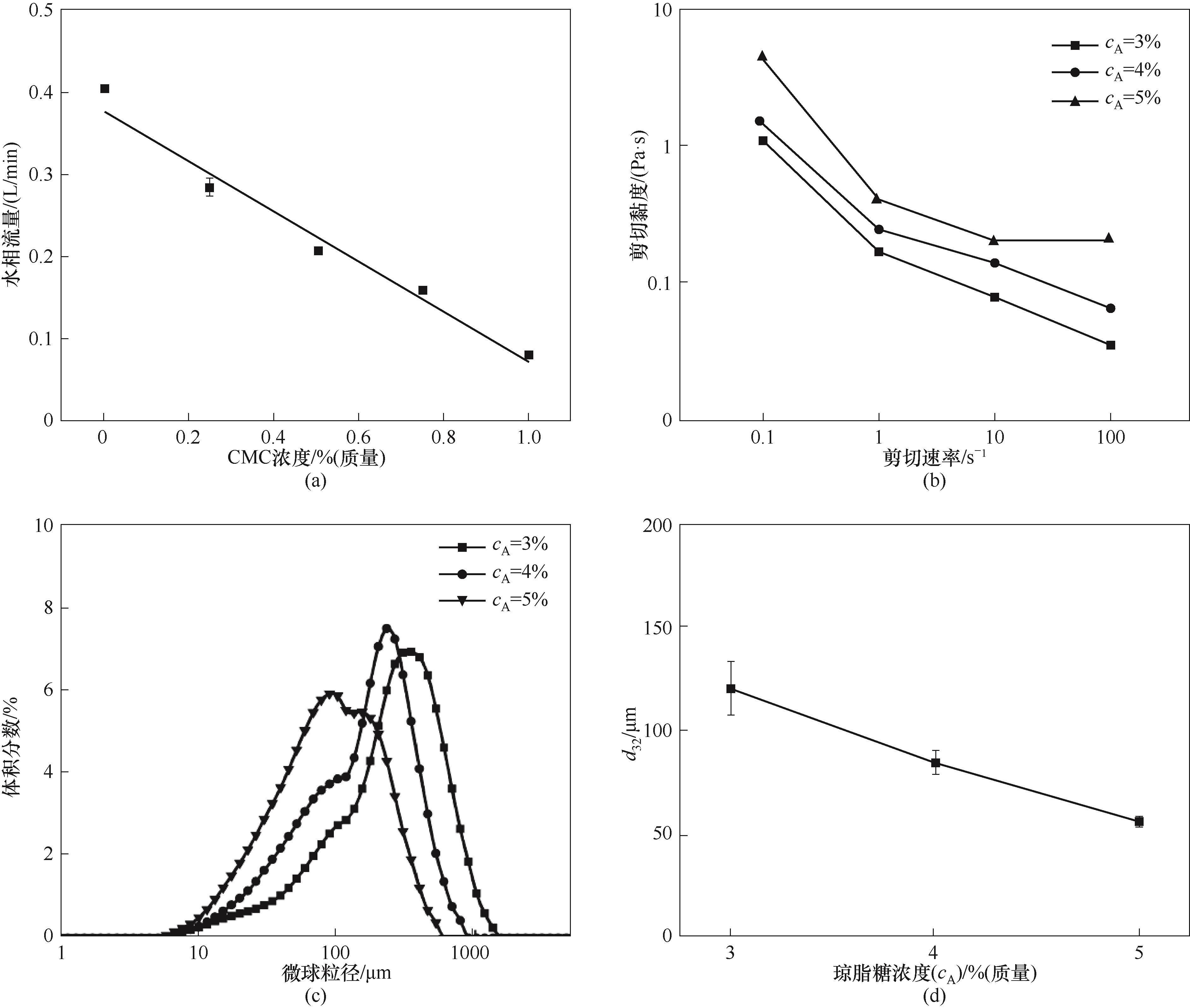

图6 水相黏度对MAM粒径的影响(a) CMC溶液的流量-CMC浓度的关系曲线;(b) 琼脂糖溶液的流变曲线(90℃);(c) 粒径分布曲线;(d) d32随琼脂糖浓度cA的变化

Fig.6 Effect of water phase viscosity on particle size of MAM(a) relationship curve between the flow rate of CMC solution and the concentration of CMC; (b) rheological curves of the agarose solution (90℃); (c) particle size distribution curves; (d) variation of d32 with agarose concentration cA

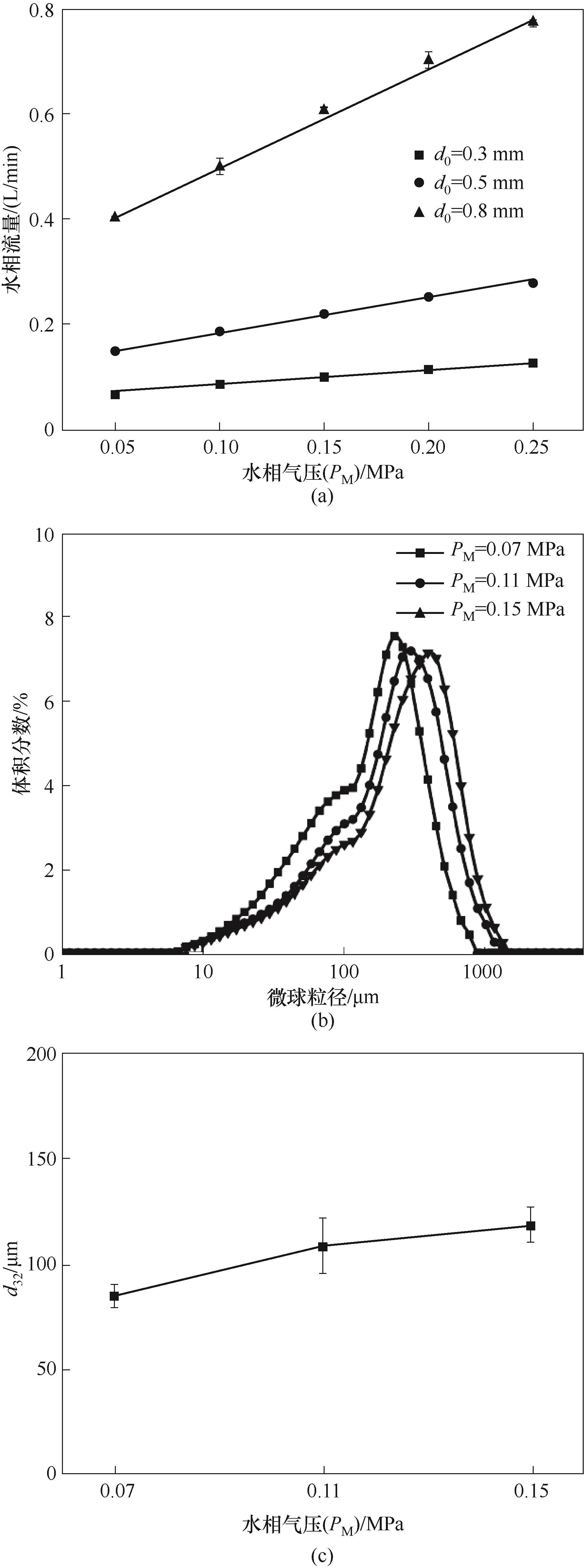

图7 水相气压对MAM粒径的影响(a) 水相流量-水相气压的关系曲线;(b) 粒径分布曲线;(c) d32随水相气压PM的变化

Fig.7 Effect of water phase pressure on particle size of MAM(a) relationship curve between the flow rate of water and the pressure of water phase; (b) particle size distribution curves; (c) variation of d32 with water phase pressure PM

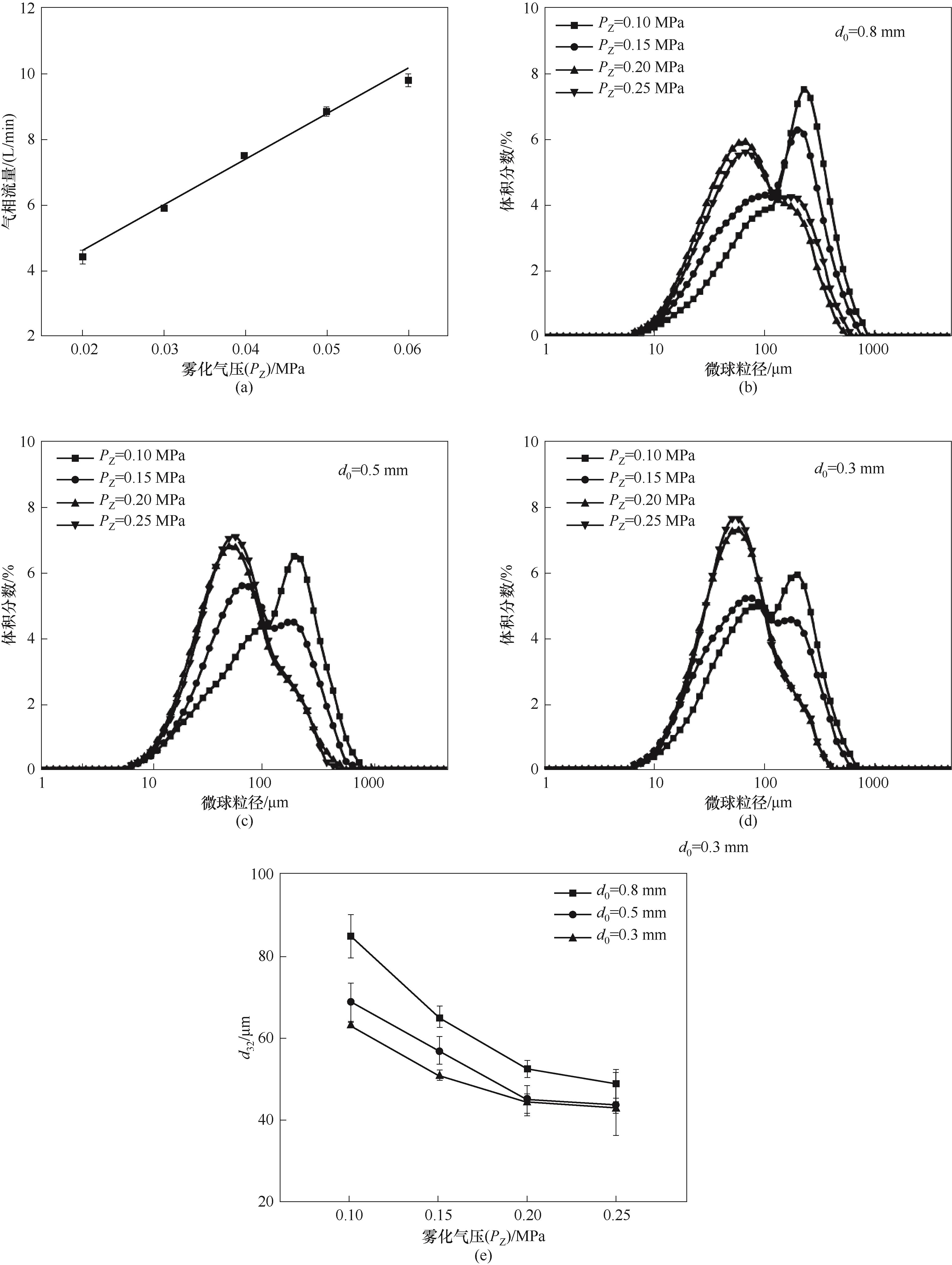

图8 雾化气压对MAM粒径的影响(a) 气相流量-雾化气压的关系曲线;(b)~(d) 粒径分布曲线;(e) 不同喷嘴孔径下 d32随雾化气压的变化

Fig.8 Effect of atomization pressure on particle size of MAM(a) relationship curve between the flow rate of gas and the atomization pressure; (b)-(d) particle size distribution curves; (e) variation of d32 with atomization pressure at different nozzle aperture

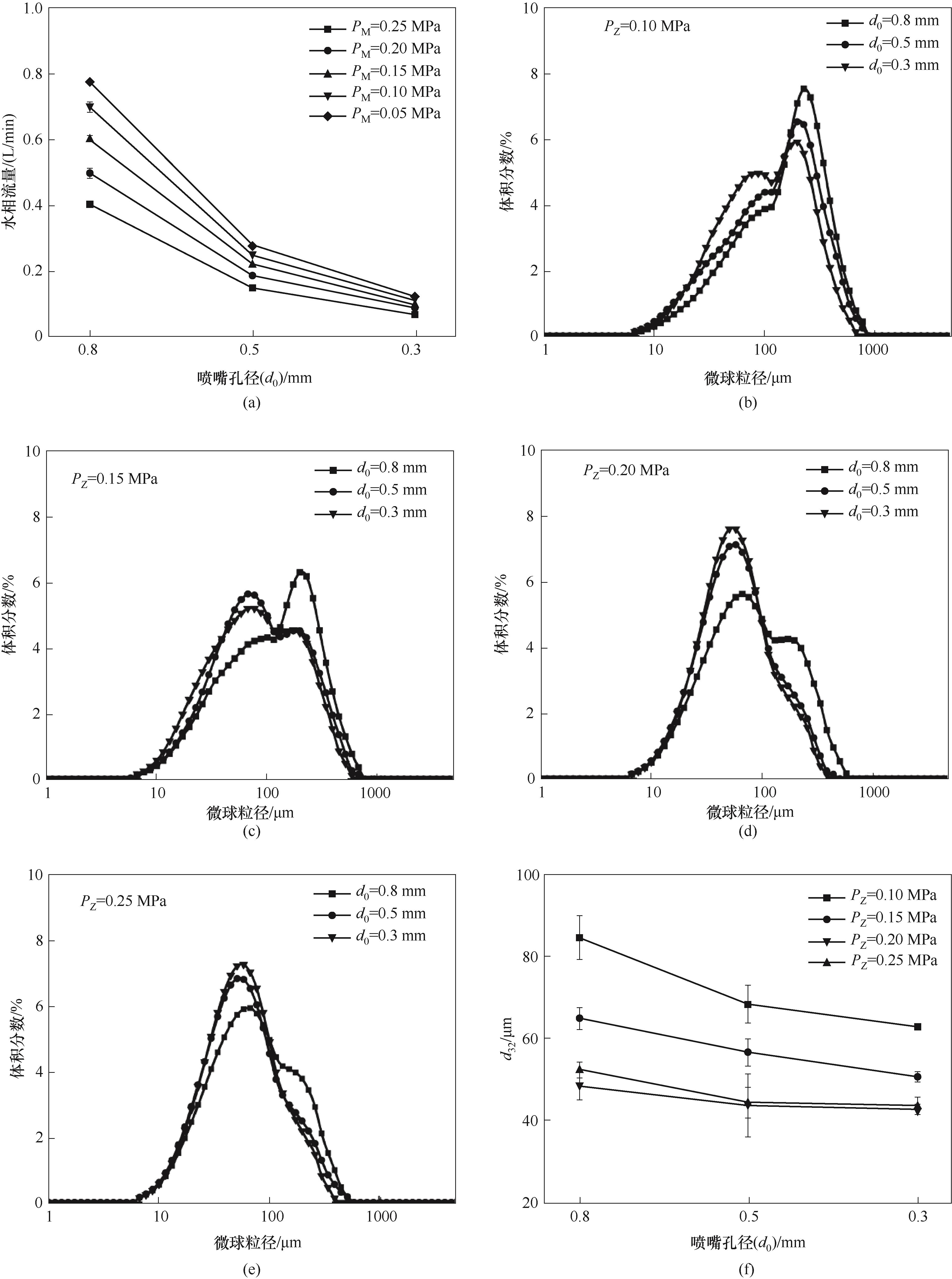

图9 喷嘴孔径对MAM粒径的影响(a) 水相流量-喷嘴孔径的关系曲线;(b)~(e) 粒径分布曲线;(f) 不同雾化气压下 d32随喷嘴孔径的变化

Fig.9 Effect of the bore diameter of the nozzles on particle size of MAM(a) relationship curve between the flow rate of water and the bore diameter of the nozzles; (b)-(e) particle size distribution curves; (f) variation of d32 with the bore diameter of the nozzles at different atomization pressure

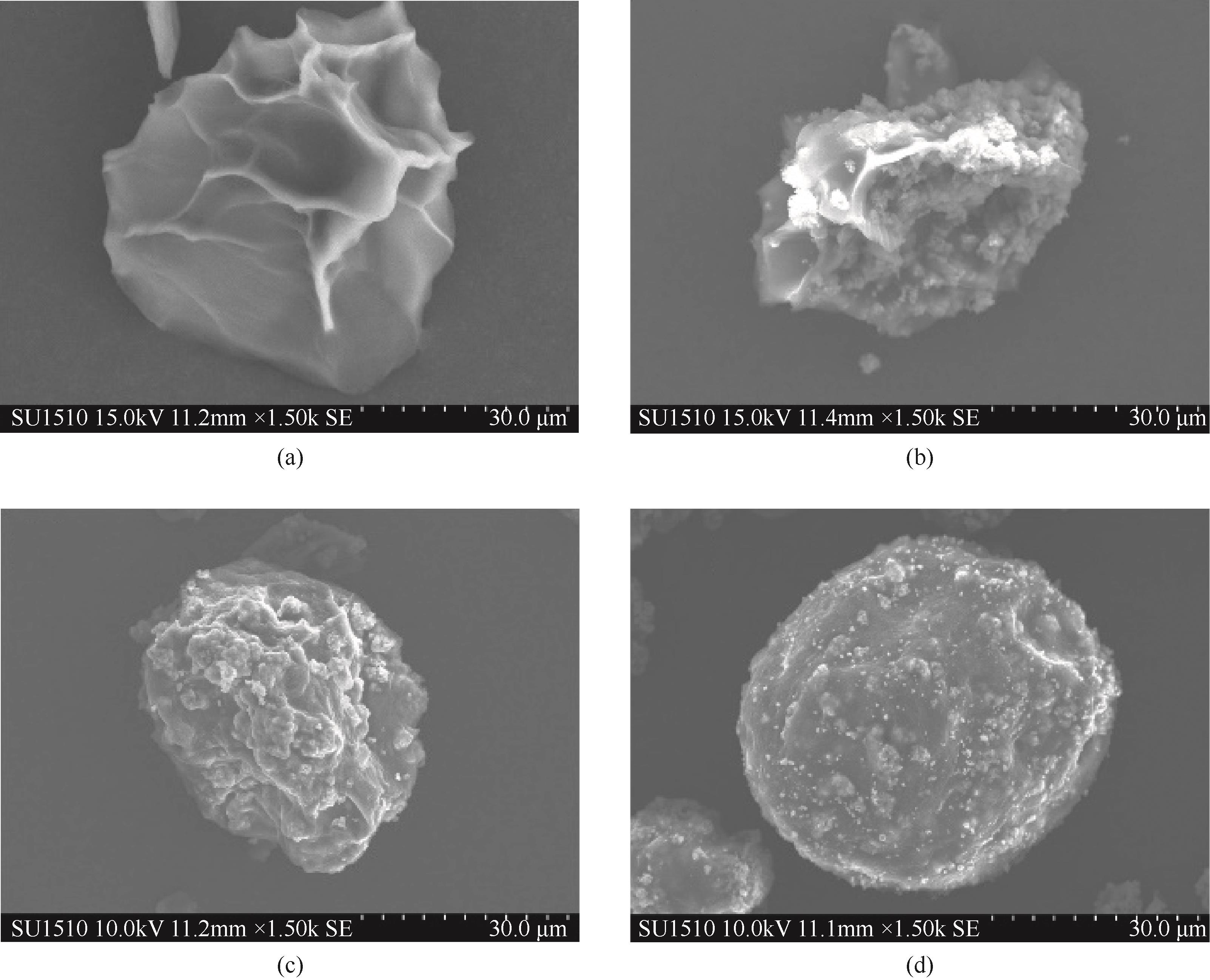

图12 不同冻干方式制备的微球的扫描电子显微镜照片(a) AB,水冷冻干燥;(b) MAM,水冷冻干燥;(c) MAM,叔丁醇冷冻干燥;(d) CL-MAM,叔丁醇冷冻干燥

Fig.12 SEM images of MAM prepared using different freeze-drying methods(a) AB, freeze-drying with water; (b) MAM, freeze-drying with water; (c) MAM, freeze-drying with tert-butyl alcohol; (d) CL-MAM, freeze-drying with tert-butyl alcohol

| DEAE-MAM | 平均粒径d32/μm | E/(μmol/ml) | Qm/(mg/ml) | Kd | R2 |

|---|---|---|---|---|---|

喷雾法(自制) | 36 | 192.5 | 150.0 | 0.0345 | 0.9927 |

| 86 | 148.2 | 143.4 | 0.0348 | 0.9729 | |

| 142 | 136.9 | 121.9 | 0.1029 | 0.9406 | |

| 乳化-冷却法[ | 50 | 100.6 | 129.4 | 0.0245 | 0.9941 |

| 文献[ | — | 168.0 | 109.3 | — | — |

表1 DEAE-MAM对BSA吸附的平衡参数

Table 1 Equilibrium parameters of DEAE-MAM for BSA adsorbtion

| DEAE-MAM | 平均粒径d32/μm | E/(μmol/ml) | Qm/(mg/ml) | Kd | R2 |

|---|---|---|---|---|---|

喷雾法(自制) | 36 | 192.5 | 150.0 | 0.0345 | 0.9927 |

| 86 | 148.2 | 143.4 | 0.0348 | 0.9729 | |

| 142 | 136.9 | 121.9 | 0.1029 | 0.9406 | |

| 乳化-冷却法[ | 50 | 100.6 | 129.4 | 0.0245 | 0.9941 |

| 文献[ | — | 168.0 | 109.3 | — | — |

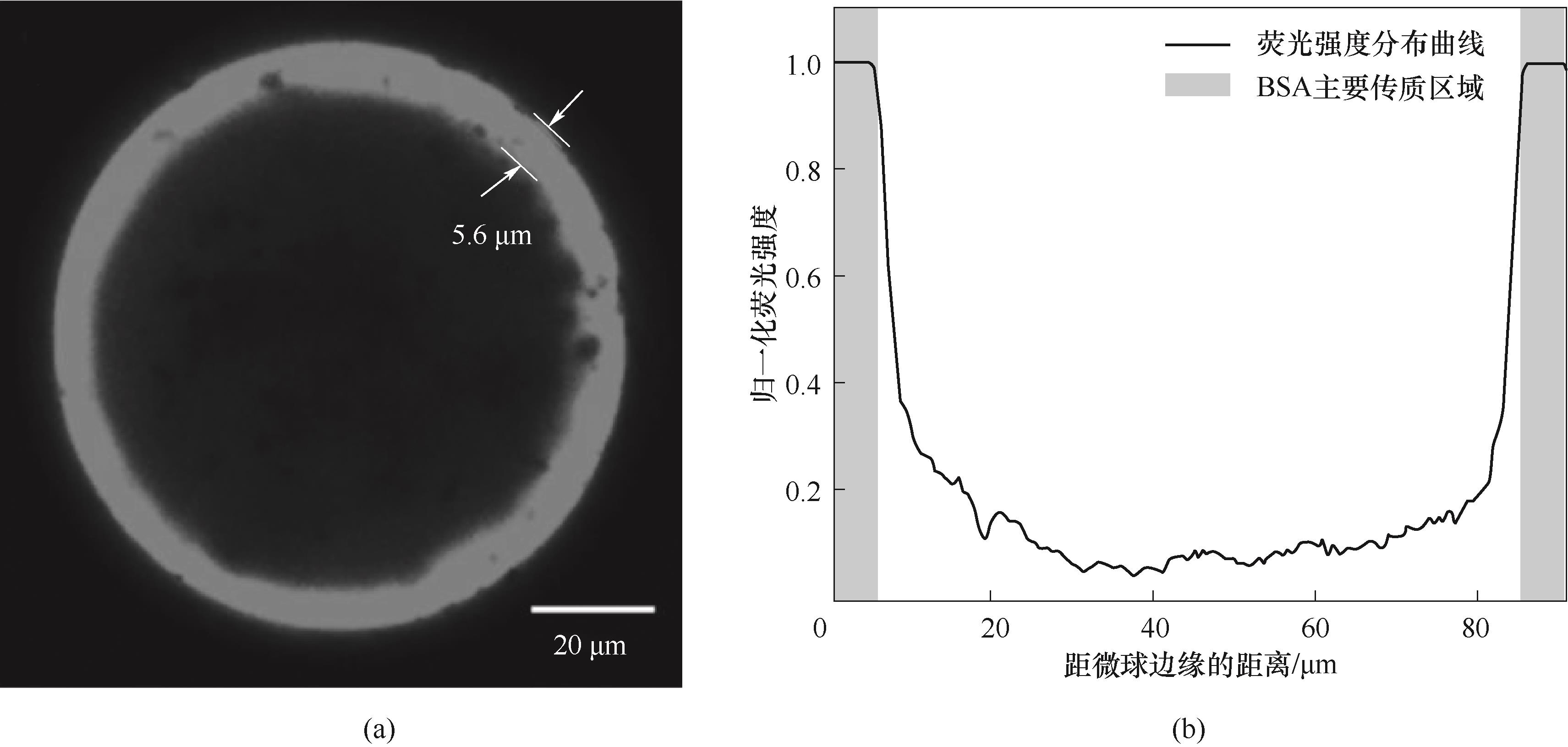

图17 BSA在DEAE-MAM上的分布(a) 激光共聚焦显微镜照片;(b) 荧光强度分布曲线

Fig.17 Distribution of the BSA on DEAE-MAM(a) CLSM image; (b) fluorescence intensity distribution curve

| 1 | Zhao L, Huang Y D, Zhu K, et al. Manipulation of pore structure during manufacture of agarose microspheres for bioseparation[J]. Engineering in Life Sciences, 2020, 20(11): 504-513. |

| 2 | Betancor L, Fuentes M, Dellamora-Ortiz G, et al. Dextran aldehyde coating of glucose oxidase immobilized on magnetic nanoparticles prevents its inactivation by gas bubbles[J]. Journal of Molecular Catalysis B: Enzymatic, 2005, 32(3): 97-101. |

| 3 | Kretzer J W, Lehmann R, Schmelcher M, et al. Use of high-affinity cell wall-binding domains of bacteriophage endolysins for immobilization and separation of bacterial cells[J]. Applied and Environmental Microbiology, 2007, 73(6): 1992-2000. |

| 4 | Kim S Y, Kim Y J, Seong H. Ni-chelated poly(acrylic acid)-grafted magnetic agarose bead for affinity-based separation of proteins[J]. Macromolecular Research, 2021, 29(11): 825-831. |

| 5 | Levison P R, Badger S E, Dennis J, et al. Recent developments of magnetic beads for use in nucleic acid purification[J]. Journal of Chromatography A, 1998, 816(1): 107-111. |

| 6 | Šafařı́k I, Šafařı́ková M. Use of magnetic techniques for the isolation of cells[J]. Journal of Chromatography B: Biomedical Sciences and Applications, 1999, 722(1-2): 33-53. |

| 7 | Tong X D, Sun Y. Application of magnetic agarose support in liquid magnetically stabilized fluidized bed for protein adsorption[J]. Biotechnology Progress, 2003, 19(6): 1721-1727. |

| 8 | 邱广亮, 栗淑媛, 金志兰, 等. 磁性琼脂糖复合微球的制备和性质[J]. 精细化工, 1999, 16(1): 38-41. |

| Qiu G L, Li S Y, Jin Z L, et al. Preparation and characterization of magnetic agarose composite microspheres[J]. Fine Chemicals, 1999, 16(1): 38-41. | |

| 9 | Kim S Y, Seong H. Modulation of physicochemical properties of magnetic agarose microspheres by hydrolysis-suppressive sequential crosslinking[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 630: 127607. |

| 10 | Bengtsson S, Philipson L. Chromatography of animal viruses on pearl-condensed agar[J]. Biochimica et Biophysica Acta, 1964, 79: 399-406. |

| 11 | Sakai S, Hashimoto I, Kawakami K. Usefulness of flow focusing technology for producing subsieve-size cell enclosing capsules: application for agarose capsules production[J]. Biochemical Engineering Journal, 2006, 30(2): 218-221. |

| 12 | Zhou Q Z, Wang L Y, Ma G H, et al. Preparation of uniform-sized agarose beads by microporous membrane emulsification technique[J]. Journal of Colloid and Interface Science, 2007, 311(1): 118-127. |

| 13 | 姚敏, 庄壮, 梁健, 等. 外混合喷嘴液相孔尺寸对雾化性能的影响[J]. 石油化工, 2019, 48(2): 157-162. |

| Yao M, Zhuang Z, Liang J, et al. Effect of liquid-phase pore sizes on the spraying performance varied in outside-atomization nozzles[J]. Petrochemical Technology, 2019, 48(2): 157-162. | |

| 14 | Jeong C S, Lee C Y. Experimental investigation on spray characteristics of twin-fluid nozzle for water mist and its heptane pool fire extinguishing performance[J]. Process Safety and Environmental Protection, 2021, 148: 724-736. |

| 15 | 施智雄, 潘科玮, 平力, 等. 喷嘴雾化参数轨迹图像法测量实验研究[J]. 化工学报, 2020, 71(8): 3527-3534. |

| Shi Z X, Pan K W, Ping L, et al. Research on experimental measurement of spray parameters of nozzle by using trajectory imaging method[J]. CIESC Journal, 2020, 71(8): 3527-3534. | |

| 16 | 滕焕银, 张志朋. 水泥厂增湿塔喷水技术的发展简介[J]. 建材世界, 2022, 43(1): 51-53. |

| Teng H Y, Zhang Z P. Development of water spraying technology for conditioning tower in cement plant[J]. The World of Building Materials, 2022, 43(1): 51-53. | |

| 17 | Barreras F, Lozano A, Barroso J, et al. Experimental characterization of industrial twin-fluid atomizers[J]. Atomization and Sprays, 2006, 16(2): 127-146. |

| 18 | Kemp I C, Hartwig T, Herdman R, et al. Spray drying with a two-fluid nozzle to produce fine particles: atomization, scale-up, and modeling[J]. Drying Technology, 2016, 34(10): 1243-1252. |

| 19 | Stähle P, Schuchmann H P, Gaukel V. Performance and efficiency of pressure-swirl and twin-fluid nozzles spraying food liquids with varying viscosity[J]. Journal of Food Process Engineering, 2017, 40(1): e12317. |

| 20 | Wang P F, Shi Y J, Zhang L Y, et al. Effect of structural parameters on atomization characteristics and dust reduction performance of internal-mixing air-assisted atomizer nozzle[J]. Process Safety and Environmental Protection, 2019, 128: 316-328. |

| 21 | 卢慧丽, 林东强, 姚善泾. 琼脂糖-DEAE离子交换介质的配基密度和孔径对BSA吸附的影响[J]. 化工学报, 2011, 62(11): 3164-3170. |

| Lu H L, Lin D Q, Yao S J. Influences of ligand density and pore size on BSA adsorption on agarose-based DEAE-ion-exchange resins[J]. CIESC Journal, 2011, 62(11): 3164-3170. | |

| 22 | 王宇. 多功能载体固定蛋白A免疫吸附材料的制备及吸附性能研究[D]. 昆明: 云南师范大学, 2019. |

| Wang Y. Preparation of immunosorbent using heterofunctional supports to immobilize protein A and study of its adsorption performance[D]. Kunming: Yunnan Normal University, 2019. | |

| 23 | Shi Q H, Zhou X, Sun Y. A novel superporous agarose medium for high-speed protein chromatography[J]. Biotechnology and Bioengineering, 2005, 92(5): 643-651. |

| 24 | Gad H M, Ibrahim I A, Abdel-baky M E, et al. Experimental study of diesel fuel atomization performance of air blast atomizer[J]. Experimental Thermal and Fluid Science, 2018, 99: 211-218. |

| 25 | 肖彬. 内混式两相流喷嘴的雾化特性研究[J]. 科学技术与工程, 2012, 12(27): 6912-6917. |

| Xiao B. Studies on internal mixing twin fluid atomization characteristics[J]. Science Technology and Engineering, 2012, 12(27): 6912-6917. | |

| 26 | Lorenzetto G E, Lefebvre A H. Measurements of drop size on a plain-jet airblast atomizer[J]. AIAA Journal, 1977, 15(7): 1006-1010. |

| 27 | Han H, Wang P F, Li Y J, et al. Effect of water supply pressure on atomization characteristics and dust-reduction efficiency of internal mixing air atomizing nozzle[J]. Advanced Powder Technology, 2020, 31(1): 252-268. |

| 28 | Chen B, Gao D R, Li Y B, et al. Investigation of the droplet characteristics and size distribution during the collaborative atomization process of a twin-fluid nozzle[J]. The International Journal of Advanced Manufacturing Technology, 2020, 107(3): 1625-1639. |

| 29 | Liu H, Cheng H Y, Dai Y, et al. Atomization characteristics of special-design pneumatic two-fluid nozzles for helicopter main reducers: a numerical and experimental investigation[J]. Aerospace, 2022, 9(12): 834. |

| 30 | Van Drooge D J, Hinrichs W L J, Frijlink H W. Incorporation of lipophilic drugs in sugar glasses by lyophilization using a mixture of water and tertiary butyl alcohol as solvent[J]. Journal of Pharmaceutical Sciences, 2004, 93(3): 713-725. |

| 31 | 张敏, 韩林, 胡月月, 等. 改性琼脂糖微球固定化甘油脱氢酶的研究[J]. 过程工程学报, 2020, 20(5): 591-598. |

| Zhang M, Han L, Hu Y Y, et al. Study of immobilized glycerol dehydrogenase on modified agarose microspheres[J]. The Chinese Journal of Process Engineering, 2020, 20(5): 591-598. | |

| 32 | Wang Y, Wei Y Y, Gao P C, et al. Preparation of Fe3O4@PMAA@Ni microspheres towards the efficient and selective enrichment of histidine-rich proteins[J]. ACS Applied Materials & Interfaces, 2021, 13(9): 11166-11176. |

| 33 | Franke A, Forrer N, Butté A, et al. Role of the ligand density in cation exchange materials for the purification of proteins[J]. Journal of Chromatography A, 2010, 1217(15): 2216-2225. |

| 34 | Wrzosek K, Gramblička M, Polakovič M. Influence of ligand density on antibody binding capacity of cation-exchange adsorbents[J]. Journal of Chromatography A, 2009, 1216(25): 5039-5044. |

| 35 | 卢慧丽, 林东强, 朱咪咪, 等. 配基密度和介质孔径对离子交换层析分离蛋白质的影响[J]. 化工进展, 2011, 30(S2): 209-213. |

| Lu H L, Lin D Q, Zhu M M, et al. Influences of ligand density and pore size on the protein adsorption with DEAE ion-exchange resins[J]. Chemical Industry and Engineering Progress, 2011, 30(S2): 209-213. | |

| 36 | 尚超, 陈历历, 黄明贤, 等. 一种连续化生产磁性琼脂糖凝胶微球的方法: 113967451A[P]. 2022-01-25. |

| Shang C, Chen L L, Huang M X, et al. Method for continuously producing magnetic agarose gel microspheres: 113967451A[P]. 2022-01-25. | |

| 37 | 王国祥, 聂峰光, 苏志国. 琼脂糖凝胶偶联DEAE基团反应的影响因素[J]. 化学反应工程与工艺, 2002, 18(1): 80-85. |

| Wang G X, Nie F G, Su Z G. Coupling reaction of diethylaminoethyl(DEAE) onto agarose gel[J]. Chemical Reaction Engineering and Technology, 2002, 18(1): 80-85. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [3] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [4] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [5] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [6] | 徐文杰, 贾献峰, 王际童, 乔文明, 凌立成, 王任平, 余子舰, 张寅旭. 有机硅/酚醛杂化气凝胶的制备和性能研究[J]. 化工学报, 2023, 74(8): 3572-3583. |

| [7] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [8] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [9] | 陈朝光, 贾玉香, 汪锰. 以低浓度废酸驱动中和渗析脱盐的模拟与验证[J]. 化工学报, 2023, 74(6): 2486-2494. |

| [10] | 杨琴, 秦传鉴, 李明梓, 杨文晶, 赵卫杰, 刘虎. 用于柔性传感的双形状记忆MXene基水凝胶的制备及性能研究[J]. 化工学报, 2023, 74(6): 2699-2707. |

| [11] | 谢诗婷, 刘壮, 谢锐, 巨晓洁, 汪伟, 潘大伟, 褚良银. 聚(N-异丙基丙烯酰胺-共聚-烯丙基硫脲)智能微凝胶的制备及其Hg2+响应性能的研究[J]. 化工学报, 2023, 74(6): 2689-2698. |

| [12] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [13] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [14] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| [15] | 范坤阳, 杨景兴, 许海波, 连兴容, 何凤梅, 陈聪慧, 李增耀. 遮光剂掺杂SiO2气凝胶传热的统一格子Boltzmann模型研究[J]. 化工学报, 2023, 74(5): 1974-1981. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号