CIESC Journal ›› 2020, Vol. 71 ›› Issue (7): 3091-3097.DOI: 10.11949/0438-1157.20200027

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Xuewen LIU( ),Jinjing LI,Xiaojun QUAN(

),Jinjing LI,Xiaojun QUAN( ),Wei XIONG

),Wei XIONG

Received:2020-01-07

Revised:2020-04-24

Online:2020-07-05

Published:2020-07-05

Contact:

Xiaojun QUAN

通讯作者:

全晓军

作者简介:刘学文(1995—),男,硕士研究生,基金资助:CLC Number:

Xuewen LIU, Jinjing LI, Xiaojun QUAN, Wei XIONG. Lattice Boltzmann study on single solid particle promoting thin liquid film rupture[J]. CIESC Journal, 2020, 71(7): 3091-3097.

刘学文, 李金京, 全晓军, 熊伟. 单个固体颗粒促进薄液膜破裂的格子Boltzmann研究[J]. 化工学报, 2020, 71(7): 3091-3097.

Add to citation manager EndNote|Ris|BibTeX

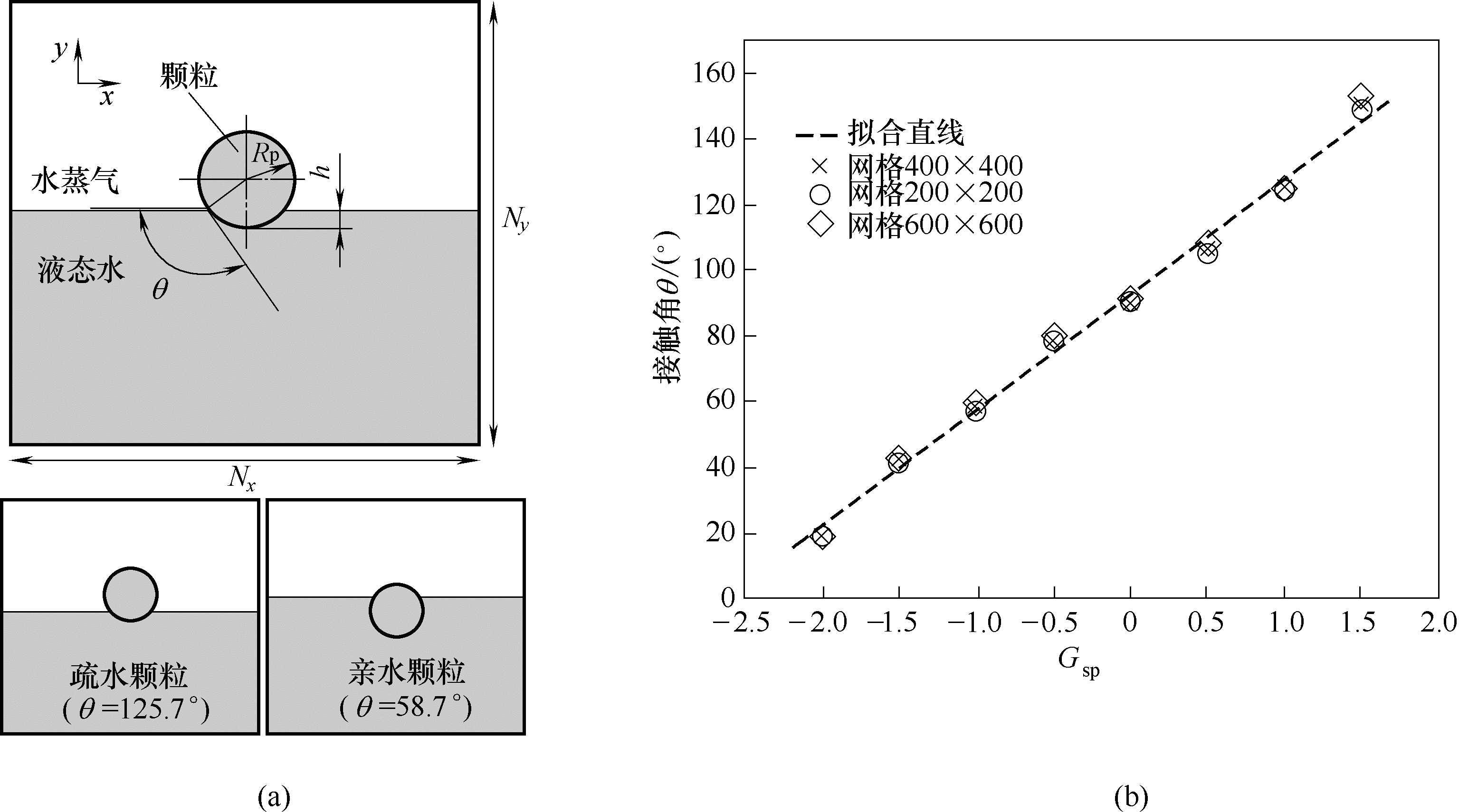

Fig.1 Schematic of the computation domain for a single particle floating on liquid surface (a); Relationship between Gsp and contact angle with different grid numbers(b)

Fig.5 Time distribution of two stages of liquid film rupture caused by particle with different contact angle at a given thickness (liquid film thickness hl*= 0.4)

| 1 | Zhu X, Wang D, Craig V S J. Interaction of particles with surfactant thin films: implications for dust suppression [J]. Langmuir, 2019, 35(24): 7641-9. |

| 2 | 邢耀文, 桂夏辉, 曹亦俊, 等. 相互作用力及液膜排液动力学研究进展 [J]. 煤炭学报, 2019, 44(10): 3185-92. |

| Xing Y W, Gui X H, Cao Y J, et al. Advance in the interaction force between bubble and particle and the thinning dynamics of thin liquid film [J]. Journal of China Coal Society, 2019, 44(10): 3185-92. | |

| 3 | Ally J, Kappl M, Butt H J, et al. Detachment force of particles from air-liquid interfaces of films and bubbles [J]. Langmuir, 2010, 26(23): 18135-43. |

| 4 | Coursey J S, Kim J, Flow F. Nanofluid boiling: the effect of surface wettability [J]. International Journal of Heat, 2008, 29(6): 1577-1585. |

| 5 | Moreira T A, Moreira D C, Ribatski G. Nanofluids for heat transfer applications: a review [J]. Journal of the Brazilian Society of Mechanical Sciences, 2018, 40(6): 303. |

| 6 | Quan X, Wang D, Cheng P. An experimental investigation on wettability effects of nanoparticles in pool boiling of a nanofluid [J]. Int. J. Heat Mass Transfer, 2017, 108: 32-40. |

| 7 | Wang D, Quan X, Liu C, et al. An experimental investigation on periodic single bubble growth and departure from a small heater submerged in a nanofluid containing moderately hydrophilic nanoparticles [J]. Int. Commun. Heat Mass Transfer, 2018, 95: 1-8. |

| 8 | Binks B P, Horozov T S. Aqueous foams stabilized solely by silica nanoparticles [J]. Angew. Chem. Int. Ed., 2010, 44(24): 3722-3725. |

| 9 | Dippenaar A. The destabilization of froth by solids(Ⅰ):The mechanism of film rupture [J]. Int. J. Miner. Process., 1982, 9(1): 1-14. |

| 10 | Horozov T. Foams and foam films stabilised by solid particles [J]. Curr. Opin. Colloid Interface Sci., 2008, 13(3): 134-140. |

| 11 | Kaptay G. Interfacial criteria for stabilization of liquid foams by solid particles [J]. Colloids Surf. A, 2003, 230(1/2/3): 67-80. |

| 12 | Kaptay G. On the equation of the maximum capillary pressure induced by solid particles to stabilize emulsions and foams and on the emulsion stability diagrams [J]. Colloids Surf. A, 2006, 282/283(1): 387-401. |

| 13 | Morris G, Neethling S J, Cilliers J J. Predicting the failure of a thin liquid film loaded with spherical particles [J]. Langmuir, 2014, 30(4): 995-1003. |

| 14 | Aveyard R, Binks B P, Fletcher P D I, et al. Aspects of aqueous foam stability in the presence of hydrocarbon oils and solid particles [J]. Adv. Colloid Interface Sci., 1994, 48(94): 93-120. |

| 15 | Aveyard R, Cooper P, Fletcher P D I, et al. Foam breakdown by hydrophobic particles and nonpolar oil [J]. Langmuir, 1993, 9(2): 604-613. |

| 16 | Aronson M P. Influence of hydrophobic particles on the foaming of aqueous surfactant solutions [J]. Langmuir, 1986, 2(5): 653-659. |

| 17 | Morris G, Pursell M R, Neethling S J, et al. The effect of particle hydrophobicity, separation distance and packing patterns on the stability of a thin film [J]. J. Colloid Interface Sci., 2008, 327(1): 138-144. |

| 18 | Garrett P R. Defoaming: antifoams and mechanical methods [J]. Curr. Opin. Colloid Interface Sci., 2015, 20(2): 81-91. |

| 19 | Hunter T N, Pugh R J, Franks G V, et al. The role of particles in stabilising foams and emulsions [J]. Adv. Colloid Interface Sci., 2008, 137(2): 57-81. |

| 20 | Thareja P, Moritz K, Velankar S S. Interfacially active particles in droplet/matrix blends of model immiscible homopolymers: particles can increase or decrease drop size [J]. Rheol. Acta, 2010, 49(3): 285-298. |

| 21 | Frye G C, Berg J C. Antifoam action by solid particles [J]. J. Colloid Interface Sci., 1988, 127(1): 222-238. |

| 22 | Ladd A J C. Numerical simulations of particulate suspensions via a discretized Boltzmann equation(Ⅰ): Theoretical foundation [J]. J. Fluid Mech., 1994, 271: 285-309. |

| 23 | Ladd A J C. Numerical simulations of particulate suspensions via a discretized Boltzmann equation(Ⅱ): Numerical results [J]. J. Fluid Mech., 1994, 271: 311-339. |

| 24 | Joshi A S, Sun Y. Multiphase lattice Boltzmann method for particle suspensions [J]. Phys. Rev. E: Stat. Nonlinear Soft Matter. Phys., 2009, 79(6): 066703. |

| 25 | Gong S, Cheng P. Numerical investigation of droplet motion and coalescence by an improved lattice Boltzmann model for phase transitions and multiphase flows [J]. Comput. Fluids, 2012, 53:93-104. |

| 26 | Aidun C K, Lu Y, Ding E J. Direct analysis of particulate suspensions with inertia using the discrete Boltzmann equation [J]. J. Fluid Mech., 1998, 373: 287-311. |

| 27 | Huang H, Thorne D T, Schaap M G, et al. Proposed approximation for contact angles in Shan-and-Chen-type multicomponent multiphase lattice Boltzmann models [J]. Phys. Rev. E Stat Nonlin. Soft. Matter. Phys., 2007, 76: 066701. |

| 28 | Gong S, Cheng P. A lattice Boltzmann method for simulation of liquid-vapor phase-change heat transfer [J]. Int. J. Heat Mass Transfer, 2012, 55(17/18): 4923-4927. |

| 29 | Xiong W, Cheng P, Quan X, et al. Droplet impact on a layer of solid particles placed above a substrate: a 3D lattice Boltzmann study [J]. Comput. Fluids, 2019, 188: 18-30. |

| 30 | Wang D, Cheng P, Quan X. Photothermal nanobubble nucleation on a plasmonic nanoparticle: a 3D lattice Boltzmann simulation [J]. Int. J. Heat Mass Transfer, 2019, 140: 786-797. |

| 31 | Liu X, Cheng P, Quan X. Lattice Boltzmann simulations for self-propelled jumping of droplets after coalescence on a superhydrophobic surface [J]. Int. J. Heat Mass Transfer, 2014, 73:195-200. |

| 32 | Garrett P R. The Science of Defoaming: Theory, Experiment and Applications [M]. CRC Press, 2014. |

| [1] | Jiahao SONG, Wen WANG. Study on coupling operation characteristics of Stirling engine and high temperature heat pipe [J]. CIESC Journal, 2023, 74(S1): 287-294. |

| [2] | Siyu ZHANG, Yonggao YIN, Pengqi JIA, Wei YE. Study on seasonal thermal energy storage characteristics of double U-shaped buried pipe group [J]. CIESC Journal, 2023, 74(S1): 295-301. |

| [3] | Ruitao SONG, Pai WANG, Yunpeng WANG, Minxia LI, Chaobin DANG, Zhenguo CHEN, Huan TONG, Jiaqi ZHOU. Numerical simulation of flow boiling heat transfer in pipe arrays of carbon dioxide direct evaporation ice field [J]. CIESC Journal, 2023, 74(S1): 96-103. |

| [4] | Zhanyu YE, He SHAN, Zhenyuan XU. Performance simulation of paper folding-like evaporator for solar evaporation systems [J]. CIESC Journal, 2023, 74(S1): 132-140. |

| [5] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [6] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [7] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [8] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [9] | Xianheng YI, Wu ZHOU, Xiaoshu CAI, Tianyi CAI. Measurable range of nanoparticle concentration using optical fiber backward dynamic light scattering [J]. CIESC Journal, 2023, 74(8): 3320-3328. |

| [10] | Chen HAN, Youmin SITU, Bin ZHU, Jianliang XU, Xiaolei GUO, Haifeng LIU. Study of reaction and flow characteristics in multi-nozzle pulverized coal gasifier with co-processing of wastewater [J]. CIESC Journal, 2023, 74(8): 3266-3278. |

| [11] | Yue YANG, Dan ZHANG, Jugan ZHENG, Maoping TU, Qingzhong YANG. Experimental study on flash and mixing evaporation of aqueous NaCl solution [J]. CIESC Journal, 2023, 74(8): 3279-3291. |

| [12] | Rubin ZENG, Zhongjie SHEN, Qinfeng LIANG, Jianliang XU, Zhenghua DAI, Haifeng LIU. Study of the sintering mechanism of Fe2O3 nanoparticles based on molecular dynamics simulation [J]. CIESC Journal, 2023, 74(8): 3353-3365. |

| [13] | Xiaosong CHENG, Yonggao YIN, Chunwen CHE. Performance comparison of different working pairs on a liquid desiccant dehumidification system with vacuum regeneration [J]. CIESC Journal, 2023, 74(8): 3494-3501. |

| [14] | Wenzhu LIU, Heming YUN, Baoxue WANG, Mingzhe HU, Chonglong ZHONG. Research on topology optimization of microchannel based on field synergy and entransy dissipation [J]. CIESC Journal, 2023, 74(8): 3329-3341. |

| [15] | Rui HONG, Baoqiang YUAN, Wenjing DU. Analysis on mechanism of heat transfer deterioration of supercritical carbon dioxide in vertical upward tube [J]. CIESC Journal, 2023, 74(8): 3309-3319. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||