CIESC Journal ›› 2022, Vol. 73 ›› Issue (2): 587-594.DOI: 10.11949/0438-1157.20211322

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Nan ZHOU( ),Zan WANG,Yingjuan SHAO(

),Zan WANG,Yingjuan SHAO( ),Wenqi ZHONG

),Wenqi ZHONG

Received:2021-09-10

Revised:2021-11-01

Online:2022-02-18

Published:2022-02-05

Contact:

Yingjuan SHAO

通讯作者:

邵应娟

作者简介:周楠(1997—),女,硕士研究生,基金资助:CLC Number:

Nan ZHOU, Zan WANG, Yingjuan SHAO, Wenqi ZHONG. Experimental study on attrition characteristics of coal tar pitch particles during gas-solid fluidization[J]. CIESC Journal, 2022, 73(2): 587-594.

周楠, 王簪, 邵应娟, 钟文琪. 煤沥青球气固流化磨损特性实验研究[J]. 化工学报, 2022, 73(2): 587-594.

Add to citation manager EndNote|Ris|BibTeX

| 床料 | 粒径范围dp/mm | 表观密度ρp/(kg/m3) | 堆积空隙率 |

|---|---|---|---|

| 煤沥青 | 0.4~1.2 | 1200 | 0.4 |

Table1 Physical properties of coal tar pitch particles

| 床料 | 粒径范围dp/mm | 表观密度ρp/(kg/m3) | 堆积空隙率 |

|---|---|---|---|

| 煤沥青 | 0.4~1.2 | 1200 | 0.4 |

| 实验参数 | 编号 | 表观气速/(m/s) | 初始粒径范围/mm | 高径比 |

|---|---|---|---|---|

| 表观气速 | A1 | 0.7 | 0.8~1.0 | 0.75 |

| N | 0.8 | 0.8~1.0 | 0.75 | |

| A2 | 0.9 | 0.8~1.0 | 0.75 | |

| A3 | 1.0 | 0.8~1.0 | 0.75 | |

| 初始粒径 | B1 | 0.8 | 0.4~0.6 | 0.75 |

| B2 | 0.8 | 0.6~0.8 | 0.75 | |

| N | 0.8 | 0.8~1.0 | 0.75 | |

| B3 | 0.8 | 1.0~1.2 | 0.75 | |

| 高径比 | C1 | 0.8 | 0.8~1.0 | 0.56 |

| N | 0.8 | 0.8~1.0 | 0.75 | |

| C2 | 0.8 | 0.8~1.0 | 0.94 | |

| C3 | 0.8 | 0.8~1.0 | 1.13 |

Table 2 Experimental condition design

| 实验参数 | 编号 | 表观气速/(m/s) | 初始粒径范围/mm | 高径比 |

|---|---|---|---|---|

| 表观气速 | A1 | 0.7 | 0.8~1.0 | 0.75 |

| N | 0.8 | 0.8~1.0 | 0.75 | |

| A2 | 0.9 | 0.8~1.0 | 0.75 | |

| A3 | 1.0 | 0.8~1.0 | 0.75 | |

| 初始粒径 | B1 | 0.8 | 0.4~0.6 | 0.75 |

| B2 | 0.8 | 0.6~0.8 | 0.75 | |

| N | 0.8 | 0.8~1.0 | 0.75 | |

| B3 | 0.8 | 1.0~1.2 | 0.75 | |

| 高径比 | C1 | 0.8 | 0.8~1.0 | 0.56 |

| N | 0.8 | 0.8~1.0 | 0.75 | |

| C2 | 0.8 | 0.8~1.0 | 0.94 | |

| C3 | 0.8 | 0.8~1.0 | 1.13 |

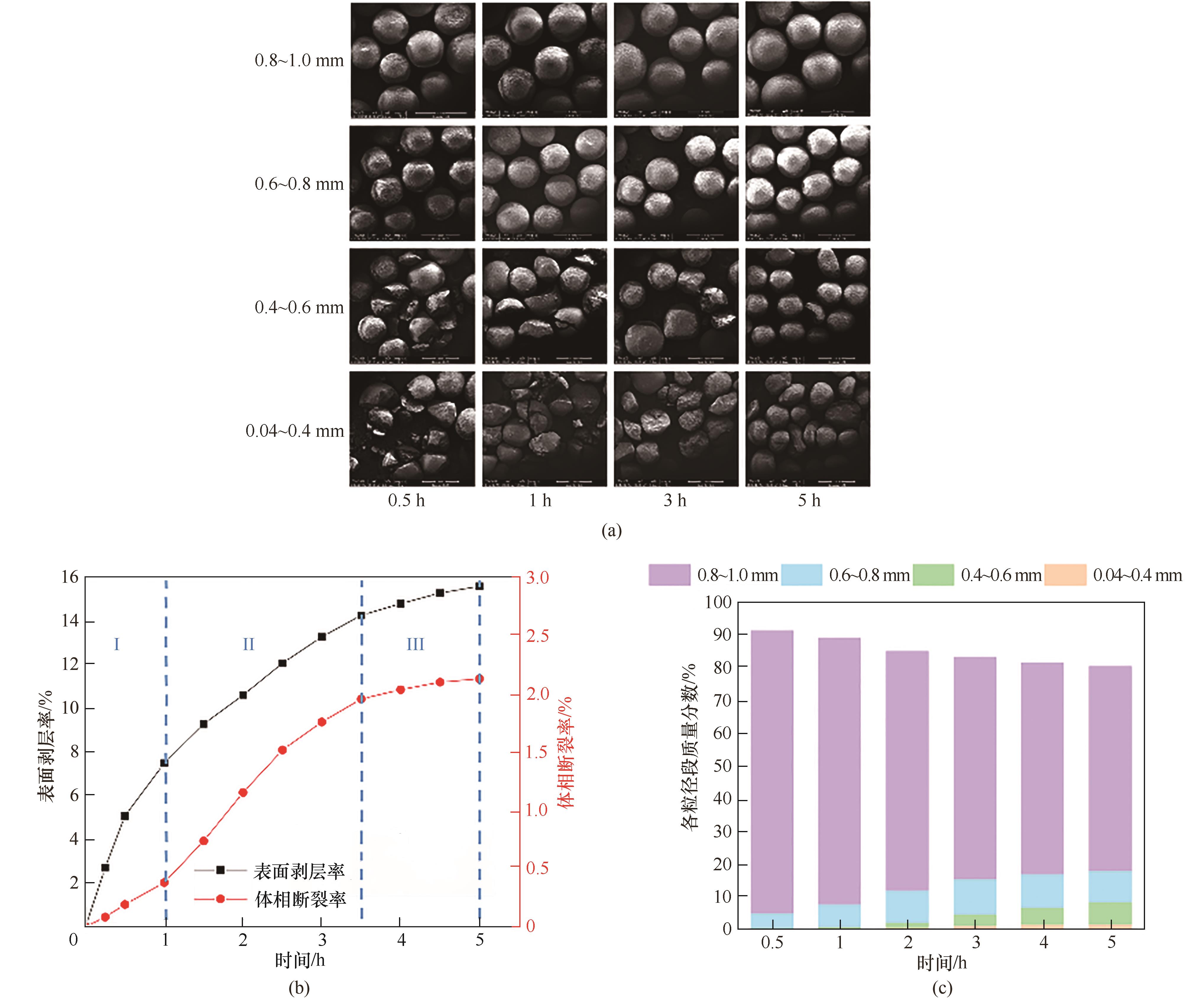

Fig.4 Attrition results of coal tar pitch particles under different fluidization time: SEM images of different particle size range(a); Changes of abrasion rate and fragmentation rate with attrition time(b); Changes of particle size distribution with time (c)

| 1 | 郭慕孙, 李洪钟. 流态化手册[M]. 北京: 化学工业出版社, 2008: 1-7. |

| Guo M S, Li H Z. Handbook of Fluidization[M]. Beijing: Chemical Industry Press, 2008: 1-7. | |

| 2 | Werther J, Reppenhagen J. Catalyst attrition in fluidized-bed systems[J]. AIChE Journal, 1999, 45(9): 2001-2010. |

| 3 | 李路明, 高新宇, 田佩玉, 等. 脱硝催化剂堵塞磨损问题工程案例分析探究[J]. 锅炉制造, 2021(3): 39-42. |

| Li L M, Gao X Y, Tian P Y, et al. Case study on blockage and wear of de-NOx catalyst[J]. Boiler Manufacturing, 2021(3): 39-42. | |

| 4 | Hatanaka T, Yoda Y. Attrition of ilmenite ore during consecutive redox cycles in chemical looping combustion[J]. Powder Technology, 2019, 356: 974-979. |

| 5 | Li D F, Ke X W, Yang H R, et al. The ash formation and attrition characteristics of an Indonesia lignite coal ash for a 550 MWe ultra supercritical CFB boiler[J]. Chemical Engineering Research and Design, 2019, 147: 579-586. |

| 6 | Bjorklund I S, Dygert J C. Small scale tests for attrition resistance of solids in slurry systems[J]. AIChE Journal, 1968, 14(4): 553-557. |

| 7 | 公铭扬, 李晓刚, 杜伟, 等. 流化催化剂磨损机制的研究进展[J]. 摩擦学学报, 2007, 27(1): 91-96. |

| Gong M Y, Li X G, Du W, et al. Research progress on fluid catalyst attrition[J]. Tribology, 2007, 27(1): 91-96. | |

| 8 | Amblard B, Bertholin S, Bobin C, et al. Development of an attrition evaluation method using a Jet Cup rig[J]. Powder Technology, 2015, 274: 455-465. |

| 9 | Thon A, Werther J. Attrition resistance of a VPO catalyst[J]. Applied Catalysis A: General, 2010, 376(1/2): 56-65. |

| 10 | Choi J H, Moon Y S, Yi C K, et al. Attrition of zinc-titanate sorbent in a bubbling fluidized bed[J]. Journal of the Taiwan Institute of Chemical Engineers, 2010, 41(6): 656-660. |

| 11 | Yao X, Zhang H, Yang H R, et al. An experimental study on the primary fragmentation and attrition of limestones in a fluidized bed[J]. Fuel Processing Technology, 2010, 91(9): 1119-1124. |

| 12 | 陶中东, 顾正东, 吴东方. 颗粒流化磨损研究进展[J]. 化工进展, 2014, 33(10): 2535-2539, 2564. |

| Tao Z D, Gu Z D, Wu D F. Research progress on fluidized particle attrition[J]. Chemical Industry and Engineering Progress, 2014, 33(10): 2535-2539, 2564. | |

| 13 | Li F, Briens C, Berruti F, et al. Particle attrition with supersonic nozzles in a fluidized bed at high temperature[J]. Powder Technology, 2012, 228: 385-394. |

| 14 | Alonso M, Arias B, Fernández J R, et al. Measuring attrition properties of calcium looping materials in a 30 kW pilot plant[J]. Powder Technology, 2018, 336: 273-281. |

| 15 | Zhang Z, Ghadiri M. Impact attrition of particulate solids. Part 2: Experimental work[J]. Chemical Engineering Science, 2002, 57(17): 3671-3686. |

| 16 | Wu D F, Gu Z D, Li Y D. Attrition of catalyst particles in a laboratory-scale fluidized-bed reactor[J]. Chemical Engineering Science, 2015, 135: 431-440. |

| 17 | 许家豪. 提升管内催化剂磨损研究及数值模拟[D]. 东营: 中国石油大学(华东), 2016. |

| Xu J H. Study and numerical simulation of catalyst attrition in the riser reactor[D]. Dongying: China University of Petroleum (East China), 2016. | |

| 18 | Yang Z Q, Ren W G, Zhang L, et al. Limestone particle attrition and size distribution in a bench scale bubbling fluidized bed[J]. Global Nest Journal, 2015, 17(2): 236-247. |

| 19 | Park Y S, Kim H S, Shun D, et al. Attrition characteristics of alumina catalyst for fluidized bed incinerator[J]. Korean Journal of Chemical Engineering, 2000, 17(3): 284-287. |

| 20 | 王永邦, 刘小军, 李泽斯, 等. 沥青球在流化床反应器中氧化不熔化及后续炭化行为的研究[J]. 炭素技术, 2010, 29(6): 5-8, 12. |

| Wang Y B, Liu X J, Li Z S, et al. Oxidative stabilization of pitch spheres in fluidized bed and their carbonization behavior[J]. Carbon Techniques, 2010, 29(6): 5-8, 12. | |

| 21 | 郭源, 邵应娟, 钟文琪, 等. 煤沥青球的氧化不熔化过程特性[J]. 化工学报, 2018, 69(1): 499-506. |

| Guo Y, Shao Y J, Zhong W Q, et al. Characteristics of oxidation stabilization process of coal pitch based spheres[J]. CIESC Journal, 2018, 69(1): 499-506. | |

| 22 | 李开喜. 一步法低能耗制备沥青球的技术: 103695019A[P]. 2014-04-02. |

| Li K X. One-step and low energy consumption preparation technology of pitch spheres: 103695019A[P]. 2014-04-02. | |

| 23 | 金涌. 流态化工程原理[M]. 北京: 清华大学出版社, 2001: 1-7. |

| Jin Y. Fluidization Engineering Principles[M]. Beijing: Tsinghua University Press, 2001: 1-7. | |

| 24 | 任伟光. 低浓度甲烷催化剂颗粒气固流化态的磨损特性研究[D]. 重庆: 重庆大学, 2016. |

| Ren W G. Experimental study on attrition characteristics of low-concentration methane catalyst particles[D]. Chongqing: Chongqing University, 2016. | |

| 25 | Wu D F, Wu F H, Gu Z D. Catalyst attrition in an ASTM fluidized bed[J]. Catalysis Today, 2016, 264: 70-74. |

| 26 | Zakeri M, Samimi A, Khorram M, et al. Effect of forming on selectivity and attrition of co-precipitated Co-Mn Fischer-Tropsch catalysts[J]. Powder Technology, 2010, 200(3): 164-170. |

| 27 | Kang D H, Ko C K, Lee D H. Attrition characteristics of iron ore by an air jet in gas-solid fluidized beds[J]. Powder Technology, 2017, 316: 69-78. |

| 28 | Reppenhagen J, Werther J. Catalyst attrition in cyclones[J]. Powder Technology, 2000, 113(1/2): 55-69. |

| 29 | Yin R L, Wang K, Han B B, et al. Structural evaluation of coal-tar-pitch-based carbon materials and their Na+ storage properties[J]. Coatings, 2021, 11(8): 948. |

| 30 | Tavares L M. Analysis of particle fracture by repeated stressing as damage accumulation[J]. Powder Technology, 2009, 190(3): 327-339. |

| 31 | Ergun S. Fluid flow through packed columns[J]. Chemical Engineering Progress, 1952, 48(2): 89-94. |

| 32 | Okhovat-Alavian S M, Behin J, Mostoufi N. Investigating bubble dynamics in a semi-cylindrical gas-solid fluidized bed[J]. Powder Technology, 2020, 370: 129-136. |

| 33 | Gao Q H, Wang T, Tang T Q, et al. Macroscopic and microscopic flow characteristics of particles in a sound assisted bubbling fluidized bed[J]. Chemical Engineering and Processing - Process Intensification, 2020, 156: 108102. |

| 34 | Miao M, Yao X, Zhang S M, et al. Attrition performance and morphology of limestone under different conditions in fluidized bed[J]. Fuel Processing Technology, 2021, 221: 106939. |

| [1] | Xin YANG, Wen WANG, Kai XU, Fanhua MA. Simulation analysis of temperature characteristics of the high-pressure hydrogen refueling process [J]. CIESC Journal, 2023, 74(S1): 280-286. |

| [2] | Siyu ZHANG, Yonggao YIN, Pengqi JIA, Wei YE. Study on seasonal thermal energy storage characteristics of double U-shaped buried pipe group [J]. CIESC Journal, 2023, 74(S1): 295-301. |

| [3] | Minghui CHANG, Lin WANG, Jiajia YUAN, Yifei CAO. Study on the cycle performance of salt solution-storage-based heat pump [J]. CIESC Journal, 2023, 74(S1): 329-337. |

| [4] | Mingkun XIAO, Guang YANG, Yonghua HUANG, Jingyi WU. Numerical study on bubble dynamics of liquid oxygen at a submerged orifice [J]. CIESC Journal, 2023, 74(S1): 87-95. |

| [5] | Lisen BI, Bin LIU, Hengxiang HU, Tao ZENG, Zhuorui LI, Jianfei SONG, Hanming WU. Molecular dynamics study on evaporation modes of nanodroplets at rough interfaces [J]. CIESC Journal, 2023, 74(S1): 172-178. |

| [6] | Hongxin YU, Shuangquan SHAO. Simulation analysis of water crystallization process [J]. CIESC Journal, 2023, 74(S1): 250-258. |

| [7] | Xiaoxiong FAN, Lifang HAO, Chuigang FAN, Songgeng LI. Study on the catalytic denitrification performance of low-temperature NH3-SCR over LaMnO3/biochar catalyst [J]. CIESC Journal, 2023, 74(9): 3821-3830. |

| [8] | Jianbo HU, Hongchao LIU, Qi HU, Meiying HUANG, Xianyu SONG, Shuangliang ZHAO. Molecular dynamics simulation insight into translocation behavior of organic cage across the cellular membrane [J]. CIESC Journal, 2023, 74(9): 3756-3765. |

| [9] | Jiali ZHENG, Zhihui LI, Xinqiang ZHAO, Yanji WANG. Kinetics of ionic liquid catalyzed synthesis of 2-cyanofuran [J]. CIESC Journal, 2023, 74(9): 3708-3715. |

| [10] | Manzheng ZHANG, Meng XIAO, Peiwei YAN, Zheng MIAO, Jinliang XU, Xianbing JI. Working fluid screening and thermodynamic optimization of hazardous waste incineration coupled organic Rankine cycle system [J]. CIESC Journal, 2023, 74(8): 3502-3512. |

| [11] | Linzheng WANG, Yubing LU, Ruizhi ZHANG, Yonghao LUO. Analysis on thermal oxidation characteristics of VOCs based on molecular dynamics simulation [J]. CIESC Journal, 2023, 74(8): 3242-3255. |

| [12] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [13] | Yue YANG, Dan ZHANG, Jugan ZHENG, Maoping TU, Qingzhong YANG. Experimental study on flash and mixing evaporation of aqueous NaCl solution [J]. CIESC Journal, 2023, 74(8): 3279-3291. |

| [14] | Rubin ZENG, Zhongjie SHEN, Qinfeng LIANG, Jianliang XU, Zhenghua DAI, Haifeng LIU. Study of the sintering mechanism of Fe2O3 nanoparticles based on molecular dynamics simulation [J]. CIESC Journal, 2023, 74(8): 3353-3365. |

| [15] | Linjing YUE, Yihan LIAO, Yuan XUE, Xuejie LI, Yuxing LI, Cuiwei LIU. Study on influence of pit defects on cavitation flow characteristics of throat of thick orifice plates [J]. CIESC Journal, 2023, 74(8): 3292-3308. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||