CIESC Journal ›› 2025, Vol. 76 ›› Issue (1): 296-310.DOI: 10.11949/0438-1157.20240657

• Surface and interface engineering • Previous Articles Next Articles

Junjie ZHANG1( ), Yuan CHEN1(

), Yuan CHEN1( ), Yuntang LI1, Xiaolu LI1, Bingqing WANG1, Xudong PENG2

), Yuntang LI1, Xiaolu LI1, Bingqing WANG1, Xudong PENG2

Received:2024-06-14

Revised:2024-07-21

Online:2025-02-08

Published:2025-01-25

Contact:

Yuan CHEN

张俊杰1( ), 陈源1(

), 陈源1( ), 李运堂1, 李孝禄1, 王冰清1, 彭旭东2

), 李运堂1, 李孝禄1, 王冰清1, 彭旭东2

通讯作者:

陈源

作者简介:张俊杰(1998—),男,硕士研究生,327405215@qq.com

基金资助:CLC Number:

Junjie ZHANG, Yuan CHEN, Yuntang LI, Xiaolu LI, Bingqing WANG, Xudong PENG. Analysis and optimization of dynamic performance of super-elliptical hole floating seal dam compliant foil face gas seal[J]. CIESC Journal, 2025, 76(1): 296-310.

张俊杰, 陈源, 李运堂, 李孝禄, 王冰清, 彭旭东. 超椭圆织构浮动坝箔片端面气膜密封动态性能分析与优化[J]. 化工学报, 2025, 76(1): 296-310.

Add to citation manager EndNote|Ris|BibTeX

| 参数 | 数值 |

|---|---|

| 密封端面内径ri/mm | 58.42 |

| 密封坝外径侧半径rg/mm | 64.87 |

| 密封端面外径ro/mm | 77.78 |

| 初始气膜厚度hb/μm | 3 |

| 楔形高度δh/μm | 15 |

| 周期数Nc | 8 |

| 节距比c | 0.4 |

| 箔坝比ξ | 2 |

| 箔片区柔度系数α1 | 0.01 |

| 浮动坝区柔度系数α2 | 1×10-4 |

| 箔片区超椭圆系数n1 | 4 |

| 浮动坝区超椭圆系数n2 | 1 |

| 箔片区超椭圆横半轴a1/mm | 2.5 |

| 箔片区超椭圆纵半轴b1/mm | 4 |

| 浮动坝区超椭圆横半轴a2/mm | 1.75 |

| 浮动坝区超椭圆纵半轴b2/mm | 0.7 |

| 箔片区织构深度Td1/μm | 5 |

| 浮动坝区织构深度Td2/μm | 5 |

| 内、外侧倾角ϕ1、ϕ2 | 40° |

| 时间步长Δt/s | 1×10-6 |

| 静环质量ms/kg | 0.5 |

| 密封坝质量md/kg | 0.2 |

| 弹簧刚度ks/(N·m-1) | 1×107 |

| 静环辅助密封圈阻尼cz/(N·s·m-1) | 2×103 |

| 外径大气压po/MPa | 0.3 |

| 内径大气压pi/MPa | 0.1 |

| 转速ω/(r·min-1) | 1.4×104 |

Table 1 Initial parameter

| 参数 | 数值 |

|---|---|

| 密封端面内径ri/mm | 58.42 |

| 密封坝外径侧半径rg/mm | 64.87 |

| 密封端面外径ro/mm | 77.78 |

| 初始气膜厚度hb/μm | 3 |

| 楔形高度δh/μm | 15 |

| 周期数Nc | 8 |

| 节距比c | 0.4 |

| 箔坝比ξ | 2 |

| 箔片区柔度系数α1 | 0.01 |

| 浮动坝区柔度系数α2 | 1×10-4 |

| 箔片区超椭圆系数n1 | 4 |

| 浮动坝区超椭圆系数n2 | 1 |

| 箔片区超椭圆横半轴a1/mm | 2.5 |

| 箔片区超椭圆纵半轴b1/mm | 4 |

| 浮动坝区超椭圆横半轴a2/mm | 1.75 |

| 浮动坝区超椭圆纵半轴b2/mm | 0.7 |

| 箔片区织构深度Td1/μm | 5 |

| 浮动坝区织构深度Td2/μm | 5 |

| 内、外侧倾角ϕ1、ϕ2 | 40° |

| 时间步长Δt/s | 1×10-6 |

| 静环质量ms/kg | 0.5 |

| 密封坝质量md/kg | 0.2 |

| 弹簧刚度ks/(N·m-1) | 1×107 |

| 静环辅助密封圈阻尼cz/(N·s·m-1) | 2×103 |

| 外径大气压po/MPa | 0.3 |

| 内径大气压pi/MPa | 0.1 |

| 转速ω/(r·min-1) | 1.4×104 |

Fig.11 Variation of dynamic performance parameters of SHFSD-CFFGS under different super-elliptical coefficients n2 and and inclination angles ϕ1 and ϕ2

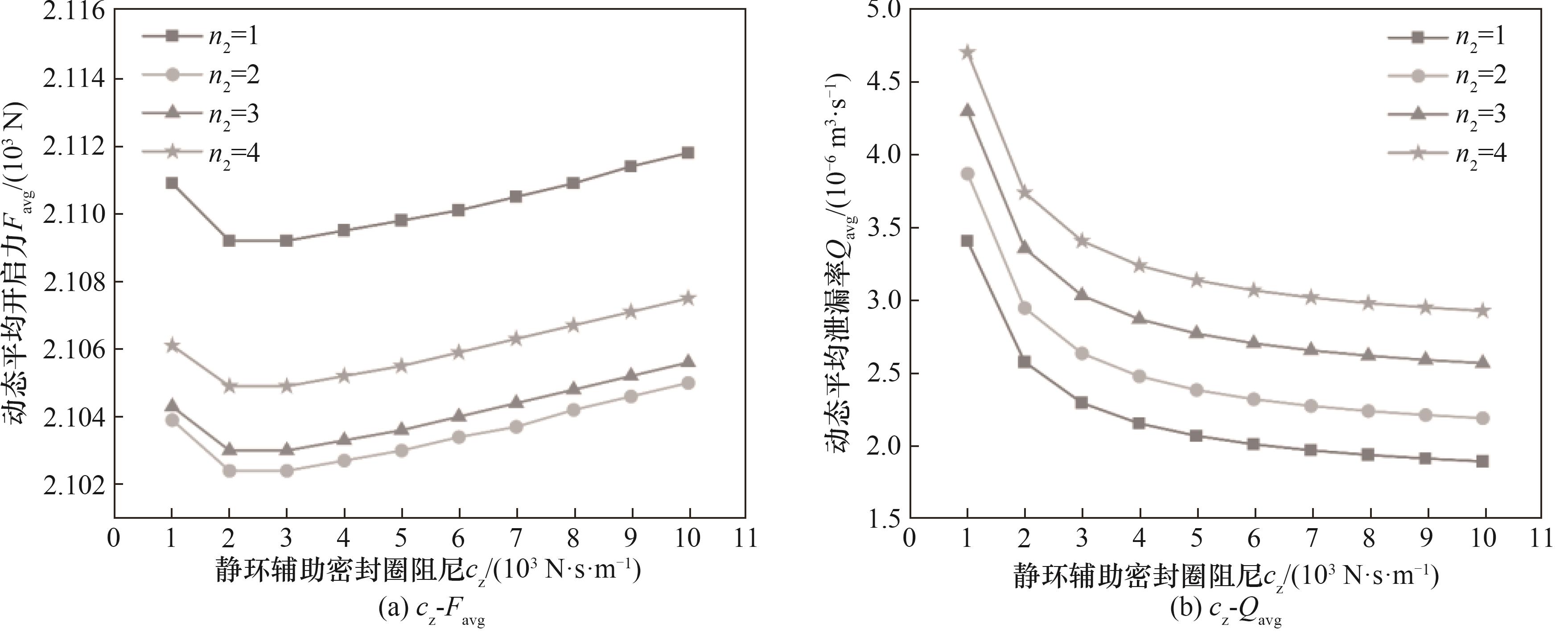

Fig.17 Variation of dynamic performance parameters of SHFSD-CFFGS with auxiliary sealing ring damping cz under different super-elliptical coefficients n2

| 1 | 彭旭东, 宗聪, 江锦波. 干气密封单向螺旋槽及其衍生结构功能演变进展[J]. 化工学报, 2017, 68(4): 1271-1281. |

| Peng X D, Zong C, Jiang J B. Progress in dry gas seal performance evolution of unidirectional spiral groove and its derivative structures[J]. CIESC Journal, 2017, 68(4): 1271-1281. | |

| 2 | Jiang J B, Peng X D, Zong C, et al. Enhancing film stiffness of spiral groove dry gas seal via shape modification at low speed: numerical results and experiment[J]. Tribology Transactions, 2019, 62(6): 931-942. |

| 3 | 丁俊华, 俞树荣, 王世鹏, 等. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| Ding J H, Yu S R, Wang S P, et al. Flow simulation and sealing performance test of ultra-high speed dry gas seal under multiple effects[J]. CIESC Journal, 2023, 74(5): 2088-2099. | |

| 4 | 于辰, 江锦波, 赵文静, 等. 基于微段组合的干气密封端面型槽结构模型及其参数影响[J]. 化工学报, 2021, 72(10): 5294-5309. |

| Yu C, Jiang J B, Zhao W J, et al. Geometrical model of surface groove based on micro-segment combination for dry gas seal and its parameter influence[J]. CIESC Journal, 2021, 72(10): 5294-5309. | |

| 5 | 王衍, 孔康杰, 何一鸣, 等. 干气密封端面型槽可控激光制备的参数模型及实验验证[J]. 湖南大学学报(自然科学版), 2023, 50(10): 142-150. |

| Wang Y, Kong K J, He Y M, et al. Parameter model and experimental verification of controllable laser preparation of dry gas seal surface groove[J]. Journal of Hunan University (Natural Sciences), 2023, 50(10): 142-150. | |

| 6 | 李双喜, 宋文博, 张秋翔, 等. 干式气体端面密封的开启特性[J]. 化工学报, 2011, 62(3): 766-772. |

| Li S X, Song W B, Zhang Q X, et al. Opening characteristics of dry gas seal[J]. CIESC Journal, 2011, 62(3): 766-772. | |

| 7 | 江锦波, 彭旭东, 白少先, 等. 仿生集束螺旋槽干式气体密封特性的数值分析[J]. 机械工程学报, 2015, 51(15): 20-26. |

| Jiang J B, Peng X D, Bai S X, et al. Numerical analysis of characteristics of a bionic cluster spiral groove dry gas seal[J]. Journal of Mechanical Engineering, 2015, 51(15): 20-26. | |

| 8 | 丁雪兴, 王平西, 张伟政, 等. 螺旋槽干气密封环端面摩擦试验及其性能分析[J]. 化工学报, 2017, 68(1): 208-214. |

| Ding X X, Wang P X, Zhang W Z, et al. Analysis of tribological test and performance under rings end faces of spiral groove dry gas seal[J]. CIESC Journal, 2017, 68(1): 208-214. | |

| 9 | Heshmat H. Compliant foil seal: US6505837[P]. 2003-01-14. |

| 10 | Munson J, Grant D, Agrawal G. Foil face seal development[C]//37th Joint Propulsion Conference and Exhibit. AIAA, 2001: AIAA2001-3483. |

| 11 | Salehi M, Heshmat H. Evaluation of large compliant gas foil seals under engine simulated conditions[C]//38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. AIAA, 2002: AIAA2002-3792. |

| 12 | Heshmat H, Walton J F. Innovative high-temperature compliant surface foil face seal development[C]//44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit.AIAA, 2008: AIAA2008-4505. |

| 13 | Chen Y, Wang Q G, Peng X D, et al. Flow field and sealing performance analysis of compliant foil face gas seal[J]. Advances in Mechanical Engineering, 2022, 14(6): 1-16. |

| 14 | Chen Y, Chen K, Peng X D, et al. Research on the operation mechanism and performance of bump-type compliant foil face gas seal[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2022, 44(8): 325-337. |

| 15 | 陈源, 熊聪, 彭旭东, 等. 不同箔坝位置关系下浮动坝箔片端面气膜密封性能研究[J]. 摩擦学学报, 2023, 43(5): 481-491. |

| Chen Y, Xiong C, Peng X D, et al. Performance of floating seal dam compliant foil face gas seal under different foil-dam positions[J]. Tribology, 2023, 43(5): 481-491. | |

| 16 | 王庆港, 陈源, 彭旭东, 等. 三自由度微扰下箔片端面气膜密封动态特性分析[J]. 中国机械工程, 2022, 33(15): 1828-1840. |

| Wang Q G, Chen Y, Peng X D, et al. Analysis on dynamic characteristics of compliant foil face gas seals with three degrees of freedom perturbation[J]. China Mechanical Engineering, 2022, 33(15): 1828-1840. | |

| 17 | 邓强国, 宋鹏云, 许恒杰, 等. 干气密封动力学研究新进展[J]. 润滑与密封, 2018, 43(6): 118-127, 148. |

| Deng Q G, Song P Y, Xu H J, et al. Current progress of dry gas seal dynamics[J]. Lubrication Engineering, 2018, 43(6): 118-127, 148. | |

| 18 | 曹登峰, 宋鹏云, 李伟, 等. 螺旋槽气体端面密封动力学研究进展[J]. 润滑与密封, 2006, 31(5): 178-182, 191. |

| Cao D F, Song P Y, Li W, et al. A review on the development of seal dynamics about the spiral grooves gas face seal[J]. Lubrication Engineering, 2006, 31(5): 178-182, 191. | |

| 19 | Miller B A, Green I. Numerical formulation for the dynamic analysis of spiral-grooved gas face seals[J]. Journal of Tribology, 2001, 123(2): 395-403. |

| 20 | Green I, Barnsby R M. A simultaneous numerical solution for the lubrication and dynamic stability of noncontacting gas face seals[J]. Journal of Tribology, 2001, 123(2): 388-394. |

| 21 | 王楠. 规则微孔端面非接触气体机械密封动态特性研究[D]. 杭州: 浙江工业大学, 2009. |

| Wang N. Study on dynamic characteristics of non-contact gas mechanical seal with regular micropore end face[D]. Hangzhou: Zhejiang University of Technology, 2009. | |

| 22 | 胡松涛, 黄伟峰, 刘向锋, 等. 螺旋槽干气密封压差扰动下的瞬态特性研究[J]. 流体机械, 2017, 45(2): 22-27. |

| Hu S T, Huang W F, Liu X F, et al. Transient response analysis of spiral groove gas face seals under pressure-drop fluctuation[J]. Fluid Machinery, 2017, 45(2): 22-27. | |

| 23 | 尹源, 黄伟峰, 刘向锋, 等. 基于本征正交分解方法的螺旋槽干气密封瞬态响应分析[J]. 机械工程学报, 2017, 53(21): 79-85. |

| Yin Y, Huang W F, Liu X F, et al. Spiral groove gas face seal transient response analysis based on proper orthogonal decomposition method[J]. Journal of Mechanical Engineering, 2017, 53(21): 79-85. | |

| 24 | Chen Y, Jiang J B, Peng X D. Dynamic characteristics and transient sealing performance analysis of hyperelliptic curve groove dry gas seals[J]. Tribology International, 2017, 116: 217-228. |

| 25 | 张璇, 彭旭东, 江锦波, 等. 型孔形状和方向对孔型阻尼密封泄漏特性影响[J]. 摩擦学学报, 2020, 40(1): 117-127. |

| Zhang X, Peng X D, Jiang J B, et al. The influence of shape and directionality of hole on leakage characteristics of hole-pattern damping seals[J]. Tribology, 2020, 40(1): 117-127. | |

| 26 | Kou G Y, Li X H, Wang Y, et al. Steady performance and dynamic characteristics of a superellipse groove dry gas seal at a high-speed condition[J]. Industrial Lubrication and Tribology, 2020, 72(6): 789-796. |

| 27 | Zirkelback N, San Andre's L. Effect of frequency excitation on force coefficients of spiral groove gas seals[J]. Journal of Tribology, 1999, 121(4): 853-861. |

| 28 | Faria M T C. An efficient finite element procedure for analysis of high-speed spiral groove gas face seals[J]. Journal of Tribology, 2001, 123(1): 205-210. |

| 29 | Heshmat H, Walowit J A, Pinkus O. Analysis of gas-lubricated foil journal bearings[J]. Journal of Lubrication Technology, 1983, 105(4): 647-655. |

| 30 | Heshmat C A, Xu D S, Heshmat H. Analysis of gas lubricated foil thrust bearings using coupled finite element and finite difference methods[J]. Journal of Tribology, 2000, 122(1): 199-204. |

| 31 | Ruan B. Numerical modeling of dynamic sealing behaviors of spiral groove gas face seals[J]. Journal of Tribology, 2002, 124(1): 186-195. |

| 32 | Iordanoff I. Maximum load capacity profiles for gas thrust bearings working under high compressibility number conditions[J]. Journal of Tribology, 1998, 120(3): 571-576. |

| 33 | Chen Y, Zhang J J, Li Y T, et al. Design and performance optimization of texture arrangement scheme for foil face gas seal with super-elliptical hole texture[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2024, 46(6): 1-12. |

| 34 | Chen Y, Xiong C, Li Y T, et al. Dynamic performance analysis and parameter collaborative optimization of floating seal dam compliant foil face gas seal[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2023, 45(12): 1-12. |

| 35 | 陈源. 高速螺旋槽干气密封动态性能理论与实验研究[D]. 杭州: 浙江工业大学, 2018. |

| Chen Y. Theoretical and experimental study on dynamic performance of high-speed spiral groove dry gas seal[D]. Hangzhou: Zhejiang University of Technology, 2018. |

| [1] | Zedong WANG, Zhiping SHI, Liyan LIU. Numerical simulation and optimization of acoustic streaming considering inhomogeneous bubble cloud dissipation in rectangular reactor [J]. CIESC Journal, 2023, 74(5): 1965-1973. |

| [2] | Qiwang HOU, Zhaolun WEN, Zhonglin ZHANG, Yegang LIU, Jingxuan YANG, Dongliang CHEN, Xiaogang HAO, Guoqing GUAN. Design and evaluation of a coal-based polygeneration system with carbon cycle [J]. CIESC Journal, 2022, 73(5): 2073-2082. |

| [3] | Rong A, Liping PANG, Dongsheng YANG, Bin QI. Design and optimization of integrated thermal management system for high-speed aircraft [J]. CIESC Journal, 2020, 71(S1): 315-321. |

| [4] | Yong MING, Yannan PENG, Wen SU, Guolong WEI, Qiang WANG, Naijun ZHOU, Li ZHAO. Thermodynamic performance comparison of ORC between mixtures and pure fluids under closed heat source [J]. CIESC Journal, 2020, 71(4): 1570-1579. |

| [5] | Weifeng DENG, Zhenhua JIANG, Shaoshuai LIU, Ankuo ZHANG, Yinong WU. Optimization design and experimental properties of high-temperature and high-capacity pulse tube cooler [J]. CIESC Journal, 2019, 70(1): 107-115. |

| [6] | LI Zhentao, HUANG Baipeng, HAO Muming, SUN Xinhui, WANG Yunlei, YANG Wenjing. Hydrodynamic performance of liquid film seals in circumferential beveled-step spiral grooves [J]. CIESC Journal, 2017, 68(5): 2016-2026. |

| [7] | PENG Xudong, ZONG Cong, JIANG Jinbo. Progress in dry gas seal performance evolution of unidirectional spiral groove and its derivative structures [J]. CIESC Journal, 2017, 68(4): 1271-1281. |

| [8] | WANG Yunlei, HAO Muming, LI Zhentao, LI Yongfan, SUN Xinhui, XU Lushuai. Hydrodynamic performance of spiral groove liquid film seals based on JFO boundary condition and power law model [J]. CIESC Journal, 2017, 68(12): 4665-4674. |

| [9] | HUANG Yan, BO Cuimei, GUAN Guofeng, DING Shuai. Steady-state simulation and integrated optimization of reactive distillation for methyl acetate hydrolysis [J]. CIESC Journal, 2016, 67(3): 912-918. |

| [10] | HU Rong, YANG Minglei, QIAN Feng. Optimization of xylene adsorption separation process based on multi-objective teaching-learning-based optimization algorithm [J]. CIESC Journal, 2015, 66(1): 326-332. |

| [11] | SONG Pengyun, HU Xiaopeng, XU Hengjie. Effect of real gas on dynamic performance of T-groove dry gas seal [J]. CIESC Journal, 2014, 65(4): 1344-1352. |

| [12] | WU Lianying, HU Yangdong, GAO Congjie. Optimization design of cogeneration of power and fresh water by desalination considering fresh water demand [J]. CIESC Journal, 2013, 64(8): 2924-2929. |

| [13] | ZHANG Yu, YAN Liexiang, LI Guojian, SHI Bin. Multi-objective optimization of coal gasifier using NSES [J]. CIESC Journal, 2013, 64(12): 4628-4633. |

| [14] | CUI Pengyi,ZHOU Xuefei,ZHANG Yalei,WU Zhigen,JIANG Ming. Optimization of Oxidation Zone Flow Field and Experimental Studying in New AmOn Bioreactor [J]. CIESC Journal, 2012, 63(6): 1842-1849. |

| [15] | ZHANG Hong. Simulation and optimization design in MOCVD reactor [J]. , 2009, 28(8): 1328-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||