CIESC Journal ›› 2025, Vol. 76 ›› Issue (3): 1243-1252.DOI: 10.11949/0438-1157.20240879

• Energy and environmental engineering • Previous Articles Next Articles

Guojia YAO1( ), Zhi WANG2, Ang SU1, Dongge FENG1, Hong TANG1(

), Zhi WANG2, Ang SU1, Dongge FENG1, Hong TANG1( ), Lingfang SUN1

), Lingfang SUN1

Received:2024-08-02

Revised:2024-10-13

Online:2025-03-28

Published:2025-03-25

Contact:

Hong TANG

姚国家1( ), 王志2, 苏昂1, 冯东阁1, 唐宏1(

), 王志2, 苏昂1, 冯东阁1, 唐宏1( ), 孙灵芳1

), 孙灵芳1

通讯作者:

唐宏

作者简介:姚国家(1996—),男,博士,讲师,yaoguojia@neepu.edu.cn

基金资助:CLC Number:

Guojia YAO, Zhi WANG, Ang SU, Dongge FENG, Hong TANG, Lingfang SUN. Investigation of the effect of air coefficient on the combustion characteristics of pulverized coal pre-pyrolysis[J]. CIESC Journal, 2025, 76(3): 1243-1252.

姚国家, 王志, 苏昂, 冯东阁, 唐宏, 孙灵芳. 空气系数对煤粉预热解燃烧特性的影响分析[J]. 化工学报, 2025, 76(3): 1243-1252.

Add to citation manager EndNote|Ris|BibTeX

| 煤 | 工业分析/% | 元素分析/% | Qar,net/(kJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Var | FCar | Car | Har | Oar | Nar | Sar | ||

| 神华烟煤 | 14.50 | 7.37 | 28.67 | 49.46 | 65.10 | 3.25 | 8.08 | 0.66 | 0.71 | 23790 |

Table 1 Coal proximate and ultimate analyses data

| 煤 | 工业分析/% | 元素分析/% | Qar,net/(kJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Var | FCar | Car | Har | Oar | Nar | Sar | ||

| 神华烟煤 | 14.50 | 7.37 | 28.67 | 49.46 | 65.10 | 3.25 | 8.08 | 0.66 | 0.71 | 23790 |

| 项目 | 模型 | 参数 |

|---|---|---|

| 湍流模型 | Realizable k-ɛ模型 | |

| 辐射模型 | 离散坐标模型 | 方位4×4;像素2×2 |

| 烟气吸收系数 | 灰色气体加权和模型 | |

| 湍流反应速率模型 | 涡耗散概念模型 | |

| 拉格朗日随机追踪 | 颗粒随机轨道模型 | 迭代次数:10 |

| 颗粒辐射参数 | 发射率:0.9;散射系数:0.6 | |

| 气固耦合模型 | particle-source-in-cell方法 | |

| 热力型NO x 模型 | extended Zeldovich机理 | |

| 燃料型NO x 模型 | de Soete机理 | |

| 焦炭表面还原模型 | AE:焦炭比表面积,m2/kg;PNO:NO分压,Pa | |

| 再燃模型 | k1=108 m3/(mol·s);k2=1.4×106e-550/T m3/(mol·s);k3=2×105 m3/(mol·s) |

Table 2 Mathematical model parameters

| 项目 | 模型 | 参数 |

|---|---|---|

| 湍流模型 | Realizable k-ɛ模型 | |

| 辐射模型 | 离散坐标模型 | 方位4×4;像素2×2 |

| 烟气吸收系数 | 灰色气体加权和模型 | |

| 湍流反应速率模型 | 涡耗散概念模型 | |

| 拉格朗日随机追踪 | 颗粒随机轨道模型 | 迭代次数:10 |

| 颗粒辐射参数 | 发射率:0.9;散射系数:0.6 | |

| 气固耦合模型 | particle-source-in-cell方法 | |

| 热力型NO x 模型 | extended Zeldovich机理 | |

| 燃料型NO x 模型 | de Soete机理 | |

| 焦炭表面还原模型 | AE:焦炭比表面积,m2/kg;PNO:NO分压,Pa | |

| 再燃模型 | k1=108 m3/(mol·s);k2=1.4×106e-550/T m3/(mol·s);k3=2×105 m3/(mol·s) |

| 反应 | 化学反应方程式 | Ar | Er /(J/kmol) | m | a | b | c | 文献 |

|---|---|---|---|---|---|---|---|---|

| R1 | Vol→x1CH4+x2CO+x3H2+x4SO2+x5N2 | 1018 | 0 | 0 | 0 | 0 | 0 | — |

| R2 | CO+0.5O2→CO2 | 2.239×1012 | 1.674×108 | 0 | 1 | 0.25 | 0.5[H2O] | [ |

| R3 | H2+0.5O2→H2O | 6.8×1015 | 1.67×108 | -1 | 0.25 | 1.5 | 0 | [ |

| R4 | CH4+2O2→CO2+2H2O | 2.119×1011 | 2.052×108 | 0 | 0.2 | 1.3 | 0 | [ |

| R5 | CO+H2O→CO2+H2 | 2.34×1010 | 2.883×108 | 0 | 0.5 | 1 | 0 | [ |

| R6 | CO2+H2→CO+H2O | 2.2×107 | 1.9×108 | 0 | 0.5 | 1 | 0 | [ |

| R7 | CH4+H2O→CO+3H2 | 8.0×107 | 2.51×108 | 0 | 0.5 | 1 | 0 | [ |

Table 3 Gas-phase reactions and related kinetic parameters

| 反应 | 化学反应方程式 | Ar | Er /(J/kmol) | m | a | b | c | 文献 |

|---|---|---|---|---|---|---|---|---|

| R1 | Vol→x1CH4+x2CO+x3H2+x4SO2+x5N2 | 1018 | 0 | 0 | 0 | 0 | 0 | — |

| R2 | CO+0.5O2→CO2 | 2.239×1012 | 1.674×108 | 0 | 1 | 0.25 | 0.5[H2O] | [ |

| R3 | H2+0.5O2→H2O | 6.8×1015 | 1.67×108 | -1 | 0.25 | 1.5 | 0 | [ |

| R4 | CH4+2O2→CO2+2H2O | 2.119×1011 | 2.052×108 | 0 | 0.2 | 1.3 | 0 | [ |

| R5 | CO+H2O→CO2+H2 | 2.34×1010 | 2.883×108 | 0 | 0.5 | 1 | 0 | [ |

| R6 | CO2+H2→CO+H2O | 2.2×107 | 1.9×108 | 0 | 0.5 | 1 | 0 | [ |

| R7 | CH4+H2O→CO+3H2 | 8.0×107 | 2.51×108 | 0 | 0.5 | 1 | 0 | [ |

| 反应 | 反应方程式 | Ar | Er /(J/kmol) | n | 文献 |

|---|---|---|---|---|---|

| R8 | C(s)+0.5O2→CO | 113 | 1.3×108 | 0.68 | [ |

| R9 | C(s)+CO2→2CO | 62.3 | 2.531×108 | 1 | [ |

| R10 | C(s)+H2O→CO+H2 | 0.465 | 1.905×108 | 1 | [ |

Table 4 Char gasification reactions and related kinetic parameters

| 反应 | 反应方程式 | Ar | Er /(J/kmol) | n | 文献 |

|---|---|---|---|---|---|

| R8 | C(s)+0.5O2→CO | 113 | 1.3×108 | 0.68 | [ |

| R9 | C(s)+CO2→2CO | 62.3 | 2.531×108 | 1 | [ |

| R10 | C(s)+H2O→CO+H2 | 0.465 | 1.905×108 | 1 | [ |

| 工况 | 煤粉质量流量/(kg/s) | 一次风质量流量/(kg/s) | 空气系数 |

|---|---|---|---|

| 1 | 1.24 | 1.93 | 0.2 |

| 2 | 1.24 | 2.89 | 0.3 |

| 3 | 1.24 | 3.85 | 0.4 |

| 4 | 1.24 | 4.82 | 0.5 |

Table 5 Numerical simulation cases setup

| 工况 | 煤粉质量流量/(kg/s) | 一次风质量流量/(kg/s) | 空气系数 |

|---|---|---|---|

| 1 | 1.24 | 1.93 | 0.2 |

| 2 | 1.24 | 2.89 | 0.3 |

| 3 | 1.24 | 3.85 | 0.4 |

| 4 | 1.24 | 4.82 | 0.5 |

| 项目 | 实验结果 | 计算结果 | 误差分析 | ||

|---|---|---|---|---|---|

| RPM-MSRM模型 | MSRM模型 | RPM-MSRM模型 | MSRM模型 | ||

| CH4体积分数/% | 2.93 | 2.81 | 1.91 | -4.09% | -34.81% |

| H2体积分数/% | 10.26 | 10.61 | 8.46 | +3.41% | -17.54% |

| CO体积分数/% | 16.83 | 17.88 | 12.97 | +6.24% | -22.94% |

| CO2体积分数/% | 9.48 | 8.95 | 12.56 | -5.59% | +32.49% |

| 出口温度/K | 1257 | 1313 | 1125 | +4.46% | -10.50% |

Table 6 Comparison between the CFD results and experimental data of case 2

| 项目 | 实验结果 | 计算结果 | 误差分析 | ||

|---|---|---|---|---|---|

| RPM-MSRM模型 | MSRM模型 | RPM-MSRM模型 | MSRM模型 | ||

| CH4体积分数/% | 2.93 | 2.81 | 1.91 | -4.09% | -34.81% |

| H2体积分数/% | 10.26 | 10.61 | 8.46 | +3.41% | -17.54% |

| CO体积分数/% | 16.83 | 17.88 | 12.97 | +6.24% | -22.94% |

| CO2体积分数/% | 9.48 | 8.95 | 12.56 | -5.59% | +32.49% |

| 出口温度/K | 1257 | 1313 | 1125 | +4.46% | -10.50% |

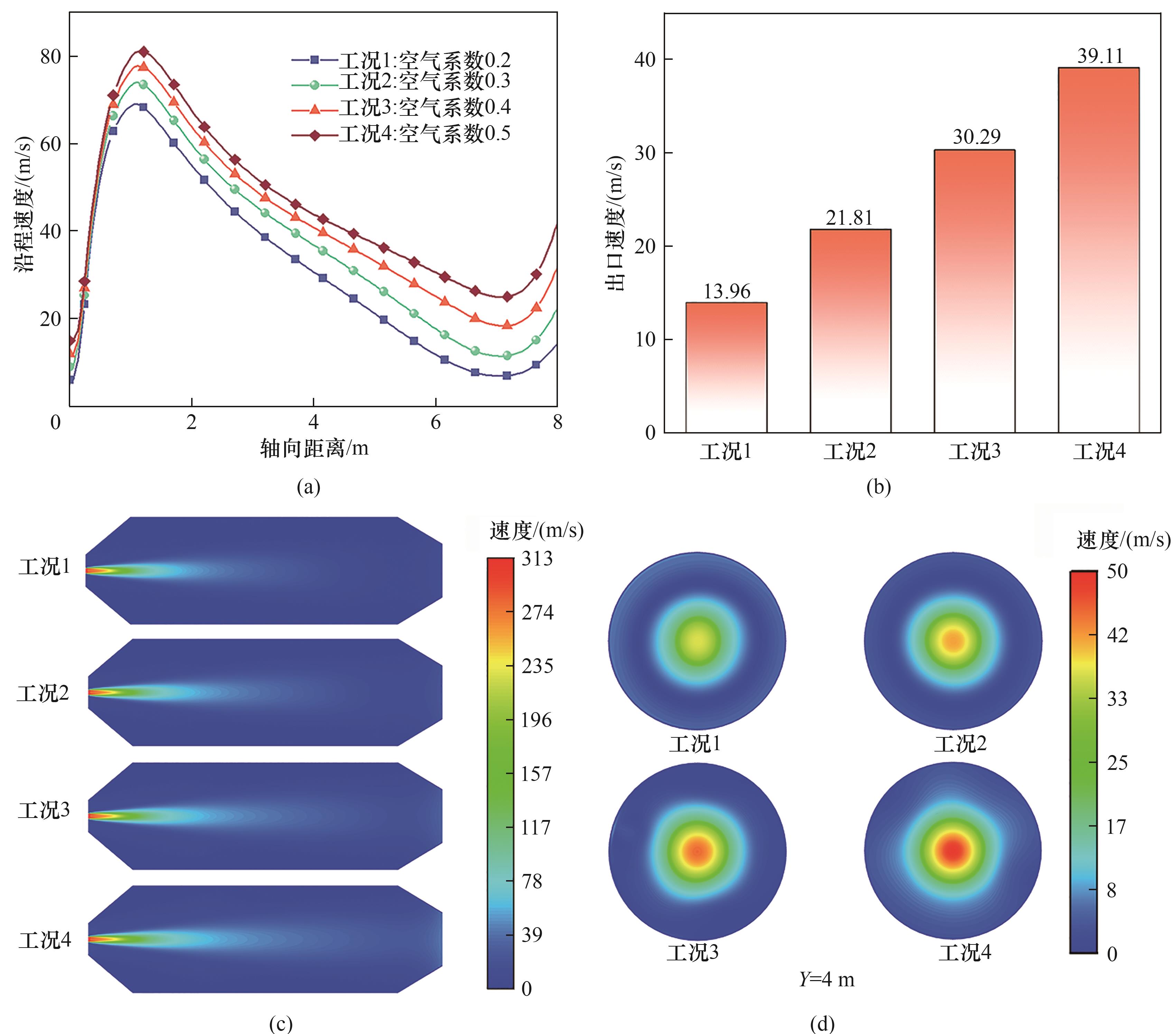

Fig.3 Velocity distribution of pre-pyrolysis device: (a) along-travel velocity; (b) outlet velocity; (c) velocity distribution contours; (d) cross-sectional velocity distribution contours (Y=4 m)

| 工况 | 空气系数 | 颗粒转化率/% | 颗粒平均停留时间/s | |

|---|---|---|---|---|

| 挥发分 | 焦炭 | |||

| 1 | 0.2 | 100 | 31.53 | 2.68 |

| 2 | 0.3 | 100 | 50.97 | 1.87 |

| 3 | 0.4 | 100 | 65.23 | 1.18 |

| 4 | 0.5 | 100 | 74.78 | 0.82 |

Table 7 Summary of particles conversion ratio and residue time

| 工况 | 空气系数 | 颗粒转化率/% | 颗粒平均停留时间/s | |

|---|---|---|---|---|

| 挥发分 | 焦炭 | |||

| 1 | 0.2 | 100 | 31.53 | 2.68 |

| 2 | 0.3 | 100 | 50.97 | 1.87 |

| 3 | 0.4 | 100 | 65.23 | 1.18 |

| 4 | 0.5 | 100 | 74.78 | 0.82 |

| 1 | Glarborg P, Miller J A, Ruscic B, et al. Modeling nitrogen chemistry in combustion[J]. Progress in Energy and Combustion Science, 2018, 67: 31-68. |

| 2 | Wang Z, Peng X Y, Cao S X, et al. NO x emission prediction using a lightweight convolutional neural network for cleaner production in a down-fired boiler[J]. Journal of Cleaner Production, 2023, 389: 136060. |

| 3 | 国家统计局. 中华人民共和国2023年国民经济和社会发展统计公报[J]. 中国统计, 2024(3): 4-21. |

| National Bureau of Statistics. Statistical communiqué of the People’s Republic of China on the 2023 national economic and social development[J]. China Statistics, 2024(3): 4-21. | |

| 4 | Wang Z, Peng X Y, Zhou H C, et al. A dynamic modeling method using channel-selection convolutional neural network: a case study of NO x emission[J]. Energy, 2024, 290: 130270. |

| 5 | Zhu S J, Hui J C, Lyu Q G, et al. Experimental study on pulverized coal combustion preheated by a circulating fluidized bed: preheating characteristics for peak shaving[J]. Fuel, 2022, 324: 124684. |

| 6 | Yao G J, Han X J, Liu Z D, et al. Low-NO x study of a 600 MW tangentially fired boiler based on pulverized coal preheating method[J]. Case Studies in Thermal Engineering, 2023, 48: 103156. |

| 7 | Rabovitser J, Bryan B, Knight R, et al. Development and testing of a novel coal preheating technology for NO x reduction from pulverized coal-fired boilers[J]. Gas, 2003, 1(2): 4. |

| 8 | Tang H, Liu Z D, Han X J, et al. Experimental study on combustion characteristics of a 40 MW pulverized coal boiler based on a new low NO x burner with preheating function[J]. Energy, 2024, 305: 132319. |

| 9 | Liu J Z, Liu Y H, Zhu J G, et al. Bituminous coal deep regulated ultra-low NO x flameless combustion with fluidized self-preheating fuel: a 2 MWth experimental study[J]. Fuel, 2021, 294: 120549. |

| 10 | Ouyang Z Q, Liu W, Man C B, et al. Experimental study on combustion, flame and NO x emission of pulverized coal preheated by a preheating burner[J]. Fuel Processing Technology, 2018, 179: 197-202. |

| 11 | Rahimipetroudi I, Rashid K, Yang J B, et al. Development of environment-friendly dual fuel pulverized coal-natural gas combustion technology for the co-firing power plant boiler: experimental and numerical analysis[J]. Energy, 2021, 228: 120550. |

| 12 | Lv Z M, Xiong X H, Ruan R H, et al. NO emission and burnout characteristics in co-combustion of coal and sewage sludge following high-temperature preheating[J]. Fuel, 2023, 331: 125887. |

| 13 | Zhu G Q, Xu L, Wang S, et al. Synergistic reduction on PM and NO source emissions during preheating-combustion of pulverized coal[J]. Fuel, 2024, 361: 130699. |

| 14 | Hui J C, Zhu S J, Zhang X Y, et al. Experimental study of deep and flexible load adjustment on pulverized coal combustion preheated by a circulating fluidized bed[J]. Journal of Cleaner Production, 2023, 418: 138040. |

| 15 | 吕清刚, 朱书骏, 朱建国, 等. 煤粉预热燃烧技术研发进展[J]. 中国电机工程学报, 2022, 42(18): 6535-6547. |

| Lyu Q G, Zhu S J, Zhu J G, et al. Research and development on preheated combustion of pulverized coal[J]. Proceedings of the CSEE, 2022, 42(18): 6535-6547. | |

| 16 | Chen D G, Zhang Z, Li Z S, et al. Optimizing in situ char gasification kinetics in reduction zone of pulverized coal air-staged combustion[J]. Combustion and Flame, 2018, 194: 52-71. |

| 17 | Zhu S J, Lyu Q G, Zhu J G, et al. Experimental study on NO x emissions of pulverized bituminous coal combustion preheated by a circulating fluidized bed[J]. Journal of the Energy Institute, 2019, 92(2): 247-256. |

| 18 | Ding H L, Ouyang Z Q, Shi Y S, et al. Effects of the T-abrupt exit configuration of riser on fuel properties, combustion characteristics and NO x emissions with coal self-preheating technology[J]. Fuel, 2023, 337: 126860. |

| 19 | Iwaszenko S, Howaniec N, Smoliński A. Determination of random pore model parameters for underground coal gasification simulation[J]. Energy, 2019, 166: 972-978. |

| 20 | Wang H Y, Zhang C Q, Liu X. Heat transfer calculation methods in three-dimensional CFD model for pulverized coal-fired boilers[J]. Applied Thermal Engineering, 2020, 166: 114633. |

| 21 | Wang H Y, Jin D H, Liu X, et al. Analytical and numerical investigations on the high temperature upgrading solution of subcritical boilers[J]. Applied Thermal Engineering, 2022, 200: 117628. |

| 22 | Adamczyk W P, Werle S, Ryfa A. Application of the computational method for predicting NO x reduction within large scale coal-fired boiler[J]. Applied Thermal Engineering, 2014, 73(1): 343-350. |

| 23 | Westbrook C K, Dryer F L. Simplified reaction mechanisms for the oxidation of hydrocarbon fuels in flames[J]. Combustion Science and Technology, 1981, 27(1/2): 31-43. |

| 24 | Jones W P, Lindstedt R P. Global reaction schemes for hydrocarbon combustion[J]. Combustion and Flame, 1988, 73(3): 233-249. |

| 25 | Bustamante F, Enick R M, Killmeyer R P, et al. Uncatalyzed and wall-catalyzed forward water-gas shift reaction kinetics[J]. AIChE Journal, 2005, 51(5): 1440-1454. |

| 26 | Ma J L, Zitney S E. Computational fluid dynamic modeling of entrained-flow gasifiers with improved physical and chemical submodels[J]. Energy & Fuels, 2012, 26(12): 7195-7219. |

| 27 | 仇鹏, 韩洋, 许建良, 等. 用于预测气流床煤气化的EDC模型参数研究[J]. 化工学报, 2023, 74(1): 428-437. |

| Qiu P, Han Y, Xu J L, et al. Study of EDC parameters for predicting entrained flow coal gasification[J]. CIESC Journal, 2023, 74(1): 428-437. | |

| 28 | Gran I R, Magnussen B F. A numerical study of a bluff-body stabilized diffusion flame(part 1): Influence of turbulence modeling and boundary conditions[J]. Combustion Science and Technology, 1996, 119(1/2/3/4/5/6): 171-190. |

| 29 | Zhang X Y, Zhu S J, Song W J, et al. Experimental study on conversion characteristics of anthracite and bituminous coal during preheating-gasification[J]. Fuel, 2022, 324: 124712. |

| 30 | Wang S, Niu Y Q, Zhu G Q, et al. NO formation and destruction during combustion of high temperature preheated pulverized coal[J]. Journal of the Energy Institute, 2021, 99: 82-87. |

| 31 | Kajitani S, Hara S, Matsuda H. Gasification rate analysis of coal char with a pressurized drop tube furnace[J]. Fuel, 2002, 81(5): 539-546. |

| 32 | Bhatia S K, Perlmutter D D. A random pore model for fluid-solid reactions(Ⅰ): Isothermal, kinetic control[J]. AIChE Journal, 1980, 26(3): 379-386. |

| 33 | Haugen N E L, Loong B K Y, Mitchell R E. Numerical approaches for thermochemical conversion of char[J]. Progress in Energy and Combustion Science, 2022, 91: 100993. |

| 34 | Smith I W. The combustion rates of coal chars: a review[J]. Symposium (International) on Combustion, 1982, 19(1):1045-1065. |

| 35 | Fluent A. Ansys Fluent Theory Guide[M]. USA: Ansys Inc, 2020. |

| 36 | Yao G J, Liu Z D, Tang H, et al. Prediction of reduction products in the preheating process[J]. Thermal Science, 2023, 27(5 Part B): 4021-4034. |

| 37 | Liu H, Liu Y H, Yi G Z, et al. Effects of air staging conditions on the combustion and NO x emission characteristics in a 600 MW wall fired utility boiler using lean coal[J]. Energy & Fuels, 2013, 27(10): 5831-5840. |

| 38 | Sánchez C, Arenas E, Chejne F, et al. A new model for coal gasification on pressurized bubbling fluidized bed gasifiers[J]. Energy Conversion and Management, 2016, 126: 717-723. |

| 39 | Zhao L L, Zhou Q T, Zhao C S. Flame characteristics in a novel petal swirl burner[J]. Combustion and Flame, 2008, 155(1/2): 277-288. |

| 40 | Glarborg P, Alzueta M U, Dam-Johansen K, et al. Kinetic modeling of hydrocarbon/nitric oxide interactions in a flow reactor[J]. Combustion and Flame, 1998, 115(1/2): 1-27. |

| [1] | Zhongqing LI, Zhiyuan WANG, Xiaojian LUAN, Sikai LIANG, Kai WANG. Preparation of MnO coating based on electroplating-low oxygen partial pressure treatment and coking inhibition properties during thermal cracking of naphtha [J]. CIESC Journal, 2025, 76(3): 1050-1063. |

| [2] | Fang XU, Rui ZHANG, Da CUI, Qing WANG. Study of pyrolysis reaction mechanism of lignin revealed by ReaxFF-MD simulation [J]. CIESC Journal, 2025, 76(3): 1253-1263. |

| [3] | Nannan XIE, He CHEN, Guanghua YE, Zhongming SHU, Songbao FU, Xinggui ZHOU. Interaction of multiple impellers for gas-liquid stirred tank and optimization of their combinations [J]. CIESC Journal, 2025, 76(2): 564-575. |

| [4] | Yan LI, Hongli GUO, Guoqing SU, Jianwen ZHANG. Gas-liquid two-phase flow and erosion-corrosion in air cooler of hydrogenation unit [J]. CIESC Journal, 2025, 76(1): 141-150. |

| [5] | Na HUANG, Yunlong JIANG, Donghan WANG, Mingting WU, Xueli JIANG, Yu ZHONG. Numerical study of influence of channel vibration frequency on flow and heat transfer of supercritical n-decane with pyrolysis reaction [J]. CIESC Journal, 2025, 76(1): 173-183. |

| [6] | Qirui GUO, Liyuan REN, Kang CHEN, Xiangyu HUANG, Weihua MA, Leqin XIAO, Weiliang ZHOU. Numerical simulation of static mixing tubes for HTPB propellant slurry [J]. CIESC Journal, 2024, 75(S1): 206-216. |

| [7] | Xuehong WU, Xin WEI, Jiawen HOU, Cai LYU, Yong LIU, He LIU, Zhijuan CHANG. Preparation of carbon nanotubes by pyrolysis method and their application in heat dissipation coatings [J]. CIESC Journal, 2024, 75(9): 3360-3368. |

| [8] | Zhengliang HUANG, Mingrui FENG, Qi SONG, Congjing REN, Yao YANG, Jingyuan SUN, Jingdai WANG, Yongrong YANG. Inhibitory effect of premixed feedstock on particle agglomeration in fluidized pyrolysis reaction of waste resin [J]. CIESC Journal, 2024, 75(9): 3094-3102. |

| [9] | Shuying WANG, Tao ZUO, Zhiwei SHI, Xiaoming FAN, Weixin ZHANG. Synthesis and sodium ion storage properties of cation exchange resin based mesoporous graphitic carbon [J]. CIESC Journal, 2024, 75(9): 3338-3347. |

| [10] | Yong DING, Wenjian LI, Zhaoyu CHEN, Lihui CAO, Xuanming LIU, Qiangqiang REN, Song HU, Jun XIANG. Aerobic pyrolysis kinetic and product characteristics of waste crystalline silicon photovo ltaic modules’ EVA [J]. CIESC Journal, 2024, 75(9): 3310-3319. |

| [11] | Qian LI, Rongmin ZHANG, Zijie LIN, Qi ZHAN, Weihua CAI. Prediction and simulation of flow and heat transfer for printed circuit plate heat exchanger based on machine learning [J]. CIESC Journal, 2024, 75(8): 2852-2864. |

| [12] | Jialei CAO, Liyan SUN, Dewang ZENG, Fan YIN, Zixiang GAO, Rui XIAO. Numerical simulation of chemical looping hydrogen generation with dual fluidized bed reactors [J]. CIESC Journal, 2024, 75(8): 2865-2874. |

| [13] | Hu JIN, Fan YANG, Mengyao DAI. The motion process of a droplet on a circular cylinder based on the lattice Boltzmann method [J]. CIESC Journal, 2024, 75(8): 2897-2908. |

| [14] | Fangming LYU, Zhiming BAO, Bowen WANG, Kui JIAO. Investigation on impact of gas diffusion layer intrusion into channel on water management in fuel cell [J]. CIESC Journal, 2024, 75(8): 2929-2938. |

| [15] | Hongzhe YAO, Feiyu HUANG, Song YANG, Mei ZHONG, Zhenghua DAI. Kinetic modeling of the high-temperature rapid pyrolysis auto-reaction network of heavy oil [J]. CIESC Journal, 2024, 75(7): 2644-2655. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||