CIESC Journal ›› 2025, Vol. 76 ›› Issue (12): 6179-6195.DOI: 10.11949/0438-1157.20250329

• Reviews and monographs • Previous Articles Next Articles

Xinyan CHEN( ), Yiling CHEN, Xinbo PENG, Jingjie HU, Xueliang JIANG, Feng YOU(

), Yiling CHEN, Xinbo PENG, Jingjie HU, Xueliang JIANG, Feng YOU( )

)

Received:2025-04-01

Revised:2025-04-19

Online:2026-01-23

Published:2025-12-31

Contact:

Feng YOU

陈欣妍( ), 陈依玲, 彭馨博, 胡靖杰, 江学良, 游峰(

), 陈依玲, 彭馨博, 胡靖杰, 江学良, 游峰( )

)

通讯作者:

游峰

作者简介:陈欣妍(2004—),女,本科生,1980215892@qq.com

CLC Number:

Xinyan CHEN, Yiling CHEN, Xinbo PENG, Jingjie HU, Xueliang JIANG, Feng YOU. Recent progress in the preparation, structure, and application of thermal insulation materials[J]. CIESC Journal, 2025, 76(12): 6179-6195.

陈欣妍, 陈依玲, 彭馨博, 胡靖杰, 江学良, 游峰. 隔热材料的制备、结构及应用研究进展[J]. 化工学报, 2025, 76(12): 6179-6195.

Add to citation manager EndNote|Ris|BibTeX

| 分类 | 典型材料 | 形态 | 热导率/ (W/(m·K)) | 性能特点 | 制备方法 | 文献 |

|---|---|---|---|---|---|---|

| 有机高分子材料 | 聚苯乙烯泡沫板(EPS) | 泡沫 | 40.0 | 轻质易切割,吸水性较高,需阻燃处理;广泛用于建筑墙体保温 | 挤出法、泡沫塑料加工法 | — |

| 聚苯乙烯泡沫挤塑板(XPS) | 泡沫 | 30.0 | 闭孔结构,抗压强度高,防潮性好;适用于地暖、冷库 | 挤出成型法 | — | |

| 聚氨酯泡沫(PUR) | 泡沫 | 20.0~30.0 | 高黏结性,无缝填充,阻燃性优于EPS;用于冷链、管道保温 | 发泡法、喷涂法 | [ | |

| 聚酰亚胺 | 泡沫 | 100.0~50.0 | 耐温性较好,低烟无毒,脆性较高 | 热固化法、发泡法 | [ | |

| 生物质材料 | 纤维素 | 颗粒 | 40.0~60.0 | 天然可再生,弹性好,但易受潮霉变;用于红酒塞、装饰保温 | — | [ |

| 壳聚糖 | 松散填充 | 50.0~200.0 | 高孔隙率,吸声性强,防虫蛀;适用于热带地区建筑隔热 | — | [ | |

| 木质素 | 板材 | 50.0~70.0 | 农业废弃物再生利用,成本低,但耐火性差;用于临时建筑夹层 | — | [ | |

| 无机材料 | 硅酸铝纤维 | 纤维棉 | 30.0~40.0 | 耐高温,抗热震,但对皮肤有刺激性;用于窑炉内衬 | 纤维化法、吹气法 | [ |

| 碳纳米线圈 | — | 20.0~40.0 | 超弹性,电磁屏蔽效能高,表面活性位点多;用于催化载体,柔性传感器 | — | [ | |

| 石墨烯 | — | 10.0~20.0 | 超高导电性,超轻,力学强度可调;应用于超级电容器电极,高效散热片 | — | [ | |

| 二氧化硅 | 气凝胶 | 10.0~20.0 | 超轻,憎水性强,柔性可裁剪;用于航天服、管道包裹 | 超临界干燥法、溶胶-凝胶法 | [ | |

| 碳 | 气凝胶 | 10.0~20.0 | 导电性可控,耐高温,纳米多孔结构;用于电池隔热、电子器件 | — | [ | |

| 玻璃棉 | 纤维卷材 | 30.0~40.0 | 成本低,吸声性能好,但易碎裂;广泛用于建筑吊顶、管道保温 | 纤维化法、吹气法 | [ | |

| 有机-无机杂化材料 | 二氧化硅气凝胶/聚酰亚胺泡沫 | 泡沫 | 24.0 | 高温稳定性强,良好的隔热性能 | 液氮气化法 | [ |

| 聚酰亚胺气凝胶/二氧化硅复合材料 | 气凝胶 | 7.4 | 卓越的低热导率和结构稳定性 | 3D打印与氢键网络调控 | [ | |

| 间位芳纶纤维/氟化空心玻璃微球 | 气凝胶 | 21.6 | 高的隔热性能及耐热性 | 溶胶-凝胶法 | [ |

Table 1 Common thermal insulation materials and their properties

| 分类 | 典型材料 | 形态 | 热导率/ (W/(m·K)) | 性能特点 | 制备方法 | 文献 |

|---|---|---|---|---|---|---|

| 有机高分子材料 | 聚苯乙烯泡沫板(EPS) | 泡沫 | 40.0 | 轻质易切割,吸水性较高,需阻燃处理;广泛用于建筑墙体保温 | 挤出法、泡沫塑料加工法 | — |

| 聚苯乙烯泡沫挤塑板(XPS) | 泡沫 | 30.0 | 闭孔结构,抗压强度高,防潮性好;适用于地暖、冷库 | 挤出成型法 | — | |

| 聚氨酯泡沫(PUR) | 泡沫 | 20.0~30.0 | 高黏结性,无缝填充,阻燃性优于EPS;用于冷链、管道保温 | 发泡法、喷涂法 | [ | |

| 聚酰亚胺 | 泡沫 | 100.0~50.0 | 耐温性较好,低烟无毒,脆性较高 | 热固化法、发泡法 | [ | |

| 生物质材料 | 纤维素 | 颗粒 | 40.0~60.0 | 天然可再生,弹性好,但易受潮霉变;用于红酒塞、装饰保温 | — | [ |

| 壳聚糖 | 松散填充 | 50.0~200.0 | 高孔隙率,吸声性强,防虫蛀;适用于热带地区建筑隔热 | — | [ | |

| 木质素 | 板材 | 50.0~70.0 | 农业废弃物再生利用,成本低,但耐火性差;用于临时建筑夹层 | — | [ | |

| 无机材料 | 硅酸铝纤维 | 纤维棉 | 30.0~40.0 | 耐高温,抗热震,但对皮肤有刺激性;用于窑炉内衬 | 纤维化法、吹气法 | [ |

| 碳纳米线圈 | — | 20.0~40.0 | 超弹性,电磁屏蔽效能高,表面活性位点多;用于催化载体,柔性传感器 | — | [ | |

| 石墨烯 | — | 10.0~20.0 | 超高导电性,超轻,力学强度可调;应用于超级电容器电极,高效散热片 | — | [ | |

| 二氧化硅 | 气凝胶 | 10.0~20.0 | 超轻,憎水性强,柔性可裁剪;用于航天服、管道包裹 | 超临界干燥法、溶胶-凝胶法 | [ | |

| 碳 | 气凝胶 | 10.0~20.0 | 导电性可控,耐高温,纳米多孔结构;用于电池隔热、电子器件 | — | [ | |

| 玻璃棉 | 纤维卷材 | 30.0~40.0 | 成本低,吸声性能好,但易碎裂;广泛用于建筑吊顶、管道保温 | 纤维化法、吹气法 | [ | |

| 有机-无机杂化材料 | 二氧化硅气凝胶/聚酰亚胺泡沫 | 泡沫 | 24.0 | 高温稳定性强,良好的隔热性能 | 液氮气化法 | [ |

| 聚酰亚胺气凝胶/二氧化硅复合材料 | 气凝胶 | 7.4 | 卓越的低热导率和结构稳定性 | 3D打印与氢键网络调控 | [ | |

| 间位芳纶纤维/氟化空心玻璃微球 | 气凝胶 | 21.6 | 高的隔热性能及耐热性 | 溶胶-凝胶法 | [ |

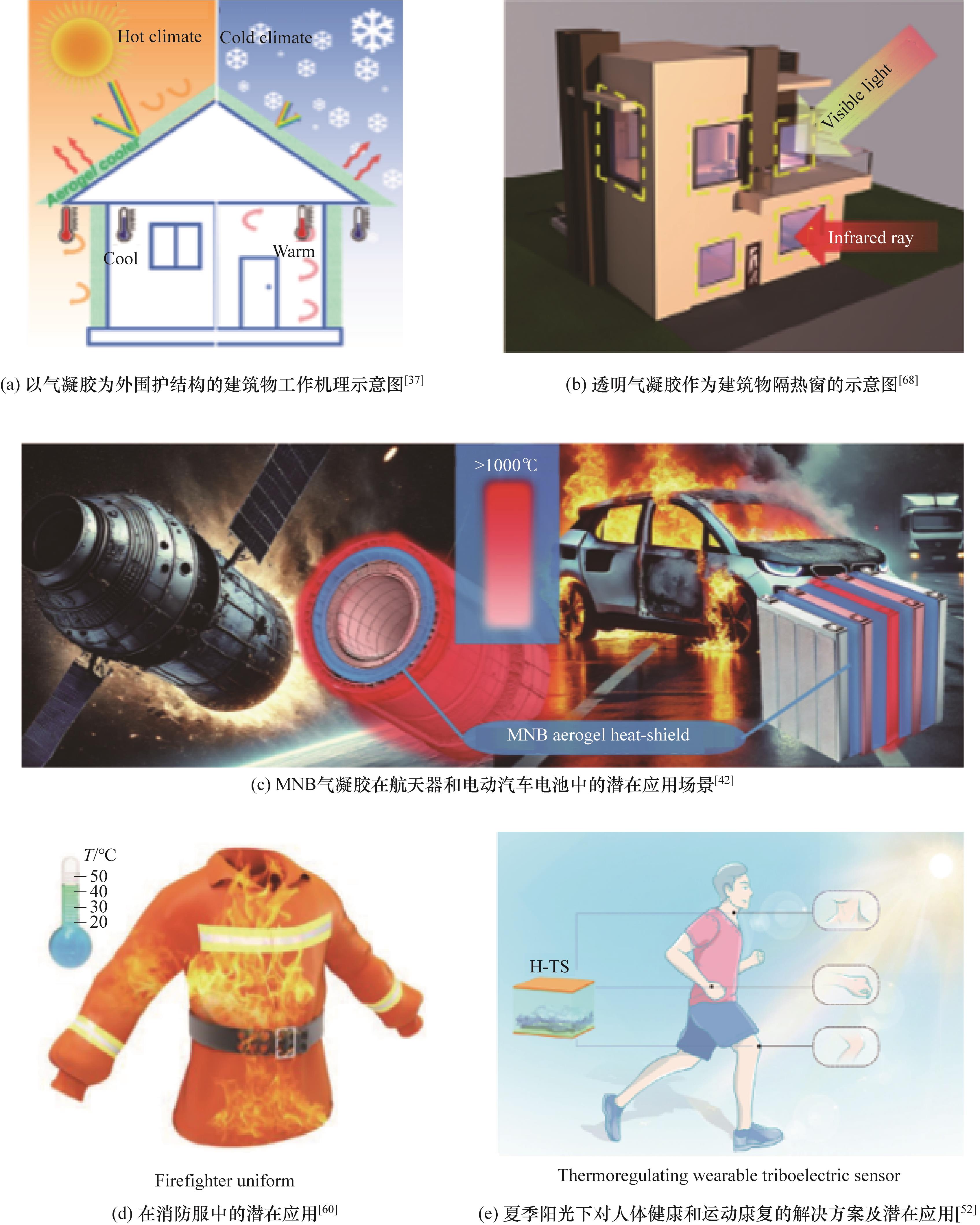

Fig.8 Research on the multifunctional applications of thermal insulation materials in the fields of construction, aerospace, batteries, and protective clothing

| [1] | Feng J B, Ma Z W, Wu J P, et al. Fire-safe aerogels and foams for thermal insulation: from materials to properties[J]. Advanced Materials, 2025, 37(3): 2411856. |

| [2] | 章婷, 赵春林, 乐弦, 等. 气凝胶研究进展[J]. 现代技术陶瓷, 2018, 39(1): 1-39. |

| Zhang T, Zhao C L, Le X, et al. Research progress of aerogels[J]. Advanced Ceramics, 2018, 39(1): 1-39. | |

| [3] | 李德富, 杨炜平, 刘小旭. 多层隔热材料传热特性研究现状及展望[J]. 航天器环境工程, 2013, 30(3): 302-309. |

| Li D F, Yang W P, Liu X X. Heat transfer characteristics of multilayer insulation materials[J]. Spacecraft Environment Engineering, 2013, 30(3): 302-309. | |

| [4] | 柳凤琦, 王鲁凯, 门静, 等. 气凝胶隔热材料制备及航天热防护应用研究进展[J]. 宇航材料工艺, 2022, 52(2): 26-47. |

| Liu F Q, Wang L K, Men J, et al. Progress on the preparation of aerogel thermal insulations and their applications in aerospace thermal protection system[J]. Aerospace Materials & Technology, 2022, 52(2): 26-47. | |

| [5] | 施伟, 谭毅, 曹作暄. 隔热材料研究现状及发展趋势[J]. 材料导报, 2012, 26(S1): 344-347. |

| Shi W, Tan Y, Cao Z X. Research status and development trend of thermal insulating materials[J]. Materials Reports, 2012, 26(S1): 344-347. | |

| [6] | 门静, 王鲁凯, 冯军宗, 等. 炭气凝胶隔热材料研究进展[J]. 材料工程, 2024, 52(6): 78-91. |

| Men J, Wang L K, Feng J Z, et al. Research progress in carbon aerogels for thermal insulations[J]. Journal of Materials Engineering, 2024, 52(6): 78-91. | |

| [7] | Zhang Y, Wu Y Y, Liu Z J, et al. Preparation and properties of waterborne polyurethane/nanocellulose/sepiolite composite aerogel for sound absorption and heat insulation[J]. International Journal of Biological Macromolecules, 2025, 298: 140015. |

| [8] | Wu H, Ren X H, Hu W X, et al. Permittivity controllable CNTs/PI composite aerogels with oriented microchannels for advanced microwave absorption and thermal isolation[J]. Carbon, 2025, 233: 119883. |

| [9] | Zhou Q Q, Hong W J, Sheng K X, et al. Direct ink writing 3D printed graphene oxide nanocomposite aerogel for intelligent fire-warning and exceptional fire-shielding[J]. Chemical Engineering Journal, 2024, 499: 156325. |

| [10] | Wang H C, Cao L Y, Liu Y, et al. Preparation of sustainable kapok fiber/chitosan composite aerogels with amphiphilic and mechanical properties for thermal insulation and packaging applications[J]. Fibers and Polymers, 2024, 25(6): 2081-2091. |

| [11] | Zhang M R, Jeong S, Cho W, et al. Green co-solvent-assisted one-pot synthesis of high-performance flexible lignin polyurethane foam[J]. Chemical Engineering Journal, 2024, 499: 156142. |

| [12] | Deng T, Li Y F, Jiang C W, et al. A facile and green preparation of aluminum silicate fiber reinforced silica aerogel composites for thermal insulation[J]. Journal of Porous Materials, 2025, 32: 1237-1251. |

| [13] | Guo Y, Duan Y P, Gu S D, et al. Carbon nanocoils-assisted formation of tunable pore graphene aerogels for lightweight broadband microwave absorption, thermal insulation, and antifreeze devices[J]. Small, 2025, 21(10): 2412270. |

| [14] | Cho J, Jang E, Kim J, et al. Development of boron nitride hydroxide/aluminum oxide/epoxy resin spheres and graphene oxide-loaded L-ascorbic acid aerogel for enhanced thermal conductivity and insulation via hot-pressing[J]. Polymers for Advanced Technologies, 2025, 36(2): e70120. |

| [15] | Wang J H, Liu L P, Dong W L, et al. Ultra-high radial elastic aerogel fibers for thermal insulation textile[J]. Advanced Functional Materials, 2025, 35(13): 2417873. |

| [16] | Sha R Y, Wang B Z, Dai J X, et al. Novel ultralight carbon foam reinforced carbon aerogel composites with low volume shrinkage and excellent thermal insulation performance[J]. Carbon, 2025, 232: 119826. |

| [17] | Tariq I, Hu J H, Chen W J, et al. Summer and winter performance evaluation of double layered PTFE dome with aerogel-glass wool thermal insulation—field experiments and numerical simulation[J]. Energy and Buildings, 2024, 319: 114538. |

| [18] | Wang Y Y, Pang N, Yin X Q, et al. Rapid preparation of stretchable, compressible and flexible nanofiber foams by one-step expansion for thermal insulation and adsorption of sound and oil[J]. Chemical Engineering Journal, 2025, 506: 159916. |

| [19] | Li M M, Wu T T, Zhao Z Y, et al. Multiscale manufacturing of recyclable polyimide composite aerogels[J]. Advanced Materials, 2025, 37(5): 2411599. |

| [35] | Zhang Z, Liu C, Li N, et al. Highly oriented SiC@SiO2 ceramic fiber aerogels with good anisotropy of the thermal conductivity and high-temperature resistance[J]. Advanced Science, 2025, 12(17): 2416740. |

| [36] | Zhou J T, Wu E J, Hu Y H, et al. Structurally resilient carbon nanofiber aerogels from aramid nanofibers for thermal insulation under extreme conditions[J]. Chemical Engineering Journal, 2025, 505: 159507. |

| [37] | Wu F S, Hu P Y, Hu F Y, et al. Multifunctional MXene/C aerogels for enhanced microwave absorption and thermal insulation[J]. Nano-Micro Letters, 2023, 15(1): 194. |

| [38] | Ma Y J, Hu Y H, Wang Y, et al. Seasonal thermal management and fire-resistant aramid nanofiber/MXene-NH2 aerogel for enhanced safety and year-round energy saving[J]. ACS Applied Nano Materials, 2024, 7(20): 23485-23493. |

| [39] | Tian Y C, Chen Y X, Wang S, et al. Energy-harvesting carbon aerogel nanofiber metafabric for high-efficiency thermoregulation[J]. Advanced Functional Materials, 2025, 35(4): 2414229. |

| [40] | Gai L X, Zhao H H, Li X A, et al. Shell engineering afforded dielectric polarization prevails and impedance amelioration toward electromagnetic wave absorption enhancement in nested-network carbon architecture[J]. Chemical Engineering Journal, 2024, 501: 157556. |

| [41] | Cheng Y J, Cheng H L, Gao J, et al. Air-drying for rapid manufacture of flexible aramid nanofiber aerogel fibers with robust mechanical properties and thermal insulation in harsh environments[J]. Small, 2025, 21(7): 2409408. |

| [42] | Luo W, Wang T, Gou X, et al. In situ assembly of nanostructured polyelectrolyte coatings by aqueous phase separation toward outstanding thermal insulation and fire resistance[J]. ACS Materials Letters, 2024, 6(12): 5418-5428. |

| [43] | Chen J, Hou X B, Chen Z L, et al. Double-crosslinked organic-inorganic hybrid polyimide aerogel composites with ultra-robust toughness for foldable mechanical-thermal-coupled protection[J]. Advanced Functional Materials, 2025, 35(23): 2420717. |

| [44] | Wang X D, Wang Y J, Zhang Z, et al. Strong and ultrahigh temperature-resistant metal oxide nanobelt aerogels[J]. Advanced Functional Materials, 2025, 35(5): 2414592. |

| [45] | Yang C G, Xu Y K, Liu H Y, et al. Multiscale porous heat insulation polypropylene foam with high infrared absorption performance[J]. Langmuir, 2025, 41(8): 5546-5556. |

| [46] | Hu L K, Luo L, Zhang F H, et al. Self-Sensing shape memory boron phenolic-formaldehyde aerogels with tunable heat insulation for smart thermal protection systems[J]. Chemical Engineering Journal, 2025, 505: 159558. |

| [20] | Yang R, Yu K X, Yu X, et al. Penguin feather-inspired flexible aerogel composite films featuring ultra-low thermal conductivity and dielectric constant[J]. Materials Horizons, 2025, 12(8): 2629-2640. |

| [21] | Niu Z Q, Qu F J, Chen F, et al. Multifunctional integrated organic-inorganic-metal hybrid aerogel for excellent thermal insulation and electromagnetic shielding performance[J]. Nano-Micro Letters, 2024, 16(1): 200. |

| [22] | Wang Z Y, Li Z C, Li B, et al. Functional carbon springs enabled dynamic tunable microwave absorption and thermal insulation[J]. Advanced Materials, 2024, 36(49): 2412605. |

| [23] | Zhang W, Liang G Q, Wang S, et al. Loofah-inspired ultralight and superelastic micro/nanofibrous aerogels for highly efficient thermal insulation[J]. Advanced Functional Materials, 2025, 35(2): 2412424. |

| [24] | Yu N, Wang T, Xu C X, et al. In-situ packing self-intumescent aerogel particles in rigid polyurethane foam towards thermal insulation, flame retardance and smoke suppression[J]. Chemical Engineering Journal, 2025, 503: 158514. |

| [25] | Cai S H, Deng X P, Beiyuan J Z, et al. Review of synthetic polymer-based thermal insulation materials in construction and building[J]. Journal of Building Engineering, 2024, 97: 110846. |

| [26] | Zhang P, Zhao S, Li K F, et al. Large-scale production of elastic SiC/SiO2 nanofibrous composite aerogels with a labyrinth structure for high-temperature insulation, fire prevention, and noise absorption[J]. Chemical Engineering Journal, 2025, 505: 159166. |

| [27] | Xie Z Q, Jiang Y G, Feng J Z, et al. Thermally insulating fiber-reinforced SiO2-TiO2 aerogel composites via a novel hydrothermal-assisted drying process[J]. Ceramics International, 2025, 51(11): 14834-14841. |

| [28] | Wen Z H, Tang Z Y, Liu Y W, et al. Ultrastrong and high thermal insulating porous high-entropy ceramics up to 2000℃[J]. Advanced Materials, 2024, 36(14): 2311870. |

| [29] | Zhang X, Huang W B, Yu J Y, et al. Nacre-mimetic multi-mechanical synergistic ceramic aerogels with interfacial bridging and stress delocalization[J]. Advanced Functional Materials, 2025, 35(10): 2416857. |

| [30] | Yu P H, Gao Y, Zhang G D, et al. 3D self-supportive structures of micro/nanofiber assemblies constructed in situ in air turbulent flow fields for thermal protection at extreme conditions[J]. Chemical Engineering Journal, 2025, 511: 161536. |

| [31] | Li L F, Yin Y G, Mi C Y, et al. Phase stability, flexibility and thermal insulation of DyTaO4 fibers[J]. Chemical Engineering Journal, 2025, 505: 159590. |

| [47] | Song L M, Wu Y Z, Xue J L, et al. A high-temperature resistant phosphate-phenolic composite foam with low density, high strength, flame retardant and thermal insulating properties[J]. Composites Part B: Engineering, 2025, 297: 112294. |

| [48] | Zhang X, Wang Z Q, Ding S, et al. Improved thermal insulation, mechanical properties, energy absorption and flame retardancy of bio-based rigid polyurethane foam modified with calcium hydroxystannate[J]. Construction and Building Materials, 2024, 456: 139251. |

| [49] | Shi T, Jing J W, Qian Z Q, et al. Sandwich-structured fluorinated polyimide aerogel/paraffin phase-change composites simultaneously enables gradient thermal protection and electromagnetic wave transmission[J]. Advanced Science, 2025, 12(5): 2411758. |

| [50] | Fu X T, Si L M, Zhang Z X, et al. Gradient all-nanostructured aerogel fibers for enhanced thermal insulation and mechanical properties[J]. Nature Communications, 2025, 16(1): 2357. |

| [51] | Chen Z L, Hou X B, Chen J, et al. Two-step phase-separated ANF/polyimide aerogel fibers with tunable in situ core-sheath structure for wearable heat-insulated fabrics[J]. Composites Part A: Applied Science and Manufacturing, 2025, 192: 108801. |

| [52] | Huang Z Y, Tong A X, Xing T H, et al. Regenerated cellulose/lignin composite aerogel with unique toast-like structure and their potential applications in thermal camouflage[J]. Advanced Functional Materials, 2025, 35(6): 2414696. |

| [53] | Liu Y M, Bu X H, Feng M X, et al. Spectrally selective and thermally insulating hybrid nanofiber aerogel coolers for building energy conservation[J]. Journal of Colloid and Interface Science, 2025, 680: 345-354. |

| [54] | Zhong S J, Lu B H, Wang D C, et al. Passive isothermal flexible sensor enabled by smart thermal-regulating aerogels[J]. Advanced Materials, 2025, 37(8): 2415386. |

| [55] | Wicklein B, Kocjan A, Salazar-Alvarez G, et al. Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide[J]. Nature Nanotechnology, 2015, 10(3): 277-283. |

| [56] | Gao C Q, Gou D M, Huang G, et al. Spiderweb-structured aerogels with high-efficiency microwave absorption and multifunctionality[J]. Nano Energy, 2025, 138: 110863. |

| [57] | Le D T, Carbonnier B, Hamadi S, et al. Toward the development of graphene/chitosan biocomposite aerogels with enhanced mechanical and thermal insulation performance[J]. ACS Applied Polymer Materials, 2024, 6(21): 13132-13146. |

| [58] | Liu Z Y, Liu T, Dong H P, et al. Diatom-inspired nanoscale heterogeneous assembly strategy for constructing thermal insulating wood-based aerogels with exceptional strength, resilience, degradability, and flame retardancy[J]. ACS Nano, 2025, 19(7): 6826-6839. |

| [59] | Zhang J Y, Zheng J J, Gao M Y, et al. Nacre-mimetic nanocomposite aerogels with exceptional mechanical performance for thermal superinsulation at extreme conditions[J]. Advanced Materials, 2023, 35(29): 2300813. |

| [60] | Men J, He C B, Wang L K, et al. Synthesis of structure controllable carbon aerogel with low drying shrinkage and scalable size as high-temperature thermal insulator[J]. Chemical Engineering Journal, 2025, 503: 157989. |

| [61] | Hu Z H, Wang S, Wu J P, et al. Robust multi-scale bionic ANF/PMSQ aerogel featuring impact protection, thermal insulation and anti-icing functions[J]. Composites Part B: Engineering, 2025, 297: 112304. |

| [62] | Wang G L, Liu L, Hu X Y, et al. Aerogel-functionalized phase change materials toward lightweight and robust thermal management[J]. Small Methods, 2025, 9(8): 2500127. |

| [63] | Wang L Y, Li W J, Wang C, et al. “Cocktail-like” double-layered polyimide/alumina composite aerogels via side-direction freezing method as designable high-temperature thermal insulations[J]. Chemical Engineering Journal, 2024, 500: 157052. |

| [64] | Kang Y F, Tang J L, Song M, et al. Electrostatic encapsulation of cobalt ions into crystalline framework derived polymer aerogel: ultra-light, pressure resistant, hydrophobic, photothermal conversion, heat insulation and infrared stealth[J]. Chinese Journal of Polymer Science, 2024, 42(7): 946-957. |

| [65] | Liu X, Zhu Q Z, Qian Y P, et al. Enhanced photothermal interface evaporation via coupling of Ag-GO aerogel with thermal insulation substrate[J]. Separation and Purification Technology, 2025, 360: 131080. |

| [66] | Ma Y L, Xing D M, Tian M W, et al. Multiwalled hollow polyurethane and graphene oxide/polyurethane fibers in Janus textiles for thermal management and sensors[J]. ACS Applied Nano Materials, 2024, 7(19): 22884-22894. |

| [67] | Jiang S, Jiang S Q, Yan J T, et al. Large-scale continuous production of cellulose/hollow SiO2 composite aerogel fibers for outdoor all-day radiation cooling[J]. Nano Energy, 2025, 136: 110688. |

| [68] | Li Y H, Zhang X, Zhang T, et al. Radiative cooling materials prepared by SiO2 aerogel microspheres@PVDF-HFP nanofilm for building cooling and thermal insulation[J]. Ceramics International, 2024, 50(22): 48031-48040. |

| [69] | Zhu T Y, Wang D B, Wang Y S, et al. Gelation-constrained freeze-casting fabrication of ultra-homogeneous nanocomposite aerogels with superelasticity and harsh environment tolerance[J]. Advanced Functional Materials, 2025, 35(12): 2503693. |

| [70] | Yu D Y, Xue T T, Ma Z C, et al. 3D printed polyimide/silica composite aerogels for customizable thermal insulation from -50℃ to 1300℃[J]. Chinese Journal of Polymer Science, 2024, 42(7): 936-945. |

| [32] | Miao J H, Song X L, Xu J X, et al. Ultralight, elastic, thermally insulating, and high-temperature resistant Al2O3-SiO2-B2O3 nanofibrous aerogels prepared via the direct foaming method[J]. ACS Applied Materials & Interfaces, 2025, 17(8): 12402-12414. |

| [33] | Dang S X, Guo J R, Deng Y P, et al. Highly-buckled nanofibrous ceramic aerogels with ultra-large stretchability and tensile-insensitive thermal insulation[J]. Advanced Materials, 2025, 37(4): 2415159. |

| [34] | Zhang X, Yu J Y, Si Y. Programmable shape-morphing enables ceramic meta-aerogel highly stretchable for thermal protection[J]. Advanced Materials, 2025, 37(3): 2412962. |

| [71] | Xue T T, Yuan S J, Yang Y, et al. Freezing-assisted direct ink writing of customized polyimide aerogels with controllable micro- and macro- structures for thermal insulation[J]. Advanced Functional Materials, 2025, 35(13): 2417734. |

| [72] | Chen Z Y, Wu Y Y, Liu S C, et al. Pottery-inspired flexible fire-shielding ceramifiable silicone foams for exceptional long-term thermal protection[J]. Advanced Functional Materials, 2025, 35(3): 2413362. |

| [73] | Zhou T P, He L B, Zhen Y, et al. Superstrong lightweight aerogel with supercontinuous layer by surface reaction[J]. Advanced Materials, 2025, 37(10): 2418083. |

| [74] | Wang G, Feng J B, Zhou Z Z, et al. Low-cost hyperelastic fuller-dome-structured nanocellulose aerogels by dual templates for personal thermal management[J]. Advanced Materials, 2024, 37(22): 2414896. |

| [75] | Yu Y, Xu C J, Hu Z X, et al. Industrial scale sea-island melt-spun continuous ultrafine fibers for highly comfortable insulated aerogel felt clothing[J]. Advanced Materials, 2024, 36(52): 2414731. |

| [76] | Hu Z Y, Zhang X Y, Sun Q, et al. Biomimetic transparent layered tough aerogels for thermal superinsulation and triboelectric nanogenerator[J]. Small, 2024, 20(24): 2307602. |

| [1] | Wei ZHAO, Wenle XING, Zhaoxu HAN, Xingzhong YUAN, Longbo JIANG. Progress of g-C3N4-based metal-free heterojunction photocatalytic degradation of organic pollutants in water [J]. CIESC Journal, 2025, 76(9): 4752-4769. |

| [2] | Yinxiang TANG, Feng ZHU, Yingying FAN, Yuxin LONG, Yong DAI, Chunling DENG, Xiaofeng HUANG. Effect of preparation conditions on low-temperature co-removal of COS and CS2 from modified calcium carbide slag [J]. CIESC Journal, 2025, 76(7): 3639-3650. |

| [3] | Zhengzheng GUO, Yidan ZHAO, Fuqiang WANG, Lu PEI, Yanling JIN, Fang REN, Penggang REN. Construction and electromagnetic wave absorption properties of MoS2/RGO/NiFe2O4 composites with heterogeneous architecture [J]. CIESC Journal, 2025, 76(7): 3719-3732. |

| [4] | Xuerui LU, Guoyan ZHOU, Qi FANG, Mengzheng YU, Xiucheng ZHANG, Shandong TU. Numerical study on the carbon deposition effect in external reformer of solid oxide fuel cells [J]. CIESC Journal, 2025, 76(7): 3295-3304. |

| [5] | Naisheng GUO, Xiaobo ZHU, Shuang WANG, Ping CHEN, Zhaoyang CHU, Zhichen WANG. Research progress on high and low temperature performance and influencing factors of polyurethane modified asphalt [J]. CIESC Journal, 2025, 76(6): 2505-2523. |

| [6] | Jian PENG, Lukai SHEN, Likun WANG, Lihong XIN, Yong LIU, Gaoling ZHAO, Sainan MA, Gaorong HAN. Preparation of tungstate nanomaterials and research progress in electrochromic field [J]. CIESC Journal, 2025, 76(6): 2451-2468. |

| [7] | Shenghua YANG, Yangjie SUN, Xiaojun XUE, Jie MI, Jiancheng WANG, Yu FENG. Research progress on gas pollutants removal by defective metal oxides [J]. CIESC Journal, 2025, 76(6): 2469-2482. |

| [8] | Zijuan LI, Xiaoyan TAN, Yongsheng WU, Chenyi YANG, Hong CHEN, Xiaogang BI, Jie LIU, Faquan YU. Molecular simulation study on CO2/N2 separation via 3D-contorted catalytic arene-norbornene annulation polymer membrane [J]. CIESC Journal, 2025, 76(5): 2348-2357. |

| [9] | Haotian AN, Zhangye HAN, Muyao LU, Awu ZHOU, Jianrong LI. Promoting industrial application of MOF: scale-up preparation and shaping [J]. CIESC Journal, 2025, 76(5): 2011-2025. |

| [10] | Jinyue WANG, Enze XIE, Hanze MA, Sheng YUAN, Guangwei HE, Zhongyi JIANG. Monoatomic layer separation membrane: progress and prospect [J]. CIESC Journal, 2025, 76(5): 1943-1959. |

| [11] | Junbing XIAO, Bo ZOU, Jiandi REN, Changhui LIU, Chuankun JIA. Research on heat storage performance of chloride composite molten salt based on phase diagram analysis [J]. CIESC Journal, 2025, 76(3): 963-974. |

| [12] | Ben’an CAI, Jianxin ZHANG, Chengjun LONG, Qiaochen DU, Xunjian CHE, Yiying ZHANG, Weihua CAI. Spray flash evaporation preparation of micro/nanoparticles [J]. CIESC Journal, 2025, 76(3): 1334-1345. |

| [13] | Junbing XIAO, Xiangyu ZHONG, Jiandi REN, Fangfang ZHONG, Changhui LIU, Chuankun JIA. Research on the heat storage properties of stearic acid phase change materials enhanced by bio-carbon materials [J]. CIESC Journal, 2025, 76(3): 1312-1322. |

| [14] | Yanbei LIU, Ruoming WANG, Juan LIU, Taimoor Raza, Yuzheng LU, Rizwan Raza, Bin ZHU, Songbo LI, Shengli AN, Sining YUN. Preparation of CeO2@La0.6Sr0.4Co0.2Fe0.8O3-δ electrolyte and its property in semiconductor ionic fuel cells performance [J]. CIESC Journal, 2025, 76(3): 1353-1362. |

| [15] | Yuanhua LI, Siqi LING, Kejun FENG, Ying FENG, Yuching KUO, Shihhuan HSIEH. Construction and catalytic application of immobilized lipase microreactors based on cMOFs for the synthesis of mandelic acid [J]. CIESC Journal, 2025, 76(3): 1170-1179. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||