CIESC Journal ›› 2021, Vol. 72 ›› Issue (S1): 170-177.DOI: 10.11949/0438-1157.20201569

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

MA Qiuming1( ),NIE Lei1,PAN Quanwen1(

),NIE Lei1,PAN Quanwen1( ),SHAN He1,CAO Weiliang2,WANG Qiang2,WANG Ruzhu1

),SHAN He1,CAO Weiliang2,WANG Qiang2,WANG Ruzhu1

Received:2020-11-03

Revised:2021-01-11

Online:2021-06-20

Published:2021-06-20

Contact:

PAN Quanwen

马秋鸣1( ),聂磊1,潘权稳1(

),聂磊1,潘权稳1( ),山訸1,曹伟亮2,王强2,王如竹1

),山訸1,曹伟亮2,王强2,王如竹1

通讯作者:

潘权稳

作者简介:马秋鸣(1989—),男,博士,助理研究员,基金资助:CLC Number:

MA Qiuming, NIE Lei, PAN Quanwen, SHAN He, CAO Weiliang, WANG Qiang, WANG Ruzhu. Heat exchange performance of a battery chiller for electric vehicles[J]. CIESC Journal, 2021, 72(S1): 170-177.

马秋鸣, 聂磊, 潘权稳, 山訸, 曹伟亮, 王强, 王如竹. 电动汽车电池冷却器换热性能[J]. 化工学报, 2021, 72(S1): 170-177.

Add to citation manager EndNote|Ris|BibTeX

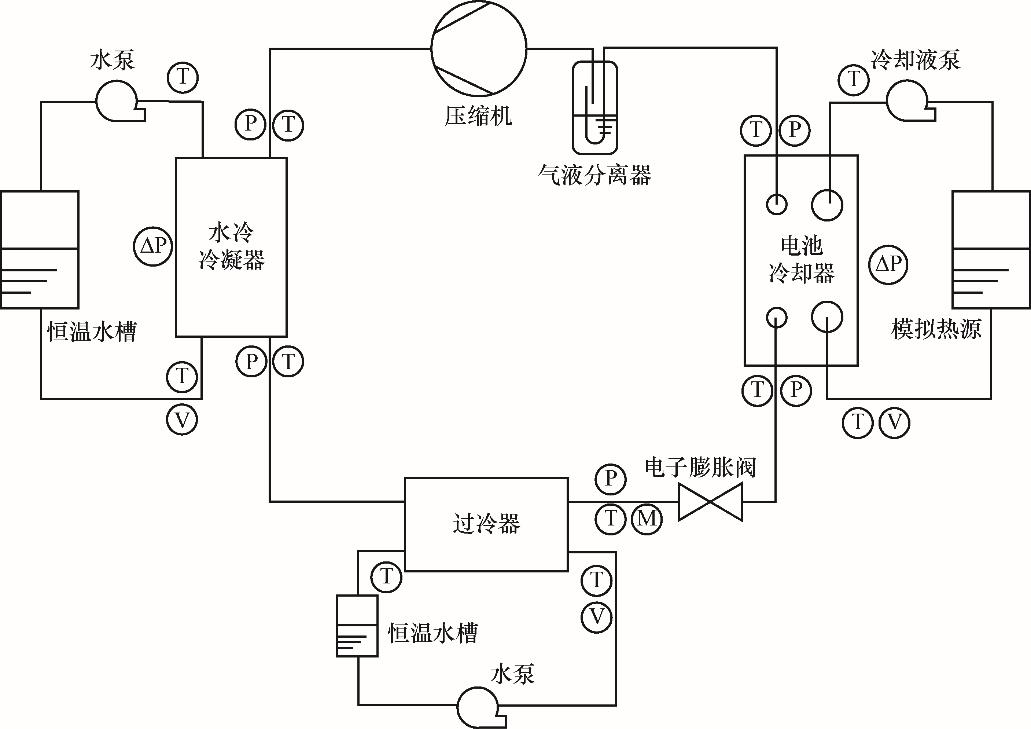

Fig.3 Experimental testing system (P—pressure measuring points; T—temperature measuring points; V—flowrate measuring points; ΔP—pressure difference measuring points)

| 部件 | 型号 | 规格 | 生产厂家 |

|---|---|---|---|

| 压缩机 | EVS50B (低压版) EVS50HLBCAA-8AA | 全封闭电动涡旋压缩机,排量50c/rev,转速1500~6000; 8.5kW~6000 r/min,0.2/1.4 MPa[G] SH/SC=10/5K; 6.3kW~6000 r/min Te/Tc=-20/45℃ SH/SC=10/5 K; 接口管径OD 15.5 mm / ID 21.3 mm 高压工作范围400~720 V;低压工作范围9~36 V 通讯协议CAN2.0;波特率500 | 上海海立新能源技术有限公司 |

| 冷凝器 | B3-020G-42D-304-4.5 | 钎焊板式换热器 总换热面积:0.8 m2 外形尺寸312 mm×76 mm×64 mm 接口管径:制冷剂侧15.5 mm,水侧19 mm | 江苏唯益换热器股份公司 |

| 过冷器 | B3-020G-10D-304-4.5 | 钎焊板式换热器 总换热面积:0.2 m2 外形尺寸312 mm×76 mm×18 mm 接口管径:制冷剂侧15.5 mm,水侧19 mm | 江苏唯益换热器股份公司 |

| 电子膨胀阀 | EAS-16K001 | 阀口通径1.6 mm 接口管径OD 11.05/ID 15.5 mm | 浙江三花汽车零部件有限公司 |

| 气液分离器 | RA-207 | 接口管径ID/OD 19/21 mm 桶身高度218 mm 配备分子筛 适用冷量10 kW | 天津双昊车用空调有限公司 |

| 高压电源 | HNX-600V-7200W | 输入380 V AC 输出6~600 V DC 12 A | 深圳市海纳信科技有限公司 |

Table 1 Type and parameters of main parts of testing system

| 部件 | 型号 | 规格 | 生产厂家 |

|---|---|---|---|

| 压缩机 | EVS50B (低压版) EVS50HLBCAA-8AA | 全封闭电动涡旋压缩机,排量50c/rev,转速1500~6000; 8.5kW~6000 r/min,0.2/1.4 MPa[G] SH/SC=10/5K; 6.3kW~6000 r/min Te/Tc=-20/45℃ SH/SC=10/5 K; 接口管径OD 15.5 mm / ID 21.3 mm 高压工作范围400~720 V;低压工作范围9~36 V 通讯协议CAN2.0;波特率500 | 上海海立新能源技术有限公司 |

| 冷凝器 | B3-020G-42D-304-4.5 | 钎焊板式换热器 总换热面积:0.8 m2 外形尺寸312 mm×76 mm×64 mm 接口管径:制冷剂侧15.5 mm,水侧19 mm | 江苏唯益换热器股份公司 |

| 过冷器 | B3-020G-10D-304-4.5 | 钎焊板式换热器 总换热面积:0.2 m2 外形尺寸312 mm×76 mm×18 mm 接口管径:制冷剂侧15.5 mm,水侧19 mm | 江苏唯益换热器股份公司 |

| 电子膨胀阀 | EAS-16K001 | 阀口通径1.6 mm 接口管径OD 11.05/ID 15.5 mm | 浙江三花汽车零部件有限公司 |

| 气液分离器 | RA-207 | 接口管径ID/OD 19/21 mm 桶身高度218 mm 配备分子筛 适用冷量10 kW | 天津双昊车用空调有限公司 |

| 高压电源 | HNX-600V-7200W | 输入380 V AC 输出6~600 V DC 12 A | 深圳市海纳信科技有限公司 |

| 参数 | 测量仪表 | 量程 | 精度 | 厂商 |

|---|---|---|---|---|

制冷剂温度T/℃ 制冷剂绝对压力 p/kPa | 高温温压传感器 | T -30~125 p 184~3518 | ±1.5% | 盾安传感 |

| 低温温压传感器 | T -30~125 p 101~1025 | ±1.5% | ||

| 冷却液温度/℃ | 水温传感器 | -40~200 | ±0.5℃ | 三花汽零 |

| 冷却液压差/kPa | 压差传感器 | 0~100 | ±1% | 杭州美控 |

| 冷却液流量/(L/min) | 体积流量传感器 | 5~25 | ±1% | 长征仪表 |

| 输入电流/A | 直流电流传感器 | 0~20 A DC | ±0.5% | 杭州美控 |

| 输入电压/V | 直流电压传感器 | 0~1000 V DC | ±0.5% | 杭州美控 |

Table 2 Sensor parameters

| 参数 | 测量仪表 | 量程 | 精度 | 厂商 |

|---|---|---|---|---|

制冷剂温度T/℃ 制冷剂绝对压力 p/kPa | 高温温压传感器 | T -30~125 p 184~3518 | ±1.5% | 盾安传感 |

| 低温温压传感器 | T -30~125 p 101~1025 | ±1.5% | ||

| 冷却液温度/℃ | 水温传感器 | -40~200 | ±0.5℃ | 三花汽零 |

| 冷却液压差/kPa | 压差传感器 | 0~100 | ±1% | 杭州美控 |

| 冷却液流量/(L/min) | 体积流量传感器 | 5~25 | ±1% | 长征仪表 |

| 输入电流/A | 直流电流传感器 | 0~20 A DC | ±0.5% | 杭州美控 |

| 输入电压/V | 直流电压传感器 | 0~1000 V DC | ±0.5% | 杭州美控 |

| 工况参数 | 数值 |

|---|---|

| 膨胀阀进口温度T3/℃ | 50 |

| 膨胀阀进口绝对压力p3/MPa | 1.5 |

| chiller出口过热度SH3/℃ | 5 |

| chiller出口绝对压力p5/MPa | 0.3 |

| 冷却液侧流量V3/(L/min) | 12 |

| 冷却液侧进口温度T11/℃ | 20 |

Table 3 Basic test conditions

| 工况参数 | 数值 |

|---|---|

| 膨胀阀进口温度T3/℃ | 50 |

| 膨胀阀进口绝对压力p3/MPa | 1.5 |

| chiller出口过热度SH3/℃ | 5 |

| chiller出口绝对压力p5/MPa | 0.3 |

| 冷却液侧流量V3/(L/min) | 12 |

| 冷却液侧进口温度T11/℃ | 20 |

| 1 | Kim S C, Won J P, Park Y S, et al. Performance evaluation of a stack cooling system using CO2 air conditioner in fuel cell vehicles [J]. International Journal of Refrigeration, 2009, 32(1): 70-77. |

| 2 | Al-Alawi B M, Bradley T H. Total cost of ownership, payback, and consumer preference modeling of plug-in hybrid electric vehicles [J]. Applied Energy, 2013, 103: 488-506. |

| 3 | Brouwer A S, Kuramochi T, van den Broek M, et al. Fulfilling the electricity demand of electric vehicles in the long term future: an evaluation of centralized and decentralized power supply systems [J]. Applied Energy, 2013, 107: 33-51. |

| 4 | Habib S, Khan M M, Abbas F, et al. A comprehensive study of implemented international standards, technical challenges, impacts and prospects for electric vehicles [J]. IEEE Access, 2018, 6: 13866-13890. |

| 5 | Opitz A, Badami P, Shen L, et al. Can Li-ion batteries be the panacea for automotive applications? [J]. Renewable and Sustainable Energy Reviews, 2017, 68: 685-692. |

| 6 | Hong S H, Jang D S, Park S, et al. Thermal performance of direct two-phase refrigerant cooling for lithium-ion batteries in electric vehicles [J]. Applied Thermal Engineering, 2020, 173: 115213. |

| 7 | Santhanagopalan S, Zhang Q, Kumaresan K, et al. Parameter estimation and life modeling of lithium-ion cells [J]. Journal of the Electrochemical Society, 2008, 155(4): A345. |

| 8 | Arora S, Kapoor A, Shen W X. A novel thermal management system for improving discharge/charge performance of Li-ion battery packs under abuse [J]. Journal of Power Sources, 2018, 378: 759-775. |

| 9 | Doucette R T, McCulloch M D. Modeling the prospects of plug-in hybrid electric vehicles to reduce CO2 emissions [J]. Applied Energy, 2011, 88(7): 2315-2323. |

| 10 | Wang H, Liu Y, Fu H, et al. Estimation of state of charge of batteries for electric vehicles [J]. International Journal of Control and Automation, 2013, 6(2): 185-194. |

| 11 | Kim D W, Lee M Y. Theoretical approach on the heating and cooling system design for an effective operation of Li-ion batteries for electric vehicles [J]. Journal of the Korea Academia-Industrial Cooperation Society, 2014, 15(5): 2545-2552. |

| 12 | Lee H S, Won J P, Lim T K, et al. Experimental study on performance characteristics of the triple fluids heat exchanger with two kinds of coolants in electric-driven air conditioning system for fuel cell electric vehicles [J]. Energy Procedia, 2017, 113: 209-216. |

| 13 | Alaoui C. Solid-state thermal management for lithium-ion EV batteries [J]. IEEE Transactions on Vehicular Technology, 2013, 62(1): 98-107. |

| 14 | Wang Q, Jiang B, Li B, et al. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles [J]. Renewable and Sustainable Energy Reviews, 2016, 64: 106-128. |

| 15 | Choi K W, Yao N P. Heat transfer in lead-acid batteries designed for electric-vehicle propulsion application [J]. Journal of the Electrochemical Society, 1979, 126(8): 1321-1328. |

| 16 | Kim G H, Pesaran A. Battery thermal management design modeling [J]. World Electric Vehicle Journal, 2007, 1(1): 126-133. |

| 17 | 黄蔚. 电动汽车电池冷却器仿真研究[D]. 贵阳: 贵州大学, 2019. |

| Huang W. Simulations of chiller for electric vehicles [D]. Guiyang: Guizhou University, 2019. | |

| 18 | Pesaran A A. Battery thermal models for hybrid vehicle simulations [J]. Journal of Power Sources, 2002, 110(2): 377-382. |

| 19 | Rao Z H, Wang S F. A review of power battery thermal energy management [J]. Renewable and Sustainable Energy Reviews, 2011, 15(9): 4554-4571. |

| 20 | Bandhauer T M, Garimella S, Fuller T F. A critical review of thermal issues in lithium-ion batteries [J]. Journal of the Electrochemical Society, 2011, 158(3): R1. |

| 21 | Drummond K P, Back D, Sinanis M D, et al. A hierarchical manifold microchannel heat sink array for high-heat-flux two-phase cooling of electronics [J]. International Journal of Heat and Mass Transfer, 2018, 117: 319-330. |

| 22 | 张荣荣, 张根祥, Stanke Edwin, 等. 电子膨胀阀在电动汽车空调和电池冷却系统中的应用[J]. 制冷与空调, 2018, 18(5): 77-80, 85. |

| Zhang R R, Zhang G X, Stanke E, et al. Electronic expansion valve in the application of the electric car air conditioning cooling system and battery [J]. Refrigeration and Air-Conditioning, 2018, 18(5): 77-80, 85. | |

| 23 | 张春秋, 罗玉林. 电动汽车电池冷却系统对空调系统性能的影响[J]. 制冷与空调, 2020, 20(2): 49-52, 72. |

| Zhang C Q, Luo Y L. Effect of battery cooling system on performance of air-conditioning system for electric vehicle [J]. Refrigeration and Air-Conditioning, 2020, 20(2): 49-52, 72. | |

| 24 | Longo G A. The effect of vapour super-heating on hydrocarbon refrigerant condensation inside a brazed plate heat exchanger [J]. Experimental Thermal and Fluid Science, 2011, 35(6): 978-985. |

| 25 | Mancin S, de del Col D, Rossetto L. R32 partial condensation inside a brazed plate heat exchanger [J]. International Journal of Refrigeration, 2013, 36(2): 601-611. |

| 26 | Sarraf K, Launay S, Tadrist L. Analysis of enhanced vapor desuperheating during condensation inside a plate heat exchanger [J]. International Journal of Thermal Sciences, 2016, 105: 96-108. |

| 27 | Longo G A, Mancin S, Righetti G, et al. HFC404A condensation inside a small brazed plate heat exchanger: comparison with the low GWP substitutes propane and propylene [J]. International Journal of Refrigeration, 2017, 81: 41-49. |

| 28 | 吴学红, 李灿, 龚毅, 等. 板式换热器相变流动的传热及压降特性[J]. 化工学报, 2017, 68(S1): 133-140. |

| Wu X H, Li C, Gong Y, et al. Heat transfer and pressure drop characteristic of phase change flow in plate heat exchanger [J]. CIESC Journal, 2017, 68(S1): 133-140. | |

| 29 | 李明春, 肖刚, 史和春, 等. 人字形波纹板相变流动及换热特性研究[J]. 工程热物理学报, 2016, 37(3): 581-585. |

| Li M C, Xiao G, Shi H C, et al. Study on phase change flow and heat transfer characteristics of chevron corrugated plate [J]. Journal of Engineering Thermophysics, 2016, 37(3): 581-585. | |

| 30 | Ian H. Bell and the CoolProp Team. CoolProp 6.1.0 documentation [EB/OL]. [2020-05-06]. . |

| 31 | Clifford A A. Multivariate error analysis: a handbook of error propagation and calculation in many-parameter system [EB/OL]. 1973. |

| [1] | Xin WU, Jianying GONG, Long JIN, Yutao WANG, Ruining HUANG. Study on the transportation characteristics of droplets on the aluminium surface under ultrasonic excitation [J]. CIESC Journal, 2023, 74(S1): 104-112. |

| [2] | Zhanyu YE, He SHAN, Zhenyuan XU. Performance simulation of paper folding-like evaporator for solar evaporation systems [J]. CIESC Journal, 2023, 74(S1): 132-140. |

| [3] | Shuangxing ZHANG, Fangchen LIU, Yifei ZHANG, Wenjing DU. Experimental study on phase change heat storage and release performance of R-134a pulsating heat pipe [J]. CIESC Journal, 2023, 74(S1): 165-171. |

| [4] | Lisen BI, Bin LIU, Hengxiang HU, Tao ZENG, Zhuorui LI, Jianfei SONG, Hanming WU. Molecular dynamics study on evaporation modes of nanodroplets at rough interfaces [J]. CIESC Journal, 2023, 74(S1): 172-178. |

| [5] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [6] | Aiqiang CHEN, Yanqi DAI, Yue LIU, Bin LIU, Hanming WU. Influence of substrate temperature on HFE7100 droplet evaporation process [J]. CIESC Journal, 2023, 74(S1): 191-197. |

| [7] | Mingxi LIU, Yanpeng WU. Simulation analysis of effect of diameter and length of light pipes on heat transfer [J]. CIESC Journal, 2023, 74(S1): 206-212. |

| [8] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [9] | Jingwei CHAO, Jiaxing XU, Tingxian LI. Investigation on the heating performance of the tube-free-evaporation based sorption thermal battery [J]. CIESC Journal, 2023, 74(S1): 302-310. |

| [10] | Cheng CHENG, Zhongdi DUAN, Haoran SUN, Haitao HU, Hongxiang XUE. Lattice Boltzmann simulation of surface microstructure effect on crystallization fouling [J]. CIESC Journal, 2023, 74(S1): 74-86. |

| [11] | Huafu ZHANG, Lige TONG, Zhentao ZHANG, Junling YANG, Li WANG, Junhao ZHANG. Recent progress and development trend of mechanical vapor compression evaporation technology [J]. CIESC Journal, 2023, 74(S1): 8-24. |

| [12] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [13] | Yubing WANG, Jie LI, Hongbo ZHAN, Guangya ZHU, Dalin ZHANG. Experimental study on flow boiling heat transfer of R134a in mini channel with diamond pin fin array [J]. CIESC Journal, 2023, 74(9): 3797-3806. |

| [14] | Cong QI, Zi DING, Jie YU, Maoqing TANG, Lin LIANG. Study on solar thermoelectric power generation characteristics based on selective absorption nanofilm [J]. CIESC Journal, 2023, 74(9): 3921-3930. |

| [15] | Ke LI, Jian WEN, Biping XIN. Study on influence mechanism of vacuum multi-layer insulation coupled with vapor-cooled shield on self-pressurization process of liquid hydrogen storage tank [J]. CIESC Journal, 2023, 74(9): 3786-3796. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||