CIESC Journal ›› 2022, Vol. 73 ›› Issue (11): 4917-4927.DOI: 10.11949/0438-1157.20220901

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Jianwei ZHANG( ), Baoshuai LI, Xin DONG(

), Baoshuai LI, Xin DONG( ), Ying FENG

), Ying FENG

Received:2022-06-27

Revised:2022-09-16

Online:2022-12-06

Published:2022-11-05

Contact:

Xin DONG

通讯作者:

董鑫

作者简介:张建伟(1964—),男,博士,教授,zhangjianwei@syuct.edu.cn

基金资助:CLC Number:

Jianwei ZHANG, Baoshuai LI, Xin DONG, Ying FENG. Numerical simulation of power-law fluid flow characteristics in impinging stream reactor[J]. CIESC Journal, 2022, 73(11): 4917-4927.

张建伟, 李保帅, 董鑫, 冯颖. 撞击流反应器内幂律流体流动特性的数值模拟[J]. 化工学报, 2022, 73(11): 4917-4927.

Add to citation manager EndNote|Ris|BibTeX

| 流体 | 喷嘴直径D/mm | 喷嘴间距L/D | 入口流速u0/(m/s) |

|---|---|---|---|

| 清水 | 10 | 1、3、5 | 1.30、1.77、2.00 |

| 0.3%CMC溶液 | 10 | 1、3、5 | 1.77 |

| 0.4%CMC溶液 | 10 | 1、3、5 | 1.30、1.77、2.00 |

| 0.5%CMC溶液 | 10 | 1、3、5 | 1.77 |

Table 1 Working conditions

| 流体 | 喷嘴直径D/mm | 喷嘴间距L/D | 入口流速u0/(m/s) |

|---|---|---|---|

| 清水 | 10 | 1、3、5 | 1.30、1.77、2.00 |

| 0.3%CMC溶液 | 10 | 1、3、5 | 1.77 |

| 0.4%CMC溶液 | 10 | 1、3、5 | 1.30、1.77、2.00 |

| 0.5%CMC溶液 | 10 | 1、3、5 | 1.77 |

| 流体 | 质量分数c/% | 稠度系数K/(Pa·s n ) | 流性指数n | 流体密度ρ/(kg/m3) |

|---|---|---|---|---|

| 清水 | 0 | 0.0010 | 1 | 998.21 |

| CMC溶液 | 0.3 | 0.0430 | 0.8363 | 1002.79 |

| 0.4 | 0.0745 | 0.8017 | 1004.54 | |

| 0.5 | 0.1685 | 0.7317 | 1005.43 |

Table 2 Physical properties and rheological parameters

| 流体 | 质量分数c/% | 稠度系数K/(Pa·s n ) | 流性指数n | 流体密度ρ/(kg/m3) |

|---|---|---|---|---|

| 清水 | 0 | 0.0010 | 1 | 998.21 |

| CMC溶液 | 0.3 | 0.0430 | 0.8363 | 1002.79 |

| 0.4 | 0.0745 | 0.8017 | 1004.54 | |

| 0.5 | 0.1685 | 0.7317 | 1005.43 |

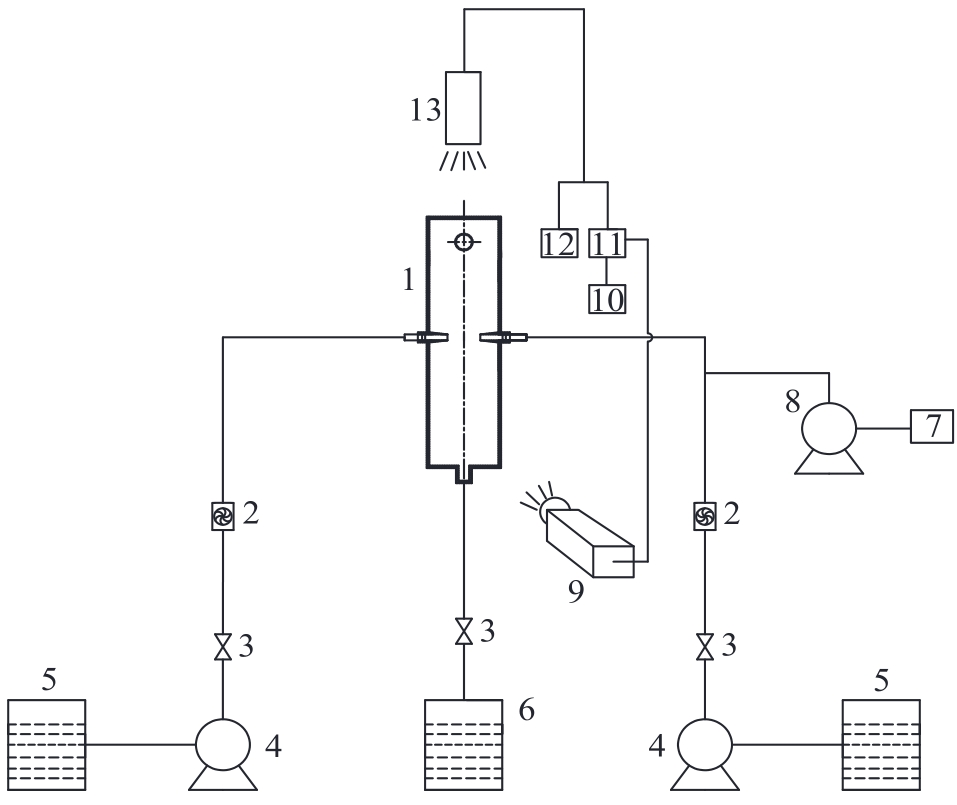

Fig.3 Experimental system of impinging stream reactor1—impinging stream reactor; 2—electromagnetic flowmeter; 3—valve; 4—centrifugal pump; 5—feed bucket; 6—discharge bucket; 7—tracer; 8—peristaltic pump; 9—CCD camera; 10—computer; 11—synchronizer; 12—laser controller; 13—laser transmitter

| 1 | 伍沅. 撞击流: 原理·性质·应用[M]. 北京: 化学工业出版社, 2006. |

| Wu Y. Impinging Stream: Principles·Nature·Application[M]. Beijing: Chemical Industry Press, 2006. | |

| 2 | Tamir A, Huang B. Impinging stream reactors: fundamentals and applications[J]. Drying Technology, 1995, 13(1/2): 503-504. |

| 3 | Brito M S C A, Fonte C P, Dias M M, et al. Flow regimes and mixing of dissimilar fluids in T-jets mixers[J]. Chemical Engineering & Technology, 2022, 45(2): 355-364. |

| 4 | Tseng Y H, Mohanty S K, McLennan J D, et al. Algal lipid extraction using confined impinging jet mixers[J]. Chemical Engineering Science: Ⅹ, 2019, 1: 100002. |

| 5 | Li C, Yue S, Li M. Numerical simulation of the drying characteristics of a high-moisture particle in a dynamic asymmetric impinging stream reactor[J]. Chemical Papers, 2022, 76(1): 41-56. |

| 6 | Sahoo K, Kumar S. Green synthesis of sub 10 nm silver nanoparticles in gram scale using free impinging jet reactor[J]. Chemical Engineering and Processing-Process Intensification, 2021, 165: 108439. |

| 7 | Zhang J, Liu Y Z, Qi G S, et al. Flow characteristics in free impinging jet reactor by particle image velocimetry (PIV) investigation[J]. Fluid Dynamics Research, 2016, 48(4): 045505. |

| 8 | Zhang J W, Yan J J, Dong X, et al. Experimental study on turbulence properties in the dual nozzle opposed impinging stream mixer[J]. The Canadian Journal of Chemical Engineering, 2017, 95(3): 550-558. |

| 9 | 张建伟, 安丰元, 董鑫, 等. 基于阶跃射流的撞击流反应器流场动态特性分析[J]. 化工学报, 2022, 73(2): 622-633. |

| Zhang J W, An F Y, Dong X, et al. Analysis of dynamic characteristics of flow field in impinging stream reactor based on step jet[J]. CIESC Journal, 2022, 73(2): 622-633. | |

| 10 | 李伟锋, 孙志刚, 刘海峰, 等. 两喷嘴对置撞击流径向射流流动特征[J]. 化工学报, 2009, 60(10): 2453-2459. |

| Li W F, Sun Z G, Liu H F, et al. Flow characteristics of radial jet from two opposed jets[J]. CIESC Journal, 2009, 60(10): 2453-2459. | |

| 11 | 陈明, 黄海津, 王多银, 等. 半封闭圆管冲击射流流动特性PIV试验研究[J]. 振动与冲击, 2021, 40(15): 90-97, 113. |

| Chen M, Huang H J, Wang D Y, et al. PIV tests for flow characteristics of impinging jet in a semi-closed circular pipe[J]. Journal of Vibration and Shock, 2021, 40(15): 90-97, 113. | |

| 12 | van Hout R, Rinsky V, Grobman Y G. Experimental study of a round jet impinging on a flat surface: flow field and vortex characteristics in the wall jet[J]. International Journal of Heat and Fluid Flow, 2018, 70: 41-58. |

| 13 | Haldenwang R, Slatter P, Chhabra R. An experimental study of non-Newtonian fluid flow in rectangular flumes in laminar, transition and turbulent flow regimes[J]. Journal of the South African Institution of Civil Engineering, 2010, 52(1): 11-19. |

| 14 | Srisamran C, Devahastin S. Numerical simulation of flow and mixing behavior of impinging streams of shear-thinning fluids[J]. Chemical Engineering Science, 2006, 61(15): 4884-4892. |

| 15 | Gharraei R, Vejdani A, Baheri S, et al. Numerical investigation on the fluid flow and heat transfer of non-Newtonian multiple impinging jets[J]. International Journal of Thermal Sciences, 2016, 104: 257-265. |

| 16 | Mejia-Alvarez R, Christensen K T. Polymer-induced turbulence modifications in an impinging jet[J]. Experiments in Fluids, 2012, 52(5): 1237-1260. |

| 17 | 杨树人, 崔海清. 石油工程非牛顿流体力学[M]. 北京: 石油工业出版社, 2013. |

| Yang S R, Cui H Q. Petroleum Engineering Colleges Teaching Non-Newtonian Fluid Mechanics[M]. Beijing: Petroleum Industry Press, 2013. | |

| 18 | Metzner A B, Reed J C. Flow of non-Newtonian fluids—correlation of the laminar, transition, and turbulent-flow regions[J]. AIChE Journal, 1955, 1(4): 434-440. |

| 19 | 戴干策, 陈敏恒. 化工流体力学[M]. 2版. 北京: 化学工业出版社, 2005. |

| Dai G C, Chen M H. Chemical Engineering Fluid Dynamics[M]. 2nd ed. Beijing: Chemical Industry Press, 2005. | |

| 20 | 刘朝霞. 湍流撞击流数值模拟与实验研究[D]. 武汉: 华中科技大学, 2007. |

| Liu Z X. Numerical simulation and experimental studies of turbulent impinging streams[D]. Wuhan: Huazhong University of Science and Technology, 2007. | |

| 21 | 云玉新, 赵富强, 张磊, 等. 结合相关系数及改进层次分析法的油浸式变压器质量评估[J]. 重庆理工大学学报(自然科学), 2022, 36(5): 203-210. |

| Yun Y X, Zhao F Q, Zhang L, et al. Quality evaluation of oil-immersed transformer based on correlation coefficient and improved analytic hierarchy process[J]. Journal of Chongqing University of Technology (Natural Science), 2022, 36(5): 203-210. | |

| 22 | 李志伟, 槐文信, 钱忠东. 静水环境中径向紊动射流数值模拟[J]. 水利学报, 2009, 40(11): 1320-1325. |

| Li Z W, Huai W X, Qian Z D. Numerical simulation of turbulent radial jets in static ambient[J]. Journal of Hydraulic Engineering, 2009, 40(11): 1320-1325. | |

| 23 | Basset T, Viggiano B, Barois T, et al. Entrainment, diffusion and effective compressibility in a self-similar turbulent jet[J/OL]. Journal of Fluid Mechanics, 2022, . |

| 24 | Morris E M, Aleyasin S S, Biswas N, et al. Turbulent properties of triple elliptic free jets with various nozzle orientation[J]. Journal of Fluids Engineering, 2020, 142(3): 031106. |

| 25 | 刘成文, 李兆敏. 用LDV研究高分子添加剂射流的流场[C]// 第十三届全国水动力学研讨会文集. 北京: 海洋出版社, 1999: 129-134. |

| Liu C W, Li Z M. Study on flow field of polymer additive jet by LDV[C]//Proceedings of the 13th National Symposium on Hydrodynamics. Beijing: China Ocean Press, 1999: 129-134. | |

| 26 | Tang Z, Rostamy N, Bergstrom D J, et al. Incomplete similarity of a plane turbulent wall jet on smooth and transitionally rough surfaces[J]. Journal of Turbulence, 2015, 16(11): 1076-1090. |

| 27 | 徐惊雷, 徐忠, 张堃元, 等. 冲击高度对半封闭紊流冲击射流流场影响的实验研究[J]. 实验力学, 2000, 15(4): 466-472. |

| Xu J L, Xu Z, Zhang K Y, et al. An experimental study for the effect of nozzle-to-plate space on the semi-confined turbulent impinging jet flow[J]. Journal of Experimental Mechanics, 2000, 15(4): 466-472. | |

| 28 | 高伟峰. 水平对置式撞击流反应器流场涡特性的大涡模拟[D]. 沈阳: 沈阳化工大学, 2021. |

| Gao W F. Large eddy simulation of vortex characteristics in horizontal opposed impinging stream reactor[D]. Shenyang: Shenyang University of Chemical Technology, 2021. | |

| 29 | Chiou C S, Gordon R J. Vortex flow of dilute polymer solutions[J]. Polymer Engineering & Science, 1980, 20(7): 456-465. |

| 30 | 胡建军, 朱晴, 王美达, 等. 近距离下射流冲击平板PIV实验研究[J]. 力学学报, 2020, 52(5): 1350-1361. |

| Hu J J, Zhu Q, Wang M D, et al. PIV measurement of close impinging jet on flat plate[J]. Chinese Journal of Theoretical and Applied Mechanics, 2020, 52(5): 1350-1361. | |

| 31 | 张建伟, 牛聚超, 董鑫, 等. 撞击流反应器流场数值模拟及其混合性能优化[J]. 过程工程学报, 2022, 22(9): 1244-1252. |

| Zhang J W, Niu J C, Dong X, et al. Mixing effect in two horizontal opposed impinging stream mixer[J]. The Chinese Journal of Process Engineering, 2022, 22(9): 1244-1252. |

| [1] | Zhanyu YE, He SHAN, Zhenyuan XU. Performance simulation of paper folding-like evaporator for solar evaporation systems [J]. CIESC Journal, 2023, 74(S1): 132-140. |

| [2] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [3] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [4] | Jiahao SONG, Wen WANG. Study on coupling operation characteristics of Stirling engine and high temperature heat pipe [J]. CIESC Journal, 2023, 74(S1): 287-294. |

| [5] | Siyu ZHANG, Yonggao YIN, Pengqi JIA, Wei YE. Study on seasonal thermal energy storage characteristics of double U-shaped buried pipe group [J]. CIESC Journal, 2023, 74(S1): 295-301. |

| [6] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [7] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [8] | Chen HAN, Youmin SITU, Bin ZHU, Jianliang XU, Xiaolei GUO, Haifeng LIU. Study of reaction and flow characteristics in multi-nozzle pulverized coal gasifier with co-processing of wastewater [J]. CIESC Journal, 2023, 74(8): 3266-3278. |

| [9] | Xiaosong CHENG, Yonggao YIN, Chunwen CHE. Performance comparison of different working pairs on a liquid desiccant dehumidification system with vacuum regeneration [J]. CIESC Journal, 2023, 74(8): 3494-3501. |

| [10] | Wenzhu LIU, Heming YUN, Baoxue WANG, Mingzhe HU, Chonglong ZHONG. Research on topology optimization of microchannel based on field synergy and entransy dissipation [J]. CIESC Journal, 2023, 74(8): 3329-3341. |

| [11] | Rui HONG, Baoqiang YUAN, Wenjing DU. Analysis on mechanism of heat transfer deterioration of supercritical carbon dioxide in vertical upward tube [J]. CIESC Journal, 2023, 74(8): 3309-3319. |

| [12] | Kexin HUANG, Tong LI, Anqi LI, Mei LIN. Mode decomposition of flow field in T-junction with rotating impeller [J]. CIESC Journal, 2023, 74(7): 2848-2857. |

| [13] | Fangzhe SHI, Yunhua GAN. Numerical simulation of start-up characteristics and heat transfer performance of ultra-thin heat pipe [J]. CIESC Journal, 2023, 74(7): 2814-2823. |

| [14] | Jinbo JIANG, Xin PENG, Wenxuan XU, Rixiu MEN, Chang LIU, Xudong PENG. Study on leakage characteristics and parameter influence of pump-out spiral groove oil-gas seal [J]. CIESC Journal, 2023, 74(6): 2538-2554. |

| [15] | Xingchi ZHU, Zhiyuan GUO, Zhiyong JI, Jing WANG, Panpan ZHANG, Jie LIU, Yingying ZHAO, Junsheng YUAN. Simulation and optimization of selective electrodialysis magnesium and lithium separation process [J]. CIESC Journal, 2023, 74(6): 2477-2485. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||