CIESC Journal ›› 2025, Vol. 76 ›› Issue (11): 6027-6039.DOI: 10.11949/0438-1157.20250586

• Energy and environmental engineering • Previous Articles

Panxi ZHANG1( ), Dayong TIAN2(

), Dayong TIAN2( ), Donghui CI2(

), Donghui CI2( ), Shuai WANG1(

), Shuai WANG1( ), Kun LUO1, Jianren FAN1

), Kun LUO1, Jianren FAN1

Received:2025-05-29

Revised:2025-08-20

Online:2025-12-19

Published:2025-11-25

Contact:

Donghui CI, Shuai WANG

张盼兮1( ), 田大勇2(

), 田大勇2( ), 次东辉2(

), 次东辉2( ), 王帅1(

), 王帅1( ), 罗坤1, 樊建人1

), 罗坤1, 樊建人1

通讯作者:

次东辉,王帅

作者简介:张盼兮(2004—),女,本科生,18374565842@163.com基金资助:CLC Number:

Panxi ZHANG, Dayong TIAN, Donghui CI, Shuai WANG, Kun LUO, Jianren FAN. Three-dimensional numerical simulation of biomass-coal mixed combustion in fluidized beds[J]. CIESC Journal, 2025, 76(11): 6027-6039.

张盼兮, 田大勇, 次东辉, 王帅, 罗坤, 樊建人. 流化床生物质与煤掺混燃烧的全三维数值模拟研究[J]. 化工学报, 2025, 76(11): 6027-6039.

Add to citation manager EndNote|Ris|BibTeX

| 燃料类型 | 工业分析/%(质量,空气干燥基) | 元素分析/%(质量,干基) | 低位热值/(kJ/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 挥发分 | 固定碳 | 灰分 | 水分 | 碳 | 氢 | 氧 | 氮 | 硫 | |||

| 烟煤 | 33.23 | 45.50 | 9.27 | 12.00 | 63.51 | 3.90 | 7.47 | 0.98 | 2.87 | 26660 | |

| 木屑 | 87.03 | 3.76 | 3.21 | 6.00 | 45.80 | 5.60 | 38.90 | 0.38 | 0.11 | 17086 | |

Table 1 Proximate analysis and ultimate analysis of fuels

| 燃料类型 | 工业分析/%(质量,空气干燥基) | 元素分析/%(质量,干基) | 低位热值/(kJ/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 挥发分 | 固定碳 | 灰分 | 水分 | 碳 | 氢 | 氧 | 氮 | 硫 | |||

| 烟煤 | 33.23 | 45.50 | 9.27 | 12.00 | 63.51 | 3.90 | 7.47 | 0.98 | 2.87 | 26660 | |

| 木屑 | 87.03 | 3.76 | 3.21 | 6.00 | 45.80 | 5.60 | 38.90 | 0.38 | 0.11 | 17086 | |

| 方程 | 反应速率 |

|---|---|

Table 2 Chemical reaction equations and reaction rates

| 方程 | 反应速率 |

|---|---|

| 参数 | 数值 | 单位 |

|---|---|---|

| 进料量 | 0.0025 | kg/s |

| 进料温度 | 300 | K |

| 入口风温度 | 643 | K |

| 辅助风速 | 0.05 | m/s |

| 辅助风温度 | 300 | K |

Table 3 Operating parameters of bubbling fluidized bed co-combustion of biomass and coal

| 参数 | 数值 | 单位 |

|---|---|---|

| 进料量 | 0.0025 | kg/s |

| 进料温度 | 300 | K |

| 入口风温度 | 643 | K |

| 辅助风速 | 0.05 | m/s |

| 辅助风温度 | 300 | K |

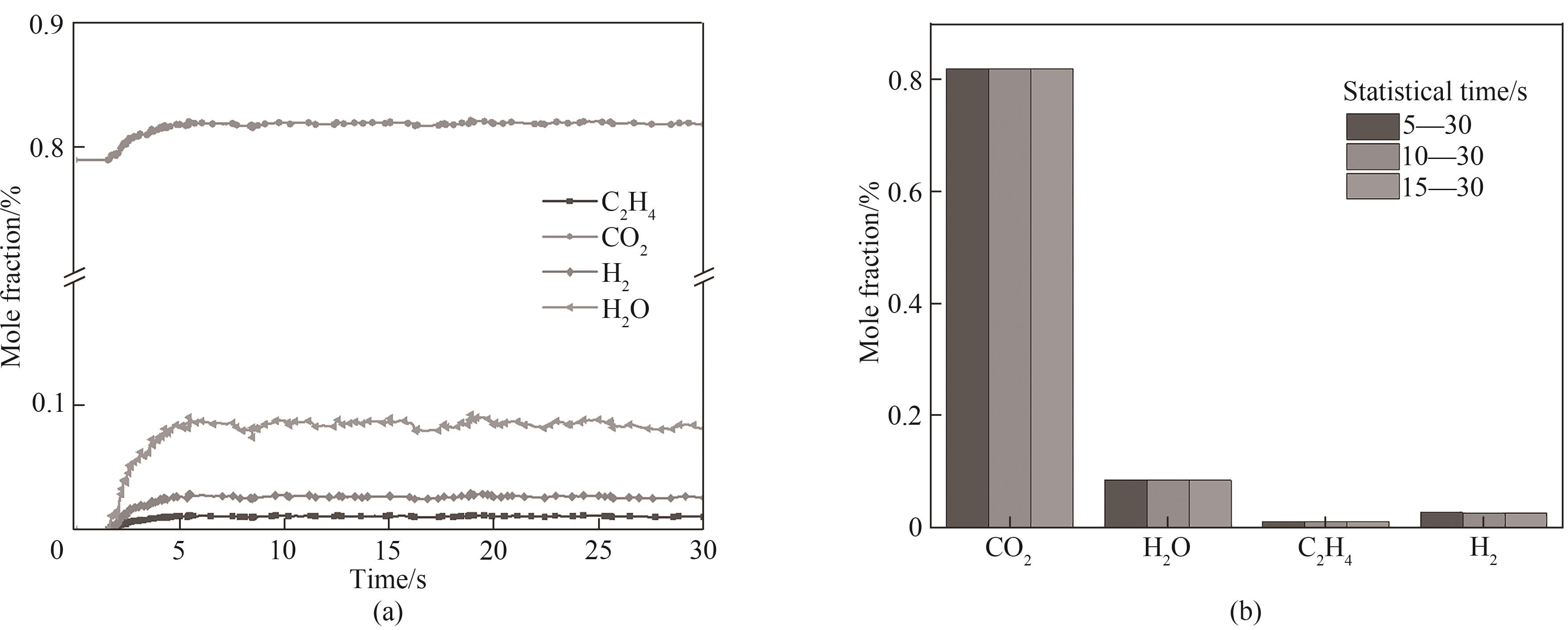

Fig.3 Gas species obtained at the reactor outlet: (a) time-evolution profiles of mass fraction of gas species; (b) time-averaged molar fraction of gas species in different statistical time periods

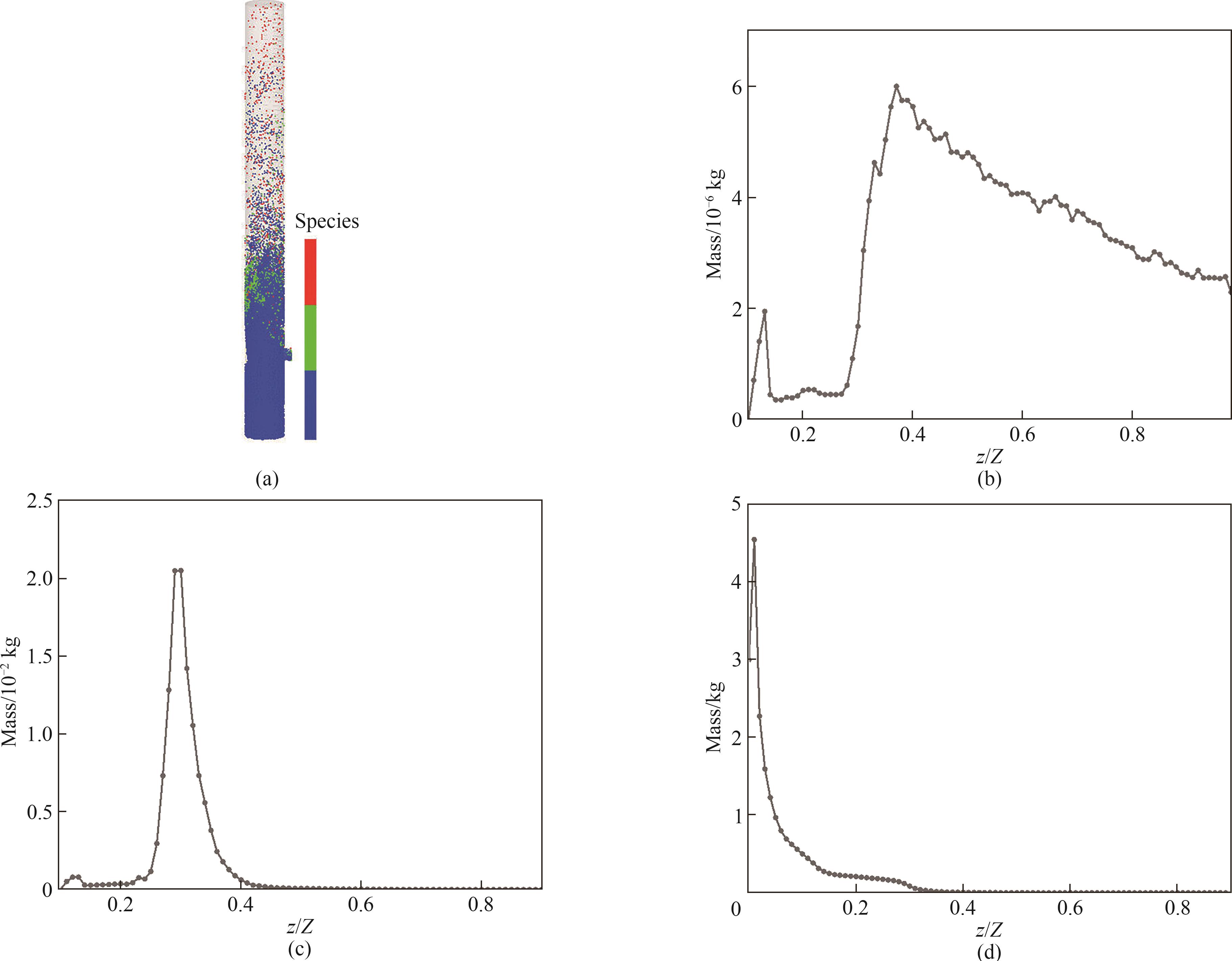

Fig.6 Particle distribution in the bubbling fluidized bed: (a) snapshot of particle components; (b) axial distribution of biomass mass; (c) axial distribution of coal mass; (d) axial distribution of sand mass

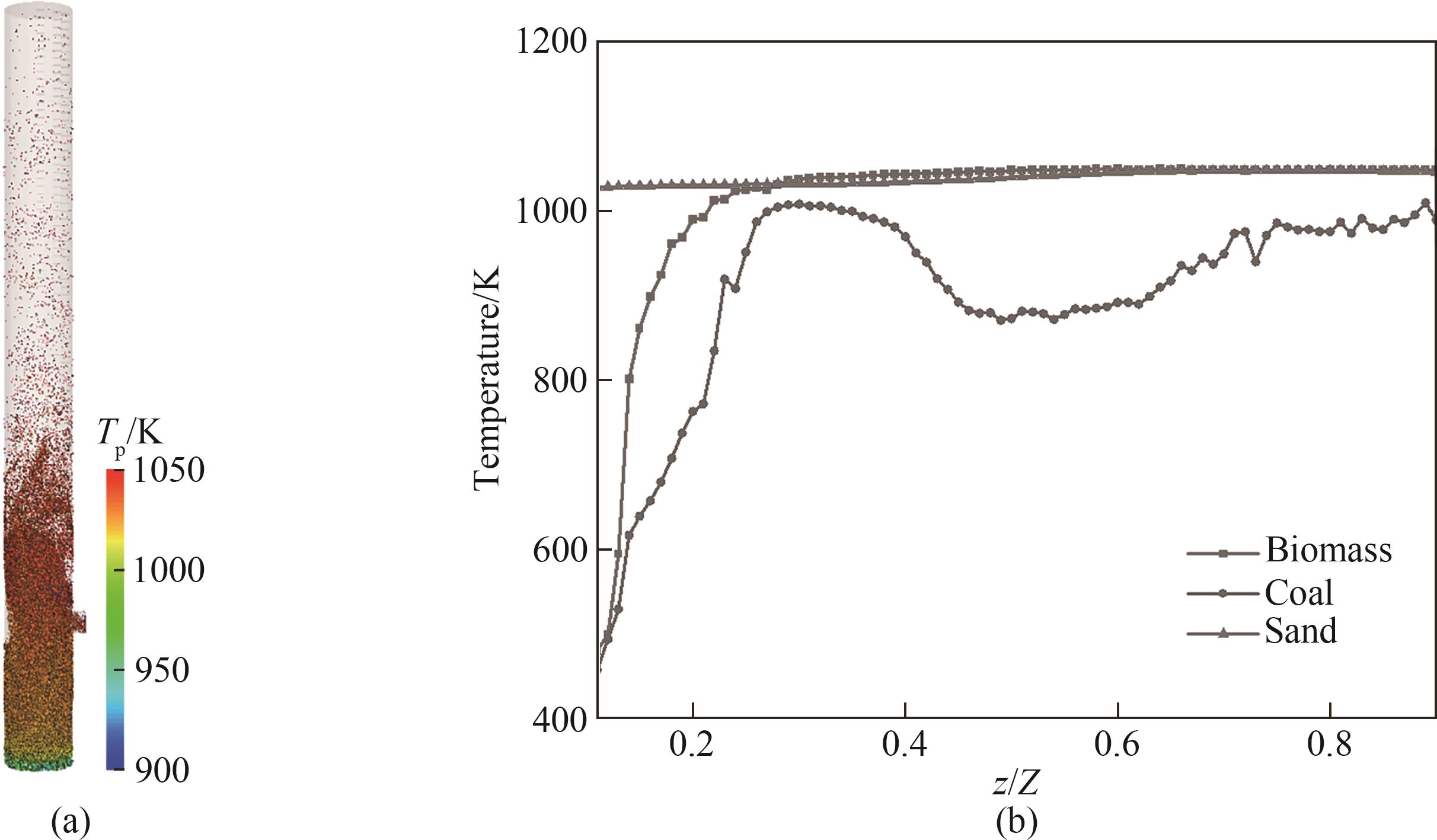

Fig.7 Temperature distribution of particles in the bubbling fluidized bed: (a) instantaneous particle temperature distribution; (b) axial distribution of particle temperature

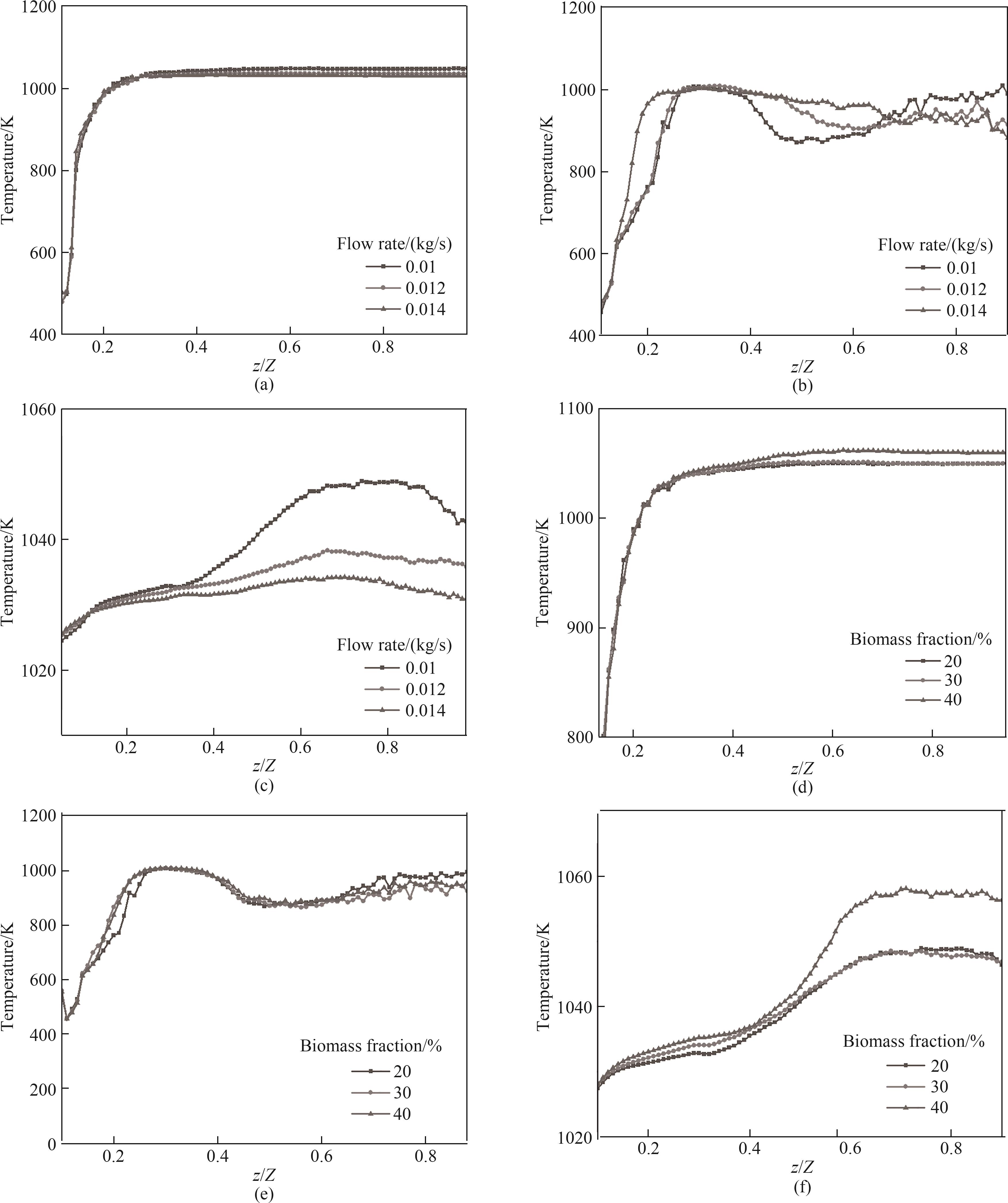

Fig.8 The influence of different operating conditions on the temperature distribution of particles: (a) biomass particles under different flow rates; (b) coal particles under different flow rates; (c) sand particles under different flow rates; (d) biomass particles under different biomass blending ratios; (e) coal particles under different biomass blending ratios; (f) sand particles under different biomass blending ratios

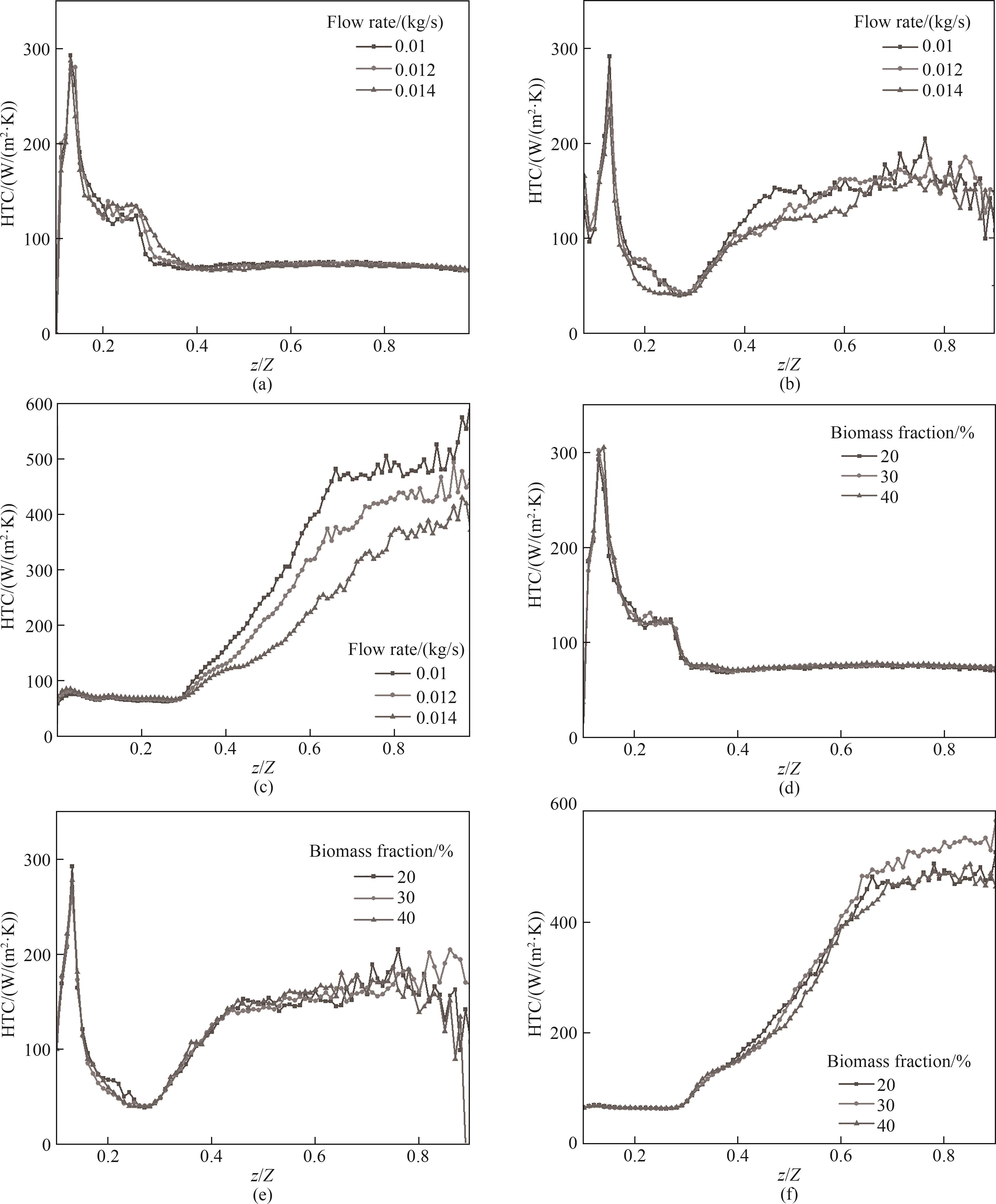

Fig.9 Axial HTC distribution of particle components under different operating conditions: (a) coal particles under different inlet flow rates; (b) biomass particles under different inlet flow rates; (c) sand particles under different inlet flow rates; (d) coal particles under different biomass blending ratios; (e) biomass particles under different biomass blending ratios; (f) sand particles under different biomass blending ratios

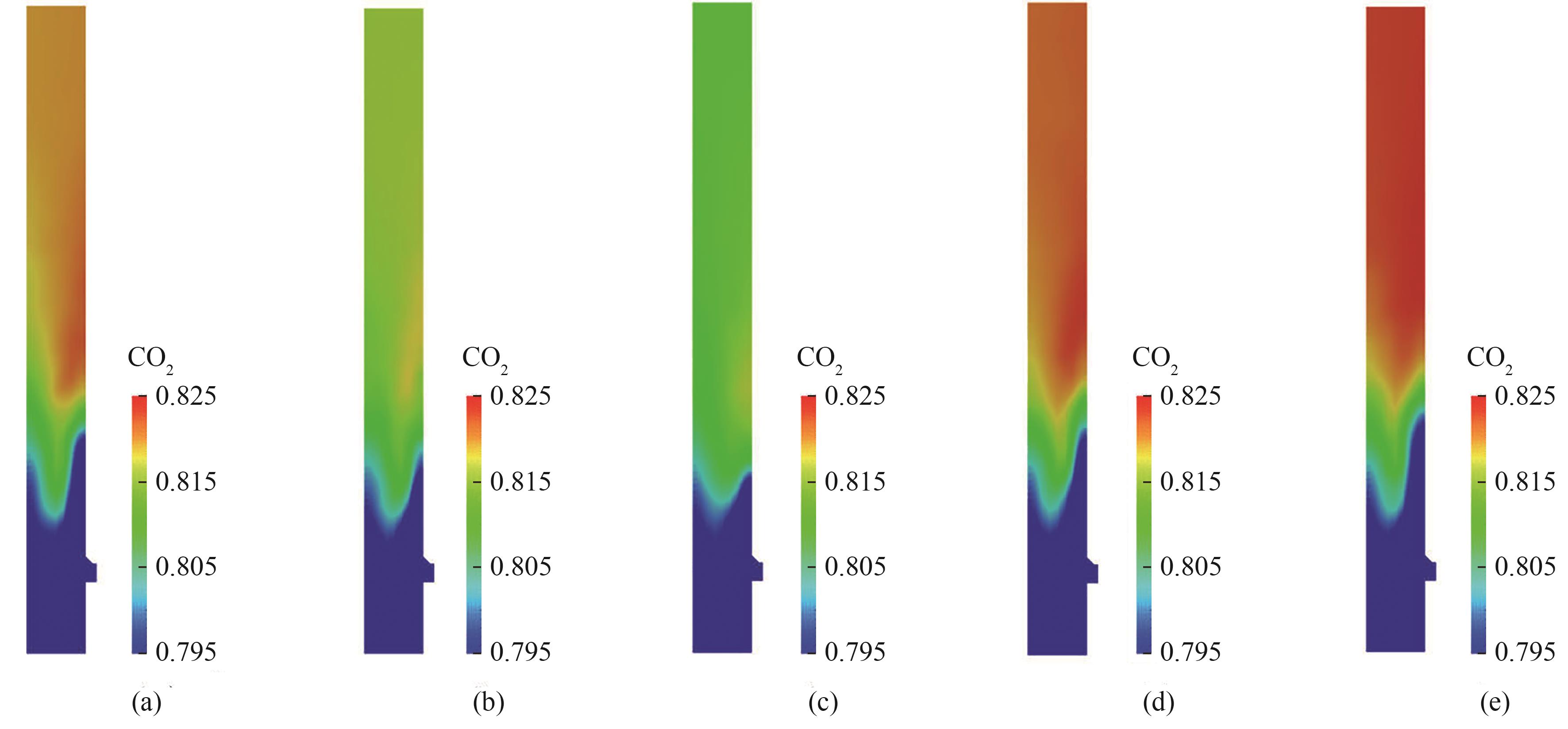

Fig.10 CO2 distribution in the reactor under different operating conditions: (a) inlet air mass flow rate of 0.01 kg/s, biomass and coal blending ratio of 1∶4; (b) inlet air mass flow rate of 0.012 kg/s, biomass and coal blending ratio of 1∶4; (c) inlet air mass flow rate of 0.014 kg/s, biomass and coal blending ratio of 1∶4; (d) inlet air mass flow rate of 0.01 kg/s, biomass and coal blending ratio of 3∶7; (e) inlet air mass flow rate of 0.01 kg/s, biomass and coal blending ratio of 2∶3

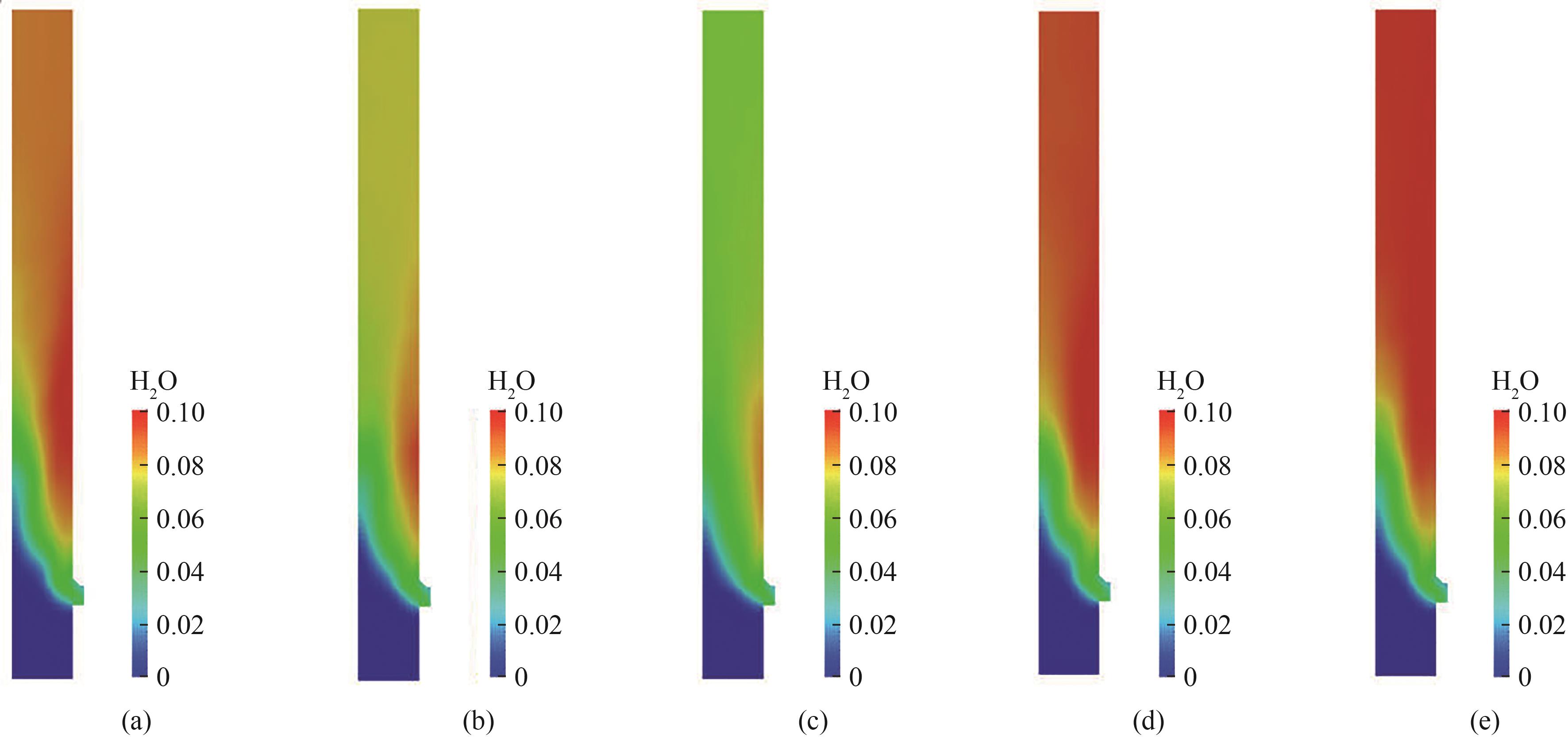

Fig.11 H2O distribution in the reactor under different operating conditions: (a) inlet air mass flow rate of 0.01 kg/s, biomass and coal blending ratio of 1∶4; (b) inlet air mass flow rate of 0.012 kg/s, biomass and coal blending ratio of 1∶4; (c) inlet air mass flow rate of 0.014 kg/s, biomass and coal blending ratio of 1∶4; (d) inlet air mass flow rate of 0.01 kg/s, biomass and coal blending ratio of 3∶7; (e) inlet air mass flow rate of 0.01 kg/s, biomass and coal blending ratio of 2∶3

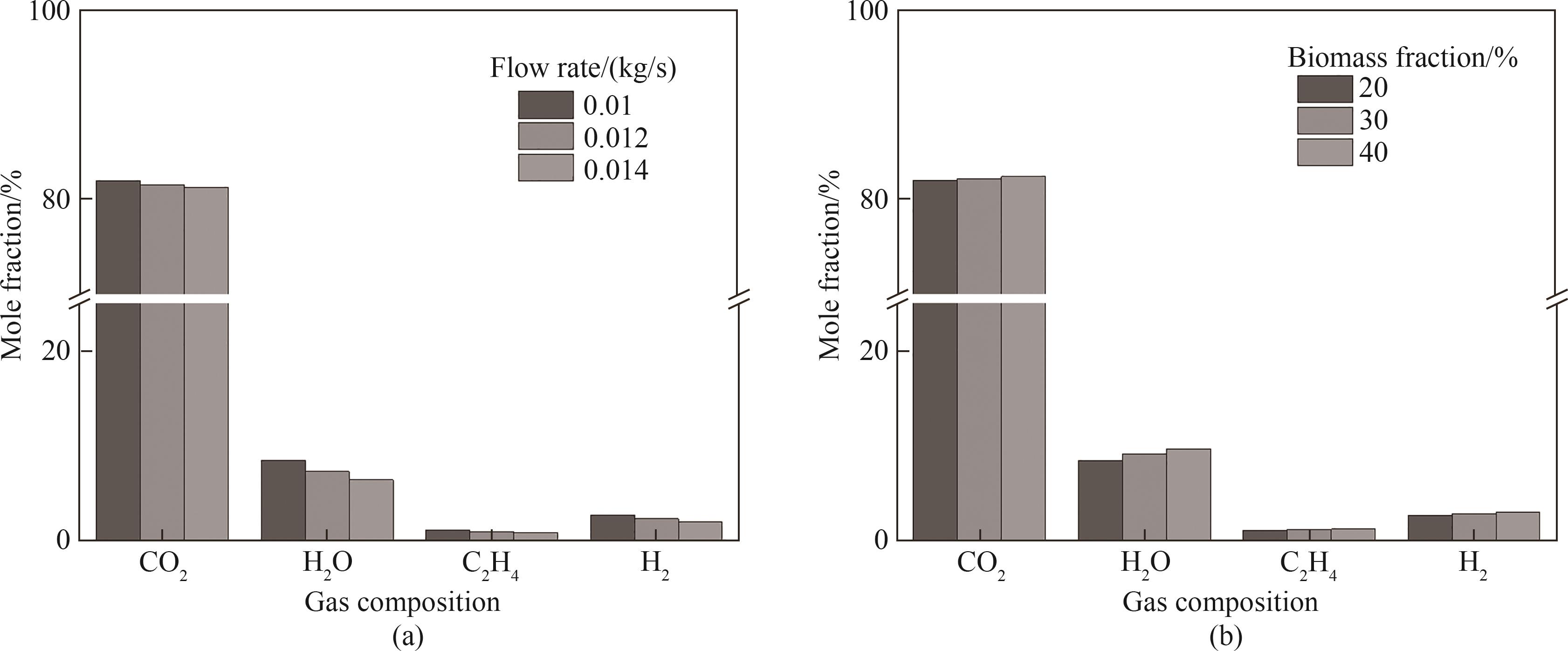

Fig.12 The influence of different operating parameters on the gas products at the reactor outlet: (a) inlet air mass flow rate; (b) biomass blending ratio

| [1] | 云慧敏,代建军,李辉,等. 生物质耦合燃煤发电经济环境效益评估[J]. 化工学报, 2021, 72(12): 6311-6327. |

| Yun H M, Dai J J, Li H, et al. Evaluation of economic and environmental benefits of biomass coupled coal-fired power generation[J]. CIESC Journal, 72(12): 6311-6327. | |

| [2] | 舒印彪,张丽英,张运洲,等. 我国电力碳达峰、碳中和路径研究[J]. 中国工程科学, 2021, 23(6): 1-14. |

| Shu Y B, Zhang L Y, Zhang Y Z, et al. Research on the path of carbon peak and carbon neutrality in China's power industry[J]. Engineering Sciences in China, 2021, 23(6): 1-14. | |

| [3] | 任喜熙,陈祁,杨海平,等. 基于CPFD方法的流化床生物质气化数值模拟[J]. 化工学报, 2020, 71(12): 5763-5773. |

| Ren X X, Cheng Q, Yang H P, et al. Numerical simulation of fluidized bed biomass gasification based on CPFD method[J]. CIESC Journal, 2020, 71(12): 5763-5773. | |

| [4] | 张溪,张立龙,李瑞,等. 基于能量集成的秸秆生物质快速热解生命周期评价[J]. 化工学报, 2021, 72(5): 2792-2800. |

| Zhang X, Zhang L L, Li R, et al. Life cycle evaluation of rapid pyrolysis of straw Biomass based on energy integration[J]. CIESC Journal, 2021, 72(5): 2792-2800. | |

| [5] | Wang H K, Yan Y T, Li Z, et al. Carbon mitigation potential and economic benefits of biomass co-firing in coal-fired power plants: a case study in Nanjing, China[J]. Energy, 2025, 314: 134262. |

| [6] | Liu Q W, Zhong W Q, Yu A B. Study on the gas-solid flow and reaction characteristics of oxy-fuel co-firing of coal and biomass in a pressurized fluidized bed by 3D Eulerian-Lagrangian modelling[J]. Powder Technology, 2025, 456: 120808. |

| [7] | Zhou M M, Wang S, Luo K, et al. Three-dimensional modeling study of the oxy-fuel co-firing of coal and biomass in a bubbling fluidized bed[J]. Energy, 2022, 247: 123496. |

| [8] | Cheng S H, Che Z C, Tong Y L, et al. Design and application of a hybrid predictive control framework for carbon capture in pressurized circulating fluidized bed coal-fired processes[J]. Energy, 2025, 322: 135701. |

| [9] | Li L F, Luo Z Y, Du L W, et al. Prediction of product yields and heating value of bio-oil from biomass fast pyrolysis: explainable predictive modeling and evaluation[J]. Energy, 2025, 332: 136087. |

| [10] | Ke Z J, Tian Y J, Li F, et al. Steady-state multiscale CFD simulation of a circulating fluidized bed riser[J]. Particuology, 2024, 93: 54-64. |

| [11] | Dellinger N, Bertier N, Dupoirieux F, et al. Hybrid Eulerian-Lagrangian method for soot modelling applied to ethylene-air premixed flames[J]. Energy, 2020, 194: 116858. |

| [12] | 吴诗鸣,陈皓宁,宗原,等. 基于MP-PIC方法的冶金硅氢氯化流化床反应器模拟[J]. 化工学报, 2022, 73(10): 4419-4428. |

| Wu S M, Chen H N, Zong Y, et al. Simulation of metallurgical silohydrochlorination fluidized bed reactor based on MP-PIC method[J]. CIESC Journal, 2022, 73(10): 4419-4428. | |

| [13] | 于潇萌,曹乐,严家德,等. 基于多相质点网格法的大气污染仿真模拟[J]. 科学技术与工程, 2020, 20(14): 5856-5863. |

| Yu X M, Cao L, Yan J D, et al. Simulation of air pollution based on multiphase particle grid method[J]. Science Technology and Engineering, 2020, 20(14): 5856-5863. | |

| [14] | Xu Y, Yang K, Zhou J H, et al. Coal-biomass co-firing power generation technology: current status, challenges and policy implications[J]. Sustainability, 2020, 12(9): 3692. |

| [15] | Chen C, Zhao L L, Wu X, et al. Numerical and experimental study on oxy-fuel coal and biomass co-firing in a bubbling fluidized bed[J]. Energy & Fuels, 2019, 33(7): 5829-5839. |

| [16] | Sher F, Yaqoob A, Saeed F, et al. Torrefied biomass fuels as a renewable alternative to coal in co-firing for power generation[J]. Energy, 2020, 209: 118444. |

| [17] | 林俊杰. 化学链燃烧过程中流动与反应的多尺度数值模拟[D]. 杭州: 浙江大学, 2022. |

| Lin J J. Multi-scale numerical simulation of flow and reaction during chemical chain combustion[D].Hangzhou: Zhejiang University, 2022. | |

| [18] | Yang S L, Liu X H, Wang S. CFD simulation of air-blown coal gasification in a fluidized bed reactor with continuous feedstock[J]. Energy Conversion and Management, 2020, 213: 112774. |

| [19] | 孔大力. 结合二氧化碳吸收的流化床生物质气化过程数值模拟研究[D]. 杭州: 浙江大学, 2023. |

| Kong D L. Numerical simulation study on fluidized bed biomass gasification process combined with carbon dioxide absorption[D]. Hangzhou: Zhejiang University, 2023. | |

| [20] | Snider D M. An incompressible three-dimensional multiphase particle-in-cell model for dense particle flows[J]. Journal of Computational Physics, 2001, 170(2): 523-549. |

| [21] | Ku X K, Jin H H, Lin J Z. Comparison of gasification performances between raw and torrefied biomasses in an air-blown fluidized-bed gasifier[J]. Chemical Engineering Science, 2017, 168: 235-249. |

| [22] | Tokmurzin D, Adair D. Development of Euler-Lagrangian simulation of a circulating fluidized bed reactor for coal gasification[J]. Eurasian Chemico-Technological Journal, 2019, 21(1): 45-49. |

| [23] | Snider D M, Clark S M, O'Rourke P J. Eulerian–Lagrangian method for three-dimensional thermal reacting flow with application to coal gasifiers[J]. Chemical Engineering Science, 2011, 66(6): 1285-1295. |

| [24] | Zabaniotou A A, Kalogiannis G, Kappas E, et al. Olive residues (cuttings and kernels) rapid pyrolysis product yields and kinetics[J]. Biomass and Bioenergy, 2000, 18(5): 411-420. |

| [25] | Yan L B, Lim C J, Yue G X, et al. Simulation of biomass-steam gasification in fluidized bed reactors: model setup, comparisons and preliminary predictions[J]. Bioresource Technology, 2016, 221: 625-635. |

| [26] | Liu H, Cattolica R J, Seiser R, et al. Three-dimensional full-loop simulation of a dual fluidized-bed biomass gasifier[J]. Applied Energy, 2015, 160: 489-501. |

| [27] | Benyahia S, Galvin J E. Estimation of numerical errors related to some basic assumptions in discrete particle methods[J]. Industrial & Engineering Chemistry Research, 2010, 49(21): 10588-10605. |

| [28] | Yang S L, Zhou T, Wei Y G, et al. Dynamical and thermal property of rising bubbles in the bubbling fluidized biomass gasifier with wide particle size distribution[J]. Applied Energy, 2020, 259: 114178. |

| [29] | Xie J, Zhong W Q, Jin B S, et al. Eulerian–Lagrangian method for three-dimensional simulation of fluidized bed coal gasification[J]. Advanced Powder Technology, 2013, 24(1): 382-392. |

| [30] | Gupta S, Choudhary S, Kumar S, et al. Large eddy simulation of biomass gasification in a bubbling fluidized bed based on the multiphase particle-in-cell method[J]. Renewable Energy, 2021, 163: 1455-1466. |

| [31] | Ocampo A, Arenas E, Chejne F, et al. An experimental study on gasification of Colombian coal in fluidised bed[J]. Fuel, 2003, 82(2): 161-164. |

| [32] | Loha C, Chattopadhyay H, Chatterjee P K, et al. Energy generation from fluidized bed gasification of rice husk[J]. Journal of Renewable and Sustainable Energy, 2013, 5(4): 043111. |

| [1] | Haolei DUAN, Haoyuan CHEN, Kunfeng LIANG, Lin WANG, Bin CHEN, Yong CAO, Chenguang ZHANG, Shuopeng LI, Dengyu ZHU, Yaru HE, Dapeng YANG. Performance analysis and comprehensive evaluation of thermal management system schemes with low GWP refrigerants [J]. CIESC Journal, 2025, 76(S1): 54-61. |

| [2] | Junpeng WANG, Jiaqi FENG, Enbo ZHANG, Bofeng BAI. Study on flow and cavitation characteristic in zigzag and array labyrinth valve core structures [J]. CIESC Journal, 2025, 76(S1): 93-105. |

| [3] | Zixiang ZHAO, Zhongdi DUAN, Haoran SUN, Hongxiang XUE. Numerical modelling of water hammer induced by two phase flow with large temperature difference [J]. CIESC Journal, 2025, 76(S1): 170-180. |

| [4] | Hao HUANG, Wen WANG, Longkun HE. Simulation and analysis on precooling process of membrane LNG carriers [J]. CIESC Journal, 2025, 76(S1): 187-194. |

| [5] | Siyuan WANG, Guoqiang LIU, Tong XIONG, Gang YAN. Characteristics of non-uniform wind velocity distribution in window air conditioner axial fans and their impact on optimizing condenser circuit optimization [J]. CIESC Journal, 2025, 76(S1): 205-216. |

| [6] | Qingtai CAO, Songyuan GUO, Jianqiang LI, Zan JIANG, Bin WANG, Rui ZHUAN, Jingyi WU, Guang YANG. Numerical study on influence of perforated plate on retention performance of liquid oxygen tank under negative gravity [J]. CIESC Journal, 2025, 76(S1): 217-229. |

| [7] | Jiuchun SUN, Yunlong SANG, Haitao WANG, Hao JIA, Yan ZHU. Study on influence of jet flow on slurry transport characteristics in slurry chamber of shield tunneling machines [J]. CIESC Journal, 2025, 76(S1): 246-257. |

| [8] | Ting HE, Shuyang HUANG, Kun HUANG, Liqiong CHEN. Research on the coupled process of natural gas chemical absorption decarbonization and high temperature heat pump based on waste heat utilization [J]. CIESC Journal, 2025, 76(S1): 297-308. |

| [9] | Lian DUAN, Xingrui ZHOU, Wenjun YUAN, Fei CHEN. Effects of continuous phase velocity pulsations on the formation and morphology of polymer droplets in microchannels [J]. CIESC Journal, 2025, 76(9): 4578-4585. |

| [10] | Yiyang LIU, Zhixiang XING, Yecheng LIU, Ming PENG, Yuyang LI, Yunhao LI, Ningzhou SHEN. Numerical simulation study on the leakage diffusion characteristics and safety monitoring of liquid hydrogen in hydrogen refueling stations [J]. CIESC Journal, 2025, 76(9): 4694-4708. |

| [11] | Zhengzong HUANG, Kecheng LIU, Zefang LI, Pingsheng ZENG, YongFu LIU, Hongjie YAN, Liu LIU. Numerical simulation and field synergy optimization of brick-built heat exchange chamber in zinc refining furnace [J]. CIESC Journal, 2025, 76(9): 4425-4439. |

| [12] | Sheng CHEN, Zizheng LI, Chao MIAO, Xuegang BAI, Fei LI, Jiaxuan LIU, Tiantian LI, Shuang YANG, Rongrong LYU, Jiangyun WANG. Three-dimensional CFD simulation of non-uniform diffusion characteristic of high-risk chlorine gas in large-scale dense scene [J]. CIESC Journal, 2025, 76(9): 4630-4643. |

| [13] | Zhiyong JIA, Xiankun SHEN, Xiaocheng LAN, Tiefeng WANG. CFD-DEM simulation of effects of gas density on pressurized fluidization [J]. CIESC Journal, 2025, 76(9): 4383-4397. |

| [14] | Yifei WANG, Yuxing LI, Xin OUYANG, Xuefeng ZHAO, Lan MENG, Qihui HU, Buze YIN, Yaqi GUO. Numerical calculation of CO2 pipeline fracture propagation based on crack tip decompression characteristics [J]. CIESC Journal, 2025, 76(9): 4683-4693. |

| [15] | Kaiyuan YANG, Xizhong CHEN. Comparison of discrete element method and finite-discrete element method for simulation of agglomerate breakage [J]. CIESC Journal, 2025, 76(9): 4398-4411. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||