CIESC Journal ›› 2025, Vol. 76 ›› Issue (3): 1288-1296.DOI: 10.11949/0438-1157.20240943

• Energy and environmental engineering • Previous Articles Next Articles

Wenlong JIA1( ), Huan XIAO1, Xiangyu LENG2, Qiaojing HUANG1, Chengwei LIU3, Xia WU1

), Huan XIAO1, Xiangyu LENG2, Qiaojing HUANG1, Chengwei LIU3, Xia WU1

Received:2024-08-21

Revised:2024-11-05

Online:2025-03-28

Published:2025-03-25

Contact:

Wenlong JIA

贾文龙1( ), 肖欢1, 冷翔宇2, 黄巧竞1, 刘程玮3, 吴瑕1

), 肖欢1, 冷翔宇2, 黄巧竞1, 刘程玮3, 吴瑕1

通讯作者:

贾文龙

作者简介:贾文龙(1986—),男,博士,教授,jiawenlong08@126.com

基金资助:CLC Number:

Wenlong JIA, Huan XIAO, Xiangyu LENG, Qiaojing HUANG, Chengwei LIU, Xia WU. Experimental and numerical simulation of ultrasonic cavitation microjet cleaning of heavy deposition in crude oil storage tank[J]. CIESC Journal, 2025, 76(3): 1288-1296.

贾文龙, 肖欢, 冷翔宇, 黄巧竞, 刘程玮, 吴瑕. 原油储罐重质沉积物超声波空化微射流清洗实验及数值模拟[J]. 化工学报, 2025, 76(3): 1288-1296.

Add to citation manager EndNote|Ris|BibTeX

| 介质 | 饱和烃/% | 芳香烃/% | 胶质/% | 沥青质/% |

|---|---|---|---|---|

| 原油 | 30.23 | 24.18 | 26.14 | 19.45 |

| 沉积物油相 | 27.29 | 21.67 | 19.43 | 31.61 |

Table 1 Crude oil and deposition oil phase fractions

| 介质 | 饱和烃/% | 芳香烃/% | 胶质/% | 沥青质/% |

|---|---|---|---|---|

| 原油 | 30.23 | 24.18 | 26.14 | 19.45 |

| 沉积物油相 | 27.29 | 21.67 | 19.43 | 31.61 |

| 介质 | 声速/(m/s) | 直径/μm | 厚度/μm | 50℃黏度/(mPa·s) | 密度/(kg/m3) | 泊松比 | 剪切模量/MPa | 屈服强度/MPa |

|---|---|---|---|---|---|---|---|---|

| 原油 | 1300.0 | 140.0 | 70.0 | 260 | 840.0 | — | — | — |

| 重质沉积物 | 2300.0 | 140.0 | 10.0 | — | 2000.0 | 0.35 | 413.6 | 1.6 |

Table 2 Crude oil deposition physical properties and model parameters

| 介质 | 声速/(m/s) | 直径/μm | 厚度/μm | 50℃黏度/(mPa·s) | 密度/(kg/m3) | 泊松比 | 剪切模量/MPa | 屈服强度/MPa |

|---|---|---|---|---|---|---|---|---|

| 原油 | 1300.0 | 140.0 | 70.0 | 260 | 840.0 | — | — | — |

| 重质沉积物 | 2300.0 | 140.0 | 10.0 | — | 2000.0 | 0.35 | 413.6 | 1.6 |

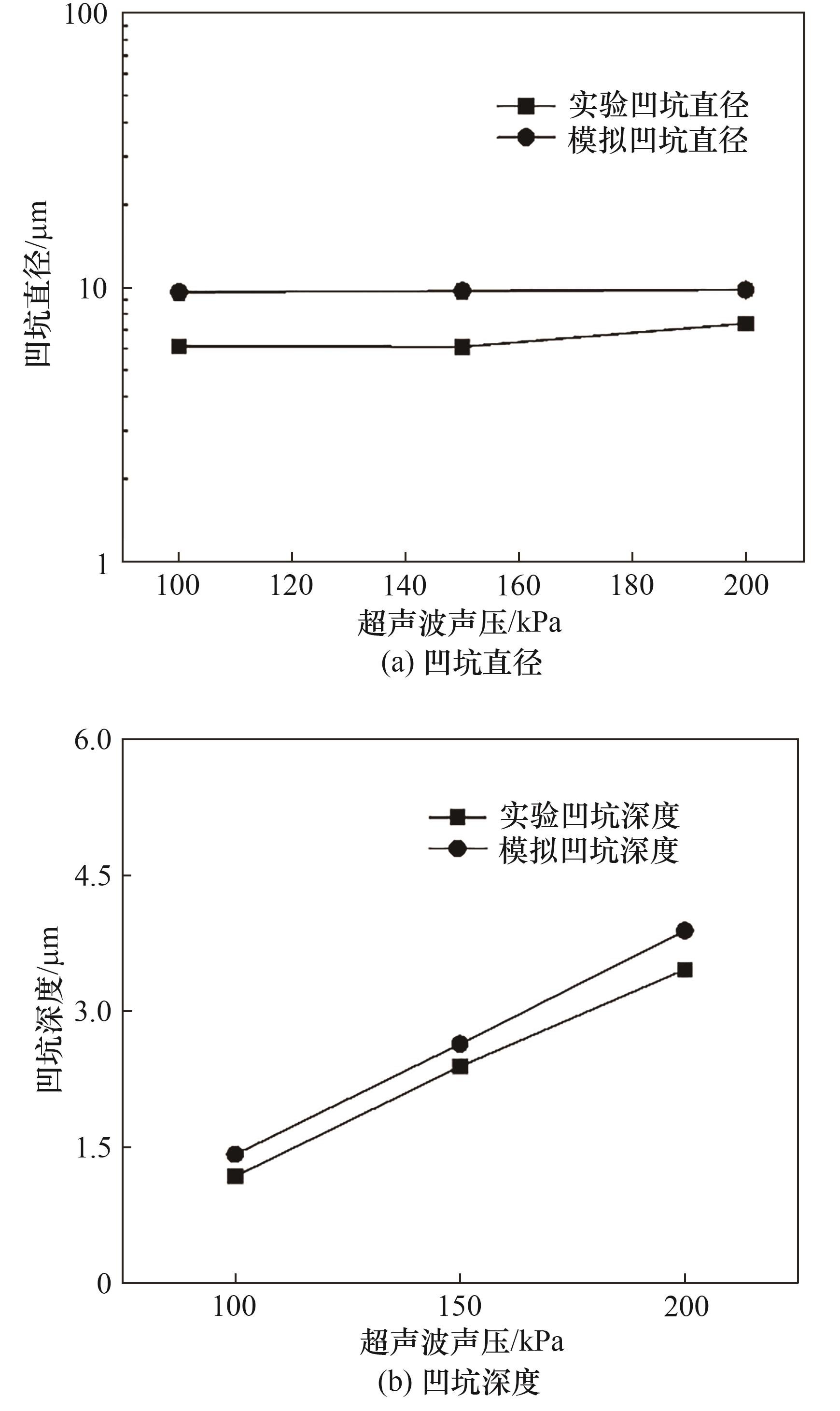

Fig.11 Experimental and numerical calculation results of cavitation pits sizes on the surface of depositions produced by different ultrasonic pressures

| 1 | Wang Q X, Zhang W, Wang C, et al. Microstructure of heavy oil components and mechanism of influence on viscosity of heavy oil[J]. ACS Omega, 2023, 8(12): 10980-10990. |

| 2 | 温燕军, 蒋驰, 李文轩, 等. 含油污泥各组分热解相互作用的反应力场模拟研究[J]. 化工学报, 2021, 72(2): 1100-1106. |

| Wen Y J, Jiang C, Li W X, et al. Study on reaction force field simulation of pyrolysis interaction among components of oily sludge[J]. CIESC Journal, 2021, 72(2): 1100-1106. | |

| 3 | Kang C H, Guo J X, Kiyingi W, et al. Sustainable treatment and recycling of oily sludge: incorporation into gel-system to improve oil recovery[J]. Journal of Cleaner Production, 2024, 436: 140640. |

| 4 | 赵健, 董航, 付小明, 等. 浮顶罐内含蜡原油静态储存中的冷却胶凝规律[J]. 化工学报, 2017, 68(12): 4882-4891. |

| Zhao J, Dong H, Fu X M, et al. Cooling and gelatinization rule of waxy crude oil during static storage in floating roof tank[J]. CIESC Journal, 2017, 68(12): 4882-4891. | |

| 5 | Gao Y X, Ding R, Chen X, et al. Ultrasonic washing for oily sludge treatment in pilot scale[J]. Ultrasonics, 2018, 90: 1-4. |

| 6 | 吴馨, 龚建英, 靳龙, 等. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| Wu X, Gong J Y, Jin L, et al. Study on the transportation characteristics of droplets on the aluminium surface under ultrasonic excitation[J]. CIESC Journal, 2023, 74(S1): 104-112. | |

| 7 | Abadshapouri R A, Amani H, Hajimohammadi R, et al. Heavy oil storage tanks clean-up using biosurfactants and investigation of the synergistic effect with silica nanoparticles[J]. Tenside Surfactants Detergents, 2021, 58(4): 259-264. |

| 8 | Brujan E A, Ikeda T, Yoshinaka K, et al. The final stage of the collapse of a cloud of bubbles close to a rigid boundary[J]. Ultrasonics Sonochemistry, 2011, 18(1): 59-64. |

| 9 | Brujan E A, Ikeda T, Matsumoto Y. Shock wave emission from a cloud of bubbles[J]. Soft Matter, 2012, 8(21): 5777-5783. |

| 10 | 叶林征, 祝锡晶, 王建青, 等. 基于CEL不同角度超声空化微射流冲击的仿真分析[J]. 振动与冲击, 2016, 35(16): 130-134, 157. |

| Ye L Z, Zhu X J, Wang J Q, et al. Simulations of ultrasonic cavitation micro-jet impact with different angles based on CEL[J]. Journal of Vibration and Shock, 2016, 35(16): 130-134, 157. | |

| 11 | Zhao F, Yan Q Q, Cheng D L. Numerical study on the desorption processes of oil droplets inside oil-contaminated sand under cavitation micro-jets[J]. Ultrasonics Sonochemistry, 2021, 78: 105745. |

| 12 | Song H X, Ye Y, Zheng W R, et al. Synthesis of nano-β-CD@Fe3O4 magnetic material and its application in ultrasonic treatment of oily sludge[J]. Ultrasonics Sonochemistry, 2023, 92: 106256. |

| 13 | Zhang P, Luo X M, Gong H Y, et al. Desorption characteristic of oil from sludge surfaces under low-frequency ultrasound[J]. Chemical Engineering and Processing, 2023, 189: 109400. |

| 14 | Mullakaev M S, Vexler G B, Mullakaev R M. Sonochemical technology for separating oil sludge and oil-contaminated soil[J]. Petroleum Science and Technology, 2018, 36(8): 604-608. |

| 15 | Tzanakis I, Eskin D G, Georgoulas A, et al. Incubation pit analysis and calculation of the hydrodynamic impact pressure from the implosion of an acoustic cavitation bubble[J]. Ultrasonics Sonochemistry, 2014, 21(2): 866-878. |

| 16 | 方伟锋, 沈本贤, 仝玉军, 等. LM-S沥青改性剂提高沥青混合料黏附性能的分子模拟计算及路用性能考察[J]. 化工进展, 2018, 37(10): 3949-3957. |

| Fang W F, Shen B X, Tong Y J, et al. Molecular simulation of LM-S asphalt modifier to improve the adhesion of asphalt mixture and investigation of road performance[J]. Chemical Industry and Engineering Progress, 2018, 37(10): 3949-3957. | |

| 17 | 时浩天, 郭力. 模拟流体冲击致结构破坏问题的SPH-PD耦合方法[J]. 振动与冲击, 2022, 41(17): 170-176, 203. |

| Shi H T, Guo L. SPH-PD coupled method for simulation of structure failure impacted by fluid[J]. Journal of Vibration and Shock, 2022, 41(17): 170-176, 203. | |

| 18 | Hedayati E, Vahedi M. Evaluating impact resistance of aluminum 6061-T651 plate using smoothed particle hydrodynamics method[J]. Defence Science Journal, 2018, 68(3): 251-259. |

| 19 | Zhang C, Zhu Y J, Wu D, et al. Smoothed particle hydrodynamics: methodology development and recent achievement[J]. Journal of Hydrodynamics, 2022, 34(5): 767-805. |

| 20 | Leng J, Ye G L, Ye B, et al. Laboratory test and empirical model for shear modulus degradation of soft marine clays[J]. Ocean Engineering, 2017, 146: 101-114. |

| 21 | 邱薛, 刘晓辉, 胡安奎, 等. 煤岩动态RHT本构模型数值模拟研究[J]. 煤炭学报, 2024, 49(S1): 261-273. |

| Qiu X, Liu X H, Hu A K, et al. Research on numerical simulation of coal dynamic RHT constitutive model[J]. Journal of China Coal Society, 2024, 49(S1): 261-273. | |

| 22 | Chen C, Tu Y L, Chen J L, et al. Dynamic constitutive relationship of TiZrHfCu0.5 high entropy alloy based on Johnson-Cook model[J]. Journal of Materials Research and Technology, 2023, 27: 3729-3740. |

| 23 | Wu H, Zhou C, Pu Z H, et al. Effect of low-frequency ultrasonic field at different power on the dynamics of a single bubble near a rigid wall[J]. Ultrasonics Sonochemistry, 2019, 58: 104704. |

| 24 | 叶永. 沥青混合料黏弹塑性本构模型的实验研究[D]. 武汉: 华中科技大学, 2009. |

| Ye Y. Experimental researches on visco-elastoplastic constitutive model of asphalt mixture[D]. Wuhan: Huazhong University of Science and Technology, 2009. | |

| 25 | 毕玉峰, 孙立军. 沥青混合料抗剪试验方法研究[J]. 同济大学学报(自然科学版), 2005, 33(8): 1036-1040. |

| Bi Y F, Sun L J. Research on test method of asphalt mixture’s shearing properties[J]. Journal of Tongji University, 2005, 33(8): 1036-1040. | |

| 26 | 陈刚, 苏慧君, 栗菁, 等. 延长管输原油的组分特征及其析蜡行为[J]. 石油学报(石油加工), 2015, 31(1): 104-111. |

| Chen G, Su H J, Li J, et al. Characteristics of Yanchang pipeline crude oil components and its wax deposition behavior[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2015, 31(1): 104-111. | |

| 27 | Ye L Z, Zhu X J, Wei X M, et al. Damage characteristics and surface description of near-wall materials subjected to ultrasonic cavitation[J]. Ultrasonics Sonochemistry, 2020, 67: 105175. |

| 28 | Luo J, Xu W L, Luo M, et al. Study on the mesoscale causes of the influence of surface tension on material erosion in a cavitation field[J]. Journal of Hydraulic Research, 2022, 60(1): 82-93. |

| 29 | 张自健, 赵军, 唐贤康, 等. 基于EDEM-Fluent耦合的挖藕机喷水系统仿真优化[J]. 山东大学学报(工学版), 2022, 52(3): 86-93, 99. |

| Zhang Z J, Zhao J, Tang X K, et al. Simulation and optimization of lotus root digging machine sprinkler system based on EDEM-Fluent[J]. Journal of Shandong University (Engineering Science), 2022, 52(3): 86-93, 99. | |

| 30 | Zhang A M, Wang S P, Wu G X. Simulation of bubble motion in a compressible liquid based the three dimensional wave equation[J]. Engineering Analysis with Boundary Elements, 2013, 37(9):1179-1188. |

| 31 | Huang G H, Zhang M D, Ma X J, et al. Dynamic behavior of a single bubble between the free surface and rigid wall[J]. Ultrasonics Sonochemistry, 2020, 67: 105147. |

| 32 | 王青祥, 王通, 唐佳旭, 等. 矸石磨料射流冲击煤体的破碎行为及其力学特性研究[J]. 采矿与安全工程学报, 2024, 41(3): 623-633. |

| Wang Q X, Wang T, Tang J X, et al. Study on the crushing behavior and mechanical properties of gangue abrasive jet impacting coal[J]. Journal of Mining & Safety Engineering, 2024, 41(3): 623-633. |

| [1] | Zhongqing LI, Zhiyuan WANG, Xiaojian LUAN, Sikai LIANG, Kai WANG. Preparation of MnO coating based on electroplating-low oxygen partial pressure treatment and coking inhibition properties during thermal cracking of naphtha [J]. CIESC Journal, 2025, 76(3): 1050-1063. |

| [2] | Ke ZHANG, Weijie REN, Mengna WANG, Kaifeng FAN, Liping CHANG, Jiabin LI, Tao MA, Jinping TIAN. Liquid-liquid mixing characteristics of Bunsen reaction products in microchannels [J]. CIESC Journal, 2025, 76(2): 623-636. |

| [3] | Zeyu ZHANG, Ping WANG, Kailun DAI, Weijia QIAN, Subhajit Roy, Ruiyang SHUAI, Antonio Ferrante. Combustion characteristics and NO production of axially staged premixed NH3/CH4 turbulent swirling flames [J]. CIESC Journal, 2025, 76(2): 835-845. |

| [4] | Chuanchao HE, Jinghong ZHOU, Yueqiang CAO, Yao SHI, Xinggui ZHOU. Bed-particle dual scale coupled simulation on Ag/SiO2 catalyzed hydrogenation of oxalate to methyl glycolate [J]. CIESC Journal, 2025, 76(2): 654-666. |

| [5] | Jiayi YAO, Donghui ZHANG, Zhongli TANG, Wenbin LI. Research on carbon capture by pressure swing adsorption based on two-stage dual reflux [J]. CIESC Journal, 2025, 76(2): 744-754. |

| [6] | Jingyu JIA, Deqi KONG, Yuanhui SHEN, Donghui ZHANG, Wenbin LI, Zhongli TANG. Simulation and analysis of ammonia separation process by pressure swing adsorption from synthetic ammonia reactor-off gas [J]. CIESC Journal, 2025, 76(2): 718-730. |

| [7] | Shuyue LI, Huan WANG, Shaoqiang ZHOU, Zhihong MAO, Yongmin ZHANG, Junwu WANG, Xiuhua WU. Current status and prospects of research on fluidization characteristics of high-density particles [J]. CIESC Journal, 2025, 76(2): 466-483. |

| [8] | Zhihua XIAO, Haonan FANG, Fangzhi ZHENG, Dong SUN, Lida TAO, Yongfeng LI, Chunming XU, Xinlong MA. NaCl assisted constructing high-performance pitch-based hard carbon anode material [J]. CIESC Journal, 2025, 76(2): 846-857. |

| [9] | Qiwo HAN, Yongfeng LIU, Pucheng PEI, Lu ZHANG, Shengzhuo YAO. Analysis of influence of operating temperature on water distribution, proton transport and performance of PEMFC [J]. CIESC Journal, 2025, 76(1): 374-384. |

| [10] | Zhicheng DENG, Huan YANG, Simin WANG, Jiarui WANG. Microtube structure impacts on hydrogen-air mixing effect and combustion performance in micromix combustor [J]. CIESC Journal, 2025, 76(1): 335-347. |

| [11] | Hanbin WANG, Shuai HU, Fenglei BI, Junsen LI, Laibin HE. Desorption performance analysis of a metal hydride reactor with novel corrugated fins based on finite element method [J]. CIESC Journal, 2025, 76(1): 221-230. |

| [12] | Xianming GAO, Wenxuan YANG, Shaohui LU, Xiaosong REN, Fangcai LU. Influence of droplet merging and jumping by dual-groove structures on superhydrophobic surfaces [J]. CIESC Journal, 2025, 76(1): 208-220. |

| [13] | Ping LIU, Yusheng QIU, Shijing LI, Ruiqi SUN, Chen SHEN. Heat transfer and flow characteristics of nanofluids in microchannels [J]. CIESC Journal, 2025, 76(1): 184-197. |

| [14] | Zhimin HAN, Xiangyu ZHOU, Hongyu ZHANG, Zhiming XU. Local deposition characteristics of CaCO3 fouling under different roughness element structures [J]. CIESC Journal, 2025, 76(1): 151-160. |

| [15] | Xinyu DONG, Longfei BIAN, Yiyi YANG, Yuxuan ZHANG, Lu LIU, Teng WANG. Study on flow and heat transfer mechanism of supercritical CO2 in inclined upward tube under cooling conditions [J]. CIESC Journal, 2024, 75(S1): 195-205. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||