CIESC Journal ›› 2025, Vol. 76 ›› Issue (1): 221-230.DOI: 10.11949/0438-1157.20240775

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Hanbin WANG( ), Shuai HU, Fenglei BI, Junsen LI, Laibin HE(

), Shuai HU, Fenglei BI, Junsen LI, Laibin HE( )

)

Received:2024-07-10

Revised:2024-08-26

Online:2025-02-08

Published:2025-01-25

Contact:

Laibin HE

通讯作者:

贺来宾

作者简介:王瀚彬(1995—),男,博士,助理研究员,wanghanbin22@163.com

CLC Number:

Hanbin WANG, Shuai HU, Fenglei BI, Junsen LI, Laibin HE. Desorption performance analysis of a metal hydride reactor with novel corrugated fins based on finite element method[J]. CIESC Journal, 2025, 76(1): 221-230.

王瀚彬, 胡帅, 毕丰雷, 李隽森, 贺来宾. 新型波纹翅片金属氢化物反应器的放氢性能有限元分析[J]. 化工学报, 2025, 76(1): 221-230.

Add to citation manager EndNote|Ris|BibTeX

Fig.2 (a) Geometry of novel corrugated fins and annulus; (b) Simulation domain including metal hydride in gray [corrugated fins in yellow, annulus wall in white and heat transfer fluid in blue]

| 结构参数 | 数值 |

|---|---|

| 反应器高度H /mm | 130 |

| 反应器直径D /mm | 56 |

| 波纹翅片单元高度Hfin /mm | 2、5、7 |

| 波纹翅片直径Dfin /mm | 52 |

| 波纹翅片单元长度Lfin /mm | 2.0、3.5、5.0 |

| 波纹翅片厚度δfin /mm | 0.5 |

| 波纹翅片间距Hfs /mm | 9.5 |

| 换热套管内径din /mm | 6 |

| 换热套管外径dout /mm | 13 |

| 换热套管壁厚δout /mm | 0.5 |

Table 1 Dimensions of the LaNi5 reactor

| 结构参数 | 数值 |

|---|---|

| 反应器高度H /mm | 130 |

| 反应器直径D /mm | 56 |

| 波纹翅片单元高度Hfin /mm | 2、5、7 |

| 波纹翅片直径Dfin /mm | 52 |

| 波纹翅片单元长度Lfin /mm | 2.0、3.5、5.0 |

| 波纹翅片厚度δfin /mm | 0.5 |

| 波纹翅片间距Hfs /mm | 9.5 |

| 换热套管内径din /mm | 6 |

| 换热套管外径dout /mm | 13 |

| 换热套管壁厚δout /mm | 0.5 |

| 拟合系数(0.1 MPa) | 数值 |

|---|---|

| c0 | 1.917e-10 |

| c1 | 5.769 |

| c2 | -8.394 |

| c3 | 6.578 |

| c4 | -2.927 |

| c5 | 0.7314 |

| c6 | -0.09496 |

| c7 | 0.004966 |

Table 2 Coefficients of the seven-order equilibrium pressure polynomial function

| 拟合系数(0.1 MPa) | 数值 |

|---|---|

| c0 | 1.917e-10 |

| c1 | 5.769 |

| c2 | -8.394 |

| c3 | 6.578 |

| c4 | -2.927 |

| c5 | 0.7314 |

| c6 | -0.09496 |

| c7 | 0.004966 |

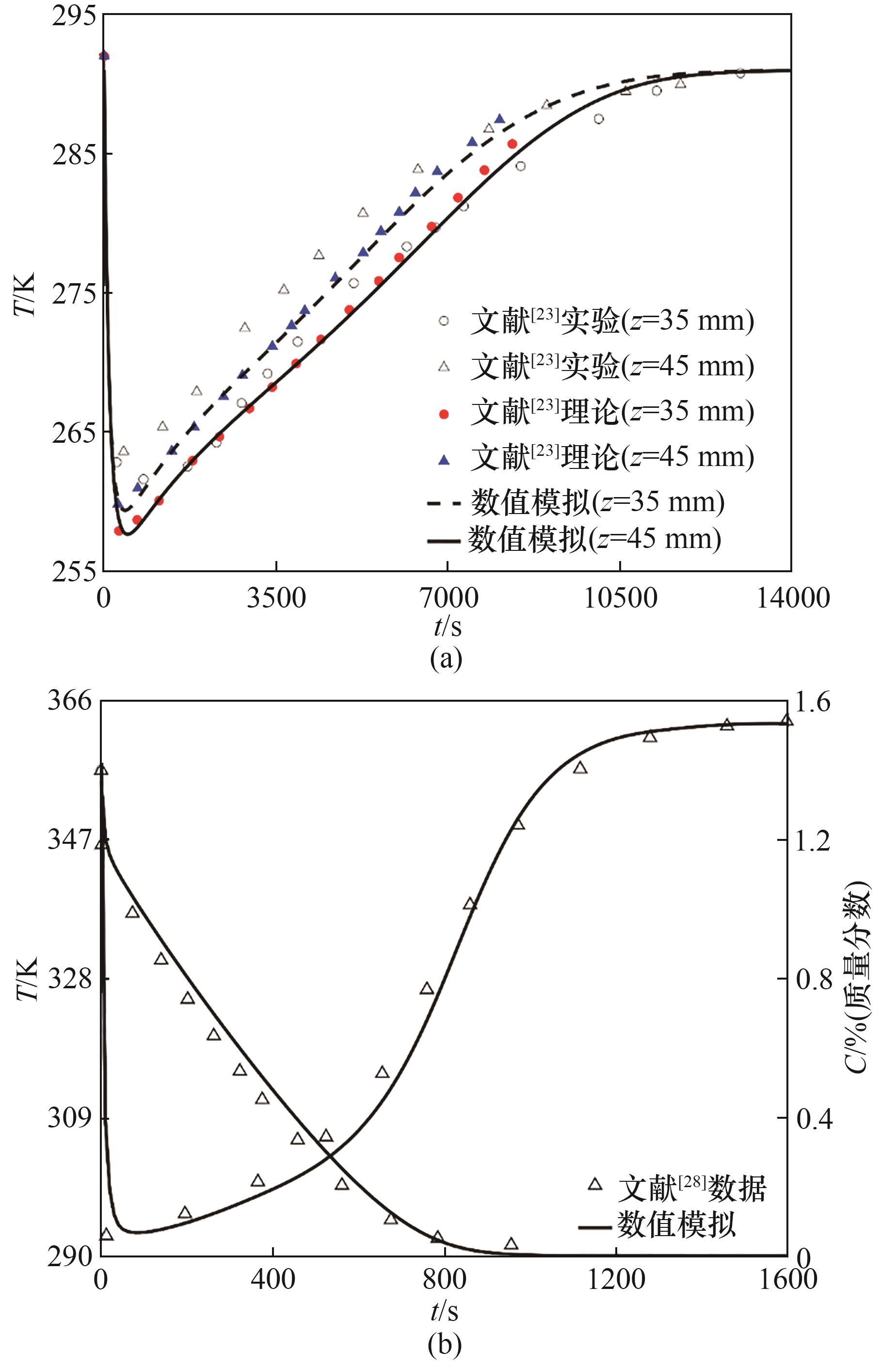

Fig.5 Model validation of hydrogen desorption in LaNi5 reactor: (a) present simulated bed temperature vs literature results[23] at r=15 mm, P=8.5×10-3 MPa and T=291 K; (b) present simulated bed temperature and bed storage capacity vs literature results[28] at P=0.1 MPa and T=363 K

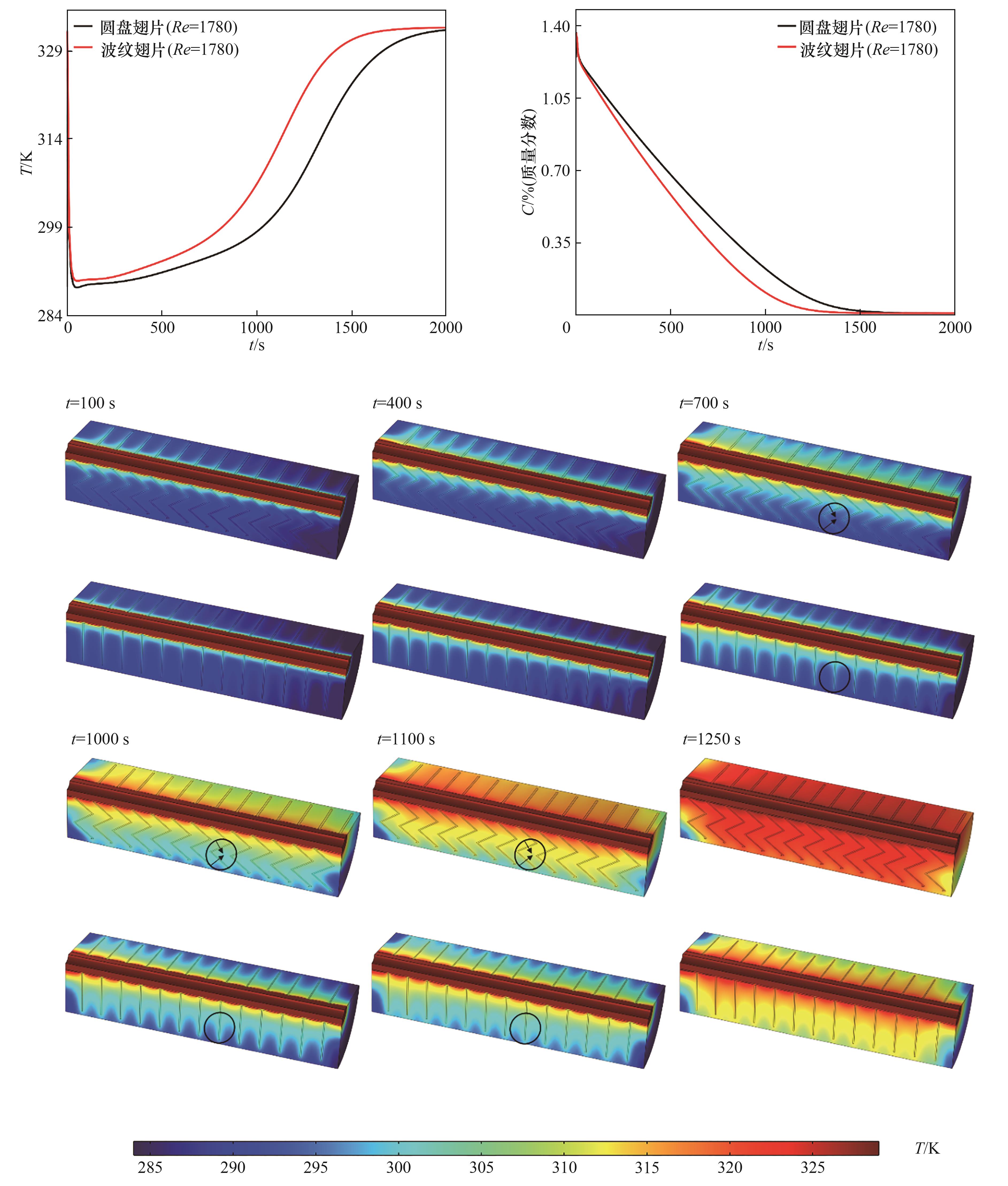

Fig.6 Comparison of circular fins and corrugated fins: (a) evolution of average bed temperature; (b) evolution of average bed storage capacity; (c) distribution of bed temperature at t=100, 400, 700, 1000, 1100, 1250 s

Fig.7 Effect of corrugated fin height on the hydrogen desorption performance in reactor at Pd=0.1 MPa, Tin=333 K and Re=1780: (a) average bed temperature for the cases with 13 fins; (b) average bed storage capacity for the cases with 13 fins; (c) average bed temperature for the cases with 7 fins; (d) average bed storage capacity for the cases with 7 fins

Fig.8 Effect of corrugated fin length on the hydrogen desorption performance in reactor at Pd=0.1 MPa, Tin=333 K and Re=1780: (a) average bed temperature for the cases with 13 fins; (b) average bed storage capacity for the cases with 13 fins; (c) average bed temperature for the cases with 7 fins; (d) average bed storage capacity for the cases with 7 fins

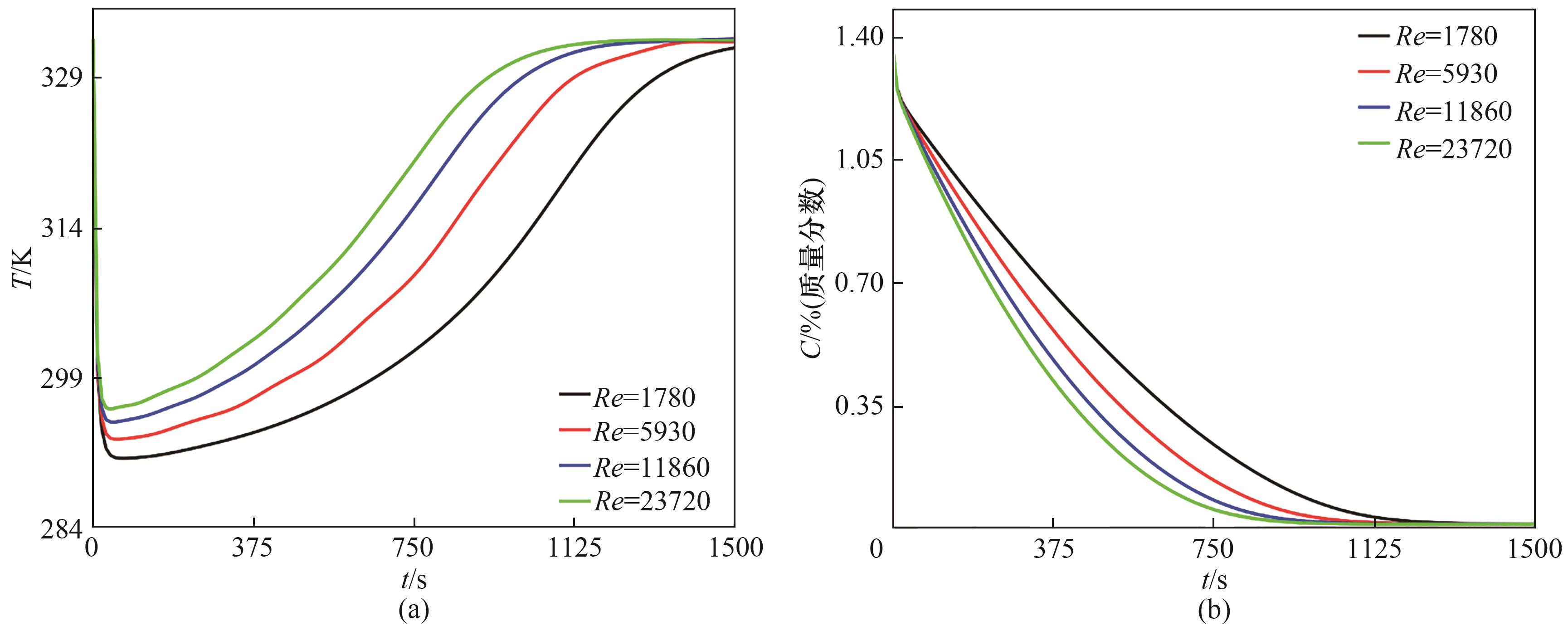

Fig.9 Effect of heating water Reynolds number on the hydrogen desorption performance in reactor with Lfin=2.0 mm, Hfin=5 mm and 13 fins (Pd=0.1 MPa,Tin=333 K)

| 1 | Hirscher M, Yartys V A, Baricco M, et al. Materials for hydrogen-based energy storage—past, recent progress and future outlook[J]. Journal of Alloys and Compounds, 2020, 827: 153548. |

| 2 | Zhang X, Zhao Y Y, Zhou S J, et al. Preparation and hydrogen storage properties of single-phase Ce2Ni7-type La-Sm-Y-Ni based hydrogen storage alloy[J]. International Journal of Hydrogen Energy, 2023, 48(20): 7181-7191. |

| 3 | Albert R, Urbanczyk R, Felderhoff M. Thermal conductivity measurements of magnesium hydride powder beds under operating conditions for heat storage applications[J]. International Journal of Hydrogen Energy, 2019, 44(55): 29273-29281. |

| 4 | Flueckiger S, Voskuilen T, Pourpoint T, et al. In situ characterization of metal hydride thermal transport properties[J]. International Journal of Hydrogen Energy, 2010, 35(2): 614-621. |

| 5 | Jana S, Muthukumar P. Design, development and hydrogen storage performance testing of a tube bundle metal hydride reactor[J]. Journal of Energy Storage, 2023, 63: 106936. |

| 6 | Singh A, Maiya M P, Srinivasa Murthy S. Experiments on solid state hydrogen storage device with a finned tube heat exchanger[J]. International Journal of Hydrogen Energy, 2017, 42(22): 15226-15235. |

| 7 | Mellouli S, Askri F, Dhaou H, et al. Numerical study of heat exchanger effects on charge/discharge times of metal-hydrogen storage vessel[J]. International Journal of Hydrogen Energy, 2009, 34(7): 3005-3017. |

| 8 | Souahlia A, Dhaou H, Mellouli S, et al. Experimental study of metal hydride-based hydrogen storage tank at constant supply pressure[J]. International Journal of Hydrogen Energy, 2014, 39(14): 7365-7372. |

| 9 | Chandra S, Sharma P, Muthukumar P, et al. Experimental hydrogen sorption study on a LaNi5-based 5 kg reactor with novel conical fins and water tubes and its numerical scale-up through a modular approach[J]. International Journal of Hydrogen Energy, 2023, 48(96): 37872-37885. |

| 10 | Karmakar A, Mallik A, Gupta N, et al. Studies on 10 kg alloy mass metal hydride based reactor for hydrogen storage[J]. International Journal of Hydrogen Energy, 2021, 46(7): 5495-5506. |

| 11 | Elhamshri F, Kayfeci M, Matik U, et al. Thermofluidynamic modelling of hydrogen absorption in metal hydride beds by using multiphysics software[J]. International Journal of Hydrogen Energy, 2020, 45(60): 34956-34971. |

| 12 | Zheng S S, Wang Y Q, Wang D, et al. Design and performance study on the primary & secondary helical-tube reactor[J]. Energy, 2023, 263: 125840. |

| 13 | Raju N N, Muthukumar P, Selvan P V, et al. Design methodology and thermal modelling of industrial scale reactor for solid state hydrogen storage[J]. International Journal of Hydrogen Energy, 2019, 44(36): 20278-20292. |

| 14 | Raju M, Kumar S. System simulation modeling and heat transfer in sodium alanate based hydrogen storage systems[J]. International Journal of Hydrogen Energy, 2011, 36(2): 1578-1591. |

| 15 | Ma J C, Wang Y Q, Shi S F, et al. Optimization of heat transfer device and analysis of heat & mass transfer on the finned multi-tubular metal hydride tank[J]. International Journal of Hydrogen Energy, 2014, 39(25): 13583-13595. |

| 16 | Andreasen G, Melnichuk M, Ramos S, et al. Hydrogen desorption from a hydride container under different heat exchange conditions[J]. International Journal of Hydrogen Energy, 2013, 38(30): 13352-13359. |

| 17 | Chandra S, Sharma P, Muthukumar P, et al. Strategies for scaling-up LaNi5-based hydrogen storage system with internal conical fins and cooling tubes[J]. International Journal of Hydrogen Energy, 2021, 46(36): 19031-19045. |

| 18 | Muthukumar P, Madhavakrishna U, Dewan A. Parametric studies on a metal hydride based hydrogen storage device[J]. International Journal of Hydrogen Energy, 2007, 32(18): 4988-4997. |

| 19 | Chibani A, Merouani S, Bougriou C, et al. Heat and mass transfer during the storage of hydrogen in LaNi5-based metal hydride: 2D simulation results for a large scale, multi-pipes fixed-bed reactor[J]. International Journal of Heat and Mass Transfer, 2020, 147: 118939. |

| 20 | Wang H B, Yi G N, Ye J H, et al. Intensification of hydrogen absorption process in metal hydride devices with novel corrugated fins: a validated numerical study[J]. Journal of Alloys and Compounds, 2022, 926: 166759. |

| 21 | Ye Y, Lu J F, Ding J, et al. Numerical simulation on the storage performance of a phase change materials based metal hydride hydrogen storage tank[J]. Applied Energy, 2020, 278: 115682. |

| 22 | Bao Z W. Performance investigation and optimization of metal hydride reactors for high temperature thermochemical heat storage[J]. International Journal of Hydrogen Energy, 2015, 40(16): 5664-5676. |

| 23 | Jemni A, Ben Nasrallah S, Lamloumi J. Experimental and theoretical study of a metal-hydrogen reactor[J]. International Journal of Hydrogen Energy, 1999, 24(7): 631-644. |

| 24 | Muthukumar P, Satheesh A, Linder M, et al. Studies on hydriding kinetics of some La-based metal hydride alloys[J]. International Journal of Hydrogen Energy, 2009, 34(17): 7253-7262. |

| 25 | 刘伟. 基于k-ε湍流模型的方锥管布浆器的流动特性[J]. 中华纸业, 2013, 34(8): 30-33. |

| Liu W. Flow characteristics of rectangularly tapered distributor based on k-ε turbulence model[J]. China Pulp & Paper Industry, 2013, 34(8): 30-33. | |

| 26 | 常书平, 王永生. 采用k-ε湍流模型的喷水推进器性能预报[J]. 华中科技大学学报(自然科学版), 2012, 40(4): 88-90, 95. |

| Chang S P, Wang Y S. Prediction of waterjet performances using k-ε turbulence models[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2012, 40(4): 88-90, 95. | |

| 27 | 李志鹏, 高正明. 涡轮桨搅拌槽内流动特性的大涡模拟[J]. 高校化学工程学报, 2007, 21(4): 592-597. |

| Li Z P, Gao Z M. Large eddy simulation of flow field in a rushton impeller stirred tank[J]. Journal of Chemical Engineering of Chinese Universities, 2007, 21(4): 592-597. | |

| 28 | Singh A, Maiya M P, Murthy S S. Effects of heat exchanger design on the performance of a solid state hydrogen storage device[J]. International Journal of Hydrogen Energy, 2015, 40(31): 9733-9746. |

| 29 | Askri F, Bouzgarrou F. Numerical investigation of two discharging procedures of a metal hydride-hydrogen storage tank[J]. International Journal of Energy Research, 2021, 45(5): 7279-7292. |

| 30 | Wu Z, Yang F S, Zhu L Y, et al. Improvement in hydrogen desorption performances of magnesium based metal hydride reactor by incorporating helical coil heat exchanger[J]. International Journal of Hydrogen Energy, 2016, 41(36): 16108-16121. |

| 31 | Kyoung S, Ferekh S, Gwak G, et al. Three-dimensional modeling and simulation of hydrogen desorption in metal hydride hydrogen storage vessels[J]. International Journal of Hydrogen Energy, 2015, 40(41): 14322-14330. |

| [1] | Chuangde ZHANG, Li CHEN. Pore-scale study of effects of preferential path on multiphase reactive transport process in porous media [J]. CIESC Journal, 2025, 76(1): 161-172. |

| [2] | Xianming GAO, Wenxuan YANG, Shaohui LU, Xiaosong REN, Fangcai LU. Influence of droplet merging and jumping by dual-groove structures on superhydrophobic surfaces [J]. CIESC Journal, 2025, 76(1): 208-220. |

| [3] | Qiwo HAN, Yongfeng LIU, Pucheng PEI, Lu ZHANG, Shengzhuo YAO. Analysis of influence of operating temperature on water distribution, proton transport and performance of PEMFC [J]. CIESC Journal, 2025, 76(1): 374-384. |

| [4] | Zhicheng DENG, Huan YANG, Simin WANG, Jiarui WANG. Microtube structure impacts on hydrogen-air mixing effect and combustion performance in micromix combustor [J]. CIESC Journal, 2025, 76(1): 335-347. |

| [5] | Ping LIU, Yusheng QIU, Shijing LI, Ruiqi SUN, Chen SHEN. Heat transfer and flow characteristics of nanofluids in microchannels [J]. CIESC Journal, 2025, 76(1): 184-197. |

| [6] | Zhimin HAN, Xiangyu ZHOU, Hongyu ZHANG, Zhiming XU. Local deposition characteristics of CaCO3 fouling under different roughness element structures [J]. CIESC Journal, 2025, 76(1): 151-160. |

| [7] | Xinyu DONG, Longfei BIAN, Yiyi YANG, Yuxuan ZHANG, Lu LIU, Teng WANG. Study on flow and heat transfer mechanism of supercritical CO2 in inclined upward tube under cooling conditions [J]. CIESC Journal, 2024, 75(S1): 195-205. |

| [8] | Qirui GUO, Liyuan REN, Kang CHEN, Xiangyu HUANG, Weihua MA, Leqin XIAO, Weiliang ZHOU. Numerical simulation of static mixing tubes for HTPB propellant slurry [J]. CIESC Journal, 2024, 75(S1): 206-216. |

| [9] | Kuangxi LI, Peiqian YU, Jiangyun WANG, Haoran WEI, Zhigang ZHENG, Liuhai FENG. Flow analysis and structure optimization of micro-bubble swirling air flotation device [J]. CIESC Journal, 2024, 75(S1): 223-234. |

| [10] | Yingyu XU, Guoqiang YANG, Jing PENG, Haining SUN, Zhibing ZHANG. Research on advanced oxidation treatment of coal chemical wastewater using microinterfaces [J]. CIESC Journal, 2024, 75(S1): 283-291. |

| [11] | Zhangzhou WANG, Tianqi TANG, Jiajun XIA, Yurong HE. Battery thermal management performance simulation based on composite phase change material [J]. CIESC Journal, 2024, 75(S1): 329-338. |

| [12] | Jian HU, Jinghua JIANG, Shengjun FAN, Jianhao LIU, Haijiang ZOU, Wanlong CAI, Fenghao WANG. Research on heat extraction performance of deep U-type borehole heat exchanger [J]. CIESC Journal, 2024, 75(S1): 76-84. |

| [13] | Guanyu REN, Yifei ZHANG, Xinze LI, Wenjing DU. Numerical study on flow and heat transfer characteristics of airfoil printed circuit heat exchangers [J]. CIESC Journal, 2024, 75(S1): 108-117. |

| [14] | Yong YANG, Zixuan ZU, Yukun LI, Dongliang WANG, Zongliang FAN, Huairong ZHOU. Numerical simulation of CO2 absorption by alkali liquor in T-junction cylindrical microchannels [J]. CIESC Journal, 2024, 75(S1): 135-142. |

| [15] | Junhao HUANG, Keliang PANG, Fangyuan SUN, Fujun LIU, Zhiyuan GU, Long HAN, Yanquan DUAN, Yanhui FENG. Influence of bell structure of coke dry quenching furnace on coke distribution [J]. CIESC Journal, 2024, 75(S1): 158-169. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||