CIESC Journal ›› 2025, Vol. 76 ›› Issue (8): 4119-4128.DOI: 10.11949/0438-1157.20250094

• Intelligent process engineering • Previous Articles Next Articles

Yuanshen DAI1,2( ), Zhijiang SHAO1, Weifeng CHEN3, Ning CHEN4(

), Zhijiang SHAO1, Weifeng CHEN3, Ning CHEN4( )

)

Received:2025-01-22

Revised:2025-04-07

Online:2025-09-17

Published:2025-08-25

Contact:

Ning CHEN

通讯作者:

陈宁

作者简介:戴元燊(1983—),男,博士研究生,yuanshen.dai@basf.com

基金资助:CLC Number:

Yuanshen DAI, Zhijiang SHAO, Weifeng CHEN, Ning CHEN. Dynamic prediction method of particle size distribution in ternary precursor crystallization process based on population balance equations[J]. CIESC Journal, 2025, 76(8): 4119-4128.

戴元燊, 邵之江, 陈伟锋, 陈宁. 基于粒数衡算方程的三元前体结晶过程粒度分布动态预测方法[J]. 化工学报, 2025, 76(8): 4119-4128.

Add to citation manager EndNote|Ris|BibTeX

| 批次 | KG | γ | b |

|---|---|---|---|

| 1st (r0=2.4 μm) | 0.00797388 | 1006.63 | 0.499995 |

| 2nd (r0=2.48 μm) | 0.00792696 | 1019.0 | 0.49995 |

| 3rd (r0=2.56 μm) | 0.0080318 | 991.77 | 0.50002 |

Table 1 Parameter estimation results based on ASL equation

| 批次 | KG | γ | b |

|---|---|---|---|

| 1st (r0=2.4 μm) | 0.00797388 | 1006.63 | 0.499995 |

| 2nd (r0=2.48 μm) | 0.00792696 | 1019.0 | 0.49995 |

| 3rd (r0=2.56 μm) | 0.0080318 | 991.77 | 0.50002 |

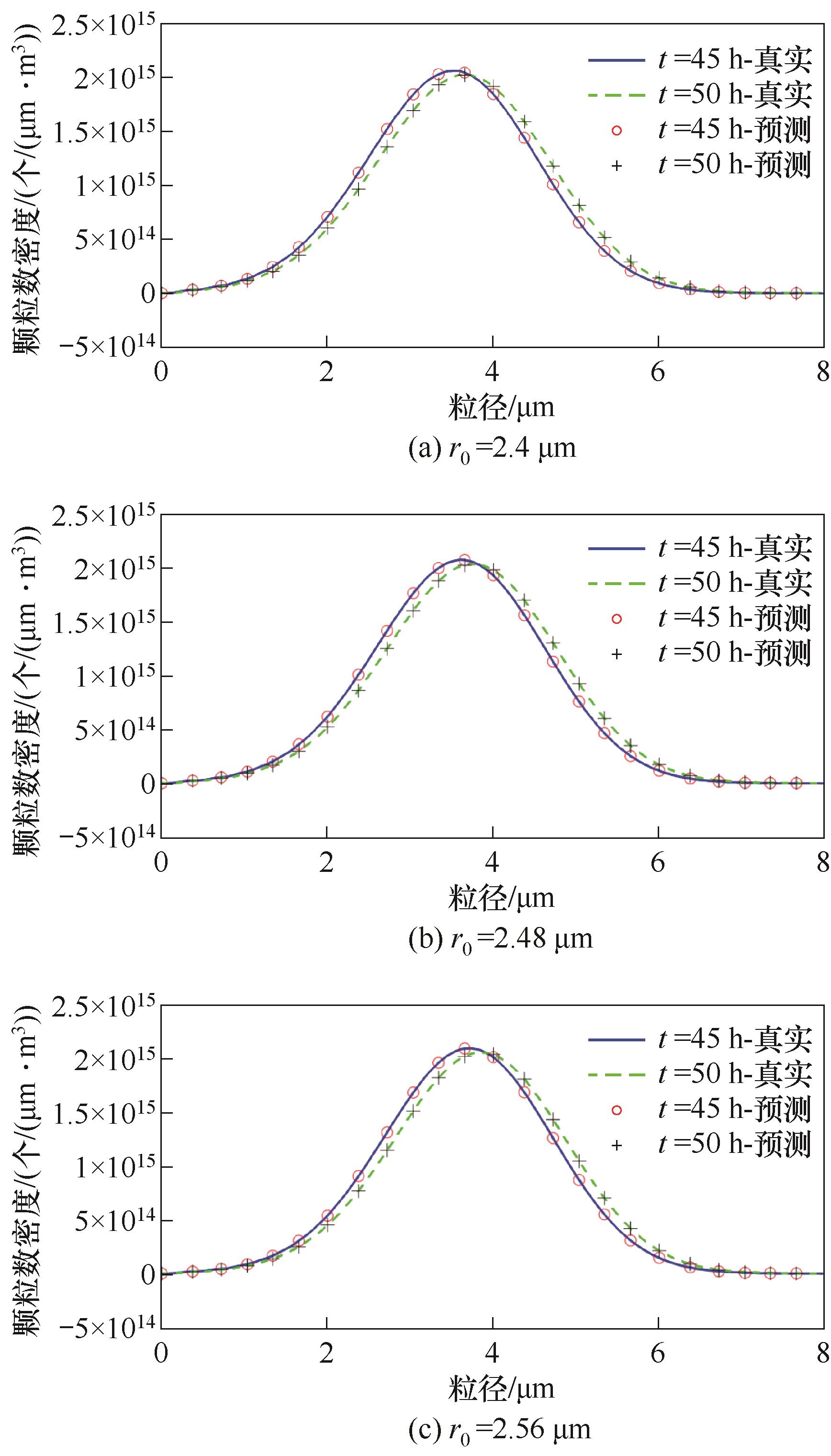

Fig.2 Under the condition that the growth rate satisfies the ASL equation, the actual particle size distribution curves (blue solid lines—45 h, green dashed lines—50 h) and predicted particle size distribution curves (red circles—45 h, black plus sign—50 h) corresponding to t=45 h and t=50 h for r0=2.4,2.48,2.56 μm

| 批次 | 相对误差/% | ||

|---|---|---|---|

| KG | γ | b | |

| 1st (r0=2.4 μm) | 0.327 | 0.663 | 0.001 |

| 2nd (r0=2.48 μm) | 0.913 | 1.907 | 0.008 |

| 3rd (r0=2.56 μm) | 0.399 | 0.822 | 0.005 |

Table 2 Relative error of parameter estimation

| 批次 | 相对误差/% | ||

|---|---|---|---|

| KG | γ | b | |

| 1st (r0=2.4 μm) | 0.327 | 0.663 | 0.001 |

| 2nd (r0=2.48 μm) | 0.913 | 1.907 | 0.008 |

| 3rd (r0=2.56 μm) | 0.399 | 0.822 | 0.005 |

| 批次 | rd | |

|---|---|---|

| t=45 h | t=50 h | |

| 1st (r0=2.4 μm) | 5.10×10-6 | 5.62×10-6 |

| 2nd (r0=2.48 μm) | 8.89×10-6 | 9.43×10-6 |

| 3rd (r0=2.56 μm) | 4.07×10-6 | 4.45×10-6 |

Table 3 The values of rd corresponding to t=45 h and t=50 h when the growth rate satisfies the ASL equation

| 批次 | rd | |

|---|---|---|

| t=45 h | t=50 h | |

| 1st (r0=2.4 μm) | 5.10×10-6 | 5.62×10-6 |

| 2nd (r0=2.48 μm) | 8.89×10-6 | 9.43×10-6 |

| 3rd (r0=2.56 μm) | 4.07×10-6 | 4.45×10-6 |

| 参数 | 1st (r0=2.4 μm) | 2nd (r0=2.48 μm) | 3rd (r0=2.56 μm) |

|---|---|---|---|

| g1 | 0.0251262 | 0.0251169 | 0.0251549 |

| g2 | 0.0557397 | 0.0556703 | 0.0556456 |

| g3 | 0.0861399 | 0.0861498 | 0.0861704 |

| g4 | 0.115193 | 0.115193 | 0.115192 |

| g5 | 0.142446 | 0.142449 | 0.142449 |

| g6 | 0.167488 | 0.167494 | 0.167497 |

| g7 | 0.189929 | 0.189931 | 0.189943 |

| g8 | 0.209357 | 0.209393 | 0.209465 |

| g9 | 0.228366 | 0.22766 | 0.227164 |

| g10 | 0.233492 | 0.233729 | 0.234133 |

| g11 | 0.237959 | 0.240243 | 0.242872 |

| g12 | 0.301832 | 0.297165 | 0.295236 |

Table 4 Parameter estimation results based on approximate growth rate equation

| 参数 | 1st (r0=2.4 μm) | 2nd (r0=2.48 μm) | 3rd (r0=2.56 μm) |

|---|---|---|---|

| g1 | 0.0251262 | 0.0251169 | 0.0251549 |

| g2 | 0.0557397 | 0.0556703 | 0.0556456 |

| g3 | 0.0861399 | 0.0861498 | 0.0861704 |

| g4 | 0.115193 | 0.115193 | 0.115192 |

| g5 | 0.142446 | 0.142449 | 0.142449 |

| g6 | 0.167488 | 0.167494 | 0.167497 |

| g7 | 0.189929 | 0.189931 | 0.189943 |

| g8 | 0.209357 | 0.209393 | 0.209465 |

| g9 | 0.228366 | 0.22766 | 0.227164 |

| g10 | 0.233492 | 0.233729 | 0.234133 |

| g11 | 0.237959 | 0.240243 | 0.242872 |

| g12 | 0.301832 | 0.297165 | 0.295236 |

Fig.3 Under the condition that the growth rate is universal, the actual particle size distribution curves (blue solid lines—45 h, green dashed lines—50 h) and predicted particle size distribution curves (red circles—45 h, black plus sign—50 h) corresponding to t=45 h and t=50 h for r0=2.4,2.48,2.56

| 批次 | rd | |

|---|---|---|

| t=45 h | t=50 h | |

| 1st (r0=2.4 μm) | 3.20×10-4 | 3.69×10-4 |

| 2nd (r0=2.48 μm) | 2.66×10-4 | 3.15×10-4 |

| 3rd (r0=2.56 μm) | 2.14×10-4 | 2.62×10-4 |

Table 5 The values of rd corresponding to t=45 h and t=50 h when the growth rate model has universality

| 批次 | rd | |

|---|---|---|

| t=45 h | t=50 h | |

| 1st (r0=2.4 μm) | 3.20×10-4 | 3.69×10-4 |

| 2nd (r0=2.48 μm) | 2.66×10-4 | 3.15×10-4 |

| 3rd (r0=2.56 μm) | 2.14×10-4 | 2.62×10-4 |

| [1] | Entwistle T, Sanchez-Perez E, Murray G J, et al. Co-precipitation synthesis of nickel-rich cathodes for Li-ion batteries[J]. Energy Reports, 2022, 8: 67-73. |

| [2] | Hua W B, Liu W Y, Chen M Z, et al. Unravelling the growth mechanism of hierarchically structured Ni1/3Co1/3Mn1/3(OH)2 and their application as precursors for high-power cathode materials[J]. Electrochimica Acta, 2017, 232: 123-131. |

| [3] | Shiea M, Querio A, Buffo A, et al. CFD-PBE modelling of continuous Ni-Mn-Co hydroxide co-precipitation for Li-ion batteries[J]. Chemical Engineering Research and Design, 2022, 177: 461-472. |

| [4] | Feng Z G, Barai P, Gim J, et al. In situ monitoring of the growth of nickel, manganese, and cobalt hydroxide precursors during co-precipitation synthesis of Li-ion cathode materials[J]. Journal of the Electrochemical Society, 2018, 165(13): A3077-A3083. |

| [5] | Lee S L, O'Connor T F, Yang X C, et al. Modernizing pharmaceutical manufacturing: from batch to continuous production[J]. Journal of Pharmaceutical Innovation, 2015, 10(3): 191-199. |

| [6] | Orehek J, Teslić D, Likozar B. Continuous crystallization processes in pharmaceutical manufacturing: a review[J]. Organic Process Research & Development, 2021, 25(1): 16-42. |

| [7] | Wang T, Lu H J, Wang J K, et al. Recent progress of continuous crystallization[J]. Journal of Industrial and Engineering Chemistry, 2017, 54: 14-29. |

| [8] | Schmuch R, Siozios V, Winter M, et al. High-Energy Lithium-Ion Batteries[Z/OL]. [2024-11-14].. |

| [9] | Myerson A S, Erdemir D, Lee A Y. Handbook of Industrial Crystallization[M]. Cambridge: Cambridge University Press, 2019. |

| [10] | Deschamps A, Hutchinson C R. Precipitation kinetics in metallic alloys: experiments and modeling[J]. Acta Materialia, 2021, 220: 117338. |

| [11] | Tavenner J P, Mendelev M I, Lawson J W. Molecular dynamics based kinetic Monte Carlo simulation for accelerated diffusion[J]. Computational Materials Science, 2023, 218: 111929. |

| [12] | Nellis C, Hin C. Kinetic Monte Carlo modeling of homogeneous precipitation of Y-O and Y-Ti-O oxides in bulk alpha iron[J]. Journal of Materials Science, 2022, 57(4): 2710-2730. |

| [13] | 贾丽霞, 王东杰, 王瑾, 等. Fe-Cr-W合金内富Cr团簇形核析出动力学的原子动力学蒙特卡罗模拟[J]. 原子能科学技术, 2023, 57(7): 1385-1396. |

| Jia L X, Wang D J, Wang J, et al. Atomic kinetic Monte Carlo simulation of nucleation kinetics of Cr-rich clusters in Fe-Cr-W alloy[J]. Atomic Energy Science and Technology, 2023, 57(7): 1385-1396. | |

| [14] | Wang Y, Yin J, Liu X B, et al. Precipitation kinetics in binary Fe-Cu and ternary Fe-Cu-Ni alloys via kMC method[J]. Progress in Natural Science: Materials International, 2017, 27(4): 460-466. |

| [15] | Shen Z Q, Gao J, Lv S S, et al. OKMC simulation of vacancy-enhanced Cu solute segregation affected by temperature/irradiation in the Fe-Cu system[J]. Nuclear Science and Techniques, 2022, 33(11): 149. |

| [16] | Miyoshi H, Kimizuka H, Ishii A, et al. Temperature-dependent nucleation kinetics of Guinier-Preston zones in Al-Cu alloys: an atomistic kinetic Monte Carlo and classical nucleation theory approach[J]. Acta Materialia, 2019, 179: 262-272. |

| [17] | Piotrowski K, Piotrowski J. Monte Carlo modelling of continuous adiabatic MSMPR crystallizer[J]. Chemical Engineering and Processing: Process Intensification, 2005, 44(5): 517-528. |

| [18] | Hutchinson C R, Nie J F, Gorsse S. Modeling the precipitation processes and strengthening mechanisms in a Mg-Al-(Zn) AZ91 alloy[J]. Metallurgical and Materials Transactions A, 2005, 36(8): 2093-2105. |

| [19] | Perez M, Dumont M, Acevedo-Reyes D. Implementation of classical nucleation and growth theories for precipitation[J]. Acta Materialia, 2008, 56(9): 2119-2132. |

| [20] | Balan A, Perez M, Chaise T, et al. Precipitation of γ" in Inconel 718 alloy from microstructure to mechanical properties[J]. Materialia, 2021, 20: 101187. |

| [21] | Assadiki A, Esin V A, Martinez R, et al. Modelling precipitation hardening in an A356+0.5 wt%Cu cast aluminum alloy[J]. Materials Science and Engineering: A, 2021, 819: 141450. |

| [22] | Xia X Y, Sanaty-Zadeh A, Zhang C, et al. Experimental investigation and simulation of precipitation evolution in Mg-3Nd-0.2Zn alloy[J]. Calphad, 2018, 60: 58-67. |

| [23] | Miao J S, Zhang C, Klarner A D, et al. Characterization and modeling of concurrent precipitation in Mg-Al-Sn alloys using an improved Kampmann-Wagner numerical (KWN) model[J]. Materialia, 2022, 21: 101348. |

| [24] | Bo G W, Wang Y L, Liu M C, et al. Experimental and modeling investigations of the non-isothermal and isothermal precipitations in an Al-Cu-Mg-Zr alloy with various pre-precipitation microstructures[J]. Materials & Design, 2022, 217: 110640. |

| [25] | Herrnring J, Sundman B, Staron P, et al. Modeling precipitation kinetics for multi-phase and multi-component systems using particle size distributions via a moving grid technique[J]. Acta Materialia, 2021, 215: 117053. |

| [26] | Li Y, Zheng X Y, Liu Y L, et al. Design of ultrahigh strength Al-Zn-Mg-Cu alloys through a hybrid approach of high-throughput precipitation simulation and decisive experiment[J]. Journal of Materials Science & Technology, 2024, 195: 234-247. |

| [27] | Sitapure N, Kwon J S. CrystalGPT: enhancing system-to-system transferability in crystallization prediction and control using time-series-transformers[J]. Computers & Chemical Engineering, 2023, 177: 108339. |

| [28] | Kokkila N. Data driven modelling of crystalliser particle size distribution[D]. Finland: University of Oulu, 2023. |

| [29] | Ramkrishna D. Population Balances: Theory and Applications to Particulate Systems in Engineering[M]. San Diego, CA: Academic Press, 2000. |

| [30] | Cao X M, Peng J P, Dong W X, et al. Theoretical study on the utilization of fluorine-containing wastewater in the aluminum industry: crystallization characteristics and particle size control of cryolite prepared by carbonization[J]. Journal of Environmental Chemical Engineering, 2024, 12(5): 113572. |

| [31] | Para M L, Alidoost M, Shiea M, et al. A modelling and experimental study on the co-precipitation of Ni0.8Mn0.1Co0.1(OH)2 as precursor for battery cathodes[J]. Chemical Engineering Science, 2022, 254: 117634. |

| [32] | Cheng J C, Yang C, Mao Z S. CFD-PBE simulation of premixed continuous precipitation incorporating nucleation, growth and aggregation in a stirred tank with multi-class method[J]. Chemical Engineering Science, 2012, 68(1): 469-480. |

| [33] | Bałdyga J, Makowski Ł, Orciuch W. Double-feed semibatch precipitation effects of mixing[J]. Chemical Engineering Research and Design, 2007, 85(5): 745-752. |

| [34] | 连斌, 龙妍, 徐啟蕾, 等. 间歇冷却结晶过程模型参数及操作敏感性分析[J]. 化工学报, 2024, 75(12): 4587-4595. |

| Lian B, Long Y, Xu Q L, et al. Sensitivity analysis of model parameters and process operation for batch cooling crystallization process[J]. CIESC Journal, 2024, 75(12): 4587-4595. | |

| [35] | Wu Z W, Zhou Y, Zeng J B, et al. Investigating the effect of pH on the growth of coprecipitated Ni0.8Co0.1Mn0.1(OH)2 agglomerates as precursors of cathode materials for Li-ion batteries[J]. Ceramics International, 2023, 49(10): 15851-15864. |

| [36] | Huang B, Cheng L, Li X Z, et al. Layered cathode materials: precursors, synthesis, microstructure, electrochemical properties, and battery performance[J]. Small, 2022, 18(20): 2107697. |

| [37] | 王伟东, 杨凯, 关豪元, 等. 三元材料前驱体: 产线设计及生产应用[M]. 北京: 化学工业出版社, 2021. |

| Wang W D, Yang K, Guan H Y. Precursors for Lithium-ion Battery Ternary Cathode Materials[M]. Beijing: Chemical Industry Press, 2021. | |

| [38] | Achermann R, Wiedmeyer V, Hosseinalipour M S, et al. Model-based design of pressure-driven product removal from stirred suspensions[J]. Chemical Engineering Research and Design, 2021, 174: 57-70. |

| [39] | Zhang W D, Przybycien T, Schmölder J, et al. Solving crystallization/precipitation population balance models in CADET(part Ⅰ): Nucleation growth and growth rate dispersion in batch and continuous modes on nonuniform grids[J]. Computers & Chemical Engineering, 2024, 183: 108612. |

| [40] | Abegg C F, Stevens J D, Larson M A. Crystal size distributions in continuous crystallizers when growth rate is size dependent[J]. AIChE Journal, 1968, 14(1): 118-122. |

| [41] | Garside J, Jančić S J. Prediction and measurement of crystal size distributions for size-dependent growth[J]. Chemical Engineering Science, 1978, 33(12): 1623-1630. |

| [42] | 刘勇, 王静康. 间歇结晶过程中几种可能的粒度分布[J]. 化工学报, 2005, 56(2): 276-280. |

| Liu Y, Wang J K. Several possible crystal size distributions for batch crystallization processes[J]. CIESC Journal, 2005, 56(2): 276-280. | |

| [43] | 李川, 洪振取, 单宝明, 等. 求解多维粒数衡算方程的高阶紧致差分方法[J]. 化工学报, 2024, 75(12): 4513-4522. |

| Li C, Hong Z Q, Shan B M, et al. High-order compact difference method for solving the multidimensional population balance equation[J]. CIESC Journal, 2024, 75(12): 4513-4522. | |

| [44] | Jie H, Zhu G Z, Hong W R. Direct approaches for PDE-constrained dynamic optimization based on space-time orthogonal collocation on finite elements[J]. Journal of Process Control, 2023, 124: 187-198. |

| [45] | Gautschi W. Orthogonal Polynomials: Computation and Approximation[M]. Oxford: Oxford University Press, 2004. |

| [1] | Mei ZHOU, Haojie ZENG, Huoyan JIANG, Ting PU, Xingxing ZENG, Baoyu LIU. Meosporous MTW zeolites modified by secondary crystallization and their catalytic properties in alkylation reaction of benzene and cyclohexene [J]. CIESC Journal, 2025, 76(8): 4071-4080. |

| [2] | Bilin LIANG, Qian YU, Siqi JIA, Fang LI, Qiming LI. Structural modulation and gas separation performance of Ni-MOF-74 metal-organic framework membranes [J]. CIESC Journal, 2025, 76(6): 2714-2721. |

| [3] | Han LIU, Jiaxin CUI, Mengfan YIN, Tao ZHENG, Rui ZHANG, Xianghai MENG, Zhichang LIU, Haiyan LIU, Chunming XU. Crystal structure of xylene·CuAlCl4 and measurement of solid-liquid equilibrium of binary system [J]. CIESC Journal, 2025, 76(5): 2241-2250. |

| [4] | Ben’an CAI, Jianxin ZHANG, Chengjun LONG, Qiaochen DU, Xunjian CHE, Yiying ZHANG, Weihua CAI. Spray flash evaporation preparation of micro/nanoparticles [J]. CIESC Journal, 2025, 76(3): 1334-1345. |

| [5] | Ju DONG, Liuyang YU, Shengzhe JIA, Lianjun SHI, Shihan WANG, Guotao HU, Weiwei TANG, Jingkang WANG, Junbo GONG. Current status and research progress of crystallization technology of electronic grade phosphoric acid [J]. CIESC Journal, 2025, 76(2): 438-453. |

| [6] | Falu DANG, Zhiguo SUN, Zhao GAO, Gang WANG, Zhengyu CHEN, Linzhou ZHANG, Jingcun LIAN, Meijia LIU, Zhongdong ZHANG, Chaowei LIU. One-step catalytic cracking of crude oil to light olefins: experimental and reaction pathway studies [J]. CIESC Journal, 2025, 76(2): 667-685. |

| [7] | Zilin PENG, Lei ZHOU, Qinghang DENG, Guanghua YE, Xinggui ZHOU. Kinetics of 3D NAND flash wet etching with phosphoric acid under the influence of H2SiO3 [J]. CIESC Journal, 2025, 76(2): 645-653. |

| [8] | Na HUANG, Yunlong JIANG, Donghan WANG, Mingting WU, Xueli JIANG, Yu ZHONG. Numerical study of influence of channel vibration frequency on flow and heat transfer of supercritical n-decane with pyrolysis reaction [J]. CIESC Journal, 2025, 76(1): 173-183. |

| [9] | Feng LIU, Rujie BI, Quan WANG, Zhao KUANG, Xiangshuai MENG, Guoqiang HUANG. Effect of vibration on the stability of on-site mixed emulsion explosive matrix with different water contents [J]. CIESC Journal, 2025, 76(1): 405-415. |

| [10] | Wenbo ZHOU, Jiangwei YIN, Dan ZHANG, Yue YANG, Jiahao YU, Bingchao ZHAO. Experimental study on evaporation of aqueous NaCl solution droplet heating by thermal irradiation [J]. CIESC Journal, 2024, 75(S1): 85-94. |

| [11] | Junhao HUANG, Keliang PANG, Fangyuan SUN, Fujun LIU, Zhiyuan GU, Long HAN, Yanquan DUAN, Yanhui FENG. Influence of bell structure of coke dry quenching furnace on coke distribution [J]. CIESC Journal, 2024, 75(S1): 158-169. |

| [12] | Shuzhen WANG, Yuting WANG, Mengxi MA, Wei ZHANG, Jiangnan XIANG, Haiying LU, Yan WANG, Binbin FAN, Jiajun ZHENG, Weijiong DAI, Ruifeng LI. Synthesis of ZSM-22 molecular sieve by two-step crystallization and its hydroisomerization performance [J]. CIESC Journal, 2024, 75(9): 3176-3187. |

| [13] | Qi QI, Liping GUO, Liming SHI, Ying ZHENG, Pengju PAN. Crystallization behavior and properties of polypropylene and its copolymers modified with sorbitol nucleating agents [J]. CIESC Journal, 2024, 75(7): 2688-2699. |

| [14] | Jing LIU, Wenbo YANG, Yingdi LYU, Shengyang TAO. Spray-anti-solvent crystallization method for preparing doped aluminum powder composite microspheres [J]. CIESC Journal, 2024, 75(4): 1724-1734. |

| [15] | Shihao LI, Zhenhua WU, Zhanfeng ZHAO, Hong WU, Dong YANG, Jiafu SHI, Zhongyi JIANG. Electron transfer, proton transfer and molecule transfer in chemical processes [J]. CIESC Journal, 2024, 75(3): 1052-1064. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||