CIESC Journal ›› 2019, Vol. 70 ›› Issue (7): 2645-2659.DOI: 10.11949/j.issn.0438-1157.20190183

• Surface and interface engineering • Previous Articles Next Articles

Wei SHEN( ),Xudong PENG(

),Xudong PENG( ),Jinbo JIANG,Jiyun LI

),Jinbo JIANG,Jiyun LI

Received:2019-03-04

Revised:2019-04-07

Online:2019-07-05

Published:2019-07-05

Contact:

Xudong PENG

通讯作者:

彭旭东

作者简介:沈伟(1993—),男,硕士研究生,<email>m15757174235@163.com</email>

基金资助:CLC Number:

Wei SHEN, Xudong PENG, Jinbo JIANG, Jiyun LI. Analysis on real effect of supercritical carbon dioxide dry gas seal at high speed[J]. CIESC Journal, 2019, 70(7): 2645-2659.

沈伟, 彭旭东, 江锦波, 李纪云. 高速超临界二氧化碳干气密封实际效应影响分析[J]. 化工学报, 2019, 70(7): 2645-2659.

Add to citation manager EndNote|Ris|BibTeX

URL: https://hgxb.cip.com.cn/EN/10.11949/j.issn.0438-1157.20190183

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 内径 ri/mm | 58.42 | 螺旋角β/(°) | 15 |

| 外径 ro/mm | 77.78 | 槽深 hg/μm | 5 |

| 内径压力 pi/MPa | 0.1 | 槽长比 α | 0.5 |

| 外径压力 po/MPa | 8/14 | 槽宽比 δ | 0.5 |

| 介质温度 T/K | 350 | 槽数 Ng | 12 |

| 非槽区膜厚 h0/μm | 3 |

Table 1 Geometric parameter and operating condition parameter

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 内径 ri/mm | 58.42 | 螺旋角β/(°) | 15 |

| 外径 ro/mm | 77.78 | 槽深 hg/μm | 5 |

| 内径压力 pi/MPa | 0.1 | 槽长比 α | 0.5 |

| 外径压力 po/MPa | 8/14 | 槽宽比 δ | 0.5 |

| 介质温度 T/K | 350 | 槽数 Ng | 12 |

| 非槽区膜厚 h0/μm | 3 |

| 生产单位和应用场地 | 介质压力 po/MPa | 密封环线速度 v/(m·s-1) | 介质温度 T/K |

|---|---|---|---|

| Man Turbo, Beula, ND | 11.03 | 146.93 | 449.97 |

| Production Pump, Texas | 13.79 | 19.41 | 377.69 |

| Flowserve, NA | 15.17 | 17.76 | 324.87 |

| MHI, Japan | 21.50 | 65.25 | 477.77 |

| American Pump, Dallas | 17.24 | 23.59 | 310.97 |

Table 2 Examples of supercritical CO2 dry gas seal application conditions

| 生产单位和应用场地 | 介质压力 po/MPa | 密封环线速度 v/(m·s-1) | 介质温度 T/K |

|---|---|---|---|

| Man Turbo, Beula, ND | 11.03 | 146.93 | 449.97 |

| Production Pump, Texas | 13.79 | 19.41 | 377.69 |

| Flowserve, NA | 15.17 | 17.76 | 324.87 |

| MHI, Japan | 21.50 | 65.25 | 477.77 |

| American Pump, Dallas | 17.24 | 23.59 | 310.97 |

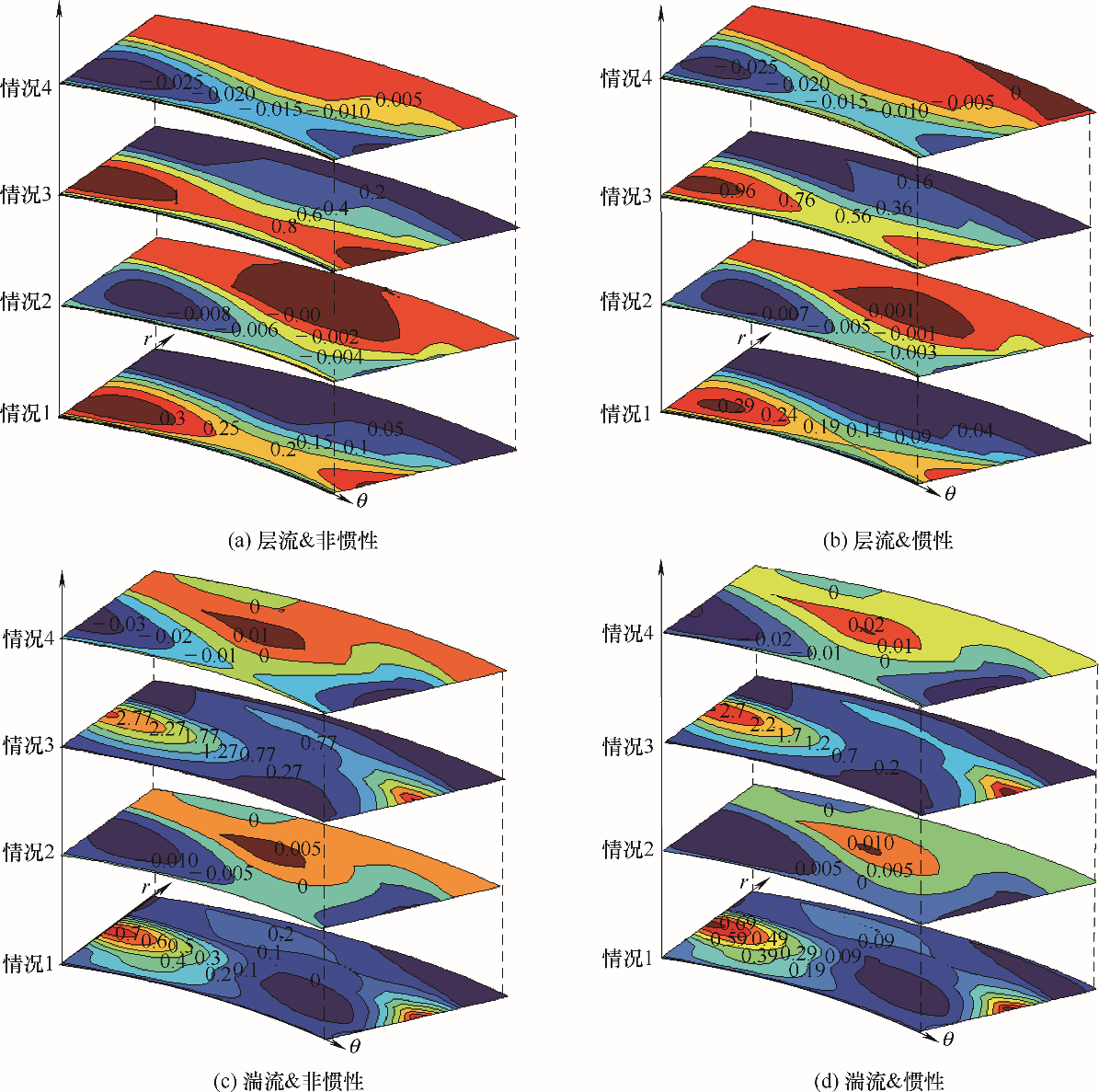

Fig.6 Pressure differential distribution of supercritical CO2 dry gas seal for real gas compared with ideal gas at different combination of pressure and temperature

| 压力 po/MPa | 线速度 v/(m·s-1) | 交互性能增量比/% | |||||

|---|---|---|---|---|---|---|---|

| 湍流对实际气体的影响 | 惯性对实际气体的影响 | 实际气体对湍流的影响 | 惯性对湍流的影响 | 实际气体对惯性的影响 | 湍流对惯性的影响 | ||

| 8 | 25 | 0.52 | 0.36 | 0.54 | 0.34 | 0.37 | 0.33 |

| 8 | 150 | 10.29 | -0.07 | 14.12 | 0.86 | -0.06 | 0.58 |

| 14 | 25 | 4.15 | 0.17 | 4.38 | 0.25 | 0.16 | 0.24 |

| 14 | 150 | 31.31 | -1.55 | 43.60 | 1.87 | -1.32 | 1.06 |

Table 3 Interactive increment ratio of film stiffness of supercritical CO2 dry gas seal of three effects at

| 压力 po/MPa | 线速度 v/(m·s-1) | 交互性能增量比/% | |||||

|---|---|---|---|---|---|---|---|

| 湍流对实际气体的影响 | 惯性对实际气体的影响 | 实际气体对湍流的影响 | 惯性对湍流的影响 | 实际气体对惯性的影响 | 湍流对惯性的影响 | ||

| 8 | 25 | 0.52 | 0.36 | 0.54 | 0.34 | 0.37 | 0.33 |

| 8 | 150 | 10.29 | -0.07 | 14.12 | 0.86 | -0.06 | 0.58 |

| 14 | 25 | 4.15 | 0.17 | 4.38 | 0.25 | 0.16 | 0.24 |

| 14 | 150 | 31.31 | -1.55 | 43.60 | 1.87 | -1.32 | 1.06 |

| 压力 po/MPa | 线速度 v/(m·s-1) | 交互性能增量比/% | |||||

|---|---|---|---|---|---|---|---|

| 湍流对实际气体的影响 | 惯性对实际气体的影响 | 实际气体对湍流的影响 | 惯性对湍流的影响 | 实际气体对惯性的影响 | 湍流对惯性的影响 | ||

| 8 | 25 | -0.21 | -0.39 | -0.17 | 0.32 | -0.32 | 0.32 |

| 8 | 150 | -5.98 | -0.89 | -4.35 | -1.32 | -0.70 | -1.44 |

| 14 | 25 | -2.36 | -0.47 | -1.55 | 0.71 | -0.31 | 0.72 |

| 14 | 150 | -24.37 | -2.14 | -12.83 | -0.37 | -1.46 | -0.50 |

Table 4 Interactive increment ratio of leakage rate of supercritical CO2 dry gas seal of three effects at

| 压力 po/MPa | 线速度 v/(m·s-1) | 交互性能增量比/% | |||||

|---|---|---|---|---|---|---|---|

| 湍流对实际气体的影响 | 惯性对实际气体的影响 | 实际气体对湍流的影响 | 惯性对湍流的影响 | 实际气体对惯性的影响 | 湍流对惯性的影响 | ||

| 8 | 25 | -0.21 | -0.39 | -0.17 | 0.32 | -0.32 | 0.32 |

| 8 | 150 | -5.98 | -0.89 | -4.35 | -1.32 | -0.70 | -1.44 |

| 14 | 25 | -2.36 | -0.47 | -1.55 | 0.71 | -0.31 | 0.72 |

| 14 | 150 | -24.37 | -2.14 | -12.83 | -0.37 | -1.46 | -0.50 |

| 1 | DostalV. A supercritical carbon dioxide cycle for next generation nuclear reactors [D]. Massachusetts: Massachusetts Institute of Technology, 2004. |

| 2 | AhnY, BaeS J, KimM, et al. Review of supercritical CO2 power cycle technology and current status of research and development[J]. Nuclear Engineering & Technology, 2015, 47(6): 647-661. |

| 3 | ThatteA, DheeradhadaV. Coupled physical performance predictions and risk assessment for dry gas seal operating in MW-scale supercritical CO2 turbine [C]//Proceedings of ASME Turbo Expo 2016, Turbomachinery Technology Conference and Exposition, Seoul, South Korea 2016. |

| 4 | FairuzZ M, JahnI H J. Performance of supercritical CO2 dry gas seal near the critical point[C]// Proceedings of ASME Turbo Expo 2016, Turbomachinery Technology Conference and Exposition, Seoul, South Korea, 2016. |

| 5 | BaltadjievN D. An investigation of real gas effects in supercritical CO2 compressors[D]. Massachusetts: Massachusetts Institute of Technology, 2012. |

| 6 | JassimE, AbdiM A, MuzychkaY. Computational fluid dynamics study for flow of natural gas through high-pressure supersonic nozzles(part 1): Real gas effects and shockwave [J]. Petroleum Science & Technology, 2008, 26(15): 1757-1772. |

| 7 | MutoD, TsuboiN, TerashimaH. Numerical study of real gas effects on shock tube problems at supercritical conditions [J]. Transactions of the Japan Society for Aeronautical & Space Sciences Aerospace Technology Japan, 2014, 12(2): 39-44. |

| 8 | FairuzZ M, JahnI. The influence of real gas effects on the performance of supercritical CO2 dry gas seals [J]. Tribology International, 2016, 102: 333-347. |

| 9 | 许恒杰, 宋鹏云, 毛文元, 等. 层流状态下高压高转速二氧化碳干气密封的惯性效应分析[J]. 化工学报, 2018, 69(10): 4311-4323. |

| XuH J, SongP Y, MaoW Y, et al. Analysis on inertia effect of carbon dioxide dry gas seal at high speed and pressure under laminar condition[J]. CIESC Journal, 2018, 69(10): 4311-4323. | |

| 10 | DuQ W, GaoK K, ZhangD, et al. Effects of grooved ring rotation and working fluid on the performance of dry gas seal[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1323-1332. |

| 11 | 温建全. 超临界二氧化碳介质箔片轴承弹流耦合研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. |

| WenJ Q. The oretical study on characteristics of compliant foil bearings lubricated with supercritical carbon dioxide[D].Haerbin: Harbin Institute of Technology, 2017. | |

| 12 | ConboyT M. Real-gas effects in foil thrust bearings operating in the turbulent regime[J]. ASME Journal of Tribology, 2013, 135: 031703-1-031703-12. |

| 13 | ConstantinescuV N. Basic relationships in turbulent lubrication and their extension to include thermal effects[J]. ASME Journal of Lubrication Technology, 1973, 95(2): 147-154. |

| 14 | ConstantinescuV N, GaletuseS. On the possibilities of improving the accuracy of the evaluation of inertia forces in laminar and turbulent films[J]. ASME Journal of Tribology, 1974, 96(1): 69-77. |

| 15 | ConstantinescuV N. On the influence of inertia forces in turbulent and laminar self-acting films[J]. ASME Journal of Tribology, 1970, 92(3): 473-480. |

| 16 | NgC W, PanC H T. A linearized turbulent lubrication theory[J]. ASME Journal of Fluids Engineering, 1965, 87(3): 675-682. |

| 17 | NgC W. Fluid dynamic foundation of turbulent lubrication theory[J]. Tribology Transactions, 1964, 7(4): 311-321. |

| 18 | ElrodH G, NgC W. A theory for turbulent fluid films and its application to bearings[J]. ASME Journal of Lubrication Technology, 1967, 89(3): 346-362. |

| 19 | HirsG G. A bulk-flow theory for turbulence in lubricant films[J]. ASME Journal of Lubrication Technology, 1973, 95(2): 137-145. |

| 20 | WangJ K, KhonsariM M. Application of Hopf bifurcation theory to rotor-bearing systems with consideration of turbulent effects[J]. Tribology International, 2006, 39(7): 701-714. |

| 21 | LuanZ, KhonsariM M. Analysis of conjugate heat transfer and turbulent flow in mechanical seals[J]. Tribology International, 2009, 42(5): 762-769. |

| 22 | HashimotoH. The effects of fluid inertia forces on the static characteristics of sector-shaped, high-speed thrust bearings in turbulent flow regime[J]. Journal of Tribology, 1989, 111: 406-412. |

| 23 | HashimotoH. Performance characteristic analysis of sector-shaped pad thrust bearings in turbulent inertial flow regime under three types of lubrication conditions[J]. ASME Journal of Tribology, 1990, 112: 477-485. |

| 24 | ConboyT M. Real-gas effects in foil thrust bearings operating in the turbulent regime[J]. ASME Journal of Tribology, 2013, 135: 031703-1-12. |

| 25 | TaylorC M, DowsonD. Turbulent lubrication theory – application to design[J]. ASME Journal of Lubrication Technology, 1974, 96(1): 36-46. |

| 26 | 江锦波, 陈源, 赵文静, 等. 干气密封螺旋槽几何参数优选交互影响[J]. 化工学报, 2018, 69(4): 1518-1527. |

| JiangJ B, ChenY, ZhaoW J, et al. Interaction effect of optimized value of geometric parameters of spiral groove of dry gas seal[J]. CIESC Journal, 2018, 69(4): 1518-1527. | |

| 27 | 彭旭东, 江锦波, 白少先, 等. 中低压干气密封螺旋槽结构参数优化[J]. 化工学报, 2014, 65(11): 4536-4542. |

| PengX D, JiangJ B, BaiS X, et al. Structural parameter optimization of spiral groove dry gas seal under low or medium pressure[J]. CIESC Journal, 2014, 65(11): 4536-4542. | |

| 28 | 徐奇超, 江锦波, 彭旭东, 等. 基于遗传算法的干气密封双向槽统一模型与参数优化[J]. 化工学报, 2019, 70(3): 995-1005. |

| XuQ C, JiangJ B, PengX D, et al. Unified model and geometrical optimization of bi-directional groove of dry gas seal based on genetic algorithm[J]. CIESC Journal, 2019, 70(3): 995-1005. | |

| 29 | GlienickeJ, LaunertA, SchlumsH, et al. Non-contacting gas lubricated face seals for high PV values[J]. Seals Flow Code Development, 1994, 1: 367-378. |

| 30 | OchiaiM, HashimotoH. Static and dynamic characteristics of high-speed, stepped thrust gas-film bearings(Theoretical analysis considering fluid inertia forces)[J]. Procedia Environmental Sciences, 1997, 63(613): 3249-3256. |

| 31 | MarquardtJ T. Successful operational experience sealing supercritical CO2 [C]// Supercritical CO2 Power Cycle Symposium. Boulder, Colorado, USA:2015: 1-5. |

| 32 | 李沛剑, 郝小龙, 宋满存, 等. 超临界二氧化碳涡轮发电机的设计及应用探讨[J]. 船舶科学技术, 2017, 39(9): 111-116. |

| LiP J, HaoX L, SongM C, et al. The design and application of a supercritical carbon dioxide turbo-generator [J]. Ship Science and Technology, 2017, 39(9): 111-116. | |

| 33 | AhnY, BaeS J, KimM, et al. Review of supercritical CO2 power cycle technology and current status of research and developmnt[J]. Nuclear Engineering Technology, 2015, 47: 647-661. |

| [1] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [2] | Junfeng LU, Huaiyu SUN, Yanlei WANG, Hongyan HE. Molecular understanding of interfacial polarization and its effect on ionic liquid hydrogen bonds [J]. CIESC Journal, 2023, 74(9): 3665-3680. |

| [3] | Rui HONG, Baoqiang YUAN, Wenjing DU. Analysis on mechanism of heat transfer deterioration of supercritical carbon dioxide in vertical upward tube [J]. CIESC Journal, 2023, 74(8): 3309-3319. |

| [4] | Yuanliang ZHANG, Xinqi LUAN, Weige SU, Changhao LI, Zhongxing ZHAO, Liqin ZHOU, Jianmin CHEN, Yan HUANG, Zhenxia ZHAO. Study on selective extraction of nicotine by ionic liquids composite extractant and DFT calculation [J]. CIESC Journal, 2023, 74(7): 2947-2956. |

| [5] | Junhua DING, Shurong YU, Shipeng WANG, Xianzhi HONG, Xin BAO, Xuexing DING. Flow simulation and sealing performance test of ultra-high speed dry gas seal under multiple effects [J]. CIESC Journal, 2023, 74(5): 2088-2099. |

| [6] | Bingguo ZHU, Jixiang HE, Jinliang XU, Bin PENG. Heat transfer characteristics of supercritical pressure CO2 in diverging/converging tube under cooling conditions [J]. CIESC Journal, 2023, 74(3): 1062-1072. |

| [7] | Hao XIONG, Xiaoyu LIANG, Chenxi ZHANG, Haolong BAI, Xiaoyu FAN, Fei WEI. Heavy oil to chemicals: multi-stage downer catalytic pyrolysis [J]. CIESC Journal, 2023, 74(1): 86-104. |

| [8] | Lingfei KONG, Yanpei CHEN, Wei WANG. Dynamic study of mesoscale structures of particles in gas-solid fluidization [J]. CIESC Journal, 2022, 73(6): 2486-2495. |

| [9] | Xiaodong XU, Chenbo MA, Jianjun SUN, Yuyan ZHANG, Qiuping YU. Influence and optimization of groove structure parameters on vaporization characteristics of liquid film mechanical seals based on optimal mass transfer coefficient [J]. CIESC Journal, 2022, 73(3): 1147-1156. |

| [10] | Senlin WANG, Zhaozhi LI, Yingjuan SHAO, Wenqi ZHONG. Numerical simulation on heat transfer deterioration of supercritical carbon dioxide in vertical tube [J]. CIESC Journal, 2022, 73(3): 1072-1082. |

| [11] | Wenjie LAN, Xiaojie HU, Dizong CAI. Determination of interaction force between droplet and solid surface using droplet probe [J]. CIESC Journal, 2022, 73(3): 1119-1126. |

| [12] | Yingjie YANG, He YANG, Jialong ZHU, Shuangqi GUO, Yan SHANG, Yang LI, Lijun JIN, Haoquan HU. Interaction between functional groups during slow pyrolysis of Naomaohu coal [J]. CIESC Journal, 2022, 73(2): 865-875. |

| [13] | Meng MA, Yonghui BAI, Juntao WEI, Lunjing YAN, Peng LYU, Jiaofei WANG, Xudong SONG, Weiguang SU, Guangsuo YU. Research and progress of volatile-char interaction during biomass and coal (co-)pyrolysis/gasification process [J]. CIESC Journal, 2022, 73(11): 5186-5200. |

| [14] | Jianguo YAN, Shumin ZHENG, Pengcheng GUO, Bo ZHANG, Zhenkai MAO. Prediction of heat transfer characteristics for supercritical CO2 based on GA-BP neural network [J]. CIESC Journal, 2021, 72(9): 4649-4657. |

| [15] | Peng JIANG, Jinbo JIANG, Xudong PENG, Xiangkai MENG, Yi MA. Influence of heat transfer model on temperature and pressure distribution and steady state performance of CO2 dry gas seal under near critical condition [J]. CIESC Journal, 2021, 72(8): 4239-4254. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||