CIESC Journal ›› 2022, Vol. 73 ›› Issue (5): 2073-2082.DOI: 10.11949/0438-1157.20211568

• Process system engineering • Previous Articles Next Articles

Qiwang HOU1( ),Zhaolun WEN1,Zhonglin ZHANG1(

),Zhaolun WEN1,Zhonglin ZHANG1( ),Yegang LIU1,2,Jingxuan YANG1,Dongliang CHEN1,2,Xiaogang HAO1(

),Yegang LIU1,2,Jingxuan YANG1,Dongliang CHEN1,2,Xiaogang HAO1( ),Guoqing GUAN3

),Guoqing GUAN3

Received:2021-11-03

Revised:2022-02-09

Online:2022-05-24

Published:2022-05-05

Contact:

Zhonglin ZHANG,Xiaogang HAO

侯起旺1( ),文兆伦1,张忠林1(

),文兆伦1,张忠林1( ),刘叶刚1,2,杨景轩1,陈东良1,2,郝晓刚1(

),刘叶刚1,2,杨景轩1,陈东良1,2,郝晓刚1( ),官国清3

),官国清3

通讯作者:

张忠林,郝晓刚

作者简介:侯起旺(1995—),男,硕士研究生,基金资助:CLC Number:

Qiwang HOU, Zhaolun WEN, Zhonglin ZHANG, Yegang LIU, Jingxuan YANG, Dongliang CHEN, Xiaogang HAO, Guoqing GUAN. Design and evaluation of a coal-based polygeneration system with carbon cycle[J]. CIESC Journal, 2022, 73(5): 2073-2082.

侯起旺, 文兆伦, 张忠林, 刘叶刚, 杨景轩, 陈东良, 郝晓刚, 官国清. 一种煤基多联产碳循环系统的设计及评价[J]. 化工学报, 2022, 73(5): 2073-2082.

Add to citation manager EndNote|Ris|BibTeX

| Proximate analysis/ %(mass,d) | Ultimate analysis/ %(mass,daf) | LHV/(MJ/kg) | ||||||

|---|---|---|---|---|---|---|---|---|

| FC | A | V | C | H | N | S | O① | |

| 47.21 | 5.8 | 46.99 | 74.35 | 5.13 | 0.72 | 0.31 | 19.49 | 23.45 |

Table 1 Proximate and ultimate analyses of coal NMH[16]

| Proximate analysis/ %(mass,d) | Ultimate analysis/ %(mass,daf) | LHV/(MJ/kg) | ||||||

|---|---|---|---|---|---|---|---|---|

| FC | A | V | C | H | N | S | O① | |

| 47.21 | 5.8 | 46.99 | 74.35 | 5.13 | 0.72 | 0.31 | 19.49 | 23.45 |

| 参数 | 值 |

|---|---|

| 压气机绝热压缩效率/% | 91 |

| 透平绝热膨胀效率/% | 86 |

| 氧气温度/℃ | 15 |

| 氧气压缩比/% | 29.6 |

| 汽轮机高压缸效率/% | 87 |

| 汽轮机中压缸效率/% | 90 |

| 汽轮机低压缸效率/% | 88 |

| 机械电机效率/% | 98 |

Table 2 Parameters of the gas turbine and steam turbine

| 参数 | 值 |

|---|---|

| 压气机绝热压缩效率/% | 91 |

| 透平绝热膨胀效率/% | 86 |

| 氧气温度/℃ | 15 |

| 氧气压缩比/% | 29.6 |

| 汽轮机高压缸效率/% | 87 |

| 汽轮机中压缸效率/% | 90 |

| 汽轮机低压缸效率/% | 88 |

| 机械电机效率/% | 98 |

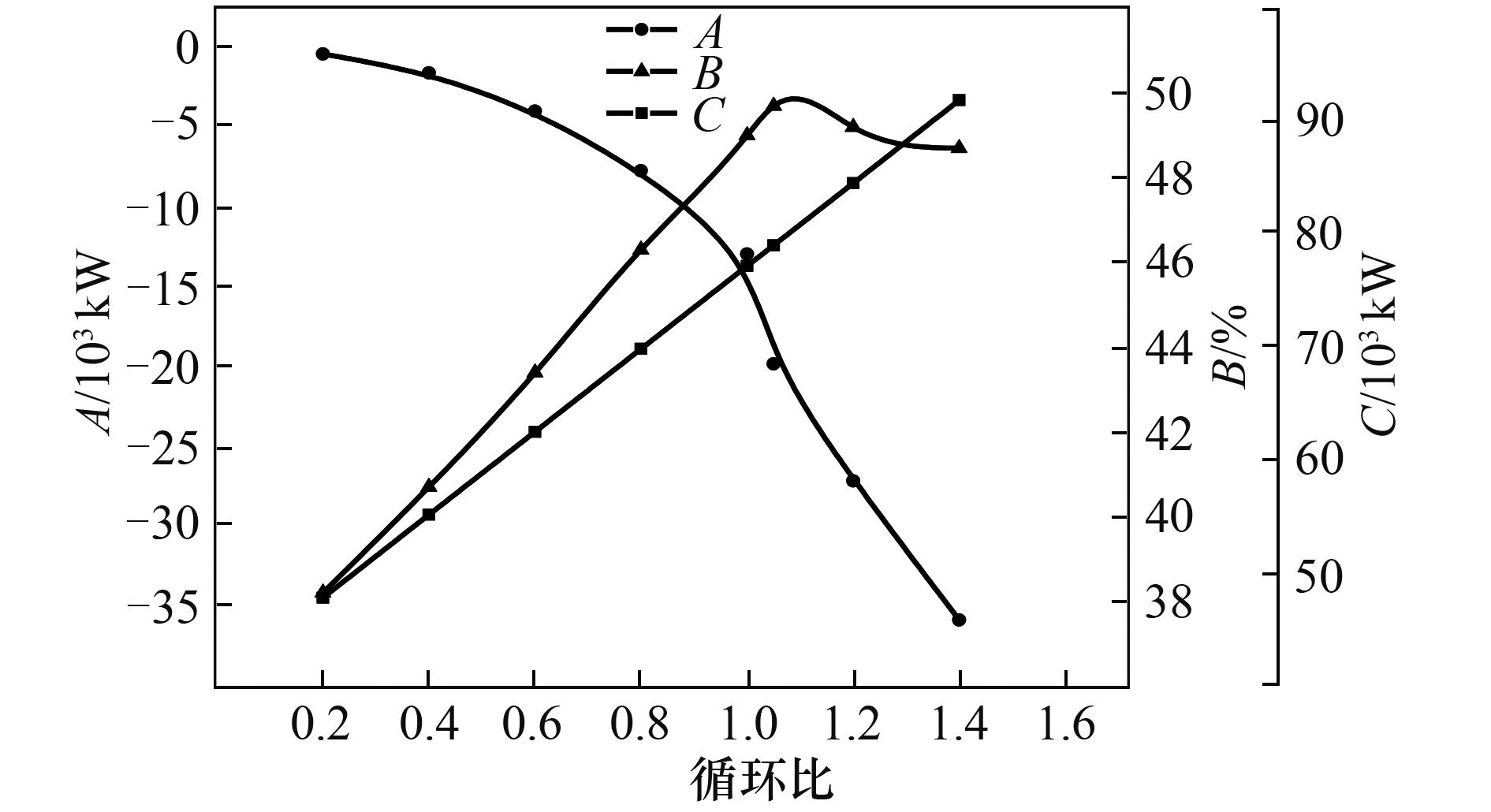

Fig.3 Effects of carbon cycle ratio on system energy utilization in the carbon-cycled polygeneration systemA—the difference between power generation and power consumption of the circulating compressor and energy consumption of distillation; B—system energy utilization efficiency; C—methanol energy

Fig.4 Effects of flue gas reinjection on power unit in the carbon-cycled polygeneration systemA—NO x emission; B—power unit output power; C—combustion chamber outlet temperature

| 物流 | 摩尔分数/% | 摩尔流量/ (kmol/h) | 质量流量/(t/h) | 温度/℃ | 压力/MPa | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H2+CH4 | CO | CO2 | N2 | O2 | H2O | CH3OH | |||||

| 1 | — | — | — | — | — | — | — | — | 37.5 | 200 | 0.1 |

| 2 | 59.1 | 27.7 | 5.4 | — | — | 7.7 | — | 1398.1 | 18.3 | 40 | 6.5 |

| 3 | 67.9 | 30.0 | 2.1 | — | — | — | — | 1204.6 | 13.2 | 35.9 | 5.57 |

| 4 | — | — | — | — | — | 10.8 | 86.6 | 462.0 | 14.3 | 65.3 | 3.5 |

| 5 | — | — | 93.6 | 1.2 | 5.1 | — | — | 885.8 | 38.3 | 843.8 | 0.1 |

| 6 | 3.6 | 3.4 | 6.8 | — | — | 85.3 | — | 599.9 | 12.0 | 593.7 | 5.0 |

| 7 | — | — | 54.6 | 0.6 | 3.0 | 41.8 | — | 1347.2 | 44.1 | 227.8 | 0.1 |

Table 3 Simulation results of main streams of polygeneration carbon cycle system

| 物流 | 摩尔分数/% | 摩尔流量/ (kmol/h) | 质量流量/(t/h) | 温度/℃ | 压力/MPa | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H2+CH4 | CO | CO2 | N2 | O2 | H2O | CH3OH | |||||

| 1 | — | — | — | — | — | — | — | — | 37.5 | 200 | 0.1 |

| 2 | 59.1 | 27.7 | 5.4 | — | — | 7.7 | — | 1398.1 | 18.3 | 40 | 6.5 |

| 3 | 67.9 | 30.0 | 2.1 | — | — | — | — | 1204.6 | 13.2 | 35.9 | 5.57 |

| 4 | — | — | — | — | — | 10.8 | 86.6 | 462.0 | 14.3 | 65.3 | 3.5 |

| 5 | — | — | 93.6 | 1.2 | 5.1 | — | — | 885.8 | 38.3 | 843.8 | 0.1 |

| 6 | 3.6 | 3.4 | 6.8 | — | — | 85.3 | — | 599.9 | 12.0 | 593.7 | 5.0 |

| 7 | — | — | 54.6 | 0.6 | 3.0 | 41.8 | — | 1347.2 | 44.1 | 227.8 | 0.1 |

| 系统 | 系统输入 总能量/MW | 系统输出 总功率/ MW | 系统输出 净功率/MW | 产生甲醇 能量/MW | 产生焦油 能量/MW | 系统能量 利用率/% | ?效率/% |

|---|---|---|---|---|---|---|---|

| 传统煤基多联产 | 244.27 | 24.32 | 18.44 | 66.53 | 32.15 | 47.9 | 39 |

| 煤基多联产碳循环 | 244.27 | 26.33 | 20.45 | 63.32 | 37.57 | 49.7 | 40 |

Table 4 Comparative analysis of two kinds of polygeneration systems

| 系统 | 系统输入 总能量/MW | 系统输出 总功率/ MW | 系统输出 净功率/MW | 产生甲醇 能量/MW | 产生焦油 能量/MW | 系统能量 利用率/% | ?效率/% |

|---|---|---|---|---|---|---|---|

| 传统煤基多联产 | 244.27 | 24.32 | 18.44 | 66.53 | 32.15 | 47.9 | 39 |

| 煤基多联产碳循环 | 244.27 | 26.33 | 20.45 | 63.32 | 37.57 | 49.7 | 40 |

| 项目 | 输入 | 输出 | 系统输出能量/MW | 相对能量节约率/% | |

|---|---|---|---|---|---|

| 煤/(t/h) | 甲醇/(t/h) | 焦油/(t/h) | |||

| 煤基多联产碳循环系统 | 37.5 | 11.46 | 4.1 | 26.33 | 13 |

| 煤气化联合循环发电系统 | 11.89 | — | — | 26.33 | — |

| 煤制甲醇系统 | 24.37 | 11.46 | — | — | — |

| 费托合成油系统 | 6.83 | — | 4.1 | — | — |

Table 5 Performance of polygeneration system and reference systems

| 项目 | 输入 | 输出 | 系统输出能量/MW | 相对能量节约率/% | |

|---|---|---|---|---|---|

| 煤/(t/h) | 甲醇/(t/h) | 焦油/(t/h) | |||

| 煤基多联产碳循环系统 | 37.5 | 11.46 | 4.1 | 26.33 | 13 |

| 煤气化联合循环发电系统 | 11.89 | — | — | 26.33 | — |

| 煤制甲醇系统 | 24.37 | 11.46 | — | — | — |

| 费托合成油系统 | 6.83 | — | 4.1 | — | — |

| 1 | An energy sector roadmap to carbon neutrality in China[EB/OL]. [2021-09]. . |

| 2 | Fushimi C, Wada T, Tsutsumi A. Inhibition of steam gasification of biomass char by hydrogen and tar[J]. Biomass and Bioenergy, 2011, 35(1): 179-185. |

| 3 | Bayarsaikhan B, Sonoyam N, Hosokai S, et al. Inhibition of steam gasification of char by volatiles in a fluidized bed under continuous feeding of a brown coal[J]. Fuel, 2006, 85(3): 340-349. |

| 4 | Zhang Y M, Wang Y, Cai L G, et al. Dual bed pyrolysis gasification of coal: process analysis and pilot test[J]. Fuel, 2013, 112: 624-634. |

| 5 | Tsutsumi A, Guan G Q, Fushimi C, et al. Flow behaviors in a high solid flux circulating fluidized bed composed of a riser, a downer and a bubbling fluidized bed[C]//Fluidization : New Paradigm in Fluidization Engineering. Gyeong‐ju, Korea, 2010: 407-414. |

| 6 | Fushimi C, Guan G Q, Ishizuka M, et al. High-flux triple bed circulating fluidized bed (TBCFB) gasifier for exergy recuperative IGCC/IGFC[C]// International Conference on Circulating Fluidized Beds & Fluidization Technology-cfb. Sunriver, Oregon, USA, 2014. |

| 7 | 郝晓刚, 王俊丽, 连文豪, 等. 一种热解气化装置和工艺: 104789245B[P]. 2017-12-05. |

| Hao X G, Wang J L, Lian W H, et al. Pyrolysis and gasification device and technology: 104789245B[P]. 2017-12-05. | |

| 8 | 王亚雄, 杨景轩, 张忠林, 等. 低阶煤热解-气化-燃烧TBCFB系统模拟及优化[J]. 化工学报, 2018, 69(8): 3596-3604. |

| Wang Y X, Yang J X, Zhang Z L, et al. TBCFB system simulation and optimization for pyrolysis-gasificationcombustion of low rank coal[J]. CIESC Journal, 2018, 69(8): 3596-3604. | |

| 9 | 陈东良, 张忠林, 杨景轩, 等. 基于自热再生的化学吸收法CO2捕集工艺模拟及节能分析[J]. 化工学报, 2019, 70(8): 2938-2945. |

| Chen D L, Zhang Z L, Yang J X, et al. Process simulation and energy saving analysis of CO2 capture by chemical absorption method based on self-heat recuperation[J]. CIESC Journal, 2019, 70(8): 2938-2945. | |

| 10 | Li H Q, Hong H, Jin H G, et al. Analysis of a feasible polygeneration system for power and methanol production taking natural gas and biomass as materials[J]. Applied Energy, 2010, 87(9): 2846-2853. |

| 11 | 林汝谋, 金红光, 高林. 化工动力多联产系统及其集成优化机理[J]. 热能动力工程, 2006, 21(4): 331-337, 433. |

| Lin R M, Jin H G, Gao L. Chemical engineering power polygeneration system and its integrated optimization mechanism[J]. Journal of Engineering for Thermal Energy and Power, 2006, 21(4): 331-337, 433. | |

| 12 | 岑建孟, 方梦祥, 王勤辉, 等. 煤分级利用多联产技术及其发展前景[J]. 化工进展, 2010, 29(S1): 705. |

| Cen J M, Fang M X, Wang Q H, et al. Development and prospect of coal staged conversion poly-generation technology[J]. Chemical Industry and Engineering Progress, 2010, 29(S1): 705. | |

| 13 | 刘敬尧, 何畅, 李璟, 等. 以合成气为核心的多联供多联产集成能源化工系统[J]. 煤炭学报, 2010, 35(2): 293-298. |

| Liu J Y, He C, Li J, et al. Syngas-based multi-fuel multi-product integrated energy and chemical system[J]. Journal of China Coal Society, 2010, 35(2): 293-298. | |

| 14 | Gong M H, Yi Q, Huang Y, et al. Coke oven gas to methanol process integrated with CO2 recycle for high energy efficiency,economic benefits and low emissions[J]. Energy Conversion and Management, 2017, 133: 318-331. |

| 15 | Moore M J. NO x emission control in gas turbines for combined cycle gas turbine plant[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 1997, 211(1): 43-52. |

| 16 | Wang Q, Wang M J, Wang H, et al. Effect of temperature and gasification gas from char on the reactions of volatiles generated from rapid pyrolysis of a low rank coal[J]. Fuel Processing Technology, 2021, 212: 106601. |

| 17 | Li X R, Jin X, Wang M J, et al. Effect of volatiles’ reaction on coking of tar during pyrolysis of Naomaohu coal in a downer-bed reactor[J]. Fuel Processing Technology, 2021, 212: 106623. |

| 18 | Jin X, Li X R, Kong J, et al. Insights into coke formation during thermal reaction of six different distillates from the same coal tar[J]. Fuel Processing Technology, 2021, 211: 106592. |

| 19 | Kuo P C, Wu W. Thermodynamic analysis of a combined heat and power system with CO2 utilization based on co-gasification of biomass and coal[J]. Chemical Engineering Science, 2016, 142: 201-214. |

| 20 | 焦树建. 燃气-蒸汽联合循环的理论基础[M]. 北京: 清华大学出版社, 2003. |

| Jiao S J. Theoretical Basis of Combined Gas-steam Cycle[M]. Beijing: Tsinghua University Press, 2003. | |

| 21 | Sun L, Smith R. Rectisol wash process simulation and analysis[J]. Journal of Cleaner Production, 2013, 39: 321-328. |

| 22 | Shi B, Wen F, Wu W. Performance evaluation of air-blown IGCC polygeneration plants using chemical looping hydrogen generation and methanol synthesis loop[J]. Energy, 2020, 200: 117564. |

| 23 | 刘叶刚, 张忠林, 侯起旺, 等. TBCFB合成气制甲醇工艺过程的概念设计和计算机模拟[J]. 化工学报, 2021, 72(9): 4838-4846. |

| Liu Y G, Zhang Z L, Hou Q W, et al. Process design and simulation of synthesis gas to methanol in TBCFB system[J]. CIESC Journal, 2021, 72(9): 4838-4846. | |

| 24 | Fu Q, Kansha Y, Song C F, et al. A cryogenic air separation process based on self-heat recuperation for oxy-combustion plants[J]. Applied Energy, 2016, 162: 1114-1121. |

| 25 | 游卓. 富氧燃烧过程中的NO x 控制及其系统效率研究[D]. 杭州: 浙江大学, 2013. |

| You Z. NO x control and efficiency optimization of oxy-fuel combustion system[D]. Hangzhou: Zhejiang University, 2013. | |

| 26 | Cengel Y A, Boles M A. Thermodynamics: An Engineering Approach[M]. New York: McGraw-Hill, 2009. |

| 27 | Zhang Y N, Zhao Y J, Gao X Y, et al. Energy and exergy analyses of syngas produced from rice husk gasification in an entrained flow reactor[J]. Journal of Cleaner Production, 2015, 95: 273-280. |

| 28 | Bilgen S, Kaygusuz K, Sari A. Second law analysis of various types of coal and woody biomass in Turkey[J]. Energy Sources, 2004, 26(11): 1083-1094. |

| 29 | 王东亮, 冯宵, 李广播, 等. 基于流程模拟的㶲计算方法及其应用[J]. 计算机与应用化学, 2012, 29(9): 1069-1074. |

| Wang D L, Feng X, Li G B, et al. Exergy calculation method based on flowsheeting simulation and its application[J]. Computers and Applied Chemistry, 2012, 29(9): 1069-1074. | |

| 30 | Al-Weshahi M A, Anderson A, Tian G H. Exergy efficiency enhancement of MSF desalination by heat recovery from hot distillate water stages[J]. Applied Thermal Engineering, 2013, 53(2): 226-233. |

| 31 | Duan W J, Yu Q B, Wang K, et al. ASPEN Plus simulation of coal integrated gasification combined blast furnace slag waste heat recovery system[J]. Energy Conversion and Management, 2015, 100: 30-36. |

| 32 | Chen S Y, Lior N, Xiang W G. Coal gasification integration with solid oxide fuel cell and chemical looping combustion for high-efficiency power generation with inherent CO2 capture[J]. Applied Energy, 2015, 146: 298-312. |

| 33 | Zhang Y N, Li B X, Li H T, et al. Exergy analysis of biomass utilization via steam gasification and partial oxidation[J]. Thermochimica Acta, 2012, 538: 21-28. |

| 34 | 张亚宁, 李炳熙, 张波, 等. 生物质氧气气化和水蒸汽气化的能量分析及㶲分析[J]. 华北电力大学学报(自然科学版), 2012, 39(1): 64-69. |

| Zhang Y N, Li B X, Zhang B. Energy and exergy analysis of biomass gasification with oxygen or steam[J]. Journal of North China Electric Power University(Natural Science Edition), 2012, 39(1): 64-69. | |

| 35 | 于戈文, 王延铭, 杨小丽, 等. 基于CO2捕集的煤基费托合成油-动力多联产系统㶲分析[J]. 化工进展, 2017, 36(10): 3682-3689. |

| Yu G W, Wang Y M, Yang X L, et al. Exergy analysis for the coal-based polygeneration system of FT syncrudes-power with CO2 capture[J]. Chemical Industry and Engineering Progress, 2017, 36(10): 3682-3689. | |

| 36 | Reddy B R, Shravani B, Das B, et al. Microwave-assisted and analytical pyrolysis of coking and non-coking coals: comparison of tar and char compositions[J]. Journal of Analytical and Applied Pyrolysis, 2019, 142: 104614. |

| 37 | He S, Li S, Gao L. Proposal and energy saving analysis of novel methanol-electricity polygeneration system based on staged coal gasification method[J]. Energy Conversion and Management, 2021, 233(2): 113931. |

| 38 | 黄宏, 杨思宇. 一种低能耗捕集CO2煤基甲醇和电力联产过程设计[J]. 化工学报, 2017, 68(10): 3860-3869. |

| Huang H, Yang S Y. Design of a coal based methanol and power polygeneration process with low energy consumption for CO2 capture[J]. CIESC Journal, 2017, 68(10): 3860-3869. | |

| 39 | 范江, 王巧荣, 王进, 等. 循环比对甲醇-电的多联产系统能耗影响的分析[J]. 化学工程, 2009, 37(4): 68-71, 78. |

| Fan J, Wang Q R, Wang J, et al. Analysis for effect of recycle ratio on energy consumption of methanol-electric polygeneration system[J]. Chemical Engineering(China), 2009, 37(4): 68-71, 78. | |

| 40 | 黄雪丽. IGCC电厂脱硝方式一体化研究[D]. 北京: 华北电力大学, 2014. |

| Huang X L. Integrated study on denitraton methods of IGCC plant[D]. Beijing: North China Electric Power University, 2014. | |

| 41 | 林汝谋, 金红光, 高林. 化工动力多联产系统评价准则问题研究综述[J]. 燃气轮机技术, 2012, 25(4): 1-14. |

| Lin R M, Jin H G, Gao L. Review on the evaluation criteria of polygeneration system for power and chemical production[J]. Gas Turbine Technology, 2012, 25(4): 1-14. | |

| 42 | Fan Y F, Ye Q, Cen H, et al. Design and optimization of reactive distillation processes for synthesis of isopropanol based on self-heat recuperation technology[J]. Chemical Engineering Research and Design, 2019, 147: 171-186. |

| [1] | Yuanchao LIU, Bin GUAN, Jianbin ZHONG, Yifan XU, Xuhao JIANG, Duan LI. Investigation of thermoelectric transport properties of single-layer XSe2 (X=Zr/Hf) [J]. CIESC Journal, 2023, 74(9): 3968-3978. |

| [2] | Zhewen CHEN, Junjie WEI, Yuming ZHANG. System integration and energy conversion mechanism of the power technology with integrated supercritical water gasification of coal and SOFC [J]. CIESC Journal, 2023, 74(9): 3888-3902. |

| [3] | Yue CAO, Chong YU, Zhi LI, Minglei YANG. Industrial data driven transition state detection with multi-mode switching of a hydrocracking unit [J]. CIESC Journal, 2023, 74(9): 3841-3854. |

| [4] | Zhaolun WEN, Peirui LI, Zhonglin ZHANG, Xiao DU, Qiwang HOU, Yegang LIU, Xiaogang HAO, Guoqing GUAN. Design and optimization of cryogenic air separation process with dividing wall column based on self-heat regeneration [J]. CIESC Journal, 2023, 74(7): 2988-2998. |

| [5] | Guixian LI, Abo CAO, Wenliang MENG, Dongliang WANG, Yong YANG, Huairong ZHOU. Process design and evaluation of CO2 to methanol coupled with SOEC [J]. CIESC Journal, 2023, 74(7): 2999-3009. |

| [6] | Yuanzhe SHAO, Zhonggai ZHAO, Fei LIU. Quality-related non-stationary process fault detection method by common trends model [J]. CIESC Journal, 2023, 74(6): 2522-2537. |

| [7] | Shanghao LIU, Shengkun JIA, Yiqing LUO, Xigang YUAN. Optimization of ternary-distillation sequence based on gradient boosting decision tree [J]. CIESC Journal, 2023, 74(5): 2075-2087. |

| [8] | Zedong WANG, Zhiping SHI, Liyan LIU. Numerical simulation and optimization of acoustic streaming considering inhomogeneous bubble cloud dissipation in rectangular reactor [J]. CIESC Journal, 2023, 74(5): 1965-1973. |

| [9] | Xiaoyong GAO, Fuyu HUANG, Wanpeng ZHENG, Diao PENG, Yixu YANG, Dexian HUANG. Scheduling optimization of refinery and chemical production process considering the safety and stability of scheduling operation [J]. CIESC Journal, 2023, 74(4): 1619-1629. |

| [10] | Sheng’an ZHANG, Guilian LIU. Multi-objective optimization of high-efficiency solar water electrolysis hydrogen production system and its performance [J]. CIESC Journal, 2023, 74(3): 1260-1274. |

| [11] | Haiou YUAN, Fangjun YE, Shuo ZHANG, Yiqing LUO, Xigang YUAN. Synthesis of heat-integrated distillation sequences with intermediate heat exchangers [J]. CIESC Journal, 2023, 74(2): 796-806. |

| [12] | Nini YUAN, Tuo GUO, Hongcun BAI, Yurong HE, Yongning YUAN, Jingjing MA, Qingjie GUO. Reaction process of CH4 on the surface of Fe2O3/Al2O3 oxygen carrier in chemical looping combustion: ReaxFF-MD simulation [J]. CIESC Journal, 2022, 73(9): 4054-4061. |

| [13] | Yu QIAN, Yaoxi CHEN, Xiaofei SHI, Siyu YANG. Big data analysis of solar energy fluctuation characteristics and integration of wind-photovoltaic to hydrogen system [J]. CIESC Journal, 2022, 73(5): 2101-2110. |

| [14] | Wenting DUAN, Siyue REN, Xiao FENG, Yufei WANG. Distillation column pressure optimization integrated with the heat exchanger network [J]. CIESC Journal, 2022, 73(5): 2052-2059. |

| [15] | Weiwei LIU, Guomin CUI, Lu ZHANG, Yuan XIAO, Qiguo YANG, Guanhua ZHANG. Damping optimization method for heat exchange network synthesis [J]. CIESC Journal, 2022, 73(5): 2060-2072. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||