CIESC Journal ›› 2022, Vol. 73 ›› Issue (5): 2242-2250.DOI: 10.11949/0438-1157.20211775

• Energy and environmental engineering • Previous Articles Next Articles

Jinsong XU1( ),Min LIN2,Xiaoping CHEN1(

),Min LIN2,Xiaoping CHEN1( ),Jiliang MA1,Pengfei GENG1,Xuebing BAO1,Daoyin LIU1,Cai LIANG1

),Jiliang MA1,Pengfei GENG1,Xuebing BAO1,Daoyin LIU1,Cai LIANG1

Received:2021-12-16

Revised:2022-03-30

Online:2022-05-24

Published:2022-05-05

Contact:

Xiaoping CHEN

徐劲松1( ),林敏2,陈晓平1(

),林敏2,陈晓平1( ),马吉亮1,耿鹏飞1,鲍学兵1,刘道银1,梁财1

),马吉亮1,耿鹏飞1,鲍学兵1,刘道银1,梁财1

通讯作者:

陈晓平

作者简介:徐劲松(1996—),男,硕士研究生,CLC Number:

Jinsong XU, Min LIN, Xiaoping CHEN, Jiliang MA, Pengfei GENG, Xuebing BAO, Daoyin LIU, Cai LIANG. Experimental study on regeneration characteristics of stainless steel pickling waste mixed acid by fluidized bed roaster[J]. CIESC Journal, 2022, 73(5): 2242-2250.

徐劲松, 林敏, 陈晓平, 马吉亮, 耿鹏飞, 鲍学兵, 刘道银, 梁财. 不锈钢酸洗废混酸流化床焙烧再生特性的实验研究[J]. 化工学报, 2022, 73(5): 2242-2250.

Add to citation manager EndNote|Ris|BibTeX

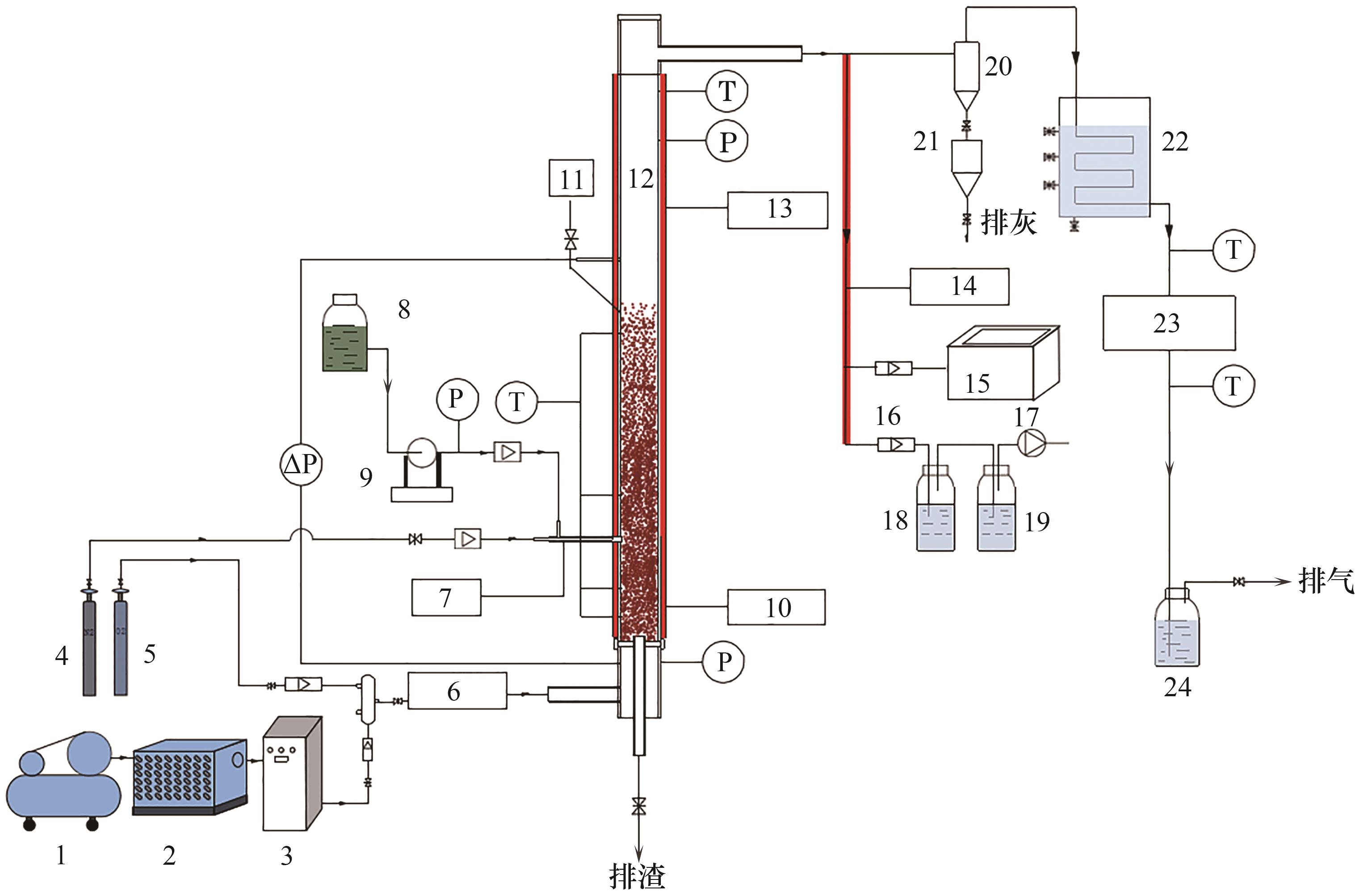

Fig.1 Schematic diagram of the experimental system for regeneration of waste mixed acid by fluidized bed method1—air compressor;2—cold dryer;3—nitrogen generator;4—nitrogen cylinder;5—oxygen cylinder;6—preheater;7—spray gun;8—waste mixed acid tank;9—electromagnetic pump;10—electric heater in the dense phase zone;11—canister;12—fluidized bed reactor;13—electric heaters in the thin phase zone;14—electric heating belt;15—flue gas analyser;16—flow meter;17—vacuum pump;18—deionised water;19—NaOH solution;20—cyclone separator;21—grey bucket;22—cooler;23—bag filter;24—alkaline washing unit

| 化学组成/(g/L) | 密度/ (g/ml) | pH | |||||||

|---|---|---|---|---|---|---|---|---|---|

| F- | NO | H+ | Cr | Ni | Fe | Mn | Ca | ||

| 28.8 | 55.5 | 2.66 | 4.13 | 3.26 | 50.75 | 0.78 | 0.0436 | 1.1141 | 0.68 |

Table 1 Physicochemical characteristics and composition analysis of waste mixed acid

| 化学组成/(g/L) | 密度/ (g/ml) | pH | |||||||

|---|---|---|---|---|---|---|---|---|---|

| F- | NO | H+ | Cr | Ni | Fe | Mn | Ca | ||

| 28.8 | 55.5 | 2.66 | 4.13 | 3.26 | 50.75 | 0.78 | 0.0436 | 1.1141 | 0.68 |

| 样品 | 元素分析/%(质量) | |||||||

|---|---|---|---|---|---|---|---|---|

| Fe | Al | Cu | Ni | Ca | Zn | Cr | Mn | |

| 床料 | 92.61 | 3.59 | 1.06 | 0.71 | 0.59 | 0.50 | 0.47 | 0.47 |

Table 2 Elemental analysis of iron oxide bed material

| 样品 | 元素分析/%(质量) | |||||||

|---|---|---|---|---|---|---|---|---|

| Fe | Al | Cu | Ni | Ca | Zn | Cr | Mn | |

| 床料 | 92.61 | 3.59 | 1.06 | 0.71 | 0.59 | 0.50 | 0.47 | 0.47 |

| 1 | 程玲俐. 不锈钢冷带退火酸洗的工艺及设备的研究[D]. 上海: 上海交通大学, 2008. |

| Cheng L L. Study on process and equipment of annealing and pickling for cold-rolled stainless strip[D]. Shanghai: Shanghai Jiao Tong University, 2008. | |

| 2 | 刘鹏. 基于生命周期评价的废盐酸再生工艺比较研究[D]. 大连: 大连理工大学, 2015. |

| Liu P. Comparison of waste hydrochloric acid regeneration technologies based on LCA[D]. Dalian: Dalian University of Technology, 2015. | |

| 3 | 代秀芝. 不锈钢酸洗废混酸回收工艺[J]. 冶金设备, 2013(S1):69-71. |

| Dai X Z. Technology of waste mixed acid recovery in stainless steel pickling[J]. Metallurgical Equipment, 2013(S1): 69-71. | |

| 4 | 朱冰. 不锈钢酸洗废水中金属离子的资源化分离回收工艺研究[D]. 重庆: 重庆大学, 2018. |

| Zhu B. Recycling and recovery of metal ions from spent steel pickling wastewater[D]. Chongqing: Chongqing University, 2018. | |

| 5 | 曹明义, 何国凯, 刘万涛. 钢铁酸洗废水资源化处理技术综述[J]. 冶金动力, 2020, 39(10): 55-56, 71. |

| Cao M Y, He G K, Liu W T. Review on resource treatment technology of steel pickling wastewater[J]. Metallurgical Power, 2020, 39(10): 55-56, 71. | |

| 6 | 于丹. 盐酸废液流化床法再生工艺的应用[J]. 天津冶金, 2014(S1):141-144. |

| Yu D. Application of the process of hydrochloric acid regeneration with fluidized bed method[J]. Tianjin Metallurgy, 2014(S1): 141-144. | |

| 7 | Negro C, Blanco M A, López-Mateos F, et al. Free acids and chemicals recovery from stainless steel pickling baths[J]. Separation Science and Technology, 2001, 36(7): 1543-1556. |

| 8 | 别如山, 李炳熙, 陆慧林, 等. 处理高浓度有机废水流化床焚烧炉[J]. 锅炉制造, 2000(1): 40-44. |

| Bie R S, Li B X, Lu H L,et al. CFB boiler for handling high consistency organic waste water[J]. Boiler Manufacturing, 2000(1):40-44. | |

| 9 | 王超. 不锈钢酸洗废酸回收[J]. 天津冶金, 2016(1): 56-59. |

| Wang C. Recovery of waste acid for stainless steel pickling[J]. Tianjin Metallurgy, 2016(1): 56-59. | |

| 10 | 王贵喜, 任艳平, 何宗健. 不锈钢酸洗混合废酸(HNO3-HF)的回收以及离子交换法在其纯化中的应用[J]. 江西化工, 2010(1):138-141. |

| Wang G X, Ren Y P, He Z J. Recovery of stainless steel pickling mixed waste acid (HNO3-HF) and the application of ion exchange in its purification[J]. Jiangxi Chemical Industry, 2010(1): 138-141. | |

| 11 | 高健. 探讨离子交换树脂在水处理中的应用[J]. 皮革制作与环保科技, 2022, 3(2): 10-12. |

| Gao J. Discuss the application of ion exchange resin in water treatment[J]. Leather Manufacture and Environmental Technology, 2022, 3(2): 10-12. | |

| 12 | 李菲, 赵俊学, 马红周, 等. 用强酸性阳离子交换树脂从不锈钢酸洗废水中富集铬[J]. 湿法冶金, 2011, 30(1): 71-73. |

| Li F, Zhao J X, Ma H Z, et al. Enrichment of chromium from stainless steel pickling wastewater by strong acidic cation ion-exchange resin[J]. Hydrometallurgy of China, 2011, 30(1): 71-73. | |

| 13 | 李菲, 赵俊学, 马红周, 等. 用强酸性阳离子交换树脂分离不锈钢酸洗废水中的铁[J]. 湿法冶金, 2011, 30(2): 155-158. |

| Li F, Zhao J X, Ma H Z, et al. Separation of iron from stainless steel pickling wastewater by strong acidic cation ion-exchange resin[J]. Hydrometallurgy of China, 2011, 30(2): 155-158. | |

| 14 | 李小明, 李文锋, 王尚杰, 等. 不锈钢酸洗废液的处理与回收技术综述[J]. 化工环保, 2012, 32(6): 511-515. |

| Li X M, Li W F, Wang S J, et al. Review of treatment and recovery technologies of waste stainless steel pickling liquor[J]. Environmental Protection of Chemical Industry, 2012, 32(6): 511-515. | |

| 15 | 曾彬. 不锈钢蚀刻废液的综合回收利用[J]. 低碳世界, 2021, 11(3): 6-7. |

| Zeng B. Comprehensive recycling of stainless steel etching waste liquor[J]. Low Carbon World, 2021, 11(3): 6-7. | |

| 16 | 赫红超. 钢铁酸洗废液处理技术研究[D]. 上海: 上海应用技术大学, 2021. |

| He H C.Study on treatment technology of steel pickling waste liquid [D]. Shanghai: Shanghai Institute of Technology, 2021. | |

| 17 | 戴丽萍,朱汉权,柯雄,等. 双极膜电渗析法去除水溶液中Cr(Ⅵ)[J]. 环境工程, 2021, 39(11): 89-95. |

| Dai L P, Zhu H Q, Ke X,et al. Removal of hexavalent chromium from aqueous solution using bipolar membrane electrodialysis technique[J].Environmental Engineering, 2021, 39(11): 89-95. | |

| 18 | 朱桂平, 郭合理, 周兵. 流化床法废盐酸再生技术在钢丝绳行业的应用[J]. 金属制品, 2013, 39(4): 47-50. |

| Zhu G P, Guo H L, Zhou B. Application of fluidized bed waste hydrochloric acid regeneration technology in wire rope industry[J]. Metal Products, 2013, 39(4): 47-50. | |

| 19 | Nandy T, Vyas R D, Kaul S N, et al. Recovery of value-added chemicals from hazardous waste pickle liquor through application of full-scale fluidized bed reactor system[J]. Environmental Engineering Science, 2001, 18(6): 329-336. |

| 20 | Regel-Rosocka M. A review on methods of regeneration of spent pickling solutions from steel processing[J]. Journal of Hazardous Materials, 2010, 177(1/2/3): 57-69. |

| 21 | 徐向东, 蔡恒君, 杨伟. 鞍钢联众不锈钢混酸再生技术改进[J]. 鞍钢技术, 2017(6): 58-61. |

| Xu X D, Cai H J, Yang W. Improvement of recycling technology for waste mixed acid produced by manufacturing stainless steel in ansteel LISCO steel[J]. Angang Technology, 2017(6): 58-61. | |

| 22 | Melnikov P, Nascimento V A, Arkhangelsky I V, et al. Thermolysis mechanism of chromium nitrate nonahydrate and computerized modeling of intermediate products[J]. Journal of Thermal Analysis and Calorimetry, 2013, 114(3): 1021-1027. |

| 23 | Yuvaraj S, Lin F Y, Tsong-Huei C, et al. Thermal decomposition of metal nitrates in air and hydrogen environments[J]. The Journal of Physical Chemistry B, 2003, 107(4): 1044-1047. |

| 24 | Ge Y, Fan L S. Droplet-particle collision mechanics with film-boiling evaporation[J]. Journal of Fluid Mechanics, 2007, 573: 311-337. |

| 25 | Hatta N, Fujimoto H, Kinoshita K, et al. Experimental study of deformation mechanism of a water droplet impinging on hot metallic surfaces above the leidenfrost temperature[J]. Journal of Fluids Engineering, 1997, 119(3): 692-699. |

| 26 | Christoph L K, Schlünder E U. Fluidized bed spray granulation: investigation of the coating process on a single sphere[J]. Chemical Engineering and Processing: Process Intensification, 1997, 36(6): 443-457. |

| 27 | 段然. 大颗粒流化床水泥熟料煅烧工艺热模试验研究[D]. 西安: 西安建筑科技大学, 2008. |

| Duan R. An investigation into the calcination of cement clinker by coarse particles fluidization-thermo dynamics of the calcination process[D]. Xi'an: Xi'an University of Architecture and Technology, 2008. | |

| 28 | 齐庆杰, 刘建忠, 曹欣玉, 等. 燃煤过程中CaO对氟析出的固定作用[J]. 燃料化学学报, 2002, 30(3): 204-208. |

| Qi Q J, Liu J Z, Cao X Y, et al. Restraining of fluoride emission by blending CaO or lime with coal during coal combustion[J]. Journal of Fuel Chemistry and Technology, 2002, 30(3): 204-208. | |

| 29 | 齐庆杰, 刘建忠, 周俊虎, 等. 燃煤过程中CaO及钙基固氟剂对氟析出的控制[J]. 化工学报, 2003, 54(2): 226-231. |

| Qi Q J, Liu J Z, Zhou J H, et al.Fluoride emission control by blending and injecting CaO and calcium-based sorbents during coal combustion[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(2): 226-231. | |

| 30 | Li W H, Ma Z Y, Yan J H, et al. Evolution and distribution characteristics of fluorine during the incineration of fluorine-containing waste in a hazardous waste incinerator[J]. Journal of Zhejiang University-SCIENCE A, 2019, 20(8): 564-576. |

| 31 | 李文瀚. 危险废物焚烧过程中重金属与氟的迁移转化及污染控制机理研究[D]. 杭州: 浙江大学, 2020. |

| Li W H. Mechanism study on the transfer and pollution control of heavy metals and fluorine in the incineration of hazardous wastes[D]. Hangzhou: Zhejiang University, 2020. | |

| 32 | 高强. MgO和Al2O3基固氟剂的制备及NF3分解反应[D]. 烟台: 烟台大学, 2021. |

| Gao Q. The preparation of MgO- and Al2O3-based fluorine-fixed reagents for NF3 decomposition[D]. Yantai: Yantai University, 2021. | |

| 33 | 李舒伶, 齐庆杰, 刘建忠, 等. 煤燃烧固氟剂及固氟效果研究[J]. 环境科学, 2004, 25(2): 174-176. |

| Li S L, Qi Q J, Liu J Z, et al. Study on the calcium-based sorbent for removal fluorine during coal combustion[J]. Environmental Science, 2004, 25(2): 174-176. | |

| 34 | 刘建忠, 齐庆杰, 盛军杰, 等. 燃煤高温固氟工艺和添加剂的实验研究[J]. 中国电机工程学报, 2004, 24(7): 227-230. |

| Liu J Z, Qi Q J, Sheng J J, et al. Experimental study on fluorine retention process and additive under high temperation during coal combustion[J]. Proceedings of the CSEE, 2004, 24(7): 227-230. | |

| 35 | 刘静, 向轶, 刘建忠. 有机钙燃煤固氟剂的固氟效果和表面形态研究[J]. 热力发电, 2020, 49(2): 65-70. |

| Liu J, Xiang Y, Liu J Z. Study on fluorine removal efficiency and surface morphology of organic calcium fluorine removal additive for coal combustion[J]. Thermal Power Generation, 2020, 49(2): 65-70. |

| [1] | Ruimin CHE, Wenqiu ZHENG, Xiaoyu WANG, Xin LI, Feng XU. Research progress on homogeneous processing of cellulose in ionic liquids [J]. CIESC Journal, 2023, 74(9): 3615-3627. |

| [2] | Zhaolun WEN, Peirui LI, Zhonglin ZHANG, Xiao DU, Qiwang HOU, Yegang LIU, Xiaogang HAO, Guoqing GUAN. Design and optimization of cryogenic air separation process with dividing wall column based on self-heat regeneration [J]. CIESC Journal, 2023, 74(7): 2988-2998. |

| [3] | Zhenghao YANG, Zhen HE, Yulong CHANG, Ziheng JIN, Xia JIANG. Research progress in downer fluidized bed reactor for biomass fast pyrolysis [J]. CIESC Journal, 2023, 74(6): 2249-2263. |

| [4] | Juhui CHEN, Qian ZHANG, Lingfeng SHU, Dan LI, Xin XU, Xiaogang LIU, Chenxi ZHAO, Xifeng CAO. Study on flow characteristics of nanoparticles in a rotating fluidized bed based on DEM method [J]. CIESC Journal, 2023, 74(6): 2374-2381. |

| [5] | Yuanyuan ZHANG, Jiangyuan QU, Xinxin SU, Jing YANG, Kai ZHANG. Gas-liquid mass transfer and reaction characteristics of SNCR denitration in CFB coal-fired unit [J]. CIESC Journal, 2023, 74(6): 2404-2415. |

| [6] | Zihan YUAN, Shuyan WANG, Baoli SHAO, Lei XIE, Xi CHEN, Yimei MA. Investigation on flow characteristics of wet particles with power-law liquid-solid drag models in fluidized bed [J]. CIESC Journal, 2023, 74(5): 2000-2012. |

| [7] | Ruizhe CHEN, Leilei CHENG, Jing GU, Haoran YUAN, Yong CHEN. Research progress in chemical recovery technology of fiber-reinforced polymer composites [J]. CIESC Journal, 2023, 74(3): 981-994. |

| [8] | Yu PAN, Zihang WANG, Jiayun WANG, Ruzhu WANG, Hua ZHANG. Heat and moisture performance study of Cur-LiCl coated heat exchanger [J]. CIESC Journal, 2023, 74(3): 1352-1359. |

| [9] | Kaiyue WANG, Yongli MA, Chen LI, Mingyan LIU. Gas-liquid mass transfer coefficients in the gas-liquid-solid micro-fluidized beds [J]. CIESC Journal, 2022, 73(8): 3529-3540. |

| [10] | Lianfeng ZHU, Chao WANG, Mengjuan ZHANG, Fangzheng LIU, Xin JIA, Ping AN, Guangwen XU, Zhennan HAN. Fluidized bed two-stage gasification of coal with steam/O2 for production of low-tar syngas [J]. CIESC Journal, 2022, 73(8): 3720-3730. |

| [11] | Dongwang ZHANG, Hairui YANG, Tuo ZHOU, Zhong HUANG, Shiyuan LI, Man ZHANG. Cold-state experimental study on ash deposition of convection heating surface of biomass boiler [J]. CIESC Journal, 2022, 73(8): 3731-3738. |

| [12] | Xinhua LIU, Zhennan HAN, Jian HAN, Bin LIANG, Nan ZHANG, Shanwei HU, Dingrong BAI, Guangwen XU. Principle and technology of low-NO x decoupling combustion based on restructuring reactions [J]. CIESC Journal, 2022, 73(8): 3355-3368. |

| [13] | Gang WANG, Zhihao XIA, Xiyan LI, Hong ZHANG, Zhennan HAN, Xingfei SONG, Guangwen XU. Effect of atmosphere on active performance of light-burned magnesium oxides from calcined magnesite in fluidized bed [J]. CIESC Journal, 2022, 73(8): 3699-3707. |

| [14] | Yong’an CHEN, Anning ZHOU, Yunlong LI, Zhiwei SHI, Xinfu HE, Weihong JIAO. Preparation and coal pyrolysis performance of magnetic MgFe2O4 and its core-shell catalysts [J]. CIESC Journal, 2022, 73(7): 3026-3037. |

| [15] | Yongli MA, Mingyan LIU, Zongding HU. Development of flow mesoscale modeling of the gas-liquid-solid fluidized beds [J]. CIESC Journal, 2022, 73(6): 2438-2451. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||