CIESC Journal ›› 2023, Vol. 74 ›› Issue (5): 2000-2012.DOI: 10.11949/0438-1157.20230265

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Zihan YUAN( ), Shuyan WANG(

), Shuyan WANG( ), Baoli SHAO, Lei XIE, Xi CHEN, Yimei MA

), Baoli SHAO, Lei XIE, Xi CHEN, Yimei MA

Received:2023-03-20

Revised:2023-04-25

Online:2023-06-29

Published:2023-05-05

Contact:

Shuyan WANG

袁子涵( ), 王淑彦(

), 王淑彦( ), 邵宝力, 谢磊, 陈曦, 马一玫

), 邵宝力, 谢磊, 陈曦, 马一玫

通讯作者:

王淑彦

作者简介:袁子涵(1995—),男,博士研究生,yuanzihan@stu.nepu.edu.cn

基金资助:CLC Number:

Zihan YUAN, Shuyan WANG, Baoli SHAO, Lei XIE, Xi CHEN, Yimei MA. Investigation on flow characteristics of wet particles with power-law liquid-solid drag models in fluidized bed[J]. CIESC Journal, 2023, 74(5): 2000-2012.

袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012.

Add to citation manager EndNote|Ris|BibTeX

| 符号 | 参数 | 文献[ | 本文模拟参数 | 文献[ | 本文模拟参数 |

|---|---|---|---|---|---|

| Din | 流化床直径/mm | 90 | 90 | 68 | 68 |

| H | 流化床高度/mm | 2000 | 1000 | 1100 | 1100 |

| h0 | 初始床高/mm | 120 | 120 | — | 200 |

| εs,max | 最大颗粒浓度 | — | 0.63 | — | 0.63 |

| ε0 | 初始颗粒浓度 | 0.578 | 0.578 | — | 0.6 |

| dp | 颗粒直径/mm | 4.6 | 4.6 | 3 | |

| ρs | 颗粒密度/(kg/m3) | 2258 | 2258 | 2500 | 2500 |

| ρl | 流体密度/(kg/m3) | 1001 | 1001 | 997 | 997 |

| K | 稠度系数/(Pa·s n ) | 0.013 | 0.013 | 0.0299 | 0.0299 |

| n | 流性指数 | 0.82 | 0.82 | 0.719 | 0.719 |

| u0 | 流体表观速度/(cm/s) | 5.35~8.96 | Same | 2.416~10.436 | Same |

| e | 法向恢复系数 | — | 0.98, ewet | — | 0.98, ewet |

| 网格数 | — | 10×100×10 | — | 10×100×10 |

Table 1 Parameters used in numerical simulations and experiments by Ref.[15-16]

| 符号 | 参数 | 文献[ | 本文模拟参数 | 文献[ | 本文模拟参数 |

|---|---|---|---|---|---|

| Din | 流化床直径/mm | 90 | 90 | 68 | 68 |

| H | 流化床高度/mm | 2000 | 1000 | 1100 | 1100 |

| h0 | 初始床高/mm | 120 | 120 | — | 200 |

| εs,max | 最大颗粒浓度 | — | 0.63 | — | 0.63 |

| ε0 | 初始颗粒浓度 | 0.578 | 0.578 | — | 0.6 |

| dp | 颗粒直径/mm | 4.6 | 4.6 | 3 | |

| ρs | 颗粒密度/(kg/m3) | 2258 | 2258 | 2500 | 2500 |

| ρl | 流体密度/(kg/m3) | 1001 | 1001 | 997 | 997 |

| K | 稠度系数/(Pa·s n ) | 0.013 | 0.013 | 0.0299 | 0.0299 |

| n | 流性指数 | 0.82 | 0.82 | 0.719 | 0.719 |

| u0 | 流体表观速度/(cm/s) | 5.35~8.96 | Same | 2.416~10.436 | Same |

| e | 法向恢复系数 | — | 0.98, ewet | — | 0.98, ewet |

| 网格数 | — | 10×100×10 | — | 10×100×10 |

Fig.4 Instantaneous concentration of particles with different flow behavior indexes and consistency coefficients at 50 s (left: dry particles; right: wet particles)

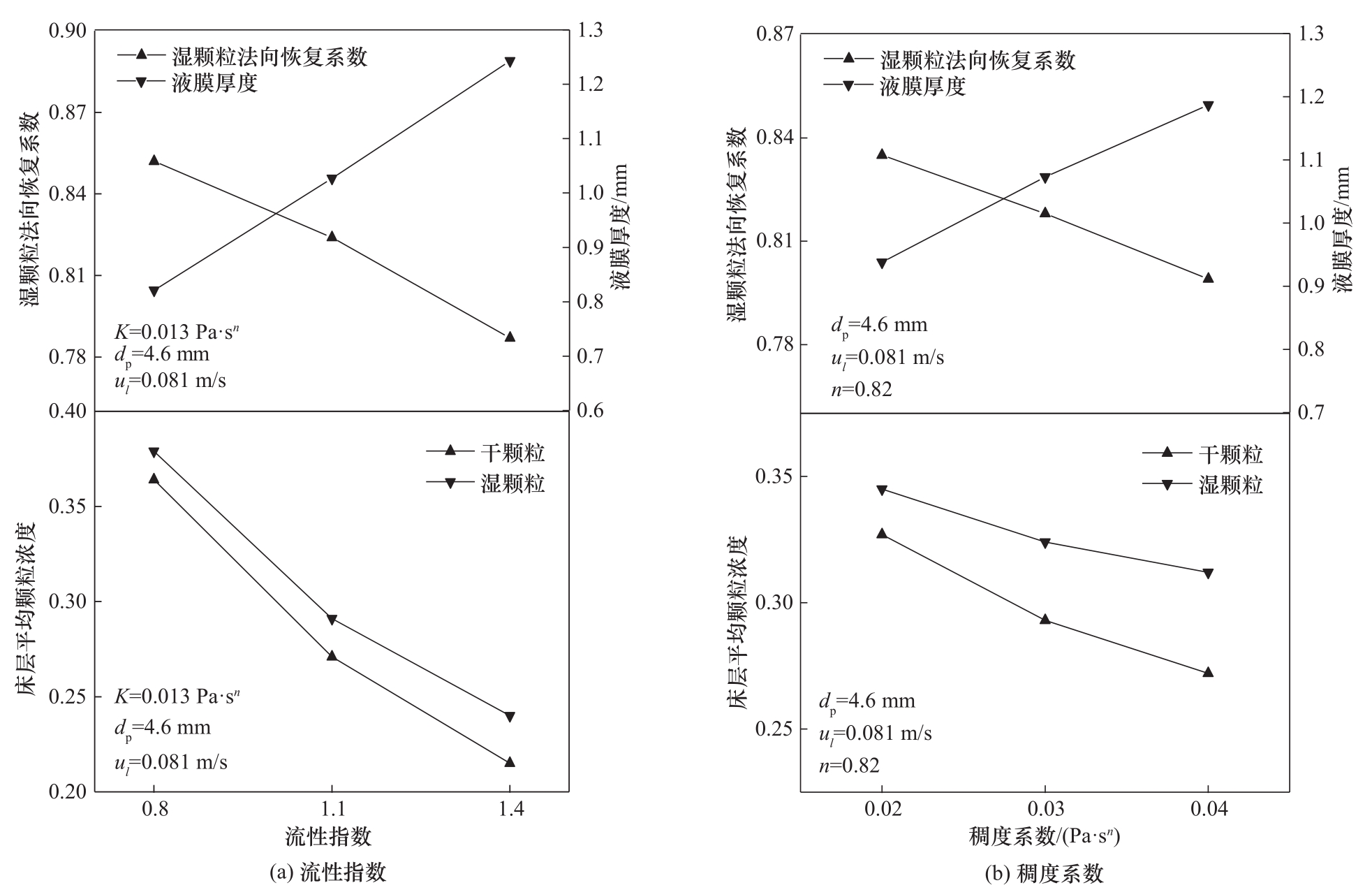

Fig.5 Time-averaged concentration of particles, normal restitution coefficient and liquid film thickness with different flow behavior indexes and consistency coefficients

Fig.6 Radial distributions of the time-averaged particles concentration with different flow behavior indexes and consistency coefficients at the same height

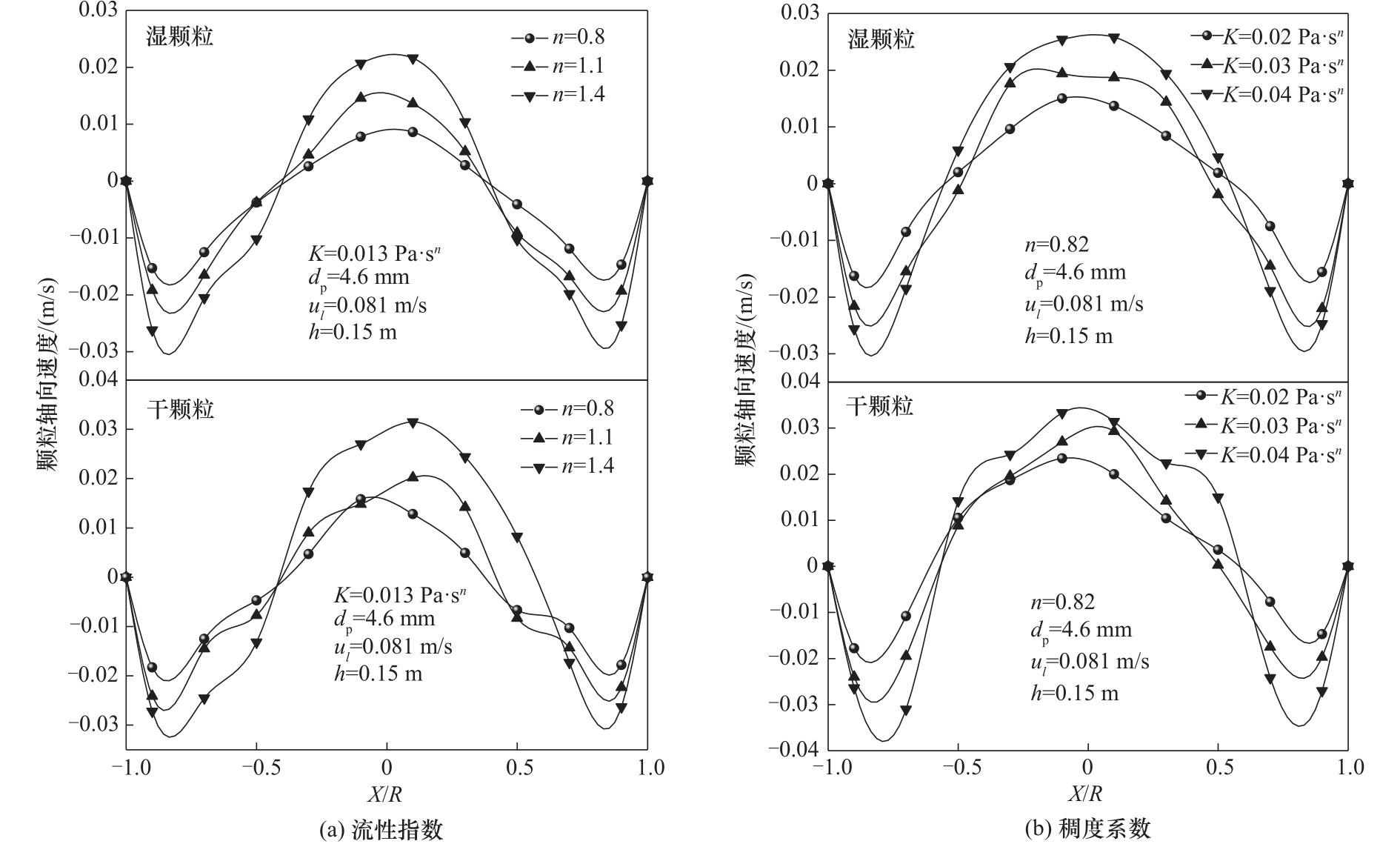

Fig.7 Radial distributions of the time-averaged axial velocity of particles with different flow behavior indexes and consistency coefficients at the same height

| 1 | Cheng Y, Zhu J X. CFD modelling and simulation of hydrodynamics in liquid-solid circulating fluidized beds[J]. The Canadian Journal of Chemical Engineering, 2005, 83(2): 177-185. |

| 2 | 郭慕孙,李洪钟.流态化手册[M].北京:石油工业出版社,1994. |

| Kwauk M S, Li H Z. Handbook of Fluidization[M]. Beijing: Petroleum Industry Press, 1994. | |

| 3 | Lu H L, Gidaspow D. Hydrodynamics of binary fluidization in a riser: CFD simulation using two granular temperatures[J]. Chemical Engineering Science, 2003, 58(16): 3777-3792. |

| 4 | Yang L, Du K. A comprehensive review on the natural, forced, and mixed convection of non-Newtonian fluids (nanofluids) inside different cavities[J]. Journal of Thermal Analysis and Calorimetry, 2020, 140(5): 2033-2054. |

| 5 | Shende T, Niasar V J, Babaei M. Effective viscosity and Reynolds number of non-Newtonian fluids using Meter model[J]. Rheologica Acta, 2021, 60(1): 11-21. |

| 6 | Qi Z, Kuang S B, Yu A B. Lattice Boltzmann investigation of non-Newtonian fluid flow through a packed bed of uniform spheres[J]. Powder Technology, 2019, 343: 225-236. |

| 7 | Kandasamy S, Venkatachalam S. Prediction of bed voidage in multi-phase fluidized bed using air/Newtonian and non-Newtonian liquid systems[J]. Desalination and Water Treatment, 2021, 211: 92-98. |

| 8 | Pang B X, Wang S Y, Lu H L. A modified drag model for power-law fluid-particle flow used in computational fluid dynamics simulation[J]. Advanced Powder Technology, 2021, 32(4): 1207-1218. |

| 9 | Shah S N, El Fadili Y, Chhabra R P. New model for single spherical particle settling velocity in power law (visco-inelastic) fluids[J]. International Journal of Multiphase Flow, 2007, 33(1): 51-66. |

| 10 | Marinack M C, Musgrave R E, C F Ⅲ Higgs. Experimental investigations on the coefficient of restitution of single particles[J]. Tribology Transactions, 2013, 56(4): 572-580. |

| 11 | Crüger B, Salikov V, Heinrich S, et al. Coefficient of restitution for particles impacting on wet surfaces: an improved experimental approach[J]. Particuology, 2016, 25: 1-9. |

| 12 | Liu G D, Yu F, Lu H L, et al. CFD-DEM simulation of liquid-solid fluidized bed with dynamic restitution coefficient[J]. Powder Technology, 2016, 304: 186-197. |

| 13 | Gao Z Y, Liu G D, Guo X Y, et al. A dynamic coefficient of restitution applied to two-fluid model in liquid-solid fluidized bed[J]. Powder Technology, 2022, 402: 117335. |

| 14 | Zhong H B, Zhang Y N, Xiong Q G, et al. Two-fluid modeling of a wet spouted fluidized bed with wet restitution coefficient model[J]. Powder Technology, 2020, 364: 363-372. |

| 15 | Broniarz-Press L, Agacinski P, Rozanski J. Shear-thinning fluids flow in fixed and fluidised beds[J]. International Journal of Multiphase Flow, 2007, 33(6): 675-689. |

| 16 | Miura H, Takahashi T, Ichikawa J, et al. Bed expansion in liquid-solid two-phase fluidized beds with Newtonian and non-Newtonian fluids over the wide range of Reynolds numbers[J]. Powder Technology, 2001, 117(3): 239-246. |

| 17 | Gidaspow D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions[M]. Boston: Academic Press, 1994. |

| 18 | Carman P C. Fluid flow through granular beds[J]. Chemical Engineering Research and Design, 1997, 75: S32-S48. |

| 19 | Sheffield R E, Metzner A B. Flows of nonlinear fluids through porous media[J]. AIChE Journal, 1976, 22(4): 736-744. |

| 20 | 田兴旺, 王平, 徐士鸣. 颗粒堆积多孔介质内幂律流体的流动阻力特性[J]. 哈尔滨工业大学学报, 2017, 49(1):126-132. |

| Tian X W, Wang P, Xu S M. Flow resistance characteristics of power law fluid flow through granular porous medium[J]. Journal of Harbin Institute of Technology, 2017, 49(1):126-132. | |

| 21 | Ergun S. Fluid flow through packed columns[J]. Chemical Engineering Progress, 1952, 48(2): 89-94. |

| 22 | Kemblowski Z, Michniewicz M. A new look at the laminar flow of power law fluids through granular beds[J]. Rheologica Acta, 1979, 18(6): 730-739. |

| 30 | Shenoy A V. Darcy-Forchheimer natural, forced and mixed convection heat transfer in non-Newtonian power-law fluid-saturated porous media[J]. Transport in Porous Media, 1993, 11(3): 219-241. |

| 31 | Richardson J F, Zaki W N. The sedimentation of a suspension of uniform spheres under conditions of viscous flow[J]. Chemical Engineering Science, 1954, 3(2): 65-73. |

| 32 | Gollwitzer F, Rehberg I, Kruelle C A, et al. Coefficient of restitution for wet particles[J]. Physical Review. E, Statistical, Nonlinear, and Soft Matter Physics, 2012, 86(1 Pt 1): 011303. |

| 33 | Åkesjö A, Vamling L, Sasic S, et al. On the measuring of film thickness profiles and local heat transfer coefficients in falling films[J]. Experimental Thermal and Fluid Science, 2018, 99: 287-296. |

| 34 | 陆慧林. 稠密颗粒流体两相流的颗粒动理学[M]. 北京: 科学出版社, 2017. |

| Lu H L. Particle Dynamics of Dense Granular Fluid Two-Phase Flow[M]. Beijing: Science Press, 2017. | |

| 35 | Jiang Z C, Hagemeier T, Bück A, et al. Experimental measurements of particle collision dynamics in a pseudo-2D gas-solid fluidized bed[J]. Chemical Engineering Science, 2017, 167: 297-316. |

| 23 | Christopher R H, Middleman S. Power-law flow through a packed tube[J]. Industrial & Engineering Chemistry Fundamentals, 1965, 4(4): 422-426. |

| 24 | Denn M M. Continuous drawing of liquids to form fibers[J]. Annual Review of Fluid Mechanics, 1980, 12: 365-387. |

| 25 | Foscolo P U, Gibilaro L G, Waldram S P. A unified model for particulate expansion of fluidised beds and flow in fixed porous media[J]. Chemical Engineering Science, 1983, 38(8): 1251-1260. |

| 26 | Dharmadhikari R V, Kale D D. Flow of non-Newtonian fluids through porous media[J]. Chemical Engineering Science, 1985, 40(3): 527-529. |

| 27 | Agarwal P K, O’Neill B K. Transport phenomena in multi-particle systems(Ⅰ): Pressure drop and friction factors: unifying the hydraulic-radius and submerged-object approaches[J]. Chemical Engineering Science, 1988, 43(9): 2487-2499. |

| 28 | Chhabra R P, Comiti J, Machač I. Flow of non-Newtonian fluids in fixed and fluidised beds[J]. Chemical Engineering Science, 2001, 56(1): 1-27. |

| 29 | Poggie J, Smits A J. Wavelet analysis of wall-pressure fluctuations in a supersonic blunt-fin flow[J]. AIAA Journal, 1997, 35(10): 1597-1603. |

| [1] | Jiahao SONG, Wen WANG. Study on coupling operation characteristics of Stirling engine and high temperature heat pipe [J]. CIESC Journal, 2023, 74(S1): 287-294. |

| [2] | Siyu ZHANG, Yonggao YIN, Pengqi JIA, Wei YE. Study on seasonal thermal energy storage characteristics of double U-shaped buried pipe group [J]. CIESC Journal, 2023, 74(S1): 295-301. |

| [3] | Mingkun XIAO, Guang YANG, Yonghua HUANG, Jingyi WU. Numerical study on bubble dynamics of liquid oxygen at a submerged orifice [J]. CIESC Journal, 2023, 74(S1): 87-95. |

| [4] | Shaohua ZHOU, Feilong ZHAN, Guoliang DING, Hao ZHANG, Yanpo SHAO, Yantao LIU, Zheming GAO. Experimental study of flow noise in short tube throttle valve and noise reduction measures [J]. CIESC Journal, 2023, 74(S1): 113-121. |

| [5] | Zhanyu YE, He SHAN, Zhenyuan XU. Performance simulation of paper folding-like evaporator for solar evaporation systems [J]. CIESC Journal, 2023, 74(S1): 132-140. |

| [6] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [7] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [8] | Kaijie WEN, Li GUO, Zhaojie XIA, Jianhua CHEN. A rapid simulation method of gas-solid flow by coupling CFD and deep learning [J]. CIESC Journal, 2023, 74(9): 3775-3785. |

| [9] | Yubing WANG, Jie LI, Hongbo ZHAN, Guangya ZHU, Dalin ZHANG. Experimental study on flow boiling heat transfer of R134a in mini channel with diamond pin fin array [J]. CIESC Journal, 2023, 74(9): 3797-3806. |

| [10] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [11] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [12] | Xiaosong CHENG, Yonggao YIN, Chunwen CHE. Performance comparison of different working pairs on a liquid desiccant dehumidification system with vacuum regeneration [J]. CIESC Journal, 2023, 74(8): 3494-3501. |

| [13] | Wenzhu LIU, Heming YUN, Baoxue WANG, Mingzhe HU, Chonglong ZHONG. Research on topology optimization of microchannel based on field synergy and entransy dissipation [J]. CIESC Journal, 2023, 74(8): 3329-3341. |

| [14] | Rui HONG, Baoqiang YUAN, Wenjing DU. Analysis on mechanism of heat transfer deterioration of supercritical carbon dioxide in vertical upward tube [J]. CIESC Journal, 2023, 74(8): 3309-3319. |

| [15] | Chen HAN, Youmin SITU, Bin ZHU, Jianliang XU, Xiaolei GUO, Haifeng LIU. Study of reaction and flow characteristics in multi-nozzle pulverized coal gasifier with co-processing of wastewater [J]. CIESC Journal, 2023, 74(8): 3266-3278. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||