CIESC Journal ›› 2024, Vol. 75 ›› Issue (2): 520-530.DOI: 10.11949/0438-1157.20231165

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Zhipeng LIU( ), Changying ZHAO(

), Changying ZHAO( ), Rui WU, Zhihao ZHANG

), Rui WU, Zhihao ZHANG

Received:2023-11-13

Revised:2023-12-26

Online:2024-04-10

Published:2024-02-25

Contact:

Changying ZHAO

通讯作者:

赵长颖

作者简介:刘志鹏(1997—),男,硕士研究生,liuzhipeng97@sjtu.edu.cn

CLC Number:

Zhipeng LIU, Changying ZHAO, Rui WU, Zhihao ZHANG. Experimental study of gas-liquid flow visualization in gradient porous transport layers based on hydrogen production by water electrolysis[J]. CIESC Journal, 2024, 75(2): 520-530.

刘志鹏, 赵长颖, 吴睿, 张智昊. 基于水电解制氢的梯度多孔传输层中气液流动可视化实验研究[J]. 化工学报, 2024, 75(2): 520-530.

Add to citation manager EndNote|Ris|BibTeX

| 名称 | 结构 | 具体参数 |

|---|---|---|

| LSL-PTL | 扩散层孔隙尺寸从催化层界面向外递增 | 孔隙边长依次为0.8、1.0和1.2 mm 每层孔隙的深度均为1.8 mm 扩散层孔隙度25.67% |

| MMM-PTL | 扩散层孔隙尺寸从催化层向外各处均匀一致 | 孔隙边长1.01 mm 孔隙深度5.4 mm 扩散层孔隙度25.67% |

| SLS-PTL | 扩散层孔隙尺寸从催化层界面向外递减 | 孔的边长依次为1.2、1.0和0.8 mm 每层孔隙的深度均为1.8 mm 扩散层孔隙度25.67% |

Table 1 Detailed parameters of three different gradients of the PTL

| 名称 | 结构 | 具体参数 |

|---|---|---|

| LSL-PTL | 扩散层孔隙尺寸从催化层界面向外递增 | 孔隙边长依次为0.8、1.0和1.2 mm 每层孔隙的深度均为1.8 mm 扩散层孔隙度25.67% |

| MMM-PTL | 扩散层孔隙尺寸从催化层向外各处均匀一致 | 孔隙边长1.01 mm 孔隙深度5.4 mm 扩散层孔隙度25.67% |

| SLS-PTL | 扩散层孔隙尺寸从催化层界面向外递减 | 孔的边长依次为1.2、1.0和0.8 mm 每层孔隙的深度均为1.8 mm 扩散层孔隙度25.67% |

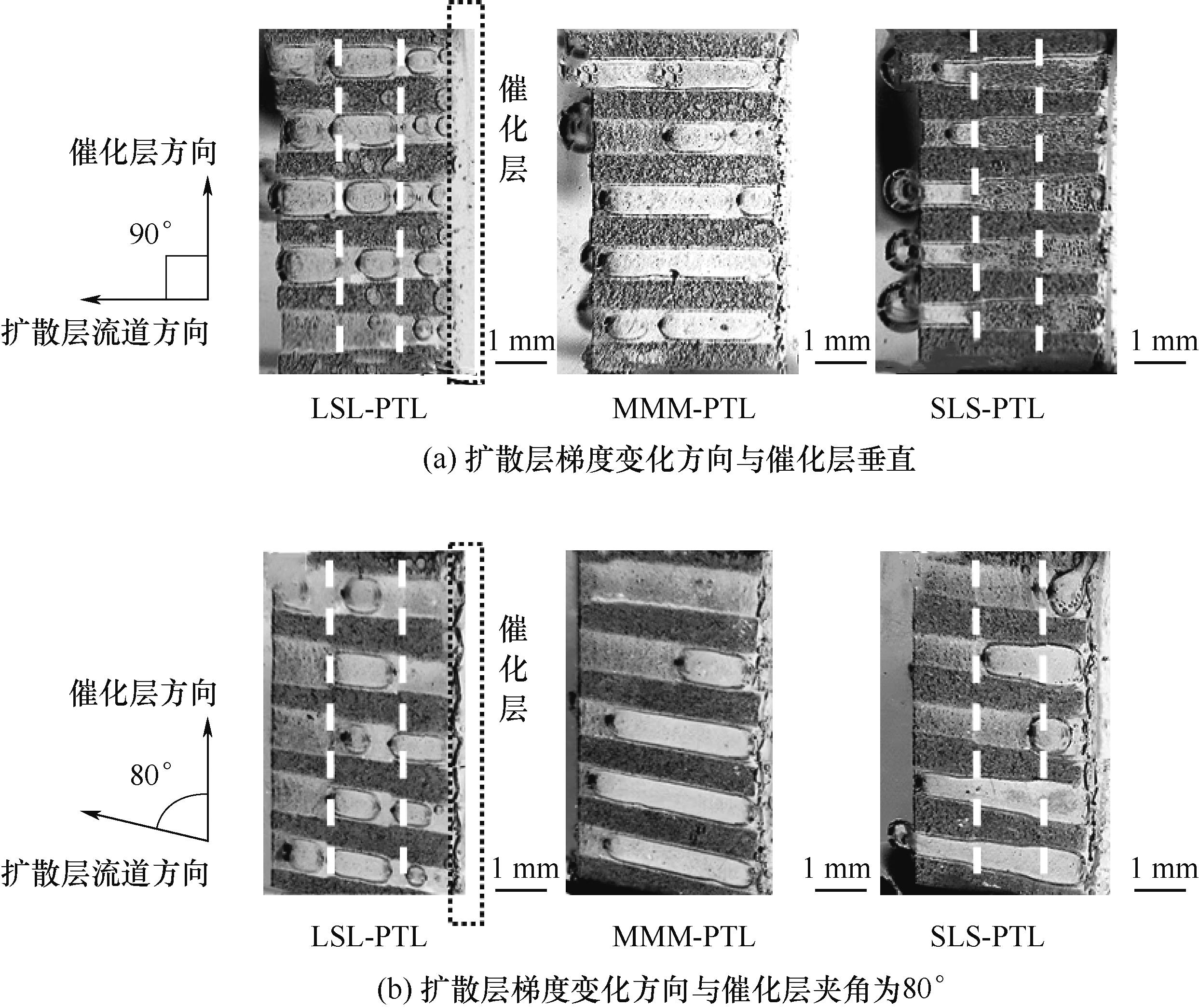

Fig.5 Morphology of bubbles generated by HER in the porous transport layer at a current of 0.1 A/cm2 for LSL-PTL, MMM-PTL, and SLS-PTL (the white dashed line represents the boundary between pores with different gradients in the diffusion layer)

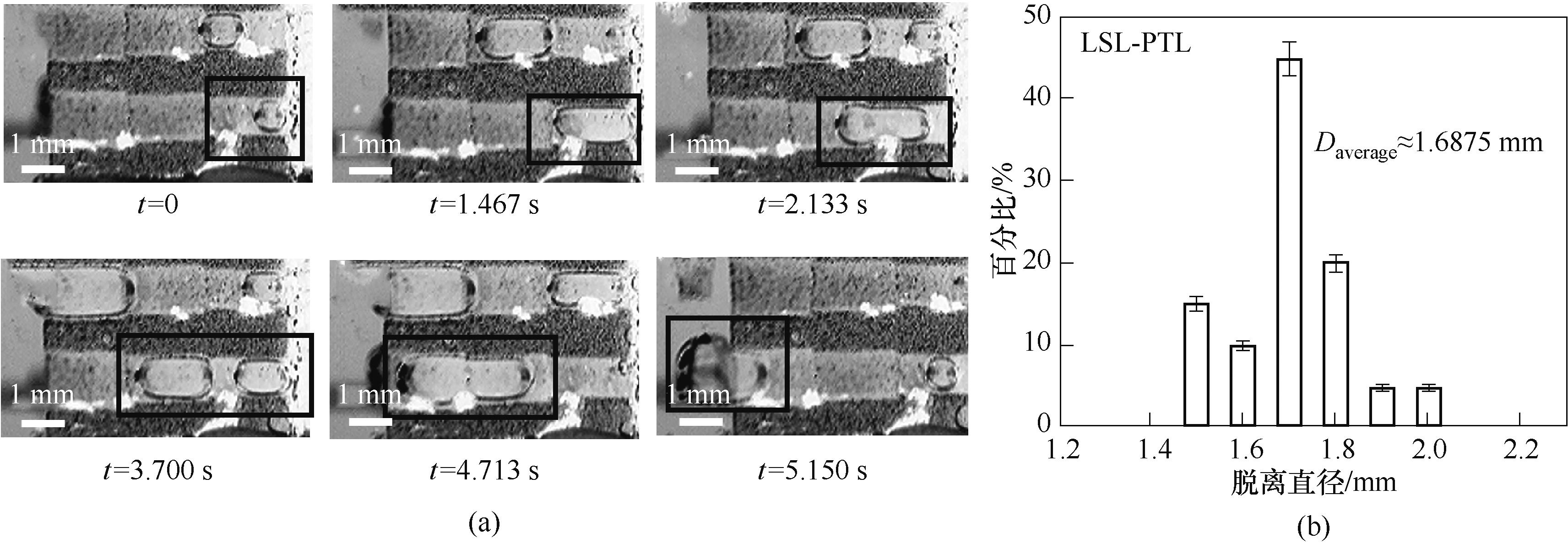

Fig.6 (a) Sets of photographs demonstrating the typical bubble removal processes releasing from LSL-PTL at 0.1 A/cm2 current density; (b) Distribution of the diameters of hydrogen bubbles that detached from LSL-PTL at 0.1 A/cm2 current density

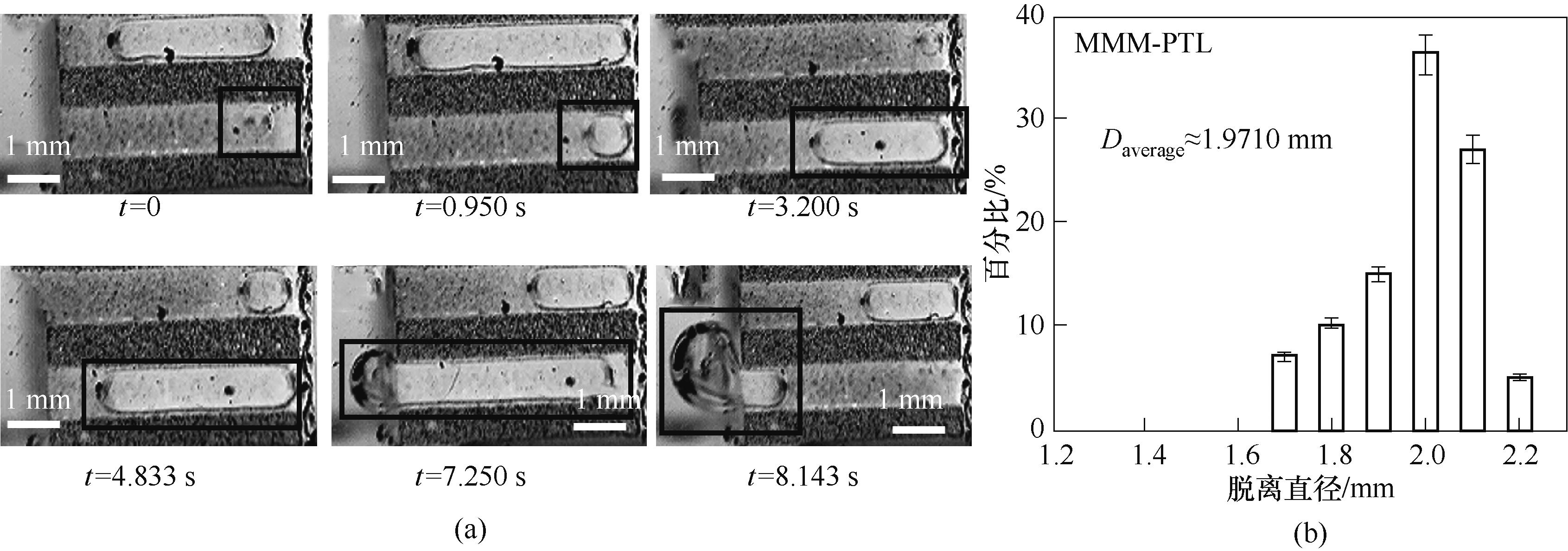

Fig.7 (a) Sets of photographs demonstrating the typical bubble removal processes releasing from MMM-PTL at 0.1 A/cm2 current density; (b) Distribution of the diameters of hydrogen bubbles that detached from MMM -PTL at 0.1 A/cm2 current density

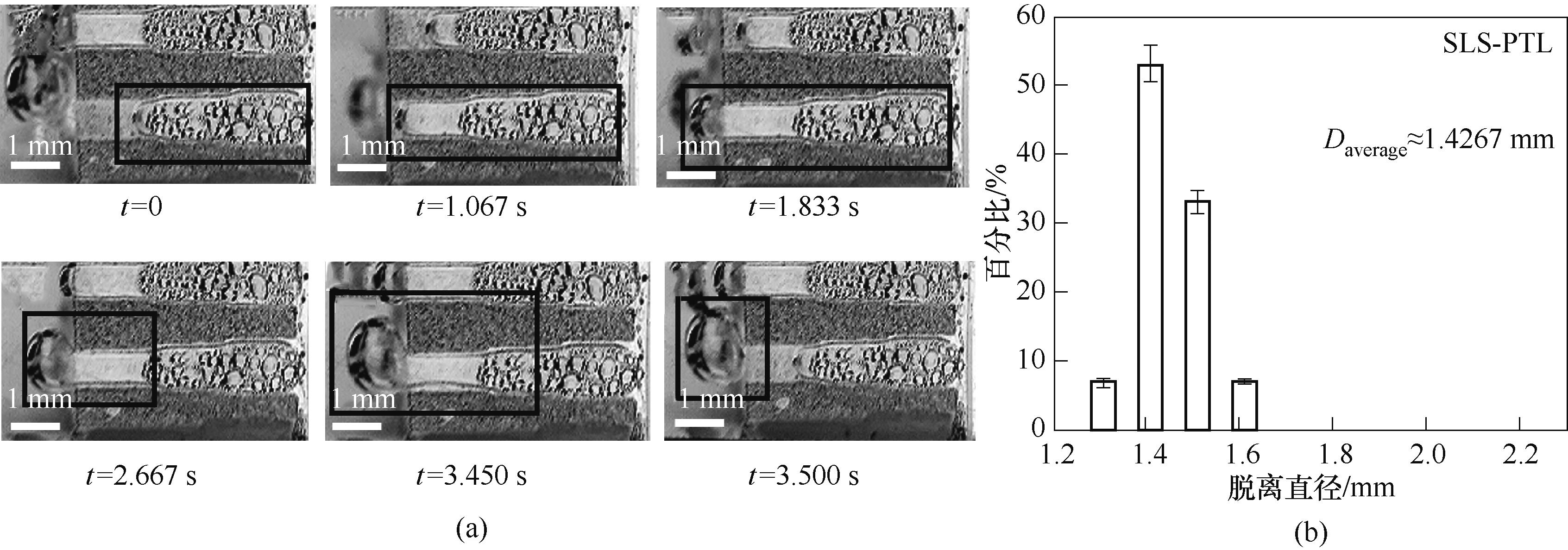

Fig.8 (a) Sets of photographs demonstrating the typical bubble removal processes releasing from SLS-PTL at 0.1 A/cm2 current density; (b) Distribution of the diameters of hydrogen bubbles that detached from SLS-PTL at 0.1 A/cm2 current density

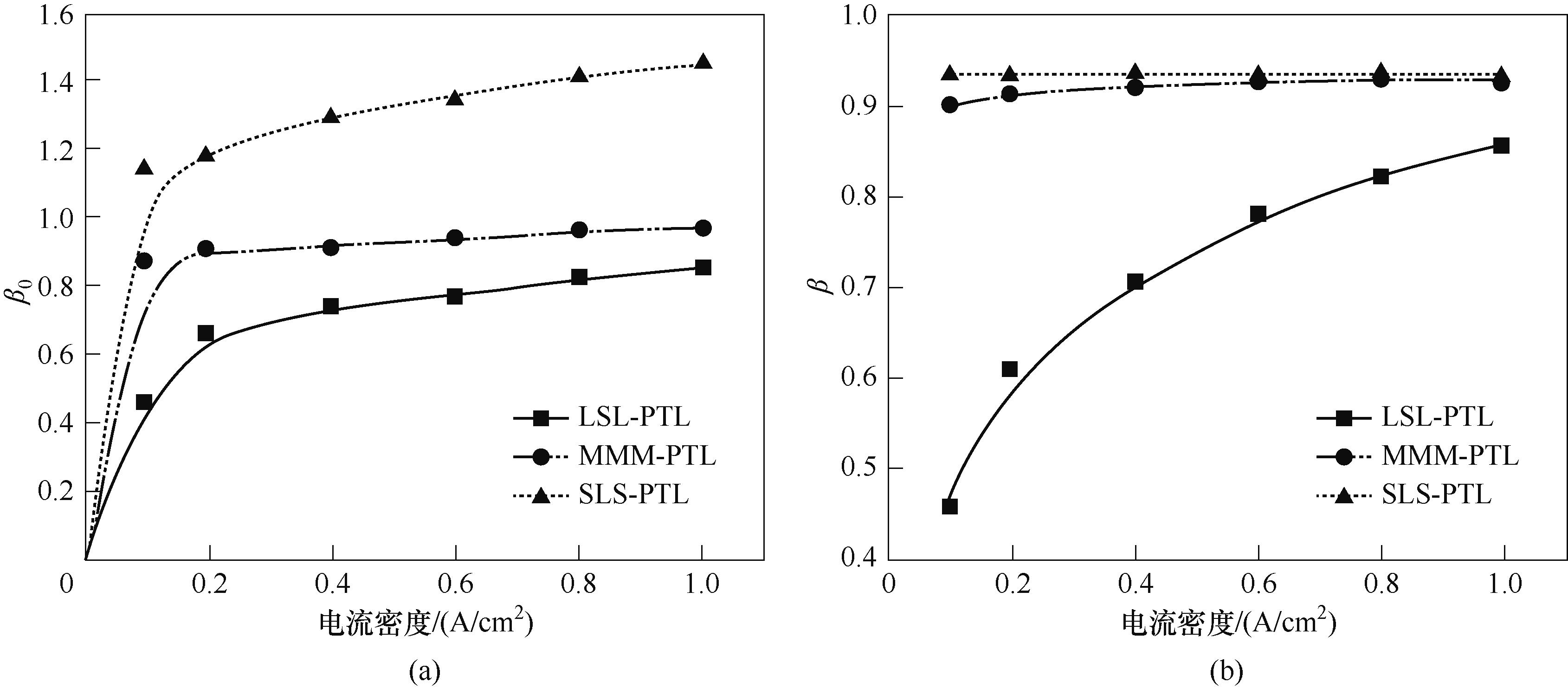

Fig.11 Maximum β0 at the moment of bubble detachment and maximum volumetric gas content β at the moment of bubble detachment for different current density conditions

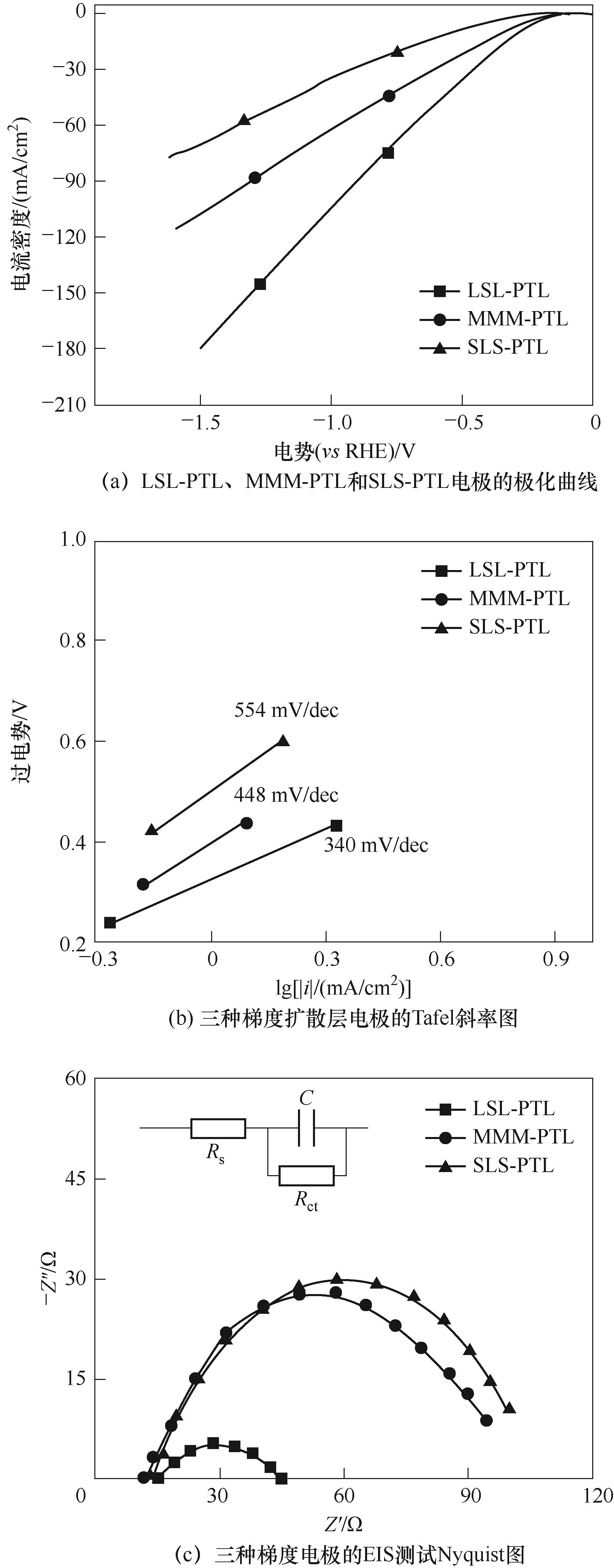

Fig.13 (a) Polarization curve of LSL-PTL, MMM-PTL and SLS-PTL electrodes; (b) Tafel plots for LSL-PTL, MMM-PTL and SLS-PTL electrodes; (c) EIS Nyquist plots of LSL-PTL, MMM-PTL and SLS-PTL electrodes

| 1 | 何钰江, 刘会灯, 王皓宇, 等. “双碳”目标下氢能发展体系构建和产业创新布局展望[J]. 电工电能新技术, 2023, 42(9): 65-76. |

| He Y J, Liu H D, Wang H Y, et al. Prospects for construction of hydrogen energy development system and industrial innovation layout under “double carbon” goal[J]. Advanced Technology of Electrical Engineering and Energy, 2023, 42(9): 65-76. | |

| 2 | Schmidt O, Gambhir A, Staffell I, et al. Future cost and performance of water electrolysis: an expert elicitation study[J]. International Journal of Hydrogen Energy, 2017, 42(52): 30470-30492. |

| 3 | Buttler A, Spliethoff H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids: a review[J]. Renewable and Sustainable Energy Reviews, 2018, 82: 2440-2454. |

| 4 | Klose C, Saatkamp T, Münchinger A, et al. Water electrolyzers: all-hydrocarbon MEA for PEM water electrolysis combining low hydrogen crossover and high efficiency[J]. Advanced Energy Materials, 2020, 10(14): 207006. |

| 5 | Kibsgaard J, Chorkendorff I. Considerations for the scaling-up of water splitting catalysts[J]. Nature Energy, 2019, 4(6): 430-433. |

| 6 | Siracusano S, Di Blasi A, Baglio V, et al. Optimization of components and assembling in a PEM electrolyzer stack[J]. International Journal of Hydrogen Energy, 2011, 36(5): 3333-3339. |

| 7 | Yuan S, Zhao C F, Cai X Y, et al. Bubble evolution and transport in PEM water electrolysis: mechanism, impact, and management[J]. Progress in Energy and Combustion Science, 2023, 96: 101075. |

| 8 | Kang Z Y, Mo J K, Yang G Q, et al. Investigation of thin/well-tunable liquid/gas diffusion layers exhibiting superior multifunctional performance in low-temperature electrolytic water splitting[J]. Energy & Environmental Science, 2017, 10(1): 166-175. |

| 9 | Wan L, Xu Z A, Xu Q, et al. Overall design of novel 3D-ordered MEA with drastically enhanced mass transport for alkaline electrolyzers[J]. Energy & Environmental Science, 2022, 15(5): 1882-1892. |

| 10 | De Angelis S, Schuler T, Charalambous M A, et al. Unraveling two-phase transport in porous transport layer materials for polymer electrolyte water electrolysis[J]. Journal of Materials Chemistry A, 2021, 9(38): 22102-22113. |

| 11 | Iwata R, Zhang L N, Wilke K L, et al. Bubble growth and departure modes on wettable/non-wettable porous foams in alkaline water splitting[J]. Joule, 2021, 5(4): 887-900. |

| 12 | Schuler T, Schmidt T J, Büchi F N. Polymer electrolyte water electrolysis: correlating performance and porous transport layer structure(part Ⅱ): Electrochemical performance analysis[J]. Journal of the Electrochemical Society, 2019, 166(10): F555-F565. |

| 13 | 唐英伦, 杨小涛, 赵军, 等. 叠层扩散层对质子交换膜电解池性能影响的实验研究[J]. 工程热物理学报, 2023, 44(2): 304-310. |

| Tang Y L, Yang X T, Zhao J, et al. Experimental study on the effects of stacked diffusion layer on the performance of proton-exchange membrane electrolysis cells[J]. Journal of Engineering Thermophysics, 2023, 44(2): 304-310. | |

| 14 | Yang Y, Li J, Yang Y R, et al. Gradient porous electrode-inducing bubble splitting for highly efficient hydrogen evolution[J]. Applied Energy, 2022, 307: 118278. |

| 15 | Huang B R, Wang X C, Li W Z, et al. Accelerating gas escape in anion exchange membrane water electrolysis by gas diffusion layers with hierarchical grid gradients[J]. Angewandte Chemie, 2023, 135(33): e2023042. |

| 16 | Van Pham C, Escalera-López D, Mayrhofer K, et al. Essentials of high performance water electrolyzers—from catalyst layer materials to electrode engineering[J]. Advanced Energy Materials, 2021, 11(44): 2101998. |

| 17 | Angulo A, van der Linde P, Gardeniers H, et al. Influence of bubbles on the energy conversion efficiency of electrochemical reactors[J]. Joule, 2020, 4(3): 555-579. |

| 18 | Chatenet M, Pollet B G, Dekel D R, et al. Water electrolysis: from textbook knowledge to the latest scientific strategies and industrial developments[J]. Chemical Society Reviews, 2022, 51(11): 4583-4762. |

| 19 | Razmjooei F, Morawietz T, Taghizadeh E, et al. Increasing the performance of an anion-exchange membrane electrolyzer operating in pure water with a nickel-based microporous layer[J]. Joule, 2021, 5(7): 1776-1799. |

| 20 | Xu Q C, Oener S Z, Lindquist G, et al. Integrated reference electrodes in anion-exchange-membrane electrolyzers: impact of stainless-steel gas-diffusion layers and internal mechanical pressure[J]. ACS Energy Letters, 2021, 6(2): 305-312. |

| 21 | Azarafza A, Ismail M S, Rezakazemi M, et al. Comparative study of conventional and unconventional designs of cathode flow fields in PEM fuel cell[J]. Renewable and Sustainable Energy Reviews, 2019, 116: 109420. |

| 22 | Wang M Y, Wang Z, Gong X Z, et al. The intensification technologies to water electrolysis for hydrogen production—a review[J]. Renewable and Sustainable Energy Reviews, 2014, 29: 573-588. |

| 23 | Zhao X, Ren H, Luo L. Gas bubbles in electrochemical gas evolution reactions[J]. Langmuir, 2019, 35(16): 5392-5408. |

| 24 | Song X Y, Li W Q, Liu X J, et al. Oxygen vacancies enable the visible light photoactivity of chromium-implanted TiO2 nanowires[J]. Journal of Energy Chemistry, 2021, 55: 154-161. |

| 25 | Park J E, Kang S Y, Oh S H, et al. High-performance anion-exchange membrane water electrolysis[J]. Electrochimica Acta, 2019, 295: 99-106. |

| 26 | Taqieddin A, Nazari R, Rajic L, et al. Review—physicochemical hydrodynamics of gas bubbles in two phase electrochemical systems[J]. Journal of the Electrochemical Society, 2017, 164(13): E448-E459. |

| 27 | Huang R L, Zhao C Y, Xu Z G. Investigation of bubble behavior in gradient porous media under pool boiling conditions[J]. International Journal of Multiphase Flow, 2018, 103: 85-93. |

| 28 | Siracusano S, Trocino S, Briguglio N, et al. Electrochemical impedance spectroscopy as a diagnostic tool in polymer electrolyte membrane electrolysis[J]. Materials, 2018, 11(8): 1368. |

| 29 | Xu X, Fu G W, Wang Y X, et al. Highly efficient all-3D-printed electrolyzer toward ultrastable water electrolysis[J]. Nano Letters, 2023, 23(2): 629-636. |

| 30 | Wang L, Huang X L, Jiang S S, et al. Increasing gas bubble escape rate for water splitting with nonwoven stainless steel fabrics[J]. ACS Applied Materials & Interfaces, 2017, 9(46): 40281-40289. |

| 31 | Sun Q Q, Dong Y J, Wang Z L, et al. Synergistic nanotubular copper-doped nickel catalysts for hydrogen evolution reactions[J]. Small, 2018, 14(14): 1704137. |

| [1] | Nailiang LI, Changsong LIU, Xueping DU, Yifan ZHANG, Dongtai HAN. Analysis of multi-scale fractal characteristics of severe slugging based on Hurst exponent [J]. CIESC Journal, 2024, 75(2): 484-492. |

| [2] | Qichao LIU, Shibo ZHANG, Yunlong ZHOU, Yuqing LI, Cong CHEN, Yiwen RAN. Gas-liquid two-phase flow regimes and transformation mechanism in horizontal tube under fluctuating vibration [J]. CIESC Journal, 2024, 75(2): 493-504. |

| [3] | Congqi HUANG, Yimei WU, Jianye CHEN, Shuangquan SHAO. Simulation study of thermal management system of alkaline water electrolysis device for hydrogen production [J]. CIESC Journal, 2023, 74(S1): 320-328. |

| [4] | He JIANG, Junfei YUAN, Lin WANG, Guyu XING. Experimental study on the effect of flow sharing cavity structure on phase change flow characteristics in microchannels [J]. CIESC Journal, 2023, 74(S1): 235-244. |

| [5] | Jiaqi YUAN, Zheng LIU, Rui HUANG, Lefu ZHANG, Denghui HE. Investigation on energy conversion characteristics of vortex pump under bubble inflow [J]. CIESC Journal, 2023, 74(9): 3807-3820. |

| [6] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [7] | Yan GAO, Peng WU, Chao SHANG, Zejun HU, Xiaodong CHEN. Preparation of magnetic agarose microspheres based on a two-fluid nozzle and their protein adsorption properties [J]. CIESC Journal, 2023, 74(8): 3457-3471. |

| [8] | Jinming GAO, Yujiao GUO, Chenglin E, Chunxi LU. Study on the separation characteristics of a downstream gas-liquid vortex separator in a closed hood [J]. CIESC Journal, 2023, 74(7): 2957-2966. |

| [9] | Xiaowen ZHOU, Jie DU, Zhanguo ZHANG, Guangwen XU. Study on the methane-pulsing reduction characteristics of Fe2O3-Al2O3 oxygen carrier [J]. CIESC Journal, 2023, 74(6): 2611-2623. |

| [10] | Yong LI, Jiaqi GAO, Chao DU, Yali ZHAO, Boqiong LI, Qianqian SHEN, Husheng JIA, Jinbo XUE. Construction of Ni@C@TiO2 core-shell dual-heterojunctions for advanced photo-thermal catalytic hydrogen generation [J]. CIESC Journal, 2023, 74(6): 2458-2467. |

| [11] | Jinbo JIANG, Xin PENG, Wenxuan XU, Rixiu MEN, Chang LIU, Xudong PENG. Study on leakage characteristics and parameter influence of pump-out spiral groove oil-gas seal [J]. CIESC Journal, 2023, 74(6): 2538-2554. |

| [12] | Xin DONG, Yongrui SHAN, Yinuo LIU, Ying FENG, Jianwei ZHANG. Numerical simulation of bubble plume vortex characteristics for non-Newtonian fluids [J]. CIESC Journal, 2023, 74(5): 1950-1964. |

| [13] | Wenxuan XU, Jinbo JIANG, Xin PENG, Rixiu MEN, Chang LIU, Xudong PENG. Comparative study on leakage and film-forming characteristics of oil-gas seal with three-typical groove in a wide speed range [J]. CIESC Journal, 2023, 74(4): 1660-1679. |

| [14] | Sheng’an ZHANG, Guilian LIU. Multi-objective optimization of high-efficiency solar water electrolysis hydrogen production system and its performance [J]. CIESC Journal, 2023, 74(3): 1260-1274. |

| [15] | Yue SONG, Qicheng ZHANG, Wenchao PENG, Yang LI, Fengbao ZHANG, Xiaobin FAN. Synthesis of MoS2-based single atom catalyst and its application in electrocatalysis [J]. CIESC Journal, 2023, 74(2): 535-545. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||