化工学报 ›› 2019, Vol. 70 ›› Issue (12): 4664-4672.DOI: 10.11949/0438-1157.20190875

收稿日期:2019-07-31

修回日期:2019-09-28

出版日期:2019-12-05

发布日期:2019-12-05

通讯作者:

苏明旭

作者简介:贾楠(1992—),女,博士研究生,基金资助:

Nan JIA( ),Chang TIAN,Mingxu SU(

),Chang TIAN,Mingxu SU( )

)

Received:2019-07-31

Revised:2019-09-28

Online:2019-12-05

Published:2019-12-05

Contact:

Mingxu SU

摘要:

结晶过程是化工单元操作中一种高效节能的固液分离与提纯技术,广泛应用于食品、医药、染料等生产过程。结合超声法、图像法和光学浊度法研究了无水醋酸钠的结晶过程,通过超声模型结合最优正则化反演算法求解晶体颗粒粒度分布,在线测量了不同降温速率和搅拌速率下的析晶温度、晶体尺寸和形貌变化。结果表明:较快的降温速率可促进晶体生长,搅拌速率较快初期晶体尺寸较大,但后期由于颗粒磨损致平均尺寸减小;相同条件下光学浊度法较超声法较早测得析出晶体,实验中析晶温度偏差低于15%;图像法直观观察到了晶体生长过程并较好表征了晶粒形貌,与超声法具有接近的晶粒增长趋势,当晶体稳定析出后两者体积中位径偏差在15%以内,均较好地反映了实验条件对结晶晶体尺寸的影响。光学方法可更精细体现结晶初期特征,而在结晶后期超声法仍可对粒径进行有效测量。

中图分类号:

贾楠, 田昌, 苏明旭. 无水醋酸钠结晶过程中析晶温度和颗粒粒径在线测量[J]. 化工学报, 2019, 70(12): 4664-4672.

Nan JIA, Chang TIAN, Mingxu SU. In situ measurement of crystallization temperature and particle size distribution during crystallization of sodium acetate[J]. CIESC Journal, 2019, 70(12): 4664-4672.

图1 结晶过程的实验装置 1—超声脉冲发射接收仪;2—超声探针;3—Pt100温度传感器;4—电动搅拌器;5—浊度计探针;6—CCD相机;7—相机光源;8—循环低温恒温水浴槽;9—样品池;10—PC

Fig.1 Schematic diagram of experimental setup during crystallization process

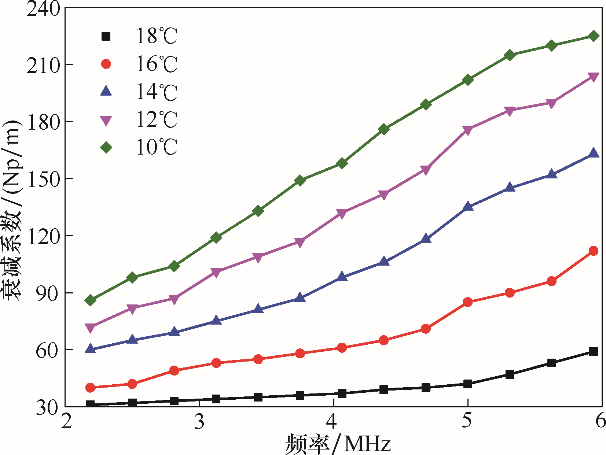

图6 无水醋酸钠的衰减谱

Fig.6 Ultrasonic attenuation spectra during crystallization of sodium acetate solution at cooling rate of 0.6℃/min, stirring rate of 200 r/min

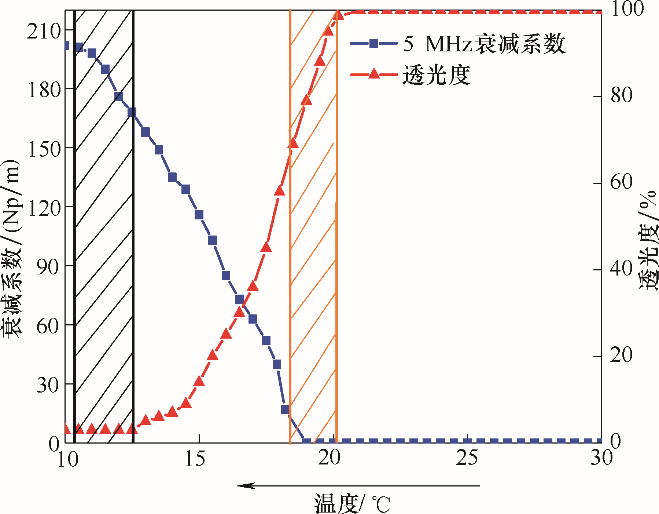

图7 超声法和浊度法的析晶温度对比

Fig.7 Comparison of turbidity and ultrasonic attenuation for determining onset of crystallization of sodium acetate at cooling rate of 0.6℃/min, stirring rate of 200 r/min

| 实验条件 | 超声法/ ℃ | 浊度法/ ℃ | 相对偏差/% |

|---|---|---|---|

| 降温速率(200 r/min)/(℃/min) | |||

| 0.3 | 22.2 | 25.3 | 12.4 |

| 0.6 | 18.2 | 20.2 | 9.9 |

| 1.0 | 16.1 | 17.5 | 8.0 |

| 搅拌速率(0.6℃/min)/(r/min) | |||

| 100 | 16.2 | 18.6 | 12.9 |

| 200 | 18.2 | 20.2 | 9.9 |

| 300 | 18.9 | 20.7 | 8.7 |

表1 不同实验条件下超声和浊度法测得析晶温度

Table 1 Crystallization temperatures measured by turbidity and ultrasonic method under different conditions

| 实验条件 | 超声法/ ℃ | 浊度法/ ℃ | 相对偏差/% |

|---|---|---|---|

| 降温速率(200 r/min)/(℃/min) | |||

| 0.3 | 22.2 | 25.3 | 12.4 |

| 0.6 | 18.2 | 20.2 | 9.9 |

| 1.0 | 16.1 | 17.5 | 8.0 |

| 搅拌速率(0.6℃/min)/(r/min) | |||

| 100 | 16.2 | 18.6 | 12.9 |

| 200 | 18.2 | 20.2 | 9.9 |

| 300 | 18.9 | 20.7 | 8.7 |

| 1 | Jordensa J , Gielena B , Braekenb L , et al . Determination of the effect of the ultrasonic frequency on the cooling crystallization of paracetamol[J]. Chemical Engineering and Processing, 2014, 84: 38-44. |

| 2 | Silvia N , Madeleine J B , Richard P S , et al . A review on possible mechanisms of sonocrystallisation in solution[J]. Ultrasonics Sonochemistry, 2019, 57(3): 125-138. |

| 3 | Gielen B , Kusters P , Jordens J , et al . Energy efficient crystallization of paracetamol using pulsed ultrasound[J]. Chemical Engineering and Processing: Process Intensification, 2017, 114(6): 55-66. |

| 4 | Nii S , Takayanagi S . Growth and size control in anti-solvent crystallization of glycine with high frequency ultrasound[J]. Ultrasonics Sonochemistry, 2014, 21(3): 1182-1186. |

| 5 | Stelzer T , Pertig D , Ulrich J . Ultrasonic crystallization monitoring technique for simultaneous in-line measurement of liquid and solid phase[J]. Journal of Crystal Growth, 2013, 362(17): 71-76. |

| 6 | Gielen B , Claes T , Janssens J , et al . Particle size control during ultrasonic cooling crystallization of paracetamol[J]. Chemical Engineering & Technology, 2017, 40(7): 1300-1308. |

| 7 | Jin M M , Patrick F , Sun Y Z , et al . Study on metastable zone width and crystal growth of a ternary system: case study MgCl2·6H2O· 1,4-dioxane[J]. Chemical Engineering Science, 2015, 133(20): 181-189. |

| 8 | 龚俊波, 陈明洋, 黄翠, 等 . 面向清洁生产的制药结晶[J]. 化工学报, 2015, 66(9): 3271-3278. |

| Gong J B , Chen M Y , Huang C , et al . Clean production of pharmaceutical crystallization[J]. CIESC Journal, 2015, 66(9): 3271-3278. | |

| 9 | Pertig D , Buchfink R , Petersen S , et al . Inline analyzing of industrial crystallization processes by an innovative ultrasonic probe technique[J]. Chemical Engineering & Technology, 2011, 34(4): 639-646. |

| 10 | Frohberg P , Ulrich J . Single-frequency ultrasonic crystallization monitoring (UCM): innovative technique for in-line analyzing of industrial crystallization processes[J]. Organic Process Research & Development, 2015, 19(1): 84-88. |

| 11 | Srisanga S , Flood A E , Galbraith S C , et al . Crystal growth rate dispersion versus size-dependent crystal growth: appropriate modeling for crystallization processes[J]. Crystal Growth & Design, 2015, 15(5): 2330-2336. |

| 12 | Luo M , Liu C , Xue J , et al . Determination of metastable zone width of potassium sulfate in aqueous solution by ultrasonic sensor and FBRM[J]. Journal of Crystal Growth, 2017, 469(23): 144-153. |

| 13 | Zhang F , Liu T , Huo Y , et al . Investigation of the operating conditions to morphology evolution of β-L-glutamic acid during seeded cooling crystallization[J]. Journal of Crystal Growth, 2017, 469(22): 136-143. |

| 14 | Kadam S S , Mesbah A , Windt E V D , et al . Rapid online calibration for ATR-FTIR spectroscopy during batch crystallization of ammonium sulphate in a semi-industrial scale crystallizer[J]. Chemical Engineering Research and Design, 2011, 89(7): 995-1005. |

| 15 | 李兰菊, 李秀喜, 徐三 . 阿司匹林结晶过程的在线分析[J]. 化工学报, 2018, 69(3): 1046-1052. |

| Li L J , Li X X , Xu S . Online monitor of Aspirin crystallization process [J]. CIESC Journal, 2018, 69(3): 1046-1052. | |

| 16 | 林春丹, 梁永燊, 张万松, 等 . 超声衰减谱法测量含蜡原油中蜡晶粒度[J]. 声学技术, 2013, 32(4): 294-298. |

| Lin C D , Liang Y S , Zhang W S , et al . Particle size characterization of wax crystal in crude oil by ultrasound attenuation spectroscopy[J]. Technical Acoustics, 2013, 32(4): 294-298. | |

| 17 | 胡边, 苏明旭, 蔡小舒 . 高浓度纳米颗粒悬浮液粒径的超声在线测量方法研究[J]. 高校化学工程学报, 2014, 28(4): 901-904. |

| Hu B , Su M X , Cai X S . Online measurement of nanoparticle size distribution in high concentration suspensions using ultrasound spectroscopy[J]. Journal of Chemical Engineering of Chinese Universities, 2014, 28(4): 901-904. | |

| 18 | Richter A , Voigt T , Ripperger S . Ultrasonic attenuation spectroscopy of emulsions with droplet sizes greater than 10 μm[J]. Journal of Colloid and Interface Science, 2007, 315(2): 482-492. |

| 19 | Povey M J W . Ultrasound particle sizing: a review[J]. Particuology, 2013, 11(2): 135-147. |

| 20 | 呼剑, 苏明旭, 蔡小舒, 等 . 高频宽带超声衰减谱表征纳米颗粒粒度的方法[J]. 化工学报, 2010, 61(11): 2985-2991. |

| Hu J , Su M X , Cai X S , et al . Broad-band high-frequency ultrasonic attenuation spectrum method for measuring nanoparticle size distribution[J]. CIESC Journal, 2010, 61(11): 2985-2991. | |

| 21 | 贾楠, 顾建飞, 苏明旭 . 基于超声谱分析的颗粒粒度测量研究[J]. 计量学报, 2019, 40(3): 466-471. |

| Jia N , Gu J F , Su M X . Characterization of particle size distribution based on ultrasonic spectra analysis[J]. Acta Metrologica Sinica, 2019, 40(3): 466-471. | |

| 22 | Wang X Z , Liu L D , Li R F , et al . Online characterisation of nanoparticle suspensions using dynamic light scattering, ultrasound spectroscopy and process tomography [J]. Chemical Engineering Research and Design, 2009, 87(6): 874-884. |

| 23 | Jia N , Gu J F , Yang H N , et al . Synchronous acquisition and analysis of ultrasonic spectral information for the characterization of particle size distribution[J]. Journal of Sensors, 2019, 2019:8251829. |

| 24 | Yang H N , Su M X , Wang X , et al . Particle sizing with particle improved genetic algorithm by ultrasound attenuation spectroscopy [J]. Powder Technology, 2016, 304(18): 20-26. |

| 25 | Gu J F , Fan F X , Li Y S , et al . Modeling and prediction of ultrasonic attenuations in liquid-solid dispersions containing mixed particles with Monte Carlo method[J]. Particuology, 2019, 43(2): 84-91. |

| 26 | 何兴学, 孙勤, 杨阿三, 等 . 醋酸钠介稳区的测定[J]. 化学工程, 2012, 40(7): 43-45. |

| He X X , Sun Q , Yang A S , et al . Determination of metastable region flor sodium acetate[J]. Chemical Engineering (China), 2012, 40(7): 43-45. | |

| 27 | 纪晓明, 苏明旭, 汪雪, 等 . 基于超声波阻抗谱的颗粒粒径表征方法[J]. 化工学报, 2016, 67(6): 2284-2290. |

| Ji X M , Su M X , Wang X , et al . Particle size characterization based on ultrasonic impedance spectrum[J]. CIESC Journal, 2016, 67(6): 2284-2290. | |

| 28 | Su M X , Xu F , Cai X S , et al . Optimization of regularization parameter of inversion in particle sizing using light extinction method[J]. China Particuology, 2007, 5(4): 295-299. |

| 29 | 章维, 苏明旭, 蔡小舒 . 基于超声衰减谱和相速度的颗粒粒径测量[J]. 化工学报, 2014, 65(3): 898-904. |

| Zhang W , Su M X , Cai X S . Particle size distribution measurement based on ultrasonic attenuation and phase velocity spectra[J]. CIESC Journal, 2014, 65(3): 898-904. | |

| 30 | Eliçabe G E , García R , Luis H . Latex particle size distribution from turbidimetry using inversion techniques [J]. Journal of Colloid and Interface Science, 1989, 129(1): 192-200. |

| [1] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [2] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [3] | 仪显亨, 周骛, 蔡小舒, 蔡天意. 光纤后向动态光散射测量纳米颗粒的浓度适用范围研究[J]. 化工学报, 2023, 74(8): 3320-3328. |

| [4] | 傅予, 刘兴翀, 王瀚雨, 李海敏, 倪亚飞, 邹文静, 雷月, 彭永姗. F3EACl修饰层对钙钛矿太阳能电池性能提升的研究[J]. 化工学报, 2023, 74(8): 3554-3563. |

| [5] | 邵伟明, 韩文学, 宋伟, 杨勇, 陈灿, 赵东亚. 基于分布式贝叶斯隐马尔可夫回归的动态软测量建模方法[J]. 化工学报, 2023, 74(6): 2495-2502. |

| [6] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| [7] | 王瑞恒, 何品晶, 吕凡, 章骅. 垃圾焚烧飞灰水洗后三种固液分离方法参数比较及优化[J]. 化工学报, 2023, 74(4): 1712-1723. |

| [8] | 陈俊先, 姬忠礼, 赵瑜, 张倩, 周岩, 刘猛, 刘震. 基于微波技术的天然气管道内颗粒物在线检测方法研究[J]. 化工学报, 2023, 74(3): 1042-1053. |

| [9] | 周璇, 李孟亚, 孙杰, 岑振凯, 吕强三, 周立山, 王海涛, 韩丹丹, 龚俊波. 添加剂对氨基酸晶体生长的影响[J]. 化工学报, 2023, 74(2): 500-510. |

| [10] | 陈毓明, 历伟, 严翔, 王靖岱, 阳永荣. 初生态聚乙烯聚集态结构调控研究进展[J]. 化工学报, 2023, 74(2): 487-499. |

| [11] | 苏伟怡, 丁佳慧, 李春利, 王洪海, 姜艳军. 酶促反应结晶研究进展[J]. 化工学报, 2023, 74(2): 617-629. |

| [12] | 鲁统鹏, 潘晓林, 吴鸿飞, 李煜, 于海燕. 有机絮凝剂对铁矿相沉降性能影响及其吸附机理[J]. 化工学报, 2022, 73(9): 4122-4132. |

| [13] | 王永倩, 王平, 程康, 毛晨林, 刘文锋, 尹智成, Ferrante Antonio. 氨气/甲烷贫预混旋转湍流火焰稳定性及NO生成[J]. 化工学报, 2022, 73(9): 4087-4094. |

| [14] | 顾仁杰, 张加威, 靳雪阳, 文利雄. 微撞击流反应器制备镍钴复合氢氧化物超级电容器材料及其性能研究[J]. 化工学报, 2022, 73(8): 3749-3757. |

| [15] | 乃学瑛, 吴鹏, 程远, 肖剑飞, 刘鑫, 董亚萍. 水热生长碱式硫酸镁纳米线结晶动力学研究[J]. 化工学报, 2022, 73(7): 3038-3044. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号