化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2436-2446.DOI: 10.11949/0438-1157.20230440

李艳辉1,2( ), 丁邵明1, 白周央1, 张一楠1, 于智红1, 邢利梅1, 高鹏飞1, 王永贞2

), 丁邵明1, 白周央1, 张一楠1, 于智红1, 邢利梅1, 高鹏飞1, 王永贞2

收稿日期:2023-05-05

修回日期:2023-06-09

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

李艳辉

作者简介:李艳辉(1989—),男,博士,副教授,yhli19@sina.com

基金资助:

Yanhui LI1,2( ), Shaoming DING1, Zhouyang BAI1, Yinan ZHANG1, Zhihong YU1, Limei XING1, Pengfei GAO1, Yongzhen WANG2

), Shaoming DING1, Zhouyang BAI1, Yinan ZHANG1, Zhihong YU1, Limei XING1, Pengfei GAO1, Yongzhen WANG2

Received:2023-05-05

Revised:2023-06-09

Online:2023-06-05

Published:2023-07-27

Contact:

Yanhui LI

摘要:

深度频繁调峰超(超)临界火电机组燃煤锅炉将服役于温度频繁、大幅度多变的非常规条件,然而,依赖于某一恒定温度下连续暴露时间的传统腐蚀动力学模型无法适用于非常规服役锅炉的腐蚀预测及安全评估。从锅炉高温受热面管内(处于超临界水环境)腐蚀的原子/分子尺度过程出发,提出了适用于超(超)临界锅炉非常服役条件的低密度超临界水环境合金腐蚀微纳尺度动力学模型构建方法,以及该模型在宏观腐蚀数据拟合及微尺度腐蚀过程解析方面的多尺度应用途径;获得了典型材料T92钢的微纳尺度腐蚀动力学模型,建立了以温度和膜厚为自变量的微纳尺度氧化膜生长速率模型,并开展超期服役(已知腐蚀程度)、频繁变负荷(非恒定温度)等非常规服役条件下锅炉的腐蚀预测,可为灵活调峰火电机组安全保障技术的开发奠定基础。

中图分类号:

李艳辉, 丁邵明, 白周央, 张一楠, 于智红, 邢利梅, 高鹏飞, 王永贞. 非常规服役超临界锅炉的微纳尺度腐蚀动力学模型建立及应用[J]. 化工学报, 2023, 74(6): 2436-2446.

Yanhui LI, Shaoming DING, Zhouyang BAI, Yinan ZHANG, Zhihong YU, Limei XING, Pengfei GAO, Yongzhen WANG. Corrosion micro-nano scale kinetics model development and application in non-conventional supercritical boilers[J]. CIESC Journal, 2023, 74(6): 2436-2446.

图1 适用于超(超)临界火电机组的低密度超临界水体系金属腐蚀点缺陷模型vm — 基体原子空位;VMχ' — 阳离子空位;Miχ+ — 阳离子间隙;VÖ — 氧空位;OO —晶格氧;MM — 氧化膜晶格阳离子;MOχ/2/MOδ/2 — 膜阻挡层/外层氧化物;MOθ/2(d) — 膜外层氧化物溶解或者二次氧化产物

Fig.1 Point defect model of metal corrosion in supercritical water at low density for ultra-supercritical thermal power generationvm—vacancy in the metal substrate; VMχ'— cation vacancy; Miχ+—cation interstitial; VÖ —oxygen (anion) vacancy; OO—lattice oxygen within the oxides; MM—cation at the cation sublattice of oxides; MOχ/2/MOδ/2 —barrier / outer layer oxide; MOθ/2(d) — products by further oxidizing outer layer oxide

| 反应 | |||

|---|---|---|---|

| R i (i = 1, 2, 3) | |||

| R i (i = 4, 5, 6, 7, 8, 9) | 0 | 0 | 0 |

表1 9个原子/分子尺度界面反应速率常数的中间参数定义

Table 1 Definition of intermediate parameters for the rate constants of reactions at the 9 atomic/molecular scale interfaces

| 反应 | |||

|---|---|---|---|

| R i (i = 1, 2, 3) | |||

| R i (i = 4, 5, 6, 7, 8, 9) | 0 | 0 | 0 |

| 反应 | ||

|---|---|---|

| R i (i = 1,2,3) | ||

| R i (i = 4,5,6,7,8,9) |

表2 基本界面反应的标准速率常数与基础速率常数表达式

Table 2 Expressions for the standard rate constants and base rate constants for basic interfacial reactions

| 反应 | ||

|---|---|---|

| R i (i = 1,2,3) | ||

| R i (i = 4,5,6,7,8,9) |

| 符号 | 参数 | 数值 |

|---|---|---|

| T/℃ | 温度 | 600 |

| DO/(mg/L) | 溶解氧量 | 0.01 |

| pH | pH | 11 |

| 阻挡层/外层界面极化率 | 0.70 | |

| 传递系数 | 0.10 | |

| 基本速率常数 | 8.26×10-11 | |

| 基本速率常数 | 9.97×10-9 | |

| 基本速率常数 | 8.55×10-9 | |

| 阻挡层/环境界面处电势降对pH的依赖性 | -0.005 | |

| V/V | 等效腐蚀电位 | 0.76 |

| ε/(V/cm) | 膜内电场强度 | 128.20 |

| 阻挡层平均密度 | 4.97 | |

| 外层平均密度 | 5.04 | |

| PBR | 平均Pilling-Bedworth比率 | 2.08 |

| n、m、q、r | 界面反应对氧浓度的动力学级数 | 0.50 |

表3 600℃下T92钢氧化增重动力学模型优化所得基本参数

Table 3 Basic parameters obtained from the optimization of the kinetic model in mass gain for T92 steel at 600℃

| 符号 | 参数 | 数值 |

|---|---|---|

| T/℃ | 温度 | 600 |

| DO/(mg/L) | 溶解氧量 | 0.01 |

| pH | pH | 11 |

| 阻挡层/外层界面极化率 | 0.70 | |

| 传递系数 | 0.10 | |

| 基本速率常数 | 8.26×10-11 | |

| 基本速率常数 | 9.97×10-9 | |

| 基本速率常数 | 8.55×10-9 | |

| 阻挡层/环境界面处电势降对pH的依赖性 | -0.005 | |

| V/V | 等效腐蚀电位 | 0.76 |

| ε/(V/cm) | 膜内电场强度 | 128.20 |

| 阻挡层平均密度 | 4.97 | |

| 外层平均密度 | 5.04 | |

| PBR | 平均Pilling-Bedworth比率 | 2.08 |

| n、m、q、r | 界面反应对氧浓度的动力学级数 | 0.50 |

| 参数 | 工况 | ||||

|---|---|---|---|---|---|

| 500℃① | 600℃ | 650℃① | 700℃① | ||

| 宏观 拟合值① | 微观 计算值② | ||||

| P1/(mg/cm2) | 0.130 | 0.130 | 0.104 | 0.130 | 0.130 |

| P2/(mg/cm2) | -0.98 | -2.60 | -2.70 | -4.30 | -5.20 |

| P3/(mg/(cm2∙s)) | 4.98×10-7 | 6.92×10-6 | 6.81×10-6 | 2.06×10-5 | 3.97×10-5 |

| P4/(mg/(cm2∙s)) | 3.46×10-8 | 3.68×10-8 | 3.74×10-8 | 3.75×10-8 | 3.85×10-8 |

| P5/(mg/(cm2∙s)) | 5.41×10-7 | 7.22×10-6 | 7.38×10-6 | 2.23×10-5 | 4.31×10-5 |

| P6/(mg/(cm2∙s)) | 3.83×10-8 | 4.07×10-8 | 4.05×10-8 | 4.12×10-8 | 4.17×10-8 |

| P7/(mg/cm2) | -22.9 | -51.0 | -55.5 | -82.7 | -96.2 |

表4 500~700℃下T92钢氧化增重动力学模型中宏观参数取值

Table 4 Macroscopic parameter values of kinetic model in mass gain for T92 at 500—700℃

| 参数 | 工况 | ||||

|---|---|---|---|---|---|

| 500℃① | 600℃ | 650℃① | 700℃① | ||

| 宏观 拟合值① | 微观 计算值② | ||||

| P1/(mg/cm2) | 0.130 | 0.130 | 0.104 | 0.130 | 0.130 |

| P2/(mg/cm2) | -0.98 | -2.60 | -2.70 | -4.30 | -5.20 |

| P3/(mg/(cm2∙s)) | 4.98×10-7 | 6.92×10-6 | 6.81×10-6 | 2.06×10-5 | 3.97×10-5 |

| P4/(mg/(cm2∙s)) | 3.46×10-8 | 3.68×10-8 | 3.74×10-8 | 3.75×10-8 | 3.85×10-8 |

| P5/(mg/(cm2∙s)) | 5.41×10-7 | 7.22×10-6 | 7.38×10-6 | 2.23×10-5 | 4.31×10-5 |

| P6/(mg/(cm2∙s)) | 3.83×10-8 | 4.07×10-8 | 4.05×10-8 | 4.12×10-8 | 4.17×10-8 |

| P7/(mg/cm2) | -22.9 | -51.0 | -55.5 | -82.7 | -96.2 |

| 参数 | 关系式 |

|---|---|

| P1 | 1.30×10-4 |

| P2 | |

| P3 | |

| P4 | |

| P5 | |

| P6 | |

| P7 |

表5 直接拟合所得增重动力学模型中宏观参数对温度的依赖性

Table 5 The dependence of macroscopic parameters on temperature in the mass gain kinetic model obtained by direct fitting

| 参数 | 关系式 |

|---|---|

| P1 | 1.30×10-4 |

| P2 | |

| P3 | |

| P4 | |

| P5 | |

| P6 | |

| P7 |

| 参数 | 关系式 | 常数 |

|---|---|---|

| — | ||

| — | ||

| — | ||

| ε | — | |

| P1 | 1.04×10-4 | — |

| P2 | ||

| P3 | ||

| P4 | ||

| P5 | ||

| P6 | ||

| P7 | — |

表6 部分原子尺度反应速率常数及增重动力学模型中间参数P1~P7与温度的函数关系

Table 6 Atomic-scale reaction rate constants and intermediate parameters P1—P7 of the mass gain kinetic model as a function of temperature

| 参数 | 关系式 | 常数 |

|---|---|---|

| — | ||

| — | ||

| — | ||

| ε | — | |

| P1 | 1.04×10-4 | — |

| P2 | ||

| P3 | ||

| P4 | ||

| P5 | ||

| P6 | ||

| P7 | — |

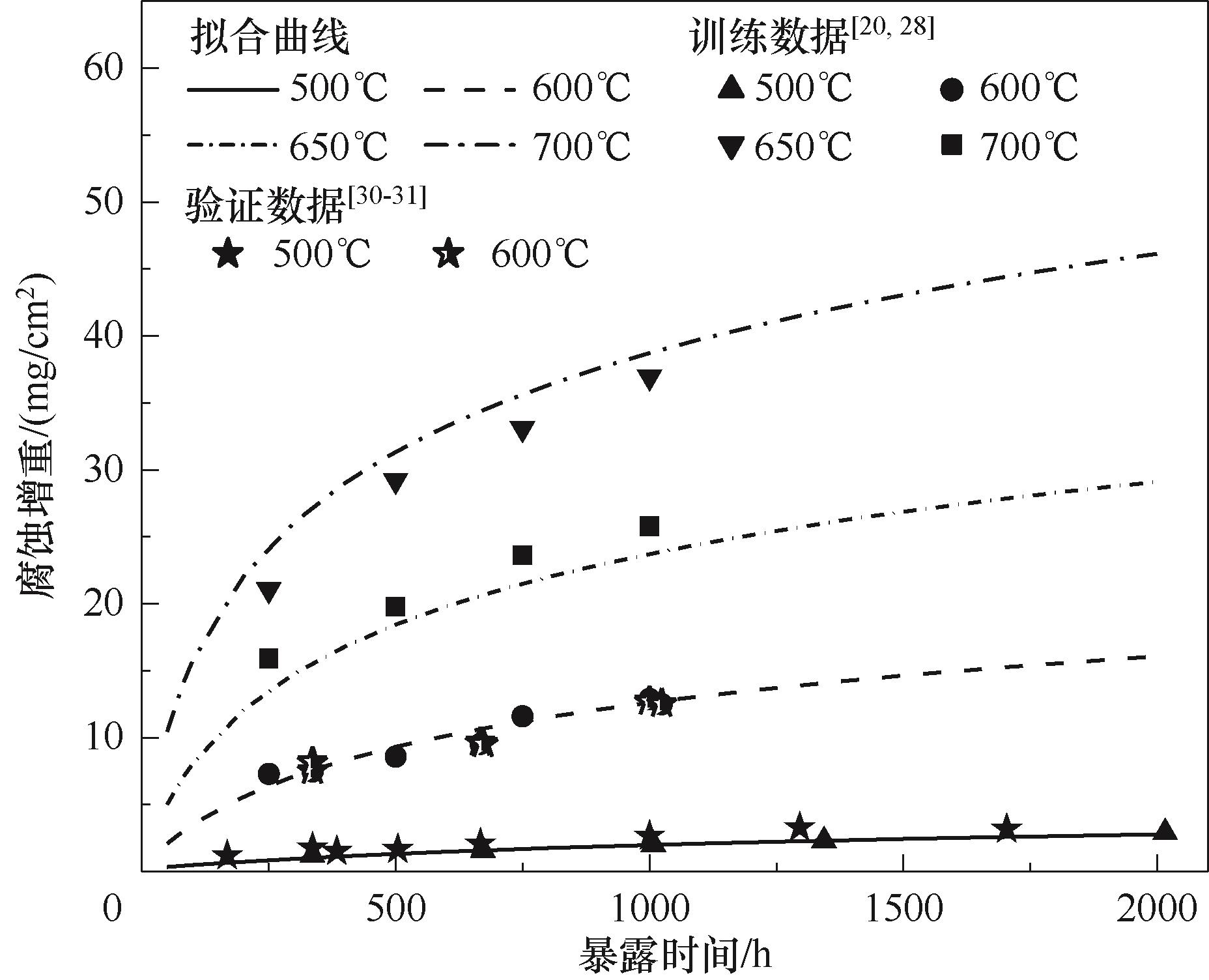

图5 基于腐蚀微纳尺度反应动力学的T92钢微纳尺度氧化增重模型的验证

Fig.5 Verification of the micro-nano scale oxidation mass gain model of steel T92 based on the kinetics of the micro-nano corrosion reactions

图6 面向具有一定腐蚀程度的在役或拟超期服役锅炉的腐蚀预测应用

Fig.6 Application of oxide film growth rate model for corrosion prediction for in-service or intended to be extended service boilers with certain degree of corrosion

| 1 | 谭增强, 王一坤, 牛拥军, 等. 双碳目标下煤电深度调峰及调频技术研究进展[J]. 热能动力工程, 2022, 37(8): 1-8. |

| Tan Z Q, Wang Y K, Niu Y J, et al. Research progress of deep peak regulation and frequency modulation technology for coal-fired power plant under double-carbon targets[J]. Journal of Engineering for Thermal Energy and Power, 2022, 37(8): 1-8. | |

| 2 | 周科, 何敏强, 牛田田, 等. 超临界660 MW褐煤锅炉深度调峰负荷水动力特性研究[J]. 热力发电, 2022, 51(9): 88-95. |

| Zhou K, He M Q, Niu T T, et al. Research on hydrodynamic characteristics at deep peak load regulation of 660 MW supercritical lignite boiler[J]. Thermal Power Generation, 2022, 51(9): 88-95. | |

| 3 | 吴鹏举, 朱超, 万李, 等. 超临界机组锅炉20%负荷深度调峰水动力实炉试验研究[J]. 热力发电, 2021, 50(4): 59-66. |

| Wu P J, Zhu C, Wan L, et al. Actual furnace test research on hydrodynamics of a supercritical boiler at 20% deep peak load[J]. Thermal Power Generation, 2021, 50(4): 59-66. | |

| 4 | 欧阳诗洁, 李娟, 董乐, 等. 超超临界锅炉低负荷运行时的流动不稳定性计算分析[J]. 西安交通大学学报, 2019, 53(7): 84-91. |

| Ouyang S J, Li J, Dong L, et al. Calculation and analysis on the flow instability of an ultra supercritical boiler under low load[J]. Journal of Xi'an Jiaotong University, 2019, 53(7): 84-91. | |

| 5 | 边彩霞, 周克毅, 朱正林, 等. 停机过程中锅炉高温受热面蒸汽侧氧化膜的应力分析[J]. 化工学报, 2013, 64(4): 1444-1452. |

| Bian C X, Zhou K Y, Zhu Z L, et al. Numerical analysis of stresses of steam-side oxide scales in boiler high-temperature heating surface in shutdown process[J]. CIESC Journal, 2013, 64(4): 1444-1452. | |

| 6 | 李海燕, 刘欢, 张秀菊, 等. HVOF喷涂用于提高锅炉换热面耐磨损耐腐蚀性能综述[J]. 化工学报, 2021, 72(4): 1833-1846. |

| Li H Y, Liu H, Zhang X J, et al. Summary of improving erosion and corrosion resistance of heat exchange surfaces in boilers through HVOF technology[J]. CIESC Journal, 2021, 72(4): 1833-1846. | |

| 7 | Gómez-Briceño D, Blázquez F, Sáez-Maderuelo A. Oxidation of austenitic and ferritic/martensitic alloys in supercritical water[J]. The Journal of Supercritical Fluids, 2013, 78: 103-113. |

| 8 | Guan X, MacDonald D D. Determination of corrosion mechanisms and estimation of electrochemical kinetics of metal corrosion in high subcritical and supercritical aqueous systems[J]. Corrosion, 2009, 65(6): 376-387. |

| 9 | Guzonas D A, Cook W G. Cycle chemistry and its effect on materials in a supercritical water-cooled reactor: a synthesis of current understanding[J]. Corrosion Science, 2012, 65: 48-66. |

| 10 | Kritzer P. Corrosion in high-temperature and supercritical water and aqueous solutions: a review[J]. The Journal of Supercritical Fluids, 2004, 29(1/2): 1-29. |

| 11 | Li Y H, Xu T T, Wang S Z, et al. Characterization of oxide scales formed on heating equipment in supercritical water gasification process for producing hydrogen[J]. International Journal of Hydrogen Energy, 2019, 44(56): 29508-29515. |

| 12 | MacDonald D D, Guan X. Volume of activation for the corrosion of type 304 stainless steel in high subcritical and supercritical aqueous systems[J]. Corrosion, 2009, 65(7): 427-437. |

| 13 | 沈朝, 汪家梅, 张乐福. 镍基合金C276在超临界水中的腐蚀行为[J]. 工程科学学报, 2016, 38(5): 706-713. |

| Shen Z, Wang J M, Zhang L F. Corrosion behavior of Ni-base alloy C276 in supercritical water[J]. Chinese Journal of Engineering, 2016, 38(5): 706-713. | |

| 14 | 张洁, 曲积钰, 卢金玲, 等. 亚临界/超临界水条件下镍基合金(Incoloy800, 825, 625)的硫化腐蚀特性研究[J]. 中国腐蚀与防护学报, 2021, 41(6): 892-898. |

| Zhang J, Qu J Y, Lu J L, et al. Sulfidation corrosion behavior of nickel-based alloys(Incoloy800, 825 and 625) in sub/supercritical water[J]. Journal of Chinese Society for Corrosion and Protection, 2021, 41(6): 892-898. | |

| 15 | Zhang N Q, Yue G Q, Lv F B, et al. Oxidation of low-alloy steel in high temperature steam and supercritical water[J]. Materials at High Temperatures, 2017, 34(3): 222-228. |

| 16 | Li Y H, Wang S Z, Sun P P, et al. Early oxidation mechanism of austenitic stainless steel TP347H in supercritical water[J]. Corrosion Science, 2017, 128: 241-252. |

| 17 | Zhu Z L, Xu H, Jiang D F, et al. Influence of temperature on the oxidation behaviour of a ferritic-martensitic steel in supercritical water[J]. Corrosion Science, 2016, 113: 172-179. |

| 18 | Li Y H, Wang S Z, Sun P P, et al. Investigation on early formation and evolution of oxide scales on ferritic-martensitic steels in supercritical water[J]. Corrosion Science, 2018, 135: 136-146. |

| 19 | Zhu Z L, Xu H, Jiang D F, et al. Temperature dependence of oxidation behaviour of a ferritic-martensitic steel in supercritical water at 600—700℃[J]. Oxidation of Metals, 2016, 86(5/6): 483-496. |

| 20 | Bischoff J, Motta A T. Oxidation behavior of ferritic-martensitic and ODS steels in supercritical water[J]. Journal of Nuclear Materials, 2012, 424(1/2/3): 261-276. |

| 21 | Fromhold A T J, Fromhold R G. Chapter 1: an overview of metal oxidation theory[M]//Reactions of Solids with Gases. Amsterdam: Elsevier, 1984: 1-117. |

| 22 | Atkinson A. Transport processes during the growth of oxide films at elevated temperature[J]. Reviews of Modern Physics, 1985, 57(2): 437-470. |

| 23 | Li Y H, Wang S Z, Xu T T, et al. Novel designs for the reliability and safety of supercritical water oxidation process for sludge treatment[J]. Process Safety and Environmental Protection, 2021, 149: 385-398. |

| 24 | Li Y H, MacDonald D D, Yang J, et al. Point defect model for the corrosion of steels in supercritical water(part Ⅰ): Film growth kinetics[J]. Corrosion Science, 2020, 163: 108280. |

| 25 | Li Y H, Xu T T, Wang S Z, et al. Predictions and analyses on the growth behavior of oxide scales formed on ferritic-martensitic in supercritical water[J]. Oxidation of Metals, 2019, 92(1/2): 27-48. |

| 26 | 王起江, 洪杰, 徐松乾, 等. 超超临界电站锅炉用关键材料[J]. 北京科技大学学报, 2012, 34(S1): 26-33. |

| Wang Q J, Hong J, Xu S Q, et al. Key materials used in ultra-supercritical power station boilers[J]. Journal of University of Science and Technology Beijing, 2012, 34(S1): 26-33. | |

| 27 | 于鸿垚, 迟成宇, 董建新, 等. 650℃长期时效过程中Super304H耐热不锈钢组织的演变[J]. 北京科技大学学报, 2010, 32(7): 877-882. |

| Yu H Y, Chi C Y, Dong J X, et al. Microstructural evolution of heat-resistant steel Super304H during 650℃ long term aging[J]. Journal of University of Science and Technology Beijing, 2010, 32(7): 877-882. | |

| 28 | Dudziak T, Łukaszewicz M, Simms N, et al. Analysis of high temperature steam oxidation of superheater steels used in coal fired boilers[J]. Oxidation of Metals, 2016, 85(1): 171-187. |

| 29 | 尹开锯, 邱绍宇, 唐睿, 等. 铁素体-马氏体钢P91和P92在超临界水中腐蚀后氧化膜多孔性分析[J]. 中国腐蚀与防护学报, 2010, 30(1): 1-5. |

| Yin K J, Qiu S Y, Tang R, et al. Characterization of the porosity of the oxide scales on ferritic-martensitic steel P91 and P92 exposed in supercritical water[J]. Journal of Chinese Society for Corrosion and Protection, 2010, 30(1): 1-5. | |

| 30 | Tan L, Ren X, Allen T R. Corrosion behavior of 9%—12% Cr ferritic-martensitic steels in supercritical water[J]. Corrosion Science, 2010, 52(4): 1520-1528. |

| 31 | Was G S, Ampornrat P, Gupta G, et al. Corrosion and stress corrosion cracking in supercritical water[J]. Journal of Nuclear Materials, 2007, 371(1/2/3): 176-201. |

| [1] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [2] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [3] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [4] | 史昊鹏, 钟达文, 廉学新, 张君峰. 朝下多尺度沟槽翅片结构表面沸腾换热实验研究[J]. 化工学报, 2023, 74(7): 2880-2888. |

| [5] | 董明, 徐进良, 刘广林. 超临界水非均质特性分子动力学研究[J]. 化工学报, 2023, 74(7): 2836-2847. |

| [6] | 王承泽, 顾凯丽, 张晋华, 石建轩, 刘艺娓, 李锦祥. 硫化协同老化零价铁增效去除水中Cr(Ⅵ)的作用机制[J]. 化工学报, 2023, 74(5): 2197-2206. |

| [7] | 郑杰元, 张先伟, 万金涛, 范宏. 丁香酚环氧有机硅树脂的制备及其固化动力学研究[J]. 化工学报, 2023, 74(2): 924-932. |

| [8] | 周桓, 张梦丽, 郝晴, 吴思, 李杰, 徐存兵. 硫酸镁型光卤石转化钾盐镁矾的过程机制与动态规律[J]. 化工学报, 2022, 73(9): 3841-3850. |

| [9] | 马语峻, 刘向军. 多孔陶瓷膜烟气水分回收理论与模型研究[J]. 化工学报, 2022, 73(9): 4103-4112. |

| [10] | 戚新刚, 路利波, 陈渝楠, 葛志伟, 郭烈锦. 造纸黑液超临界水气化制氢与高附加值化学品回收研究进展[J]. 化工学报, 2022, 73(8): 3338-3354. |

| [11] | 王沛, 魏荣阔. 光热驱动多孔氧化铈热化学循环解水制氢非热质平衡模型[J]. 化工学报, 2022, 73(7): 2885-2894. |

| [12] | 刘伟, 孙彦. β-淀粉样蛋白的聚集及其调控[J]. 化工学报, 2022, 73(6): 2381-2396. |

| [13] | 胡善伟, 刘新华. 气固流化系统多尺度跨流域EMMS建模[J]. 化工学报, 2022, 73(6): 2514-2528. |

| [14] | 钱宇, 陈耀熙, 史晓斐, 杨思宇. 太阳能波动特性大数据分析与风光互补耦合制氢系统集成[J]. 化工学报, 2022, 73(5): 2101-2110. |

| [15] | 黄志豪, 李光熙, 唐桂华, 李小龙, 范元鸿. 单侧加热方形通道内超临界水传热研究[J]. 化工学报, 2022, 73(4): 1523-1533. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号