化工学报 ›› 2024, Vol. 75 ›› Issue (10): 3557-3567.DOI: 10.11949/0438-1157.20240420

从文杰1( ), 黄嘉雯1, 范小强1,2(

), 黄嘉雯1, 范小强1,2( ), 杨遥1,3, 王靖岱1,3, 阳永荣1,3

), 杨遥1,3, 王靖岱1,3, 阳永荣1,3

收稿日期:2024-04-16

修回日期:2024-05-23

出版日期:2024-10-25

发布日期:2024-11-04

通讯作者:

范小强

作者简介:从文杰(1999—),男,硕士研究生,22128056@zju.edu.cn

基金资助:

Wenjie CONG1( ), Jiawen HUANG1, Xiaoqiang FAN1,2(

), Jiawen HUANG1, Xiaoqiang FAN1,2( ), Yao YANG1,3, Jingdai WANG1,3, Yongrong YANG1,3

), Yao YANG1,3, Jingdai WANG1,3, Yongrong YANG1,3

Received:2024-04-16

Revised:2024-05-23

Online:2024-10-25

Published:2024-11-04

Contact:

Xiaoqiang FAN

摘要:

高压管式反应器是生产低密度聚乙烯(LDPE)和乙烯-醋酸乙烯酯共聚物(EVA)等产品的重要装备。高压聚合反应条件苛刻,高压管式反应器的设计不仅要满足聚合反应工艺要求,还要满足装备的机械强度和疲劳寿命要求。以高压法LDPE管式反应器为研究对象提出了管式反应器结构的两步法优化策略,首先根据超高压容器标准确定反应器的管径比要求,并基于管式反应器的详细模型计算引发剂配方对管式反应器升温速率的影响规律,然后以单位转化率下的年度总费用作为目标函数,采用遗传算法优化得到反应器的管径、分区长度等结构参数。所提出的管式反应器的结构优化方法具有较高的准确性,可为高压法LDPE管式反应器的优化设计和技术改造提供理论指导。

中图分类号:

从文杰, 黄嘉雯, 范小强, 杨遥, 王靖岱, 阳永荣. 高压法LDPE管式反应器的结构优化方法[J]. 化工学报, 2024, 75(10): 3557-3567.

Wenjie CONG, Jiawen HUANG, Xiaoqiang FAN, Yao YANG, Jingdai WANG, Yongrong YANG. Structure optimization method for high-pressure LDPE tubular reactor[J]. CIESC Journal, 2024, 75(10): 3557-3567.

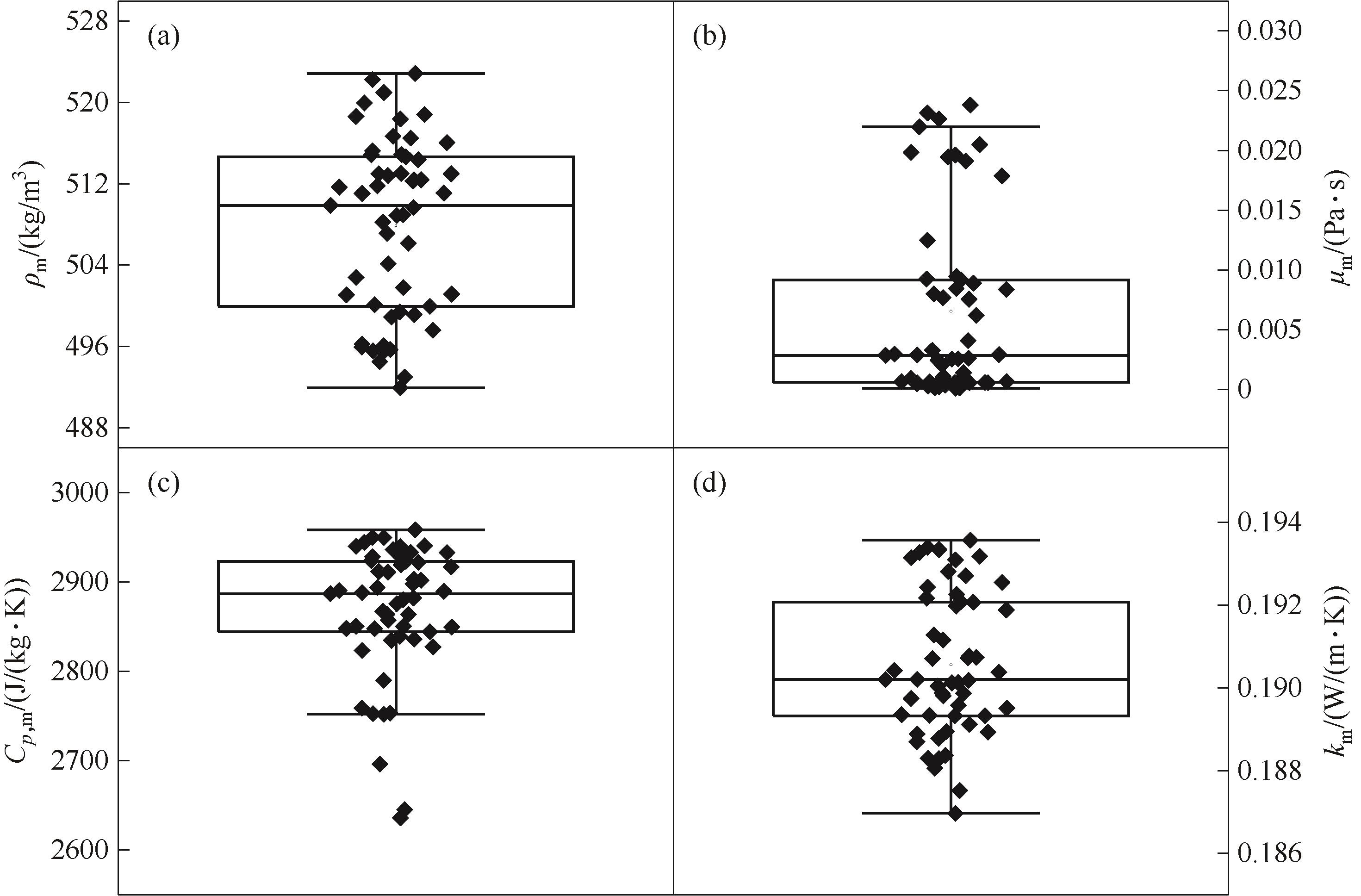

图2 混合物料物性在反应器内的分布:(a)密度;(b)黏度;(c)比定压热容;(d)热导率

Fig.2 Variation of properties of mixed feedstock in LDPE tubular reactor: (a) density; (b) viscosity; (c) specific heat at constant pressure; (d) thermal conductivity

| 参数 | DTBP∶TBPB∶TBPEH(摩尔比) | ||

|---|---|---|---|

| 1∶1∶1 | 1∶2∶2 | 1∶2∶4 | |

| 引发剂用量指数 | 1.000 | 1.327 | 1.762 |

| 乙烯摩尔转化率 | 0.30 | 0.30 | 0.30 |

表1 引发剂配比对乙烯转化率和引发剂用量的影响

Table 1 Effect of initiator’s formula on ethylene conversion and consumption of initiator

| 参数 | DTBP∶TBPB∶TBPEH(摩尔比) | ||

|---|---|---|---|

| 1∶1∶1 | 1∶2∶2 | 1∶2∶4 | |

| 引发剂用量指数 | 1.000 | 1.327 | 1.762 |

| 乙烯摩尔转化率 | 0.30 | 0.30 | 0.30 |

| 参数 | 数值 |

|---|---|

| 工业用电费用pe /(CNY/(kW·h)) | 0.95 |

| 反应器运行时间t/h | 7200 |

| 反应管费用系数Cr | 3 |

| 反应管密度ρr /(kg/m3) | 7900 |

| 压缩机进口压力p1,出口压力p2 /bar | 300,3000 |

表2 目标函数中的主要参数及取值

Table 2 Main parameters and values in the objective function

| 参数 | 数值 |

|---|---|

| 工业用电费用pe /(CNY/(kW·h)) | 0.95 |

| 反应器运行时间t/h | 7200 |

| 反应管费用系数Cr | 3 |

| 反应管密度ρr /(kg/m3) | 7900 |

| 压缩机进口压力p1,出口压力p2 /bar | 300,3000 |

| 基元反应 | 化学方程式 |

|---|---|

| 引发剂分解(链引发) | |

| 链增长 | |

| 耦合终止 | |

| 歧化终止 | |

| 链转移至单体 | |

| 链转移至聚合物 | |

| 链转移至链转移剂 | |

| β裂解 | |

| 链间转移 |

表3 自由基聚合的基元反应[31]

Table 3 Elementary reactions of free radical polymerization[31]

| 基元反应 | 化学方程式 |

|---|---|

| 引发剂分解(链引发) | |

| 链增长 | |

| 耦合终止 | |

| 歧化终止 | |

| 链转移至单体 | |

| 链转移至聚合物 | |

| 链转移至链转移剂 | |

| β裂解 | |

| 链间转移 |

| 基元反应 | 速率常数 | k0/(L/(mol·s)) | (Ea/R)/K | Va/(cm3/mol) |

|---|---|---|---|---|

| DTBP分解 | kDTBP | 2.00×1016 | 19846 | 10 |

| TBPB分解 | kTBPB | 2.23×1016 | 18233 | 0 |

| TBPEH分解 | kTBPEH | 1.63×1014 | 15167 | 4.9 |

| 链增长 | kp | 1.25×108 | 4061 | -19.7 |

| 链终止 | ktc= ktd | 1.25×109 | 503 | 13 |

| 链转移至单体 | ktm | 1.25×105 | 4061 | -19.7 |

| 链转移至聚合物 | ktp | 4.38×108 | 6606 | 4.4 |

| 链转移至链转移剂 | ktra | 2.62×107 | 5973 | -19.5 |

| β裂解 | kβ | 1.292×107 s-1 | 5671 | -16.8 |

| 链间转移 | kbb | 7.8×108 s-1 | 5319 | -15.9 |

表4 引发剂分解及乙烯均聚动力学参数[31]

Table 4 Kinetic rate constants for initiator decomposition and ethylene homopolymerization[31]

| 基元反应 | 速率常数 | k0/(L/(mol·s)) | (Ea/R)/K | Va/(cm3/mol) |

|---|---|---|---|---|

| DTBP分解 | kDTBP | 2.00×1016 | 19846 | 10 |

| TBPB分解 | kTBPB | 2.23×1016 | 18233 | 0 |

| TBPEH分解 | kTBPEH | 1.63×1014 | 15167 | 4.9 |

| 链增长 | kp | 1.25×108 | 4061 | -19.7 |

| 链终止 | ktc= ktd | 1.25×109 | 503 | 13 |

| 链转移至单体 | ktm | 1.25×105 | 4061 | -19.7 |

| 链转移至聚合物 | ktp | 4.38×108 | 6606 | 4.4 |

| 链转移至链转移剂 | ktra | 2.62×107 | 5973 | -19.5 |

| β裂解 | kβ | 1.292×107 s-1 | 5671 | -16.8 |

| 链间转移 | kbb | 7.8×108 s-1 | 5319 | -15.9 |

| 参数 | 数值 |

|---|---|

| 进料温度Tin /℃ | 170~180 |

| 温度上升速率ΔTup /(℃/m) | 0.5~2.0 |

| 冷却水温度tin /℃ | 160~170 |

| 进料压力pin /MPa | 200~300 |

| 反应器内径di /m | 0.056 |

| 物料密度ρm /(kg/m3) | 510 |

| 物料比热容cp,m /(kJ/(kg·K)) | 2.88 |

| 物料热导率km/(W/(m·K)) | 0.19 |

| 物料黏度μm | 式(1) |

| 反应器段数n | 4 |

表5 物性参数和反应器参数

Table 5 Physical and reactor parameters

| 参数 | 数值 |

|---|---|

| 进料温度Tin /℃ | 170~180 |

| 温度上升速率ΔTup /(℃/m) | 0.5~2.0 |

| 冷却水温度tin /℃ | 160~170 |

| 进料压力pin /MPa | 200~300 |

| 反应器内径di /m | 0.056 |

| 物料密度ρm /(kg/m3) | 510 |

| 物料比热容cp,m /(kJ/(kg·K)) | 2.88 |

| 物料热导率km/(W/(m·K)) | 0.19 |

| 物料黏度μm | 式(1) |

| 反应器段数n | 4 |

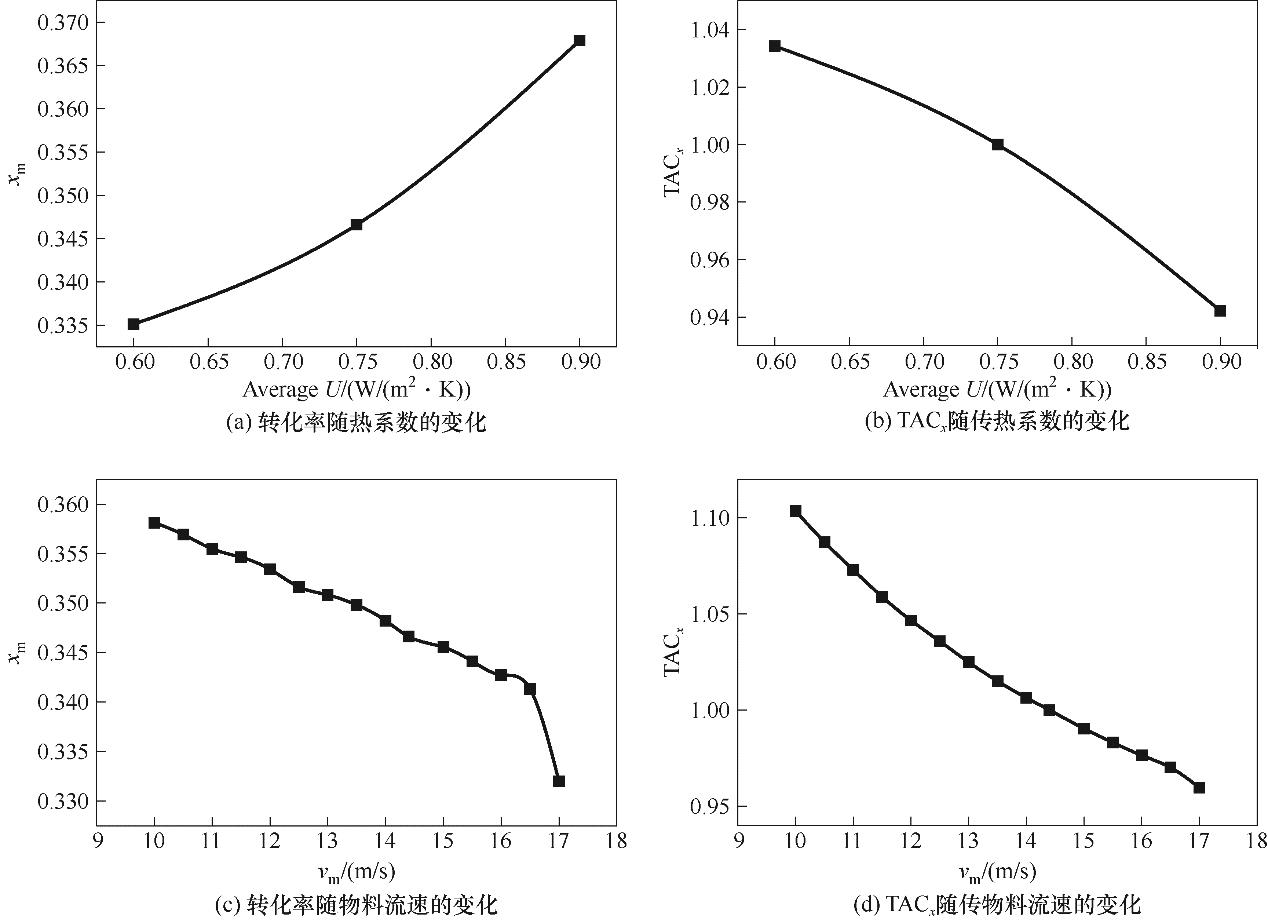

图9 (a)转化率随传热系数的变化;(b)TAC x 随传热系数的变化;(c)转化率随物料流速的变化;(d)TAC x 随物料流速的变化

Fig.9 (a) Variation of conversion rate with heat transfer coefficient; (b) Variation of TAC x with heat transfer coefficient; (c) Variation of conversion rate with flow rate; (d) Variation of TAC x with flow rate

| 项目 | 转化率/% | 总长度/m | 第一反应区 长度/m | 第一冷却区 长度/m |

|---|---|---|---|---|

| 设计值 | 34.0 | 1772 | 118 | 391 |

| 工业值 | 34.0 | 1800 | 120~160 | 400~460 |

表6 管式反应器结构设计值与工业值的比较

Table 6 Comparison between design values and industrial values of tubular reactor structures

| 项目 | 转化率/% | 总长度/m | 第一反应区 长度/m | 第一冷却区 长度/m |

|---|---|---|---|---|

| 设计值 | 34.0 | 1772 | 118 | 391 |

| 工业值 | 34.0 | 1800 | 120~160 | 400~460 |

| 1 | Mummudi Boopathy M B. A comprehensive dynamic model for high-pressure tubular low-density polyethylene (LDPE) reactors[D]. Ann Arbor: Iowa State University, 2006. |

| 2 | Katz S, Saidel G M. Moments of the size distribution in radical polymerization[J]. AIChE Journal, 1967, 13(2): 319-326. |

| 3 | Ehrlich P, Mortimer G A. Fundamentals of the free-radical polymerization of ethylene[M]// Advances in Polymer Science. Berlin/Heidelberg: Springer-Verlag, 2006: 386-448. |

| 4 | Hollar W, Ehrlich P. An improved model for temperature and conversion profiles in tubular high pressure polyethylene reactors[J]. Chemical Engineering Communications, 1983, 24(1/2/3): 57-70. |

| 5 | Azmi A, Aziz N. Effect of initiator concentration to low-density polyethylene production in a tubular reactor[J]. IOP Conference Series: Materials Science and Engineering, 2016, 162(1): 012023. |

| 6 | Small P A. The effects of crosslinking and chain scission on molecular weight distributions[J]. Journal of Polymer Science, 1955, 18(89): 431-435. |

| 7 | Scanlan J. Molecular weight distribution functions in random reactions of polymers[J]. Transactions of the Faraday Society, 1956, 52: 1286. |

| 8 | Asteasuain M, Brandolin A. Mathematical modeling of bivariate polymer property distributions using 2D probability generating functions. 1.Numerical inversion methods[J]. Macromolecular Theory and Simulations, 2010, 19(6): 342-359. |

| 9 | Dietrich M L, Sarmoria C, Brandolin A, et al. LDPE production in tubular reactors: comprehensive model for the prediction of the joint molecular weight-short (long) chain branching distributions[J]. Industrial & Engineering Chemistry Research, 2019, 58(11): 4412-4424. |

| 10 | Lu J M, Zhang H D, Yang Y L. Monte Carlo simulation of kinetics and chain-length distribution in radical polymerization[J]. Macromolecular Theory and Simulations, 1993, 2(5): 747-760. |

| 11 | Tobita H. Molecular weight distribution in free radical polymerization with long-chain branching[J]. Journal of Polymer Science Part B: Polymer Physics, 1993, 31(10): 1363-1371. |

| 12 | Kim D M, Busch M, Hoefsloot H C J, et al. Molecular weight distribution modeling in low-density polyethylene polymerization; impact of scission mechanisms in the case of CSTR[J]. Chemical Engineering Science, 2004, 59(3): 699-718. |

| 13 | Meimaroglou D, Kiparissides C. A novel stochastic approach for the prediction of the exact topological characteristics and rheological properties of highly-branched polymer chains[J]. Macromolecules, 2010, 43(13): 5820-5832. |

| 14 | Kiparissides C, Krallis A, Meimaroglou D, et al. From molecular to plant-scale modeling of polymerization processes: a digital high-pressure low-density polyethylene production paradigm[J]. Chemical Engineering & Technology, 2010, 33(11): 1754-1766. |

| 15 | Neuhaus E, Herrmann T, Vittorias I, et al. Modeling the polymeric microstructure of LDPE in tubular and autoclave reactors with a coupled deterministic and stochastic simulation approach[J]. Macromolecular Theory and Simulations, 2014, 23(7): 415-428. |

| 16 | Pladis P, Meimaroglou D, Kiparissides C. Prediction of the viscoelastic behavior of low-density polyethylene produced in high-pressure tubular reactors[J]. Macromolecular Reaction Engineering, 2015, 9(3): 271-284. |

| 17 | Wang J, Ren Y, Yang Y, et al. A graph theory assisted Monte Carlo algorithm for simulating the topology structure of LDPE and connection with molecular dynamics simulation[J]. AIChE Journal, 2023, 69(8): e18111. |

| 18 | Terrazas-Moreno S, Flores-Tlacuahuac A, Grossmann I E. Simultaneous design, scheduling, and optimal control of a methyl-methacrylate continuous polymerization reactor[J]. AIChE Journal, 2008, 54(12): 3160-3170. |

| 19 | Tobita H. Model-based reactor design in free-radical polymerization with simultaneous long-chain branching and scission[J]. Processes, 2015, 3(4): 731-748. |

| 20 | 李晓霞, 吴黎涛. 流化床聚合反应器分布器设计[J]. 石油化工设备技术, 2021, 42(3): 11-13. |

| Li X X, Wu L T. Design of gas distributor in fluidized bed polymerization reactor[J]. Petrochemical Equipment Technology, 2021, 42(3): 11-13. | |

| 21 | 张雷鸣, 王靖岱, 阳永荣. 高压法聚乙烯管式反应器的数学模拟[J]. 浙江大学学报(工学版), 2011, 45(3): 551-556, 570. |

| Zhang L M, Wang J D, Yang Y R. Mathematical modeling of a high-pressure ethylene polymerization tubular reactor[J]. Journal of Zhejiang University (Engineering Science), 2011, 45(3): 551-556, 570. | |

| 22 | Donati G, Marini L, Marziano G, et al. Mathematical model of low density polyethylene tubular reactor[M]//ACS Symposium Series. Washington, D C: American Chemical Society, 1982: 579-590. |

| 23 | Yoon B J, Rhee H K. A study of the high pressure polyethylene tubular reactor[J]. Chemical Engineering Communications, 1985, 34(1/2/3/4/5/6): 253-265. |

| 24 | Buchelli A, Call M L, Brown A L, et al. Modeling fouling effects in LDPE tubular polymerization reactors. 1. Fouling thickness determination[J]. Industrial & Engineering Chemistry Research, 2005, 44(5): 1474-1479. |

| 25 | 冯霄, 何潮洪. 化工原理-下册[M]. 2版. 北京: 科学出版社, 2007. |

| Feng X, He C H. Principles of Chemical Engineering-volume Ⅱ[M]. 2nd ed. Beijing: Science Press, 2007. | |

| 26 | 中国特种设备检测研究院, 浙江大学, 锅容标技术服务中心有限公司, 等. 超高压容器: [S]. 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会, 2017: 88. |

| China Special Equipment Inspection and Research Institute, Zhejiang University, Guorong Standard Technical Service Center Co., Ltd., et al. Ultra high pressure vessel: [S]. State Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, China National Standardization Administration, 2017: 88. | |

| 27 | Egloff G, Schaad R. Polymerization and explosive decomposition of ethylene under pressure [J]. Journal of Petroleum Technology, 1933, 19: 800. |

| 28 | Zhang S X, Read N K, Ray W H. Runaway phenomena in low-density polyethylene autoclave reactors[J]. AIChE Journal, 1996, 42(10): 2911-2925. |

| 29 | Joule J P, Thomson W. ⅬⅩⅩⅥ. On the thermal effects experienced by air in rushing through small apertures[J]. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1852, 4(28): 481-492. |

| 30 | 郁永章, 姜培正, 孙嗣莹. 压缩机工程手册[M]. 北京: 中国石化出版社, 2012. |

| Yu Y Z, Jiang P Z, Sun S Y. Compressor Engineering Manual[M]. Beijing: China Petrochemical Press, 2012. | |

| 31 | Pladis P, Kiparissides C. 110th anniversary: nonideal mixing phenomena in high-pressure low-density polyethylene autoclaves: prediction of variable initiator efficiency and ethylene decomposition[J]. Industrial & Engineering Chemistry Research, 2019, 58(29): 13093-13111. |

| 32 | Chen C H, Vermeychuk J G, Howell J A, et al. Computer model for tubular high-pressure polyethylene reactors[J]. AIChE Journal, 1976, 22(3): 463-471. |

| [1] | 张丽萍, 孟晓荣, 宋锦峰, 杜金晶. VO2@KH550/570@PS复合薄膜的制备及其热致相变性能[J]. 化工学报, 2024, 75(9): 3348-3359. |

| [2] | 李彦熹, 王晔春, 谢向东, 王进芝, 王江, 周煜, 潘盈秀, 丁文涛, 郭烈锦. 蜗壳式多通道气液旋流分离器结构优化及分离特性研究[J]. 化工学报, 2024, 75(8): 2875-2885. |

| [3] | 杜海燕, 朱凯, 游峰, 王金凤, 赵一帆, 张楠, 李英. 用于应变传感器的自愈合抗冻离子水凝胶[J]. 化工学报, 2024, 75(7): 2709-2722. |

| [4] | 黄志鸿, 周利, 柴士阳, 吉旭. 耦合加氢装置优化的多周期氢网络集成[J]. 化工学报, 2024, 75(5): 1951-1965. |

| [5] | 王瑞瑞, 金颖, 刘玉梅, 李梦悦, 朱胜文, 闫瑞一, 刘瑞霞. 聚合离子液体设计及催化环己烷选择性氧化性能研究[J]. 化工学报, 2024, 75(4): 1552-1564. |

| [6] | 程骁恺, 历伟, 王靖岱, 阳永荣. 镍催化可控/活性自由基聚合反应研究进展[J]. 化工学报, 2024, 75(4): 1105-1117. |

| [7] | 张文惠, 唐茹意, 崔希利, 邢华斌. 羧酸端基Y型全氟聚醚的氟谱解析及结构表征[J]. 化工学报, 2024, 75(4): 1718-1723. |

| [8] | 肖扬可, 常印龙, 李平, 王文俊, 李伯耿, 刘平伟. 动态化学交联聚烯烃类弹性体研究进展[J]. 化工学报, 2024, 75(4): 1394-1413. |

| [9] | 刘静, 杨文博, 吕英迪, 陶胜洋. 喷雾-反溶剂结晶法制备掺杂铝粉的复合微球[J]. 化工学报, 2024, 75(4): 1724-1734. |

| [10] | 吴立盛, 刘杰, 王添添, 罗正鸿, 周寅宁. 开环易位烯烃聚合物的动态交联改性研究进展[J]. 化工学报, 2024, 75(4): 1118-1136. |

| [11] | 何宇航, 谢丹, 吕阳成. 微反应器内阳离子聚合研究进展[J]. 化工学报, 2024, 75(4): 1302-1316. |

| [12] | 潘娜, 田昌, 怀兰坤, 刘玉玉, 张芬芬, 高晓梅, 刘伟, 闫良国, 赵艳侠. 聚合铝钛基絮凝剂的合成与应用[J]. 化工学报, 2024, 75(3): 1009-1018. |

| [13] | 成文凯, 颜金钰, 王嘉骏, 冯连芳. 卧式捏合反应器及其在聚合工业中的研究进展[J]. 化工学报, 2024, 75(3): 768-781. |

| [14] | 邢雷, 关帅, 蒋明虎, 赵立新, 蔡萌, 刘海龙, 陈德海. 高气液比井下气液旋流分离器结构设计与性能分析[J]. 化工学报, 2024, 75(3): 900-913. |

| [15] | 陈彦松, 阮达, 刘渊博, 郑通, 张帅帅, 马学虎. 微通道换热器拓扑结构优化与性能研究[J]. 化工学报, 2024, 75(3): 823-835. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号