化工学报 ›› 2024, Vol. 75 ›› Issue (4): 1302-1316.DOI: 10.11949/0438-1157.20231117

收稿日期:2023-10-30

修回日期:2023-12-27

出版日期:2024-04-25

发布日期:2024-06-06

通讯作者:

吕阳成

作者简介:何宇航(1996—),男,博士研究生,heyh19@mails.tsinghua.edu.cn

基金资助:

Yuhang HE( ), Dan XIE, Yangcheng LYU(

), Dan XIE, Yangcheng LYU( )

)

Received:2023-10-30

Revised:2023-12-27

Online:2024-04-25

Published:2024-06-06

Contact:

Yangcheng LYU

摘要:

阳离子聚合是制备高分子材料的重要方法之一。因阳离子聚合反应活性高、可控性差,采用传统的方式对其进行深入研究难度往往很大。微反应器技术因其优异的过程控制能力在阳离子聚合研究中表现出得天独厚的优势。本文介绍了微反应器内传统阳离子聚合和活性阳离子聚合的研究进展,论述了微反应器对提高异丁烯、乙烯基醚类单体阳离子聚合反应可控性、反应效率以及机理研究的重要作用,探讨了阳离子聚合体系和装备理性设计的方向。

中图分类号:

何宇航, 谢丹, 吕阳成. 微反应器内阳离子聚合研究进展[J]. 化工学报, 2024, 75(4): 1302-1316.

Yuhang HE, Dan XIE, Yangcheng LYU. Research progress of cationic polymerization in microreactor[J]. CIESC Journal, 2024, 75(4): 1302-1316.

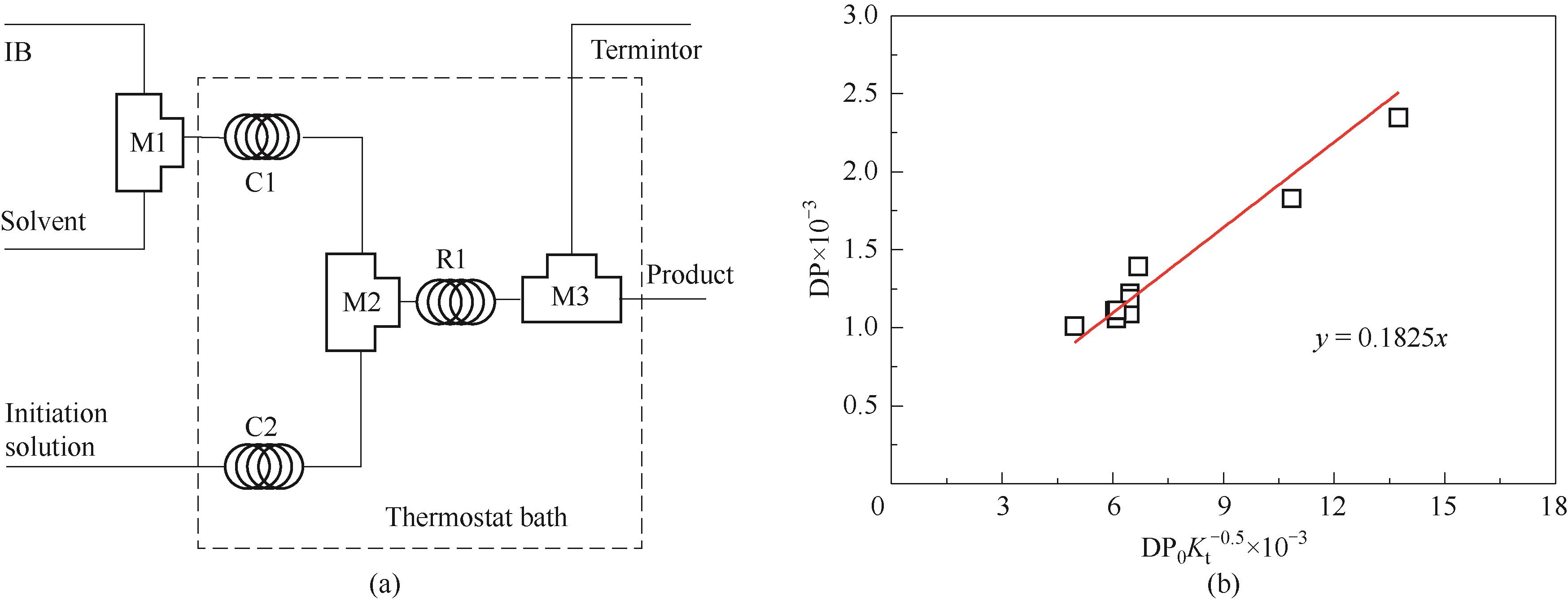

图1 (a)流动合成平台示意图(M1、M2和M3为微型混合器的三通;C1和C2是用于达到预设温度的弯曲管;R1是微管反应器);(b)引发体系组成与产品聚合度的定量关系[F(IB+IP) + F(CH2Cl2) = 8 ml/min, F(引发剂) = 8 ml/min][57]

Fig.1 (a) Schematic diagram of flow synthesis setup (M1, M2 and M3 are tees for micromixers; C1 and C2 are curved tubes for achieving the pre-set temperature; R1 is the microtube reactor); (b) Effect of the reaction system composition on DP[F(IB+IP) + F(CH2Cl2) = 8 ml/min, F(initiator) = 8 ml/min][57]

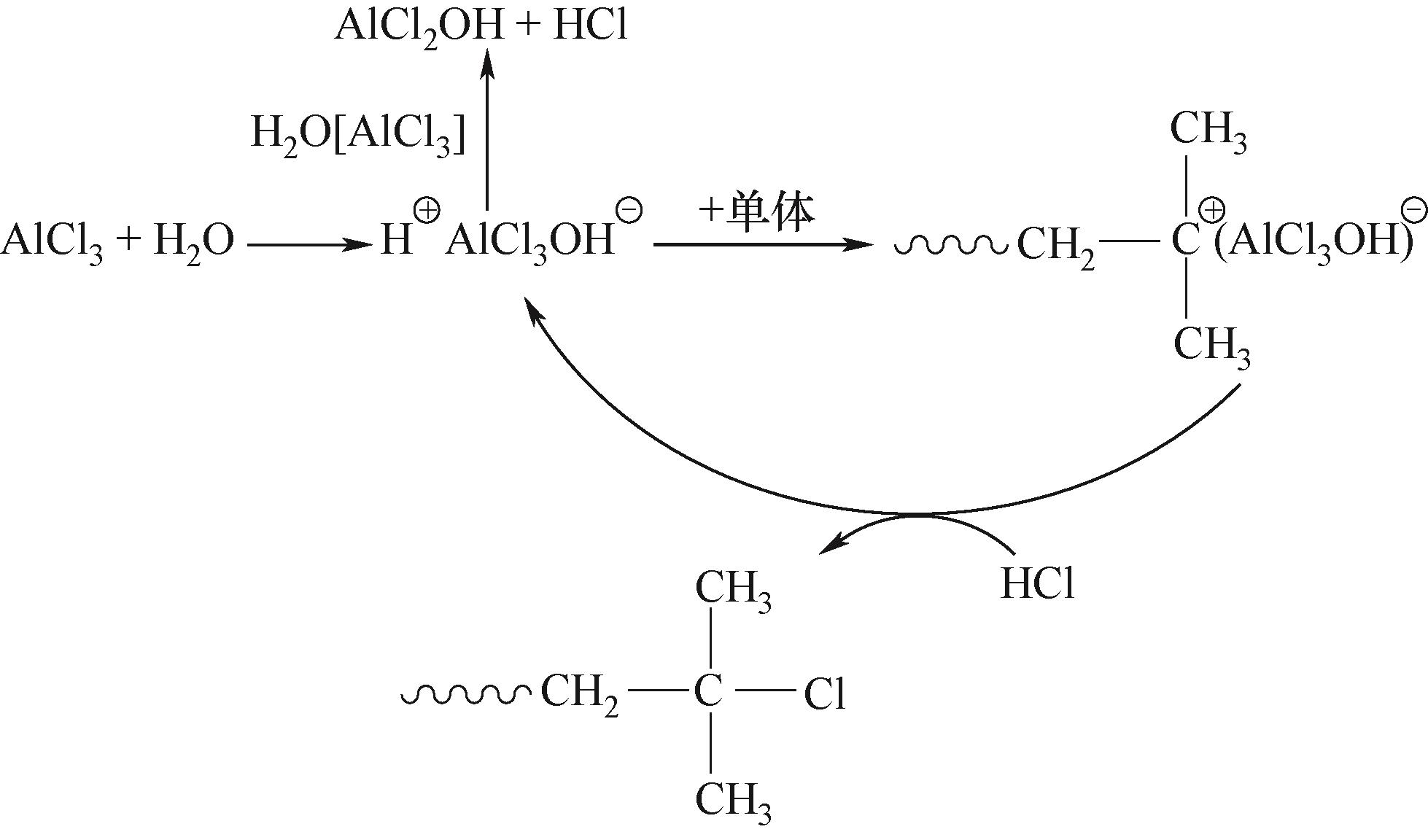

图2 引发体系中物质转化的可能途径和决定链终止的机制[57]

Fig.2 Possible routes of species transformation in the initiation system and the mechanism dominating chain termination[57]

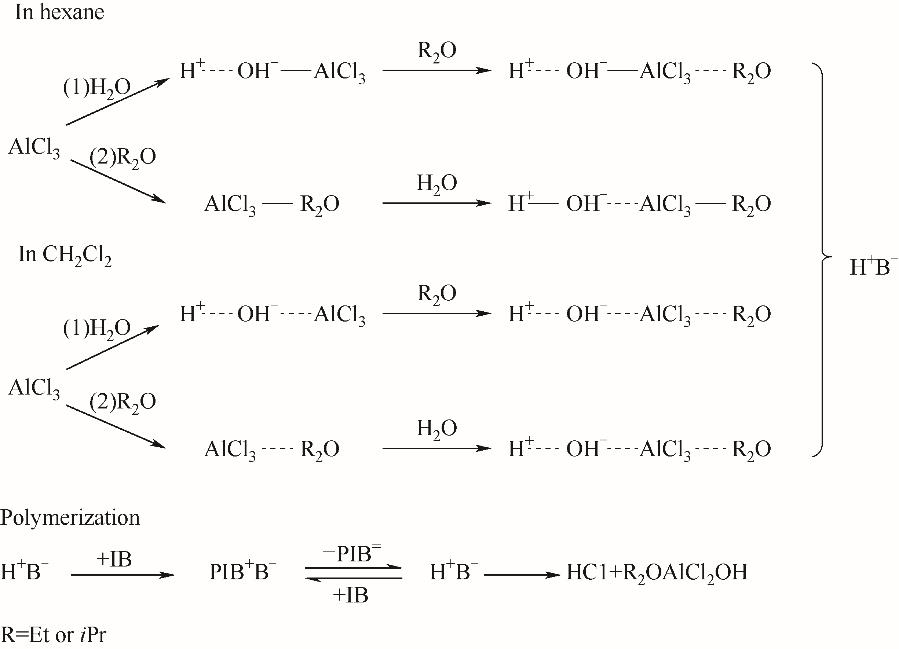

图5 含AlCl3和醚的引发剂溶液制备过程中与AlCl3相互作用的演化途径[73]

Fig.5 Evolution routes of AlCl3-involved interactions during the preparation of initiator solutions containing AlCl3 and ether[73]

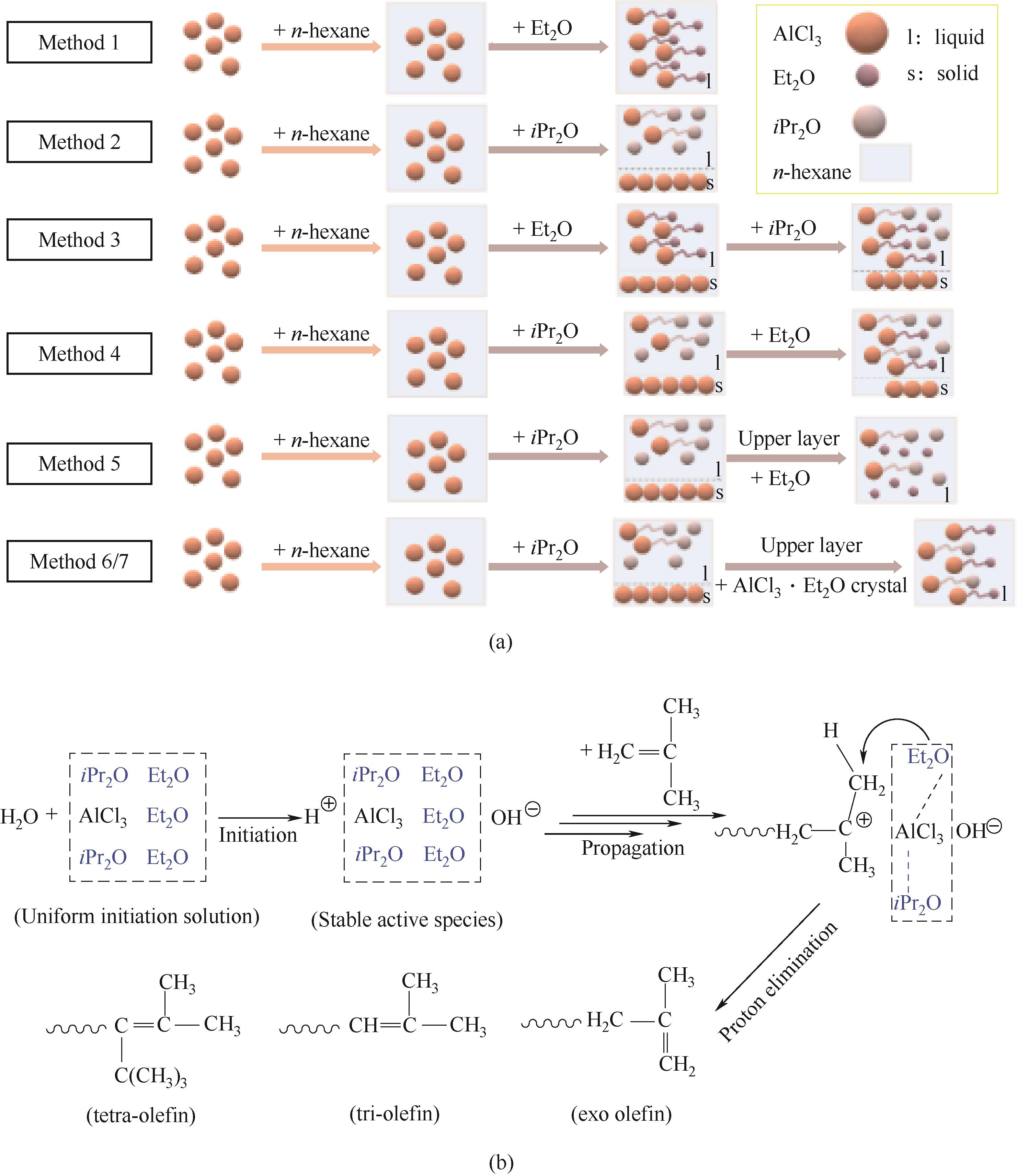

图6 (a)引发剂溶液的各种制备方法示意图;(b)利用双醚引发IB阳离子聚合机理[74]

Fig.6 (a) Schematic of various preparation methods of initiation solution; (b) Proposed mechanism of cationic polymerization of IB utilizing dual ethers[74]

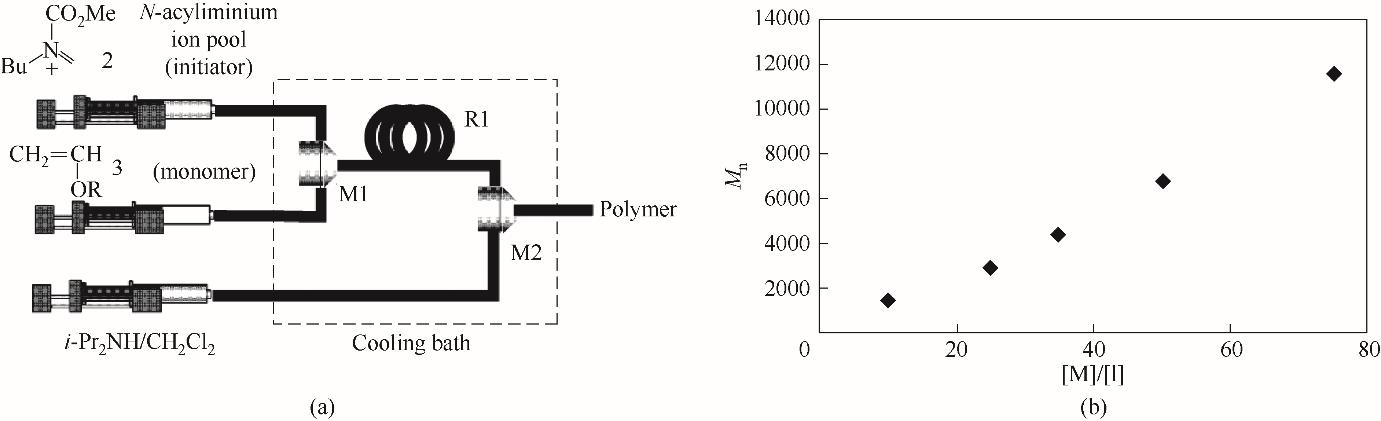

图8 (a)用于聚合的微流动系统(M1和M2为微型混合器,R1为微管反应器)[38];(b)使用微流控系统通过N-酰基亚胺离子池引发的NBVE阳离子聚合中分子量(Mn)与单体/引发剂比率的关系[39]

Fig.8 (a) Microsystem for polymerization(M1, M2—micromixers; R1—microtube reactor)[38]; (b) Plots of molecular weight (Mn) against monomer/initiator ratio in cationic polymerization of NBVE initiated by an N-acyliminium ion pool using a microflow system[39]

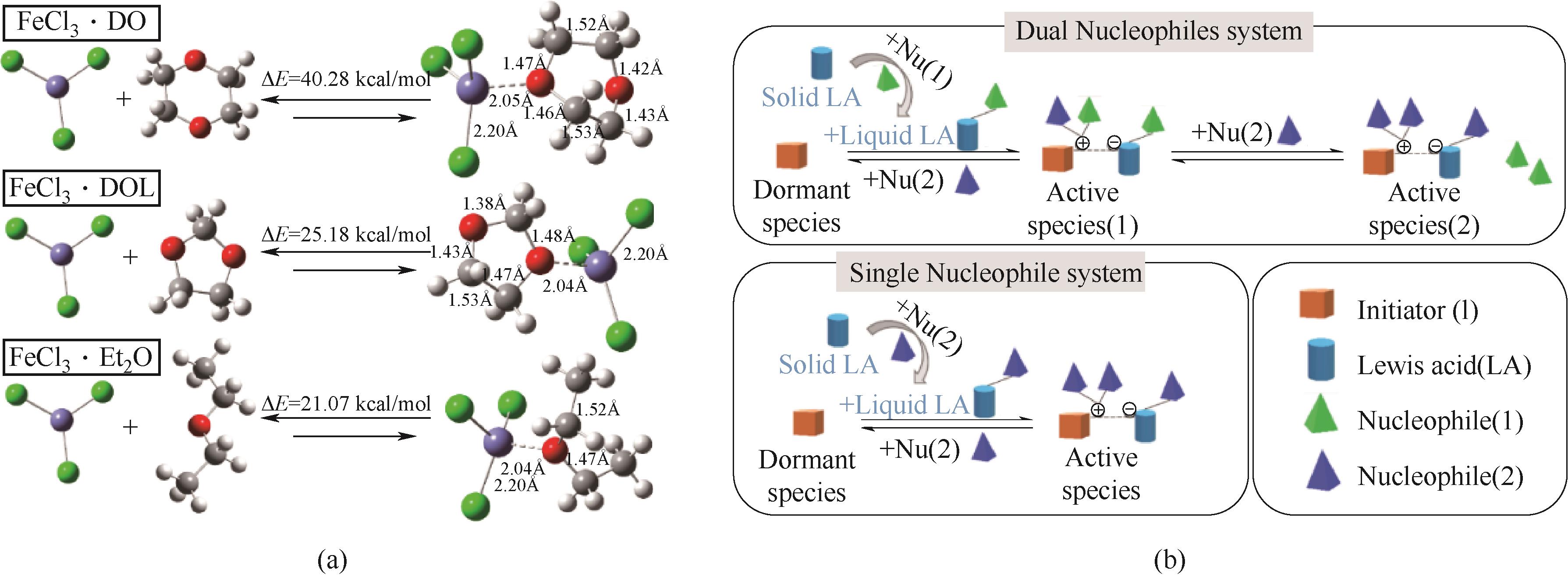

图11 (a)基于Gaussian 09w计算出FeCl3·Nu的结合能和优化结构[B3LYP / 6-311G(++,d,p), 1 Å =0.1 nm];(b)在双亲核和单亲核试剂条件下IBVE活性阳离子聚合机理[88]

Fig.11 (a) Binding energies and optimized structure of FeCl3·Nu calculated by Gaussian 09w[B3LYP/6-311G(++,d,p)]; (b) Proposed mechanisms of living cationic polymerization of IBVE under dual and single nucleophiles conditions[88]

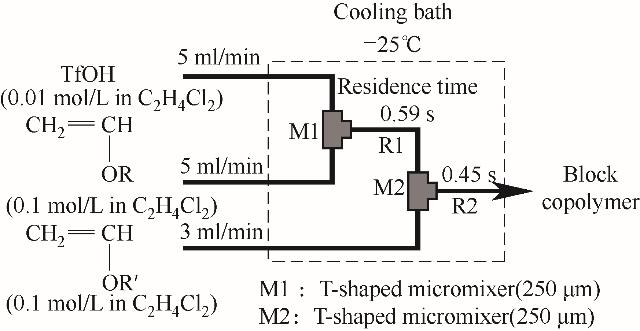

图12 基于T型微混合器的微流动系统用于嵌段共聚的示意图[M1和M2为T型微混合器(250 mm)。R1和R2为微管反应器(R1:Φ= 500 μm,长度= 50 cm;R2:Φ = 500 μm,长度= 50 cm)][39]

Fig.12 Schematic diagram of the microflow system based on the T-shaped micromixer for block copolymerization [M1 and M2: T-shape micromixer (250 mm). R1 and R2: microtube reactor (R1: Φ=500 μm, length=50 cm; R2: Φ=500 μm, length=50 cm)][39]

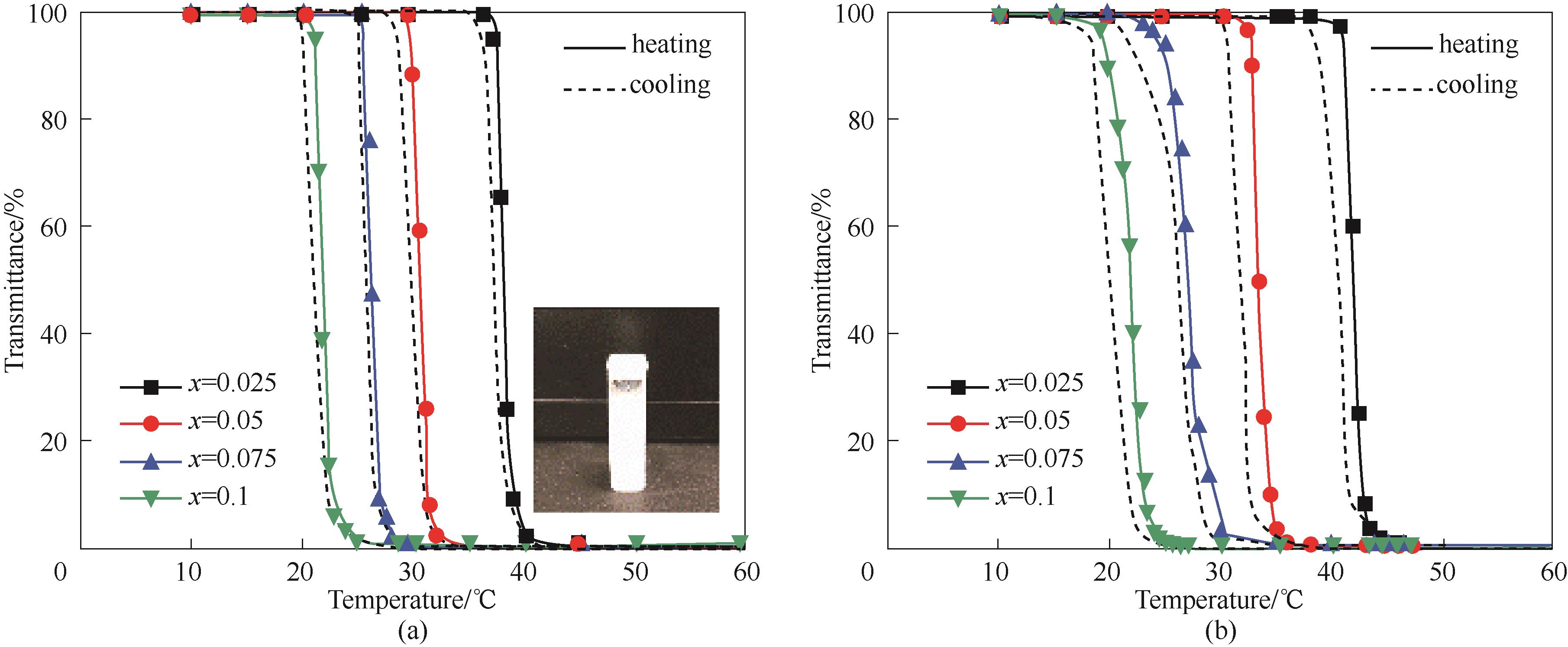

图13 聚(IBVE x -co-HBVE1-x )200(DP n 约200)的1.0%(质量分数)水溶液透光率与温度的关系曲线:(a)在微流控系统中制备(Mw/Mn = 1.10);(b)在间歇反应器中制备(Mw/Mn = 1.41~1.57)[74]

Fig.13 Temperature dependence of the transmittance at 500 nm of a 1.0%(mass) aqueous solution of poly(IBVE x -co-HBVE1-x )200 (DP n about 200): (a) prepared in a microflow system(Mw/Mn = 1.10); (b) prepared in a batch reactor(Mw/Mn = 1.41—1.57)[74]

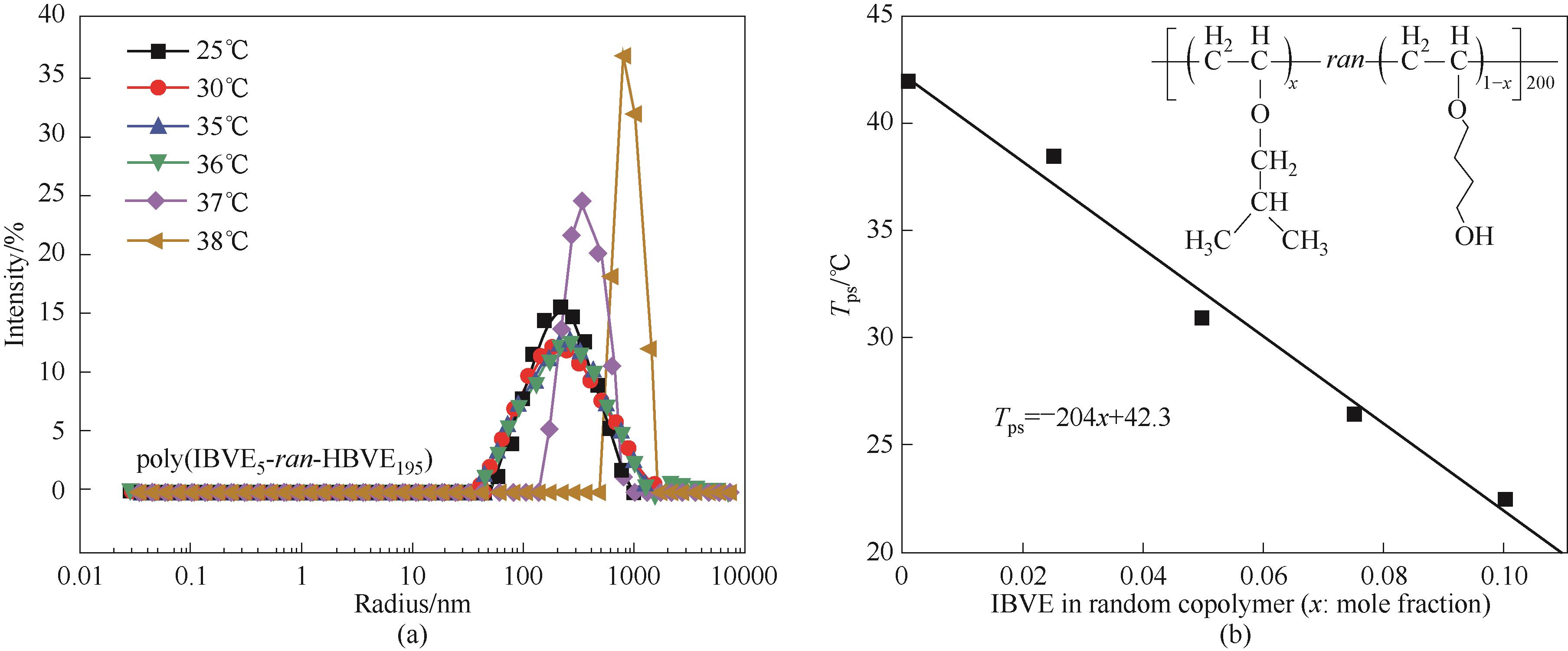

图14 (a)聚(IBVE5-co-HBVE195)在1.0%(质量分数)水溶液中的半径变化;(b)水中Tps与共聚物组成(IBVE x -co-HBVE1-x )200 (DP n 约200)之间的关系(Mw/Mn = 1.10)[74]

Fig.14 (a) The radius variation of the poly(IBVE5-co-HBVE195) in 1.0%(mass) aqueous solutions; (b) Relationships between Tps in water and the composition of copolymers (IBVE x -co-HBVE1-x )200 (DP n about 200, Mw/Mn = 1.10)[74]

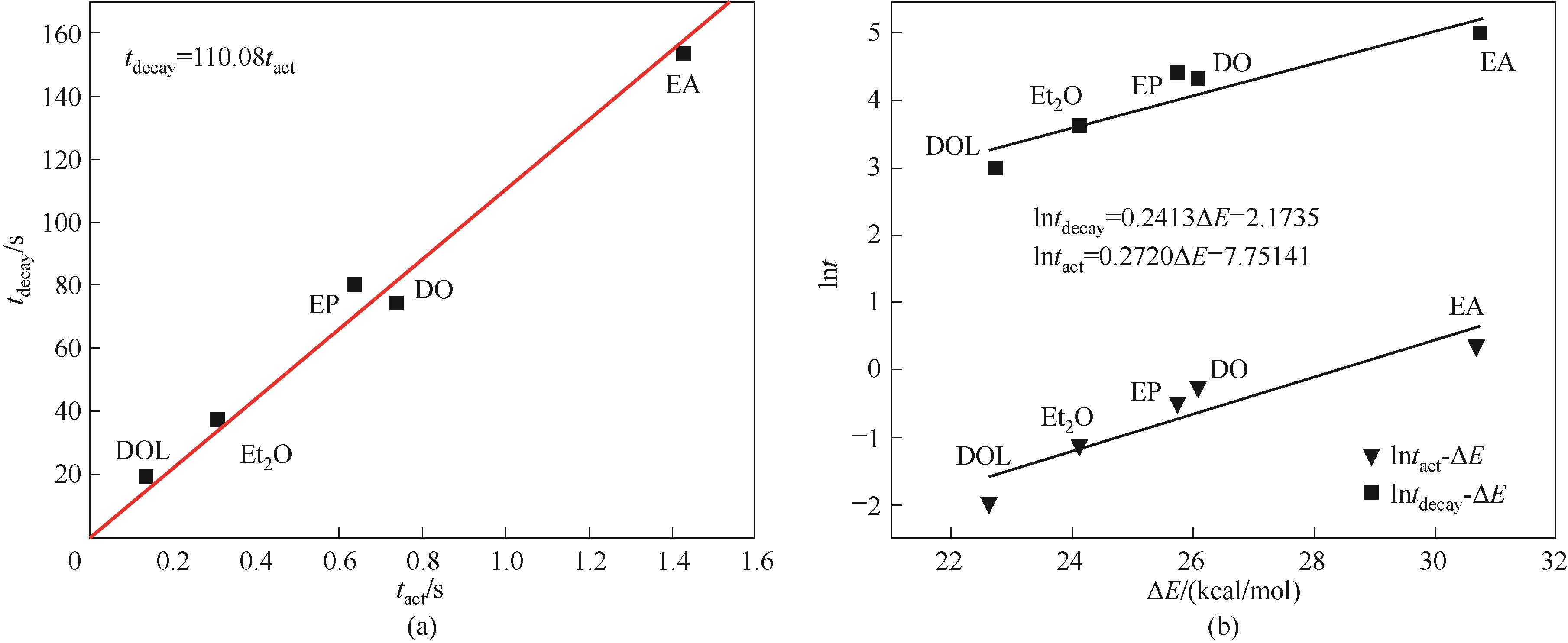

图15 IBVE 聚合反应中tdecay与tact之间的关系(a)及lntact、lntdecay与解离能之间关系(b)[78]

Fig.15 Plot of tdecay as a function of tact (a) and plots of lntact or lntdecay as a function of the dissociation energy (b) in the IBVE polymerization reactions initiated by the SnCl4/X (X = EA, DO, EP, Et2O or DOL) system[78]

| 1 | 何宇航, 刘晴捷, 吕阳成. 微反应器内丁基橡胶溶液法制备体系的反应特性研究[J]. 化工学报, 2021, 72(2): 1001-1008. |

| He Y H, Liu Q J, Lyu Y C. Study on reaction characteristics of solution polymerization system for butyl rubber preparation in microreactor[J]. CIESC Journal, 2021, 72(2): 1001-1008. | |

| 2 | Mcdonald M F, Shaffer T D, Tsou A H. Commercial Isobutylene Polymers[M]. US: John Wiley & Sons, Inc., 2016. |

| 3 | Chen J F, Gao H, Zou H K, et al. Cationic polymerization in rotating packed bed reactor: experimental and modeling[J]. AIChE Journal, 2010, 56(4): 1053-1062. |

| 4 | Gronowski A A. Synthesis of butyl rubber in hexane using a mixture of Et2AlCl and EtAlCl2 in the initiating system[J]. Journal of Applied Polymer Science, 2003, 87(14): 2360-2364. |

| 5 | Huang Q, He P, Wang J, et al. Synthesis of high molecular weight polyisobutylene via cationic polymerization at elevated temperatures[J]. Chinese Journal of Polymer Science, 2013, 31(8): 1139-1147. |

| 6 | Prez F E D, Goethals E J, Hoogenboom R. Cationic Polymerizations[M]. US: John Wiley & Sons, Ltd., 2013. |

| 7 | Puskas J E, Kaszas G. Living carbocationic polymerization of resonance-stabilized monomers[J]. Progress in Polymer Science, 2000, 25(3): 403-452. |

| 8 | Aoshima S, Yoshida T, Kanazawa A, et al. New stage in living cationic polymerization: an array of effective Lewis acid catalysts and fast living polymerization in seconds[J]. Journal of Polymer Science A Polymer Chemistry, 2007, 45(10): 1801-1813. |

| 9 | Dimitrov P, Emert J, Hua J, et al. Mechanism of isomerization in the cationic polymerization of isobutylene[J]. Macromolecules, 2011, 44(7): 1831-1840. |

| 10 | Szwarc M. ‘Living’ polymers[J]. Nature, 1956, 178: 1168-1169. |

| 11 | Bae Y C, Fodor Z, Faust R. Living coupling reaction in living cationic polymerization(1): Coupling reaction of living polyisobutylene[J]. Macromolecules, 1997, 30(2): 198-203. |

| 12 | Faust R, Kennedy J P. Living carbocationic polymerization[J]. Polymer Bulletin, 1986, 15(4): 317-323. |

| 13 | Faust R, Kennedy J P. Living carbocationic polymerization(Ⅳ): Living polymerization of isobutylene[J]. Journal of Polymer Science Part A: Polymer Chemistry, 1987, 25(7): 1847-1869. |

| 14 | Gyor M, Wang H C, Faust R. Living carbocationic polymerization of isobutylene with blocked bifunctional initiators in the presence of di-tert-butylpyridine as a proton trap[J]. Journal of Macromolecular Science, Part A, 1992, 29(8): 639-653. |

| 15 | Yonezumi M, Takano N, Kanaoka S, et al. Living cationic polymerization of vinyl ethers in the presence of a strong base: poisonous or helpful?[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2008, 46(20): 6746-6753. |

| 16 | Miyamoto M, Sawamoto M, Higashimura T. Synthesis of monodisperse living poly(vinyl ethers) and block copolymers by the hydrogen iodide/iodine initiating system[J]. Macromolecules, 1984, 17(11): 2228-2230. |

| 17 | Aoshima S, Higashimura T. Living cationic polymerization of vinyl monomers by organoaluminium halides[J]. Polymer Bulletin, 1986, 15(5): 417-423. |

| 18 | Aoshima S, Higashimura T. Living cationic polymerization of vinyl monomers by organoaluminum halides(3): Living polymerization of isobutyl vinyl ether by ethyldichloroaluminum in the presence of ester additives[J]. Macromolecules, 1989, 22(3): 1009-1013. |

| 19 | Kishimoto Y, Aoshima S, Higashimura T. Living cationic polymerization of vinyl monomers by organoaluminum halides(4): Polymerization of isobutyl vinyl ether by ethylaluminum dichloride (EtAlCl2) in the presence of ether additives[J]. Macromolecules, 1989, 22(10): 3877-3882. |

| 20 | Cho C G, Feit B A, Webster O W. Cationic polymerization of isobutyl vinyl ether: livingness enhancement by dialkyl sulfides[J]. Macromolecules, 1990, 23(7): 1918-1923. |

| 21 | Matyjaszewski K, Lin C H. Cationic polymerization of styrenes by activated covalent species. Direct 1H-NMR observation of complexes of 1-phenylethyl acetates with Lewis acids[J]. Journal of Polymer Science A Polymer Chemistry, 1991, 29(10): 1439-1446. |

| 22 | Kamigaito M, Maeda Y, Sawamoto M, et al. Living cationic polymerization of isobutyl vinyl ether by hydrogen chloride/Lewis acid initiating systems in the presence of salts: in situ direct NMR analysis of the growing species[J]. Macromolecules, 1993, 26(7): 1643-1649. |

| 23 | Higashimura T, Ishihama Y, Sawamoto M. Living cationic polymerization of styrene: new initiating systems based on added halide salts and the nature of the growing species[J]. Macromolecules, 1993, 26(4): 744-751. |

| 24 | Kanazawa A, Hirabaru Y, Kanaoka S, et al. Fast living cationic polymerization of vinyl ethers with iron(Ⅲ) chloride in the presence of a cyclic ether: most active and environmentally benign catalyst for the living cationic polymerization of vinyl ethers[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2006, 44(19): 5795-5800. |

| 25 | Yoshida T, Tsujino T, Kanaoka S, et al. Fast living cationic polymerization accelerated by SnCl4(Ⅰ): New base-stabilized living system for various vinyl ethers with SnCl4/EtAlCl2 [J]. Journal of Polymer Science Part A: Polymer Chemistry, 2005, 43(2): 468-472. |

| 26 | Yoshida T, Kanazawa A, Kanaoka S, et al. Instant living cationic polymerization using SnCl4/EtAlCl2 with a weak Lewis base: ultrafast polymerization in seconds[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2005, 43(18): 4288-4291. |

| 27 | Shinke Y, Kanazawa A, Kanaoka S, et al. Living cationic polymerization of vinyl ethers with a naphthyl group: decisive effect of the substituted position on naphthalene ring[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2012, 50(24): 5041-5048. |

| 28 | Shibata T, Kanaoka S, Aoshima S. Quantitative synthesis of star-shaped poly(vinyl ether)s with a narrow molecular weight distribution by living cationic polymerization[J]. Journal of the American Chemical Society, 2006, 128(23): 7497-7504. |

| 29 | Kanazawa A, Kanaoka S, Aoshima S. Major progress in catalysts for living cationic polymerization of isobutyl vinyl ether: effectiveness of a variety of conventional metal halides[J]. Macromolecules, 2009, 42(12): 3965-3972. |

| 30 | Aoshima S, Kanaoka S. A renaissance in living cationic polymerization[J]. Chemical Reviews, 2009, 109(11): 5245-5287. |

| 31 | Iwasaki T, Nagaki A, Yoshida J I. Microsystem controlled cationic polymerization of vinyl ethers initiated by CF3SO3H[J]. Chemical Communications, 2007(12): 1263-1265. |

| 32 | Cui Y J, Song J, Du C C, et al. Determination of the kinetics of chlorobenzene nitration using a homogeneously continuous microflow[J]. AIChE Journal, 2022, 68(4): e17564. |

| 33 | Song J, Cui Y J, Luo G S, et al. Kinetic study of o-nitrotoluene nitration in a homogeneously continuous microflow[J]. Reaction Chemistry & Engineering, 2022, 7(1): 111-122. |

| 34 | Song J, Cui Y J, Sheng L, et al. Determination of nitration kinetics of p-nitrotoluene with a homogeneously continuous microflow[J]. Chemical Engineering Science, 2022, 247: 117041. |

| 35 | Duan X N, Tu J C, Teixeira A R, et al. An automated flow platform for accurate determination of gas-liquid-solid reaction kinetics[J]. Reaction Chemistry & Engineering, 2020, 5(9): 1751-1758. |

| 36 | Duan X N, Wang X P, Chen X K, et al. Continuous and selective hydrogenation of heterocyclic nitroaromatics in a micropacked bed reactor[J]. Organic Process Research & Development, 2021, 25(9): 2100-2109. |

| 37 | Lan Z, Lu Y C. Enhancing the amination reaction of 4-nitrochlorobenzene in a tubular reactor[J]. Chemical Engineering and Processing - Process Intensification, 2021, 169: 108636. |

| 38 | Nagaki A, Kawamura K, Suga S, et al. Cation pool-initiated controlled/living polymerization using microsystems[J]. Journal of the American Chemical Society, 2004, 126(45): 14702-14703. |

| 39 | Nagaki A, Iwasaki T, Kawamura K, et al. Microflow system controlled carbocationic polymerization of vinyl ethers[J]. Chemistry-An Asian Journal, 2008, 3(8/9): 1558-1567. |

| 40 | Xie D, Lu Y C. Achieving low-cost and accelerated living cationic polymerization of isobutyl vinyl ether in microflow system[J]. Industrial & Engineering Chemistry Research, 2018, 57(22): 7441-7449. |

| 41 | Wong S, Ward M, Wharton C. Micro T-mixer as a rapid mixing micromixer[J]. Sensors and Actuators B: Chemical, 2004, 100(3): 359-379. |

| 42 | Bothe D, Stemich C, Warnecke H J. Fluid mixing in a T-shaped micro-mixer[J]. Chemical Engineering Science, 2006, 61(9): 2950-2958. |

| 43 | Matsunaga T, Lee H J, Nishino K. An approach for accurate simulation of liquid mixing in a T-shaped micromixer[J]. Lab on a Chip, 2013, 13(8): 1515-1521. |

| 44 | Galletti C, Roudgar M, Brunazzi E, et al. Effect of inlet conditions on the engulfment pattern in a T-shaped micro-mixer[J]. Chemical Engineering Journal, 2012, 185/186: 300-313. |

| 45 | Fani A, Camarri S, Salvetti M V. Investigation of the steady engulfment regime in a three-dimensional T-mixer[J]. Physics of Fluids, 2013, 25(6): 064102. |

| 46 | Sultan M A, Krupa K, Fonte C P, et al. High-throughput T-jets mixers: an innovative scale-up concept[J]. Chemical Engineering & Technology, 2013, 36(2): 323-331. |

| 47 | 赵玉潮, 应盈, 陈光文, 等. T形微混合器内的混合特性[J]. 化工学报, 2006, 57(8): 1884-1890. |

| Zhao Y C, Ying Y, Chen G W, et al. Characterization of micro-mixing in T-shaped micro-mixer[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(8): 1884-1890. | |

| 48 | Chen M, Johnson J A. Improving photo-controlled living radical polymerization from trithiocarbonates through the use of continuous-flow techniques[J]. Chemical Communications, 2015, 51(31): 6742-6745. |

| 49 | Corrigan N, Almasri A, Taillades W, et al. Controlling molecular weight distributions through photoinduced flow polymerization[J]. Macromolecules, 2017, 50(21): 8438-8448. |

| 50 | Qiu L, Wang K, Zhu S, et al. Kinetics study of acrylic acid polymerization with a microreactor platform[J]. Chemical Engineering Journal, 2016, 284: 233-239. |

| 51 | Xie P, Wang K, Wang P J, et al. Synthesizing bromobutyl rubber by a microreactor system[J]. AIChE Journal, 2017, 63(3): 1002-1009. |

| 52 | Nagaki A, Tomida Y, Yoshida J I. Microflow-system-controlled anionic polymerization of styrenes[J]. Macromolecules, 2008, 41(17): 6322-6330. |

| 53 | Iwasaki T, Yoshida J I. Free radical polymerization in microreactors. Significant improvement in molecular weight distribution control[J]. Macromolecules, 2005, 38(4): 1159-1163. |

| 54 | Li J J, Chen M, Lin X, et al. Controlled microflow cationic polymerization of vinyl ethers under ambient conditions[J]. Chemical Engineering Journal, 2022, 435: 134828. |

| 55 | Toyoda T, Ohishi T, Yamanaka Y, et al. Process intensification of living cationic polymerization of isobutylene by a flow reaction system[J]. Chemical Engineering & Technology, 2019, 42(12): 2666-2672. |

| 56 | Flory P J. Effects of molecular structure on physical properties of butyl rubber[J]. Industrial & Engineering Chemistry, 1946, 38(4): 417-436. |

| 57 | Lu Y C, Zhu S, Wang K, et al. Generation of poly(isobutene-co-isoprene) in a microflow device[J]. Industrial & Engineering Chemistry Research, 2016, 55(5): 1215-1220. |

| 58 | Zhu S, Lu Y C, Wang K, et al. Flow synthesis of medium molecular weight polyisobutylene coinitiated by AlCl3 [J]. European Polymer Journal, 2016, 80: 219-226. |

| 59 | Mach H, Rath P. Highly reactive polyisobutene as a component of a new generation of lubricant and fuel additives[J]. Lubrication Science, 1999, 11(2): 175-185. |

| 60 | Harrison J J, Mijares C M, Cheng M T, et al. Negative ion electrospray ionization mass spectrum of polyisobutenylsuccinic anhydride: implications for isobutylene polymerization mechanism[J]. Macromolecules, 2002, 35(7): 2494-2500. |

| 61 | Zhu S, Lu Y C, Wang K, et al. Fast flow synthesis of highly reactive polyisobutylene co-initiated by an AlCl3/isopropyl ether complex[J]. RSC Advances, 2016, 6(12): 9827-9834. |

| 62 | Bergbreiter D E, Su H L, Koizumi H, et al. Polyisobutylene-supported N-heterocyclic carbene palladium catalysts[J]. Journal of Organometallic Chemistry, 2011, 696(6): 1272-1279. |

| 63 | Li Y, Wu Y X, Xu X, et al. Electron-pair-donor reaction order in the cationic polymerization of isobutylene coinitiated by AlCl3 [J]. Journal of Polymer Science Part A: Polymer Chemistry, 2007, 45(14): 3053-3061. |

| 64 | Li Y, Wu Y X, Liang L H, et al. Cationic polymerization of isobutylene coinitiated by AlCl3 in the presence of ethyl benzoate[J]. Chinese Journal of Polymer Science, 2010, 28(1): 55-62. |

| 65 | Zhu S, Lu Y C, Wang K, et al. Cationic polymerization of isobutylene catalysed by AlCl3 with multiple nucleophilic reagents[J]. RSC Advances, 2016, 6(100): 97983-97989. |

| 66 | Vasilenko I V, Frolov A N, Kostjuk S V. Cationic polymerization of isobutylene using AlCl3OBu2 as a coinitiator: synthesis of highly reactive polyisobutylene[J]. Macromolecules, 2010, 43(13): 5503-5507. |

| 67 | Liu Q, Wu Y X, Zhang Y, et al. A cost-effective process for highly reactive polyisobutylenes via cationic polymerization coinitiated by AlCl3 [J]. Polymer, 2010, 51(25): 5960-5969. |

| 68 | Vasilenko I V, Shiman D I, Kostjuk S V. Highly reactive polyisobutylenes via AlCl3OBu2-coinitiated cationic polymerization of isobutylene: effect of solvent polarity, temperature, and initiator[J]. Journal of Polymer Science. Part A: Polymer Chemistry, 2012, 50(4): 750-758. |

| 69 | Zhang L B, Wu Y X, Zhou P, et al. Synthesis of highly reactive polyisobutylene by selective polymerization with o-cresol/AlCl3 initiating system[J]. Polymers for Advanced Technologies, 2012, 23(3): 522-528. |

| 70 | Shiman D I, Vasilenko I V, Kostjuk S V. Cationic polymerization of isobutylene by AlCl3/ether complexes in non-polar solvents: effect of ether structure on the selectivity of β-H elimination[J]. Polymer, 2013, 54(9): 2235-2242. |

| 71 | Kostjuk S V, Yeong H Y, Voit B. Cationic polymerization of isobutylene at room temperature[J]. Journal of Polymer Science. Part A: Polymer Chemistry, 2013, 51(3): 471-486. |

| 72 | Kostjuk S V, Vasilenko I V, Shiman D I, et al. Highly reactive polyisobutylenes via cationic polymerization of isobutylene by AlCl3/ether complexes in non-polar media: scope and limitations[J]. Macromolecular Symposia, 2015, 349(1): 94-103. |

| 73 | Zhu S, Wang K, Lu Y C. Effects of ether on the cationic polymerization of isobutylene catalyzed by AlCl3 [J]. ACS Omega, 2018, 3(2): 2033-2039. |

| 74 | Xie D, Zhu S, Lu Y C. Tailoring the AlCl3/iPr2O/Et2O initiation system for highly reactive polyisobutylene synthesis in pure n-hexane[J]. RSC Advances, 2020, 10(9): 5183-5190. |

| 75 | Liu Q, Wu Y X, Yan P F, et al. Polyisobutylene with high exo-olefin content via β-H elimination in the cationic polymerization of isobutylene with H2O/FeCl3/dialkyl ether initiating system[J]. Macromolecules, 2011, 44(7): 1866-1875. |

| 76 | Kumar R, Dimitrov P, Bartelson K J, et al. Polymerization of isobutylene by GaCl3 or FeCl3/ether complexes in nonpolar solvents[J]. Macromolecules, 2012, 45(21): 8598-8603. |

| 77 | Bartelson K J, De P, Kumar R, et al. Cationic polymerization of isobutylene by FeCl3/ether complexes in hexanes: aninvestigation of the steric and electronic effects of ethers[J]. Polymer, 2013, 54(18): 4858-4863. |

| 78 | Xie D, Lu Y C. Understanding the effects of nucleophiles in fast living cationic polymerisation of isobutyl vinyl ether in a microflow system from stability and activity of propagating chains[J]. Polymer Chemistry, 2021, 12(17): 2542-2550. |

| 79 | Zhu Y L, Storey R F. Synthesis of polyisobutylene-based miktoarm star polymers from a dicationic monoradical dual initiator[J]. Macromolecules, 2012, 45(13): 5347-5357. |

| 80 | Xie Y, Chang J J, Wu Y B, et al. Synthesis and properties of bromide-functionalized poly(isobutylene-co-p-methylstyrene) random copolymer[J]. Polymer International, 2017, 66(3): 468-476. |

| 81 | Faust R, Kennedy J P. Living carbocationic polymerization(Ⅲ): Demonstration of the living polymerization of isobutylene[J]. Polymer Bulletin, 1986, 15(4): 317-323. |

| 82 | Kaszas G, Puskas J E, Kennedy J P, et al. Electron-pair donors in carbocationic polymerization(Ⅲ): Carbocation stabilization by external electron-pair donors in isobutylene polymerization[J]. Journal of Macromolecular Science. Part A: Chemistry, 1989, 26(8): 1099-1114. |

| 83 | Rajabalitabar B, Nguyen H A, Cheradame H. Synthesis of polymers containing pseudohalide groups by cationic polymerization(14): Functionalizing “living” polymerization of 2-methylpropene initiated by the system 1,4-bis(1-azido-1-methylethyl)benzene/diethylaluminum chloride[J]. Macromolecules, 1996, 29(2): 514-518. |

| 84 | Murachev V B, Nesmelov A I, Byrikhin V S, et al. Effect of the composition of the initiating complex acyl halides/aluminium bromide on the cationic polymerization of isobutylene[J]. Polymer International, 2000, 49(6): 501-508. |

| 85 | He Y H, Lu Y C. Living cationic polymerization of isobutylene in seconds based on microflow system[J]. European Polymer Journal, 2022, 174: 111335. |

| 86 | Sheng L, Ma L, Chen Y C, et al. A comprehensive study of droplet formation in a capillary embedded step T-junction: from squeezing to jetting[J]. Chemical Engineering Journal, 2022, 427: 132067. |

| 87 | Iwasaki T, Yoshida J I. CF3SO3H initiated cationic polymerization of diisopropenylbenzenes in macrobatch and microflow systems[J]. Macromolecular Rapid Communications, 2007, 28(11): 1219-1224. |

| 88 | Xie D, Lu Y C. Precise synthesis of poly(IBVE-co-HBVE) with tunable thermo-response via fast flow polymerization[J]. Polymer, 2020, 190: 122223. |

| 89 | Yoshida J I, Suga S. Basic concepts of “cation pool” and “cation flow” methods and their applications in conventional and combinatorial organic synthesis[J]. Chemistry - A European Journal, 2002, 8(12): 2650. |

| 90 | Bally F, Serra C A, Hessel V, et al. Micromixer-assisted polymerization processes[J]. Chemical Engineering Science, 2011, 66(7): 1449-1462. |

| 91 | Aoshima S, Oda H, Kobayashi E. Synthesis of thermally-induced phase separating polymer with well-defined polymer structure by living cationic polymerization(Ⅰ): Synthesis of poly(vinyl ether)s with oxyethylene units in the pendant and its phase separation behavior in aqueous solution[J]. Journal of Polymer Science. Part A: Polymer Chemistry, 1992, 30(11): 2407-2413. |

| 92 | Sugihara S, Hashimoto K, Matsumoto Y, et al. Thermosensitive polyalcohols: synthesis via living cationic polymerization of vinyl ethers with a silyloxy group[J]. Journal of Polymer Science. Part A: Polymer Chemistry, 2003, 41(21): 3300-3312. |

| 93 | Sugihara S, Kanaoka S, Aoshima S. Thermosensitive random copolymers of hydrophilic and hydrophobic monomers obtained by living cationic copolymerization[J]. Macromolecules, 2004, 37(5): 1711-1719. |

| 94 | Tonhauserc, Natalello A, weH Lö, et al. Microflow technology in polymer synthesis[J]. Macromolecules, 2012, 45(24): 9551-9570. |

| 95 | He Y H, Xie D, Lu Y C. Living copolymerization of EOVE and MOVE: fast flow synthesis and thermal responsive behavior[J]. Chinese Journal of Polymer Science, 2022, 40(10): 1193-1200. |

| 96 | He Y H, Zhang Z E, Ke H, et al. Microflow system for controlled synthesis of ethylene-vinyl acetate copolymers: continuous copolymerization and kinetic study[J]. Chemical Engineering Journal, 2023, 470: 143940. |

| 97 | Shen Y Q, Zhu S P, Pelton R. Packed column reactor for continuous atom transfer radical polymerization: methyl methacrylate polymerization using silica gel supported catalyst[J]. Macromolecular Rapid Communications, 2000, 21(14): 956-959. |

| 98 | Xue F, Deng H P, Xue C W, et al. Reaction discovery using acetylene gas as the chemical feedstock accelerated by the “stop-flow” micro-tubing reactor system[J]. Chemical Science, 2017, 8(5): 3623-3627. |

| 99 | Huo F L, Lu Y C. Homogeneous synthesis of hydroxyethyl acrylate catalyzed by organochromium(Ⅲ) complexes: kinetics and ligand effect[J]. Chemical Engineering Journal, 2022, 440: 135804. |

| 100 | Tian J X, Tang T Y, Deng J, et al. An integrated system of a microreactor with a Taylor-Couette reactor for 2,2′- dibenzothiazole disulfide synthesis[J]. AIChE Journal, 2023, 69(4): e17924. |

| [1] | 薛潇, 商敏静, 苏远海. 微反应器内药物连续流合成的研究进展[J]. 化工学报, 2024, 75(4): 1439-1454. |

| [2] | 陈饶, 赵鑫, 陈戴欣, 姜圣坤, 廉应江, 王金波, 杨梅, 陈光文. 微反应器内甲苯连续二硝化制备二硝基甲苯[J]. 化工学报, 2024, 75(3): 867-876. |

| [3] | 王婷, 王忠东, 项星宇, 何呈祥, 朱春英, 马友光, 付涛涛. 微反应器内环酯类锂电池添加剂合成研究进展[J]. 化工学报, 2024, 75(1): 95-109. |

| [4] | 康飞, 吕伟光, 巨锋, 孙峙. 废锂离子电池放电路径与评价研究[J]. 化工学报, 2023, 74(9): 3903-3911. |

| [5] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [6] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| [7] | 张中秋, 李宏光, 石逸林. 基于人工预测调控策略的复杂化工过程多任务学习方法[J]. 化工学报, 2023, 74(3): 1195-1204. |

| [8] | 张江淮, 赵众. 碳三加氢装置鲁棒最小协方差约束控制及应用[J]. 化工学报, 2023, 74(3): 1216-1227. |

| [9] | 章承浩, 罗京, 张吉松. 微反应器内基于氮氧自由基催化剂连续氧气/空气氧化反应的研究进展[J]. 化工学报, 2023, 74(2): 511-524. |

| [10] | 谢煜, 张民, 胡卫国, 王玉军, 骆广生. 利用膜分散微反应器高效溶解D-7-ACA的研究[J]. 化工学报, 2023, 74(2): 748-755. |

| [11] | 杨星宇, 马优, 朱春英, 付涛涛, 马友光. 梳状并行微通道内液液分布规律研究[J]. 化工学报, 2023, 74(2): 698-706. |

| [12] | 付家崴, 陈帅帅, 方凯伦, 蒋新. 微反应器共沉淀反应制备铜锰催化剂[J]. 化工学报, 2023, 74(2): 776-783. |

| [13] | 李祥宇, 隋璘, 马君霞, 熊伟丽. 基于时序迁移与双流加权的ONLSTM软测量建模[J]. 化工学报, 2023, 74(11): 4622-4633. |

| [14] | 李晨亚, 刘捷, 王建芝, 刘艳萍, 林笑, 喻发全. 螺旋微通道反应器贝克曼重排制备己内酰胺[J]. 化工学报, 2023, 74(10): 4182-4190. |

| [15] | 顾仁杰, 张加威, 靳雪阳, 文利雄. 微撞击流反应器制备镍钴复合氢氧化物超级电容器材料及其性能研究[J]. 化工学报, 2022, 73(8): 3749-3757. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号