化工学报 ›› 2024, Vol. 75 ›› Issue (4): 1394-1413.DOI: 10.11949/0438-1157.20231408

肖扬可1,2( ), 常印龙1,2(

), 常印龙1,2( ), 李平3,4(

), 李平3,4( ), 王文俊1,2, 李伯耿1,2, 刘平伟1,2(

), 王文俊1,2, 李伯耿1,2, 刘平伟1,2( )

)

收稿日期:2023-12-31

修回日期:2024-01-28

出版日期:2024-04-25

发布日期:2024-06-06

通讯作者:

李平,刘平伟

作者简介:肖扬可(1997—),女,博士研究生,xiaoyangke@zju.edu.cn基金资助:

Yangke XIAO1,2( ), Yinlong CHANG1,2(

), Yinlong CHANG1,2( ), Ping LI3,4(

), Ping LI3,4( ), Wenjun WANG1,2, Bogeng LI1,2, Pingwei LIU1,2(

), Wenjun WANG1,2, Bogeng LI1,2, Pingwei LIU1,2( )

)

Received:2023-12-31

Revised:2024-01-28

Online:2024-04-25

Published:2024-06-06

Contact:

Ping LI, Pingwei LIU

摘要:

聚烯烃类弹性体是由乙烯与丙烯或其他高碳α-烯烃共聚而成的高端聚烯烃材料,具有出色的化学稳定性、耐候性和电绝缘性,广泛应用于光伏、汽车、电缆等领域。通过动态化学交联可在保证其加工性的前提下,进一步提高其力学性能与热稳定性,拓展应用范围。综述了动态化学交联聚烯烃弹性体的制备工艺,包括一步法直接交联和功能化后再交联(多步法)。详细介绍了后功能化、乙烯与功能化单体共聚等功能化方法。讨论了动态化学交联聚烯烃类弹性体的表征手段及其链结构、聚集态结构和性能之间的关系。展望了动态交联聚烯烃类弹性体的未来发展。为动态化学交联聚烯烃类弹性体的可控制备、构效关系研究以及高值应用提供理论指导与技术支持,推动高端聚烯烃材料的创新和发展。

中图分类号:

肖扬可, 常印龙, 李平, 王文俊, 李伯耿, 刘平伟. 动态化学交联聚烯烃类弹性体研究进展[J]. 化工学报, 2024, 75(4): 1394-1413.

Yangke XIAO, Yinlong CHANG, Ping LI, Wenjun WANG, Bogeng LI, Pingwei LIU. Review on polyolefin elastomers with dynamic-chemical cross-linking[J]. CIESC Journal, 2024, 75(4): 1394-1413.

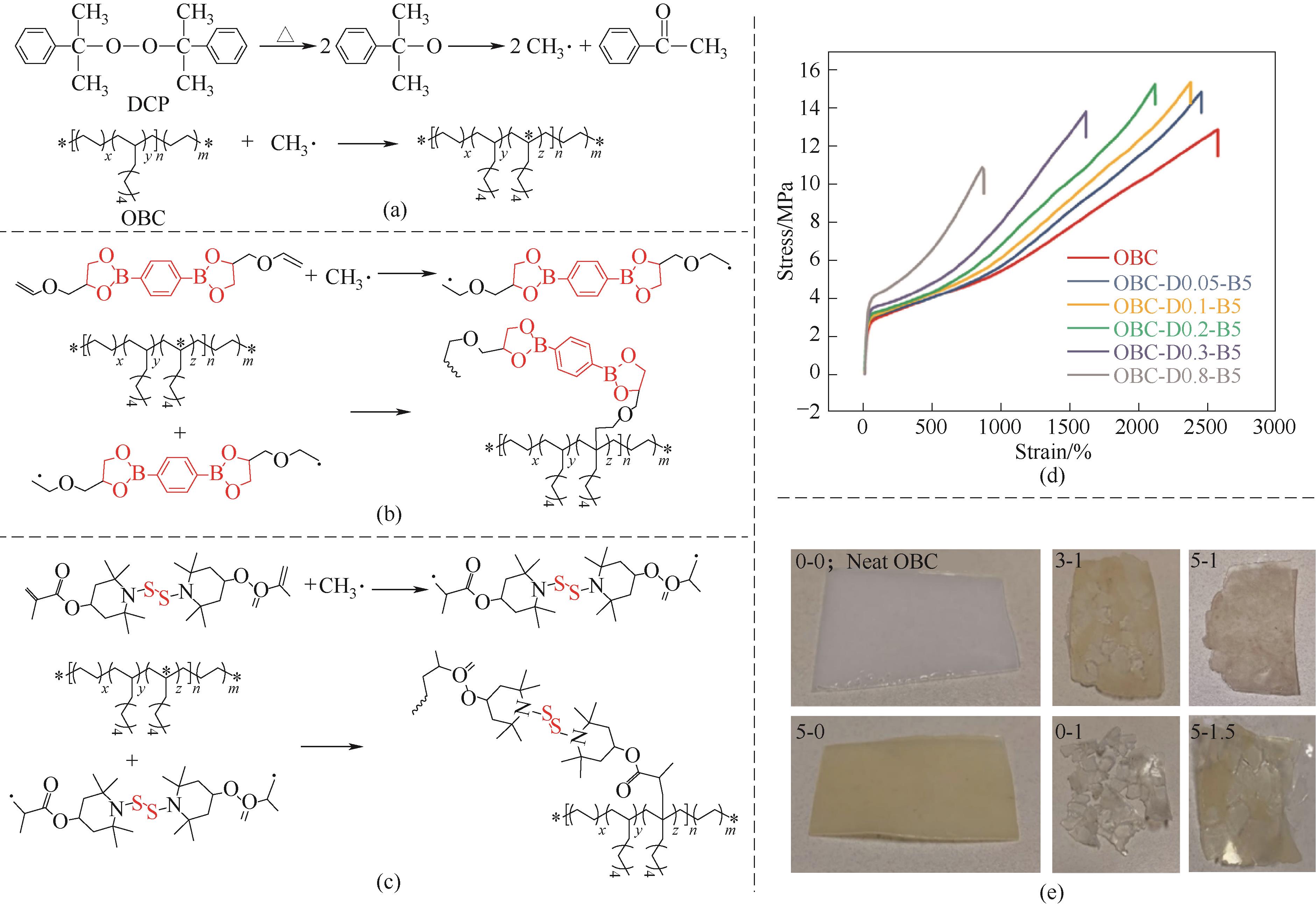

图2 (a)DCP与OBC的自由基引发反应;(b)双端乙烯基硼酸酯的自由基引发交联OBC;(c)含二硫键小分子交联剂的自由基引发交联OBC;(d)不同DCP用量下硼酸酯动态交联OBC的应力-应变曲线;(e)动态交联剂用量与DCP用量变化下二硫键交联OBC的加工成膜情况[图中数字比例,如3-1,代表3%(质量分数)的交联剂用量与1%(质量分数)的DCP用量]

Fig.2 (a) Free radical initiation reaction of DCP and OBC; (b) Free radical triggering double-ended vinyl boronic ester to cross-link OBC; (c) Free radical initiating small molecule cross-linker with disulfide bond to cross-link OBC; (d) Stress-strain curves of boronic ester dynamically cross-linked OBC using different DCP amount; (e) Processing of disulfide cross-linked OBC films using different dynamic cross-linker and DCP amount [the ratio of numbers in the figures, such as 3-1, represents 3%(mass) cross-linker loading and 1%(mass) DCP loading]

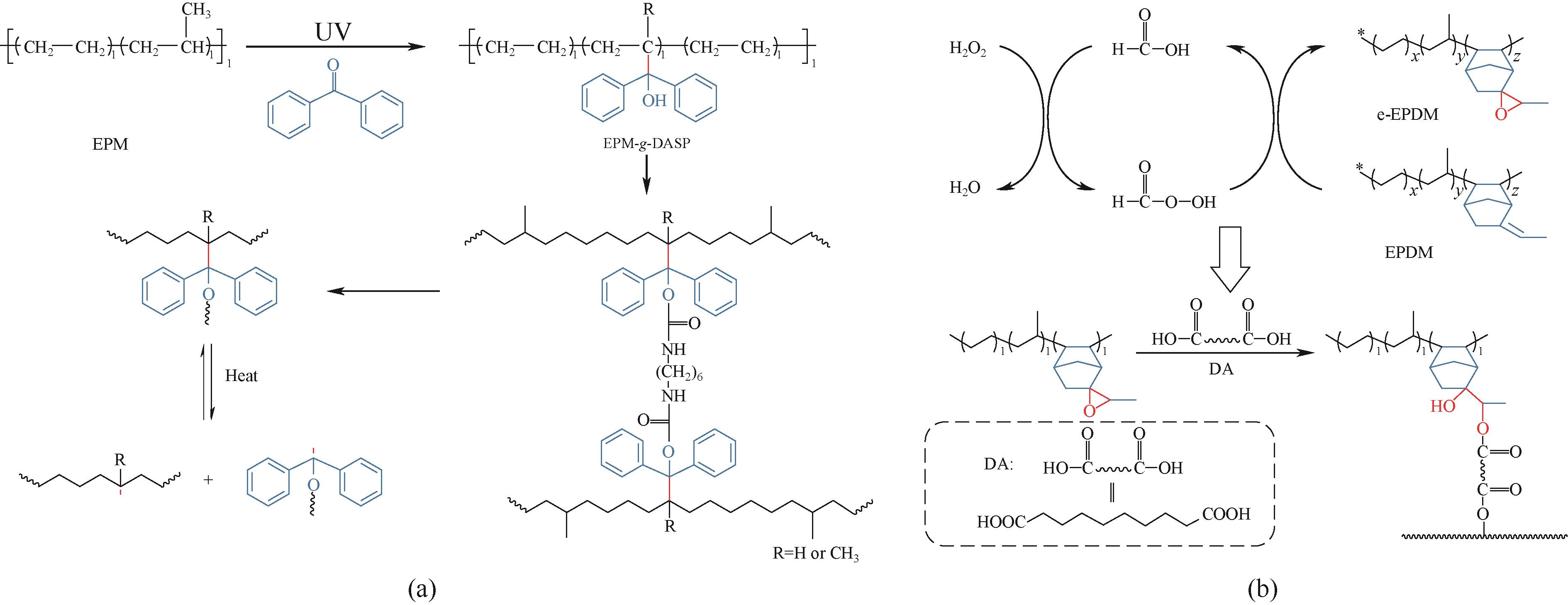

图3 (a)EPR的DASP功能化与交联;(b)环氧化EPDM与生物基癸二酸交联

Fig.3 (a) The DASP functionalization and cross-linking of EPR; (b) Epoxidized EPDM cross-linked with biobased sebacic acid

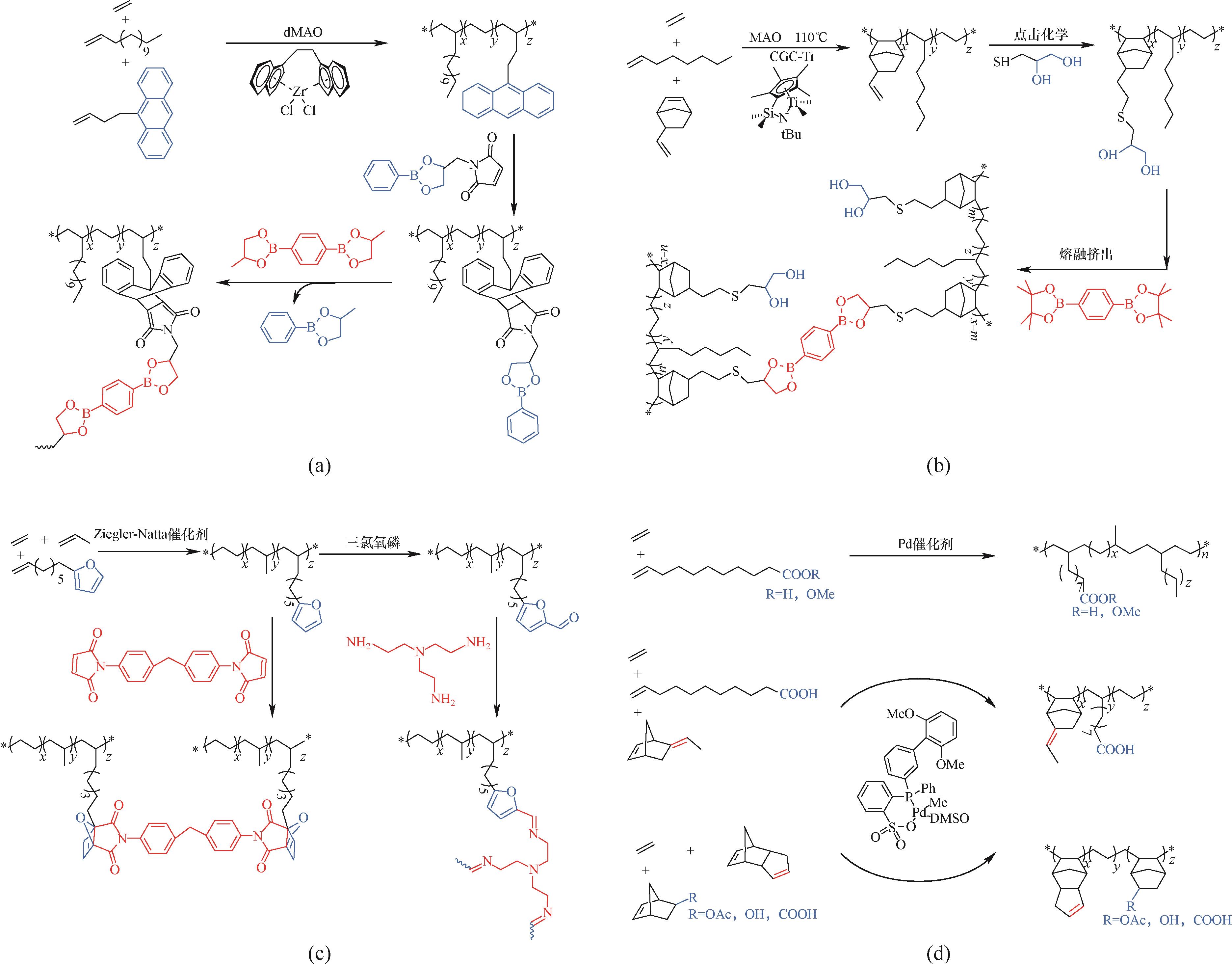

图4 (a)乙烯/1-十四烯/蒽烯共聚物的合成与硼酸酯交联;(b)乙烯/1-辛烯/5-乙烯基-2-降冰片烯共聚物合成与硼酸酯交联;(c)乙烯/丙烯/8-呋喃-1-辛烯的共聚物合成与DA键或亚胺键交联;(d)采用Pd催化剂合成含支链羧基POE、含乙烯基和极性官能团POE

Fig.4 (a) Synthesis of ethylene/1-tetradecene/9-(but-3-en-1-yl)anthracene copolymers with boronic ester cross-linking; (b) Synthesis of ethylene/1-octene/5-vinyl-2-norbornene copolymer with boronic ester cross-linking; (c) Synthesis of ethylene/propylene /8-furan-1-octene copolymer with DA or imine bond cross-linking; (d) Synthesis of branched POE with carboxyl group and POE with vinyl and polar functional group using Pd catalyst

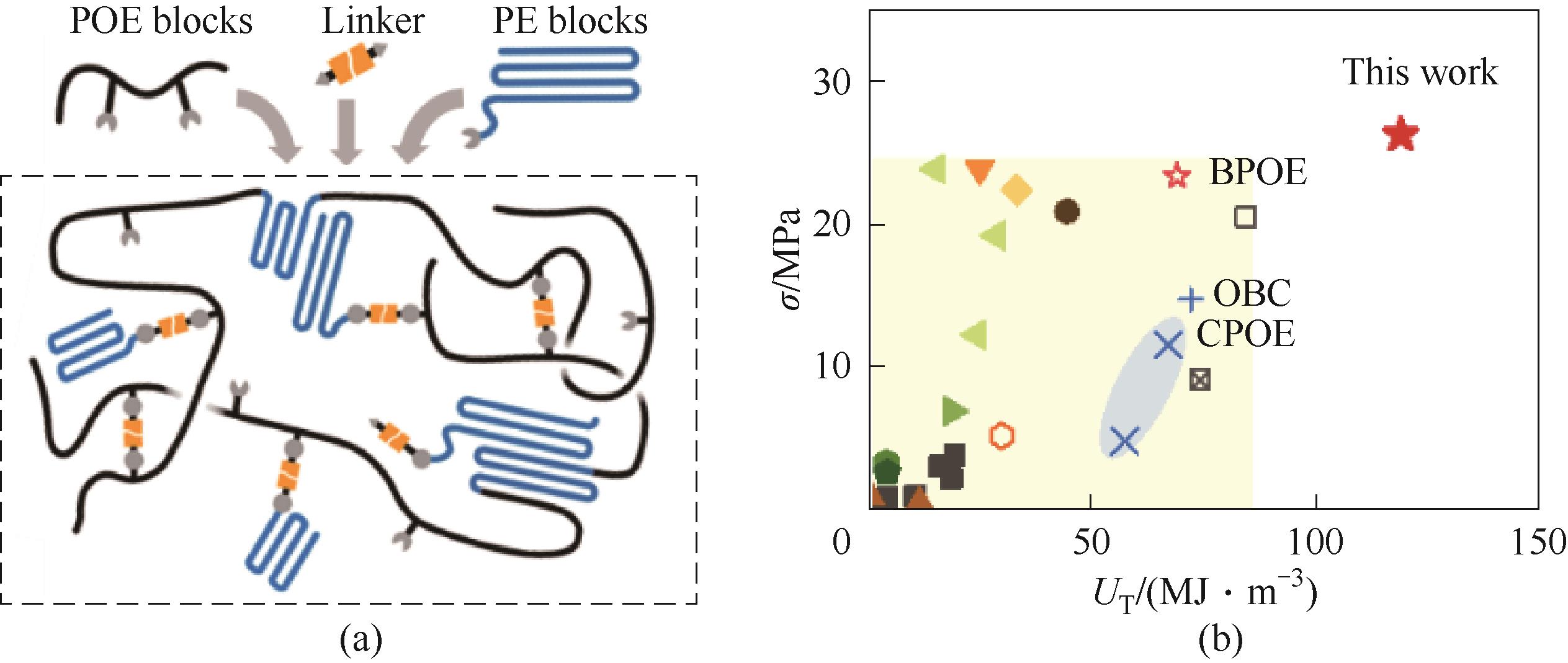

图5 (a)动态化学组合的方法制备高性能聚烯烃类TPE示意图;(b)新型TPE样品与其他已报道的动态交联弹性体、OBC和CPOE的拉伸性能比较

Fig.5 (a) Preparation of high-performance polyolefin based TPE by dynamic-chemical combination method; (b) Comparison of tensile properties of novel TPE with other dynamically cross-linked elastomers, OBC, and CPOE

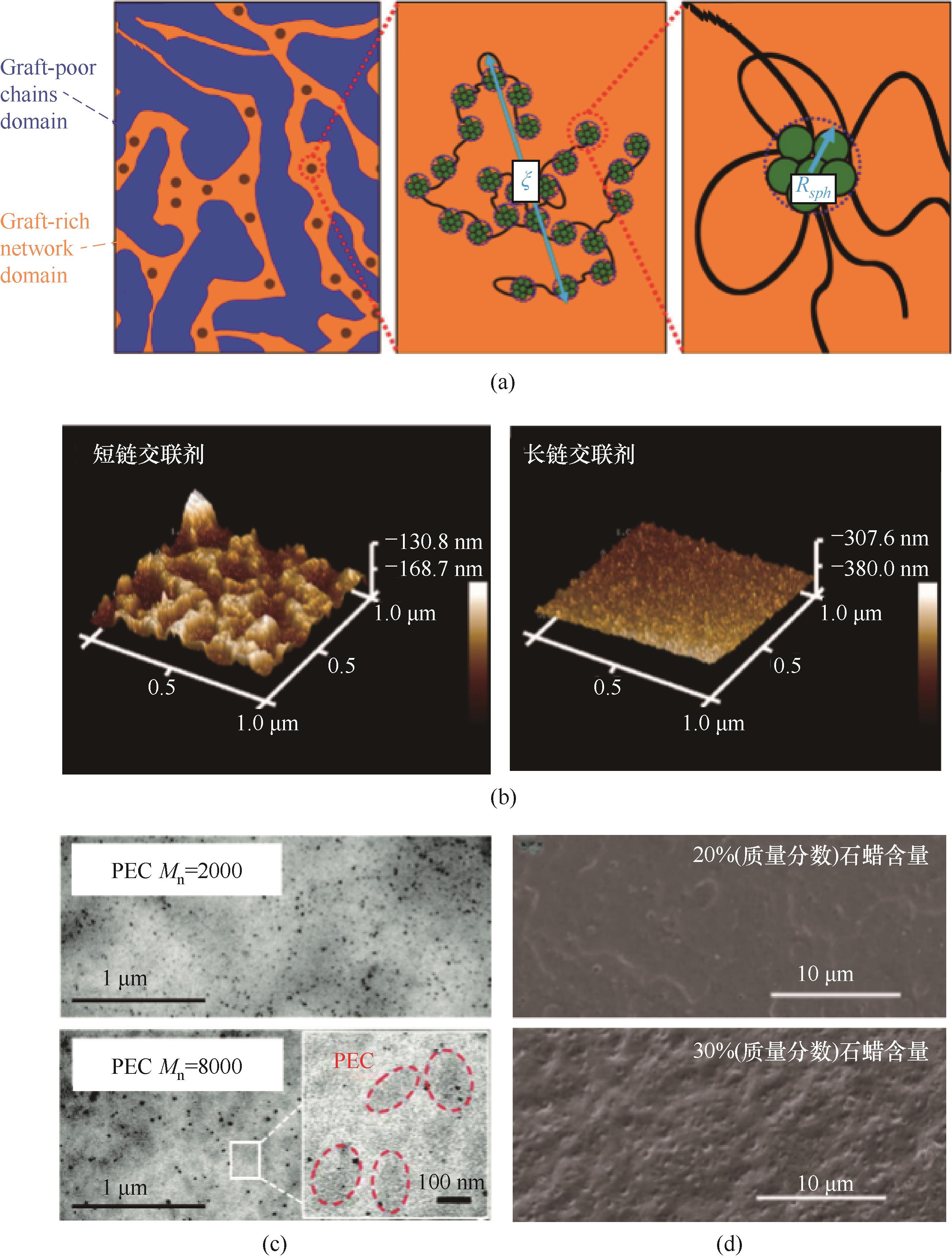

图7 (a)硼酸酯交联PE的介观结构示意图、分形结构、聚集体结构;(b)采用不同链长交联剂的环氧化月桂烯/异戊二烯共聚物的AFM图像;(c)不同分子量PEG动态交联的EPR的TEM图像;(d)石蜡动态交联POE的SEM图像

Fig.7 (a) Schematic of proposed mesostructure, fractal structure, and aggregate structure of boronic ester cross-linked PE; (b) AFM images of epoxidized myrcene and isoprene copolymers using cross-linkers with different chain length; (c) TEM images of dynamically cross-linked EPR with PEG of different number-average molecular weight(Mn); (d) SEM image of paraffin wax dynamically cross-linked POE

| 样品类型 | 动态化学键 | Tm/℃ | 杨氏模量/MPa | 断裂强度/MPa | 断裂伸长/ % | 文献 |

|---|---|---|---|---|---|---|

| 商品EPDM | — | — | — | 8.0~17.7 | 184~324 | [ |

| 商品POE | — | 36~104 | 3.8~5.8 | 1.4~38 | 600~1000 | [ |

| 商品OBC | — | 120 | 10.6 | 3~15 | 1300 | [ |

| EPDM | 酯键 | — | 2.5~4.5 | 19.4~22.7 | 240~390 | [ |

| EPR | DA键 | — | 0.84~26.04 | 4~6 | <380 | [ |

| EPR | 亚胺键 | — | 0.99~5.41 | 0.83~1.81 | 42~135 | [ |

| EPR | DA键 | — | — | 0.006~0.01 | 40~750 | [ |

| POE | 硼酸酯键 | — | 4.2~12.8 | 2.5~21.3 | 250~1950 | [ |

| POE | 硼酸酯键 | 55~80 | 14.8~29.0 | 12.8~23.8 | 470~630 | [ |

| POE | 硼酸酯键 | 75.9~79.8 | — | 27.5~35.3 | >800 | [ |

| OBC | 硼酸酯键 | — | — | 15.3 | 2375 | [ |

表1 动态交联聚烯烃类弹性体的力学性能

Table 1 Mechanical properties of dynamically cross-linked polyolefin based elastomers

| 样品类型 | 动态化学键 | Tm/℃ | 杨氏模量/MPa | 断裂强度/MPa | 断裂伸长/ % | 文献 |

|---|---|---|---|---|---|---|

| 商品EPDM | — | — | — | 8.0~17.7 | 184~324 | [ |

| 商品POE | — | 36~104 | 3.8~5.8 | 1.4~38 | 600~1000 | [ |

| 商品OBC | — | 120 | 10.6 | 3~15 | 1300 | [ |

| EPDM | 酯键 | — | 2.5~4.5 | 19.4~22.7 | 240~390 | [ |

| EPR | DA键 | — | 0.84~26.04 | 4~6 | <380 | [ |

| EPR | 亚胺键 | — | 0.99~5.41 | 0.83~1.81 | 42~135 | [ |

| EPR | DA键 | — | — | 0.006~0.01 | 40~750 | [ |

| POE | 硼酸酯键 | — | 4.2~12.8 | 2.5~21.3 | 250~1950 | [ |

| POE | 硼酸酯键 | 55~80 | 14.8~29.0 | 12.8~23.8 | 470~630 | [ |

| POE | 硼酸酯键 | 75.9~79.8 | — | 27.5~35.3 | >800 | [ |

| OBC | 硼酸酯键 | — | — | 15.3 | 2375 | [ |

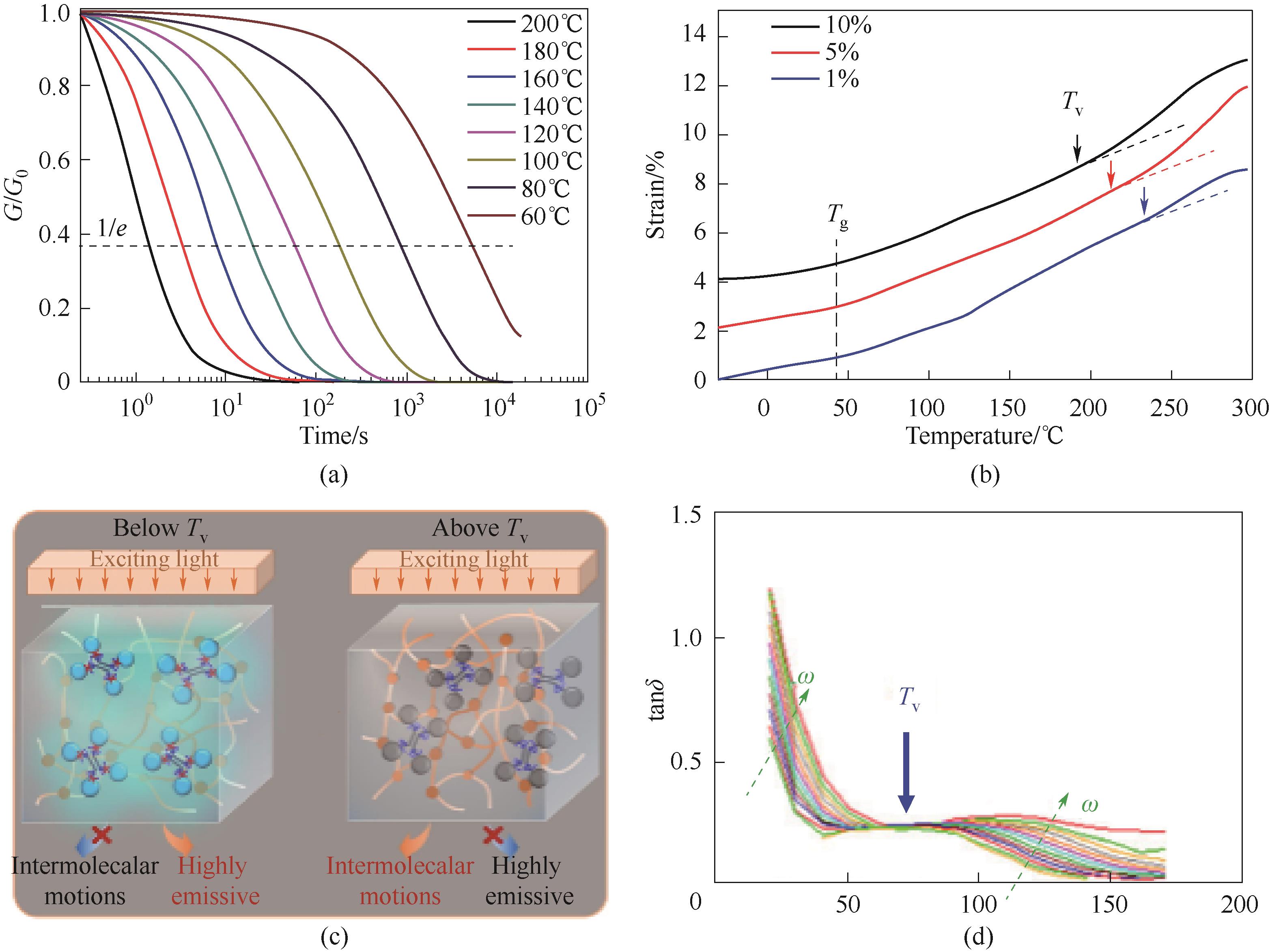

图8 (a)不同温度下归一化应力松弛曲线;(b)体积膨胀实验测定Tv;(c)温度的AIE示意图;(d)与频率相关的模量-温度曲线在Tv处重合

Fig.8 (a) Normalized stress relaxation curves at different temperatures; (b) Dilatometry test to determine Tv; (c) Illustration of the temperature-dependent AIE; (d) Coalesce of frequency-dependent material functions at Tv for tanδ

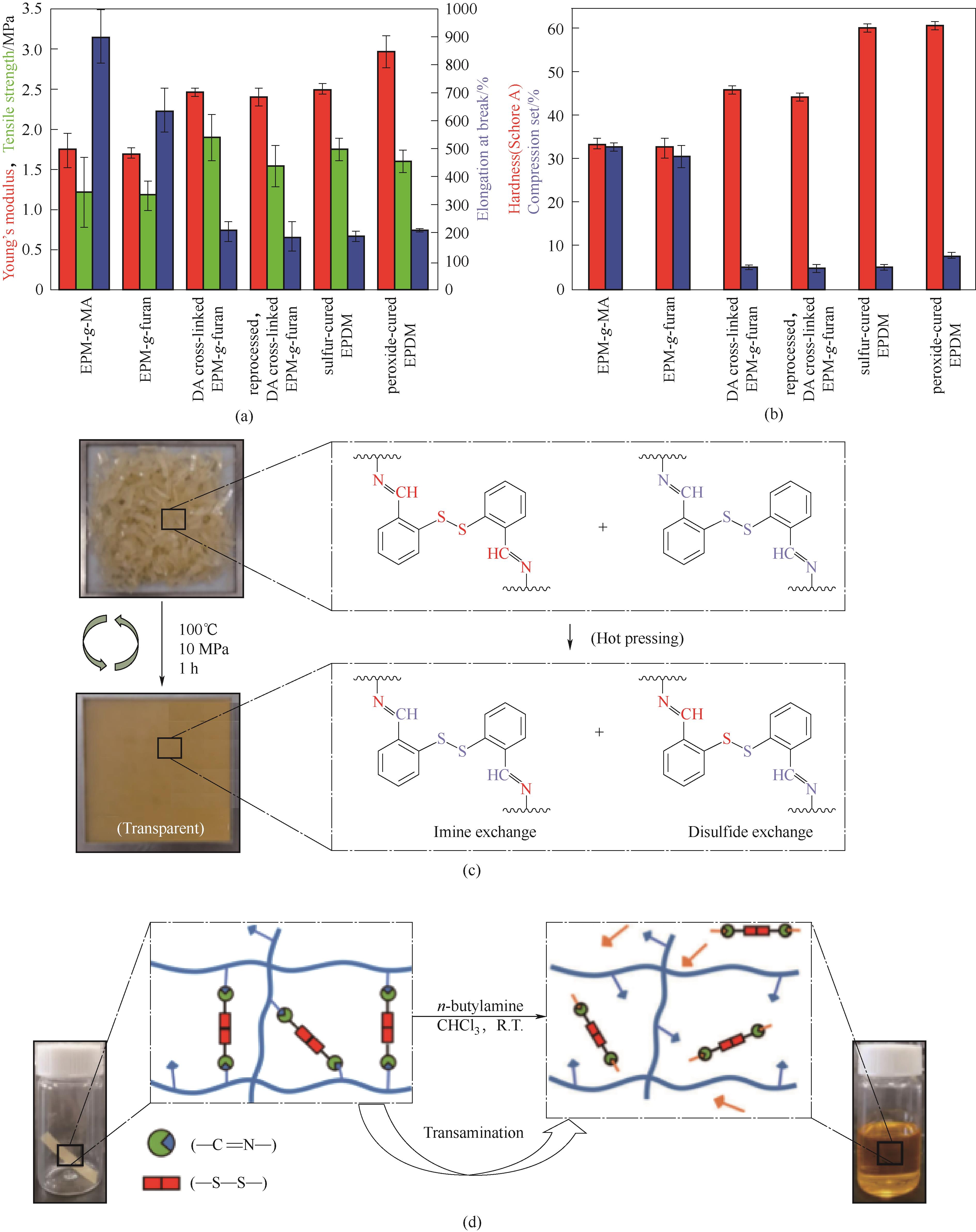

图9 功能化EPDM、DA键交联的EPDM与硫固化或过氧化物固化EPDM的杨氏模量、拉伸断裂强度和断裂伸长率对比(a),以及硬度和压缩比结果(b);亚胺和二硫键双重动态化学交联PB热压过程照片及再加工机理(c);亚胺和二硫键双重动态化学交联PB化学回收的照片与反应机理示意图(d)

Fig.9 Comparison of functional EPDM, DA bond cross-linked EPDM, and sulfur-cured or peroxide-cured EPDM in Young’s modulus, tensile strength at break and elongation at break (a), and hardness and compression ratio (b); Hot pressing process and reprocessing mechanism of imide and disulfide dynamic chemical cross-linked PB (c); Photos and reaction mechanism of imide and disulfide dynamic chemical cross-linked PB via chemical recycling (d)

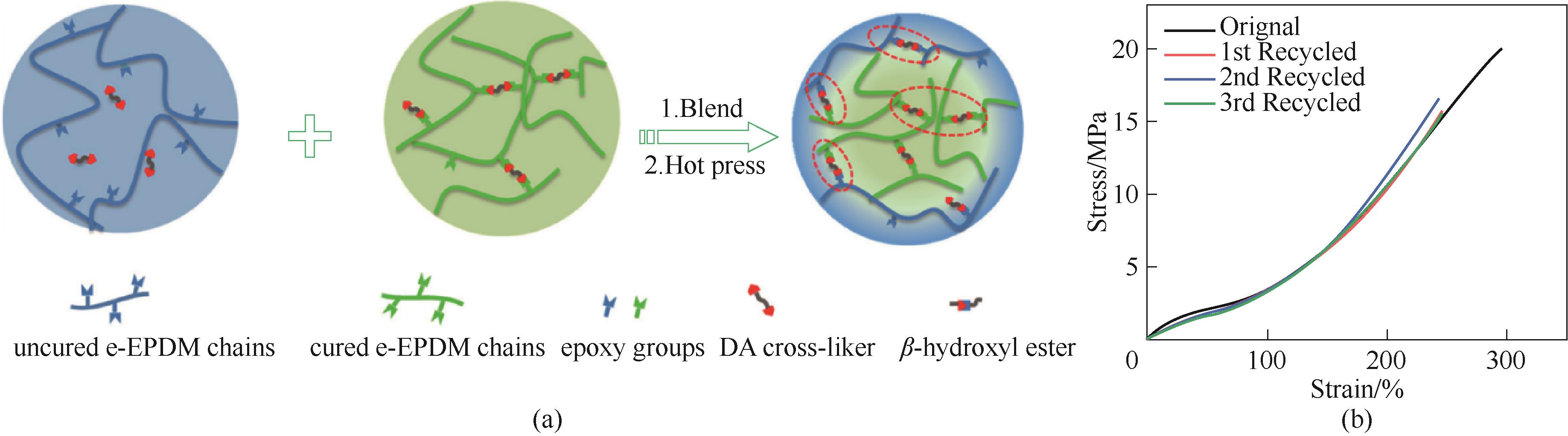

图10 (a)酯键交联EPDM回收过程中交联和交换反应的拓扑重排示意图;(b)多次再加工循环后的典型应力-应变曲线

Fig.10 (a) Schematic illustrating cross-linking reaction and topological rearrangements via exchange reactions in ester bond cross-linked EPDM; (b) Typical stress-strain curves after multiple reprocessing cycles

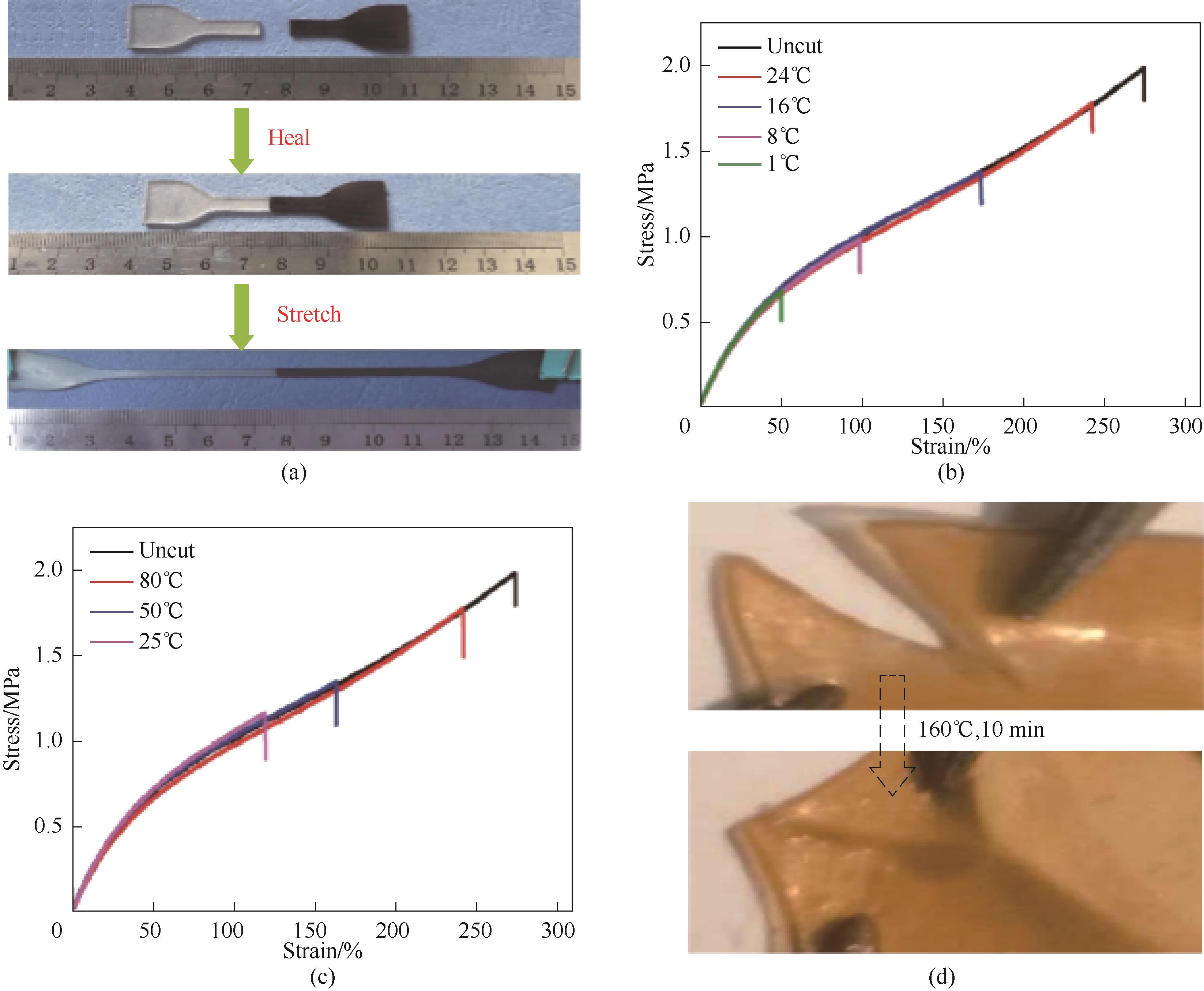

图11 硼酸酯交联的SBR断裂和修复的照片以及修复的SBR拉伸照片(a);硼酸酯交联的SBR在80℃下经过不同时间修复后(b)和在不同温度下24 h修复后(c)的典型应力-应变曲线;断裂的EPDM/SiO2复合物以及在外力、加热作用下EPDM/SiO2复合物的自修复(d)

Fig.11 Photos of fractured and repaired boronic ester cross-linked SBR, and photos of stretching repaired SBR (a); The typical stress-strain curves of the boronic ester cross-linked SBR repaired at 80℃ for various time (b) and repaired at different temperatures for 24 h (c); Fractured EPDM/SiO2 composites, and self-healing of EPDM/SiO2 composites under external force and heating (d)

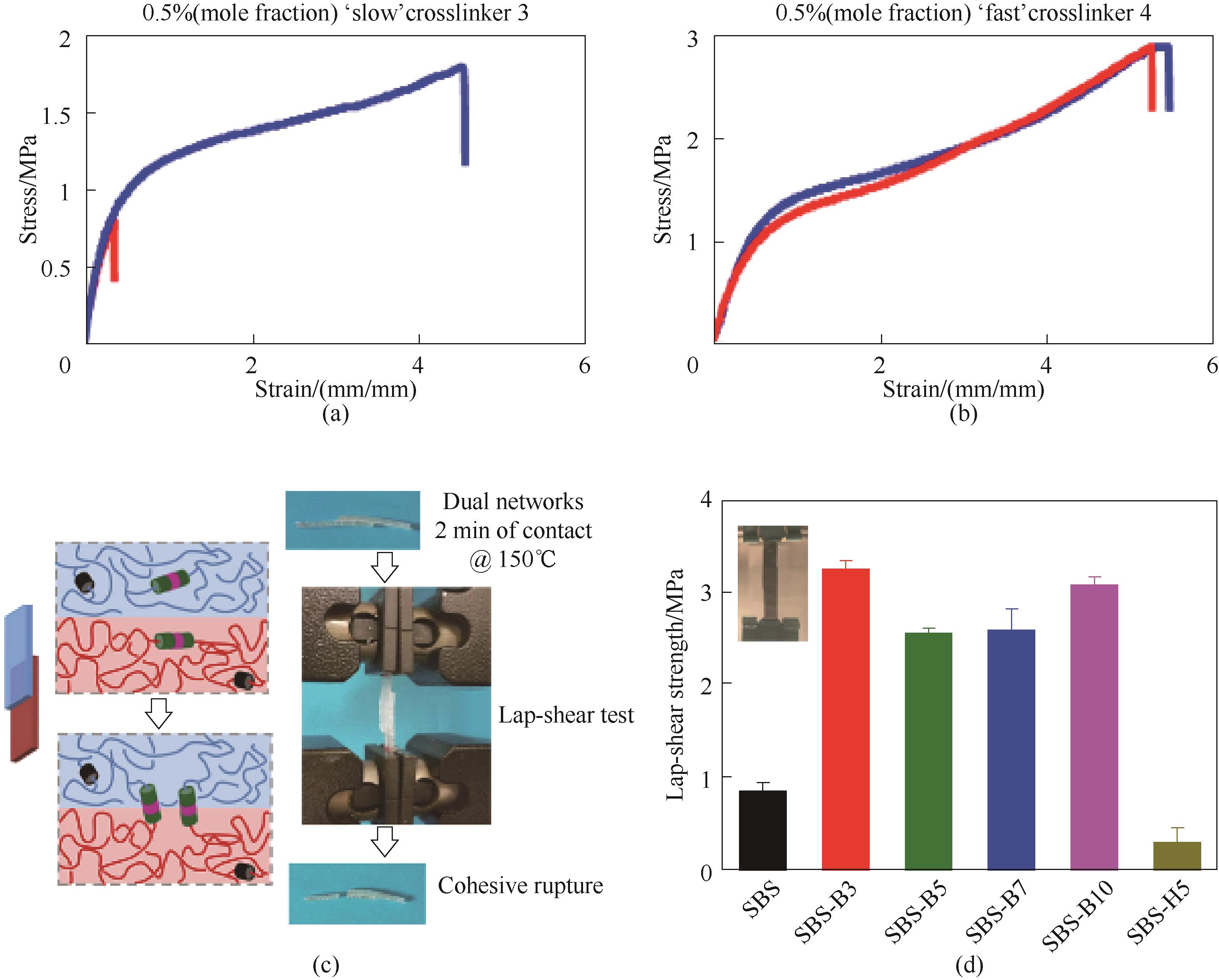

图12 交联的聚环辛烯及自修复后的应力-应变曲线对比(红色曲线为修复后样品,蓝色曲线为原始样品):含0.5%(摩尔分数)慢速硼酸酯交联样品(a);含0.5%(摩尔分数)快速硼酸酯交联样品(b);具有硼酸酯动态化学交联和永久交联的PB样品的黏附性能测试照片与黏附机理图(c);动态硼酸酯交联SBS(SBS-B)与原始SBS、不可逆交联SBS(SBS-H)的黏附性能对比(d)

Fig.12 Comparison of cross-linked polycycloctene (blue curve) and self-healing samples (red curve): the self-healing sample containing 0.5%(mole fraction) slow boronic ester cross-linking (a), and the self-healing sample containing 0.5%(mole fraction) fast boronic ester cross-linking (b); adhesion test and adhesion mechanism of PB samples with boronic ester cross-linking and permanent cross-linking (c); Adhesion properties of dynamic boronic ester cross-linked SBS (SBS-B) compared with original SBS and irreversible cross-linked SBS (SBS-H) (d)

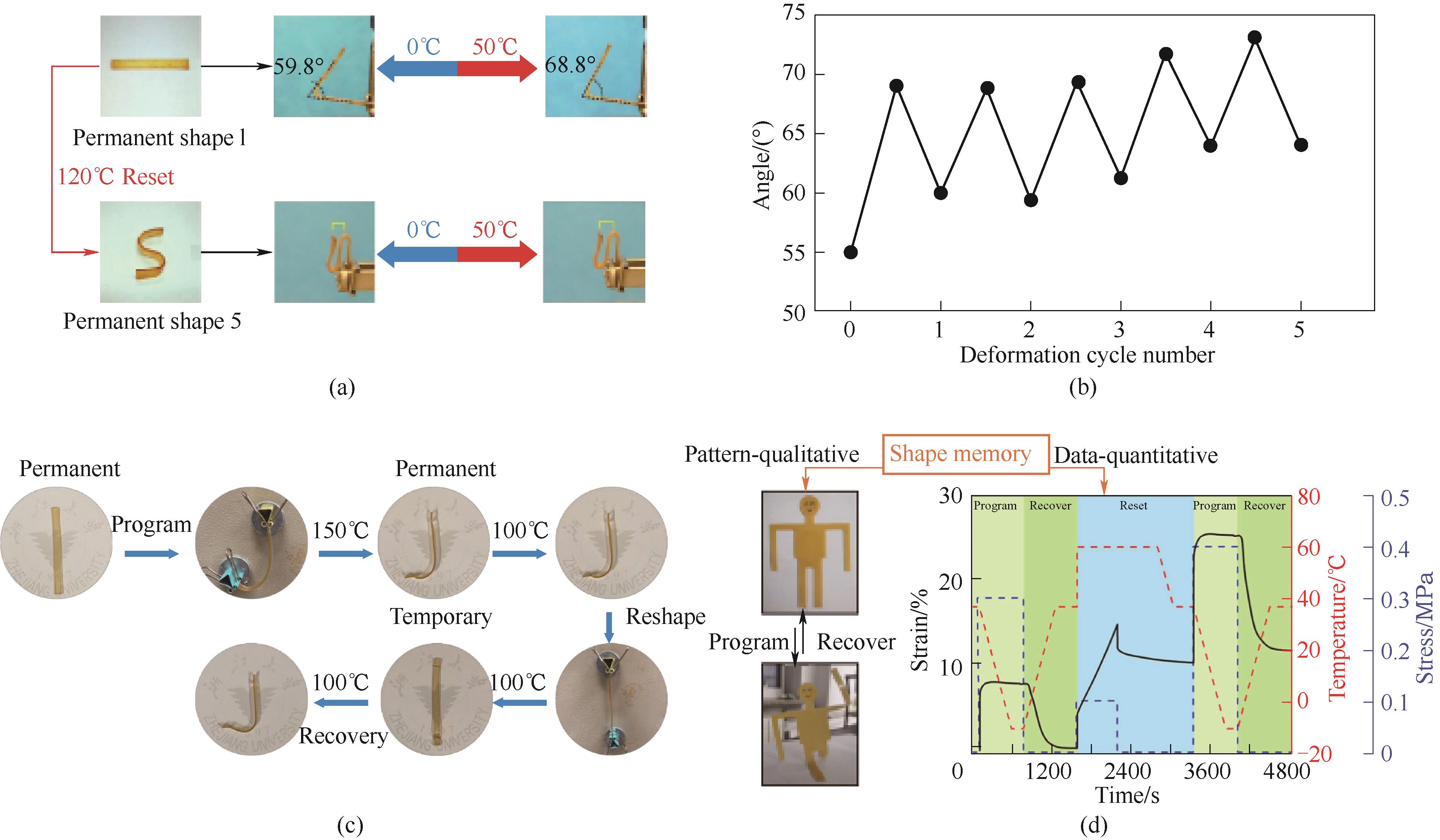

图13 (a)酯键交联的PEVA可逆形状记忆效应的照片;(b)酯键交联的PEVA在加热和冷却循环中临时形状“V”的角度变化;(c)SBS的热触发形状恢复性能;(d)形状记忆行为的定性和定量表征

Fig.13 (a) Reversible shape memory effects of ester bond cross-linked PEVA; (b) Angular variation in the temporary shape “V” of ester cross-linked PEVA during heating and cooling cycles; (c) Heat-triggered shape recovery performance of SBS; (d) Qualitative and quantitative characterization of shape memory behaviour

| 1 | 李伯耿, 张明轩, 刘伟峰, 等. 聚烯烃类弹性体: 现状与进展[J]. 化工进展, 2017, 36(9): 3135-3144. |

| Li B G, Zhang M X, Liu W F, et al. State-of-the-art and research progress of polyolefin-based elastomer[J]. Chemical Industry and Engineering Progress, 2017, 36(9): 3135-3144. | |

| 2 | 张腾, 沈安, 曹育才. 聚烯烃弹性体和塑性体产品及应用现状[J]. 上海塑料, 2021, 49(2): 14-20. |

| Zhang T, Shen A, Cao Y C. Product and application statu of polyolefin elastomers and plastomers[J]. Shanghai Plastics, 2021, 49(2): 14-20. | |

| 3 | Dai S Y, Li S K, Xu G Y, et al. Direct synthesis of polar functionalized polyethylene thermoplastic elastomer[J]. Macromolecules, 2020, 53(7): 2539-2546. |

| 4 | Ghanbari A, Seyedin S, Nofar M, et al. Mechanical properties and foaming behavior of polypropylene/elastomer/recycled carbon fiber composites[J]. Polymer Composites, 2021, 42(7): 3482-3492. |

| 5 | Helal E, Pottier C, David E, et al. Polyethylene/thermoplastic elastomer/zinc oxide nanocomposites for high voltage insulation applications: dielectric, mechanical and rheological behavior[J]. European Polymer Journal, 2018, 100: 258-269. |

| 6 | Hu S X, Wang W, Dang B, et al. Thermal properties and space charge behavior of thermally aged polypropylene/elastomer blends nanocomposite[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2020, 27(2): 521-527. |

| 7 | Ge Y S, Hu L, Zhang L F, et al. Polyolefin elastomer as the anode interfacial layer for improved mechanical and air stabilities in nonfullerene solar cells[J]. ACS Applied Materials & Interfaces, 2020, 12(9): 10706-10716. |

| 8 | Luo L Q, Liu P W, Zhang K L, et al. Vinyl-functionalized polyolefins for fast photovoltaic cell encapsulation[J]. ACS Applied Polymer Materials, 2020, 2(7): 2571-2577. |

| 9 | Mohite A S, Rajpurkar Y D, More A P. Bridging the gap between rubbers and plastics: a review on thermoplastic polyolefin elastomers[J]. Polymer Bulletin, 2022, 79(2): 1309-1343. |

| 10 | Singh A N, Thakre R D, More J C, et al. Block copolymer nanostructures and their applications: a review[J]. Polymer-Plastics Technology and Engineering, 2015, 54(10): 1077-1095. |

| 11 | Sun M H, Xiao Y K, Liu K, et al. Synthesis and characterization of polyolefin thermoplastic elastomers: a review[J]. The Canadian Journal of Chemical Engineering, 2023, 101(9): 4886-4906. |

| 12 | Mark J E, Erman B, Roland C M. The Science and Technology of Rubber [M]. 4th ed. Boston: Elsevier, 2013. |

| 13 | Bensason S, Minick J, Moet A, et al. Classification of homogeneous ethylene-octene copolymers based on comonomer content[J]. Journal of Polymer Science B Polymer Physics, 1996, 34(7): 1301-1315. |

| 14 | Wang W J, Kolodka E, Zhu S P, et al. Continuous solution copolymerization of ethylene and octene-1 with constrained geometry metallocene catalyst[J]. Journal of Polymer Science A Polymer Chemistry, 1999, 37(15): 2949-2957. |

| 15 | Wang W J, Ye Z B, Fan H, et al. Dynamic mechanical and rheological properties of metallocene-catalyzed long-chain-branched ethylene/propylene copolymers[J]. Polymer, 2004, 45(16): 5497-5504. |

| 16 | Wang W J, Kharchenko S, Migler K, et al. Triple-detector GPC characterization and processing behavior of long-chain-branched polyethylene prepared by solution polymerization with constrained geometry catalyst[J]. Polymer, 2004, 45(19): 6495-6505. |

| 17 | Arriola D J, Carnahan E M, Hustad P D, et al. Catalytic production of olefin block copolymers via chain shuttling polymerization[J]. Science, 2006, 312(5774): 714-719. |

| 18 | Zintl M, Rieger B. Novel olefin block copolymers through chain-shuttling polymerization[J]. Angewandte Chemie International Edition, 2007, 46(3): 333-335. |

| 19 | Ohtaki H, Deplace F, Vo G D, et al. Allyl-terminated polypropylene macromonomers: a route to polyolefin elastomers with excellent elastic behavior[J]. Macromolecules, 2015, 48(20): 7489-7494. |

| 20 | Zhang K L, Liu P W, Wang W J, et al. Preparation of comb-shaped polyolefin elastomers having ethylene/1-octene copolymer backbone and long chain polyethylene branches via a tandem metallocene catalyst system[J]. Macromolecules, 2018, 51(21): 8790-8799. |

| 21 | Formon G J M, Storch S, Delplanque A Y G, et al. Overcoming the tradeoff between processability and mechanical performance of elastomeric vitrimers[J]. Advanced Functional Materials, 2023, 33(52): 2306065. |

| 22 | Wu S L, Chen Q. Advances and new opportunities in the rheology of physically and chemically reversible polymers[J]. Macromolecules, 2022, 55(3): 697-714. |

| 23 | Lu Y X, Tournilhac F, Leibler L, et al. Making insoluble polymer networks malleable via olefin metathesis[J]. Journal of the American Chemical Society, 2012, 134(20): 8424-8427. |

| 24 | Zhang H, Wang D, Liu W X, et al. Recyclable polybutadiene elastomer based on dynamic imine bond[J]. Journal of Polymer Science A Polymer Chemistry, 2017, 55(12): 2011-2018. |

| 25 | Zhang H, Wu Y Z, Yang J X, et al. Superstretchable dynamic polymer networks[J]. Advanced Materials, 2019, 31(44): e1904029. |

| 26 | Zhang H, Wang D, Wu N N, et al. Recyclable, self-healing, thermadapt triple-shape memory polymers based on dual dynamic bonds[J]. ACS Applied Materials & Interfaces, 2020, 12(8): 9833-9841. |

| 27 | Zhu L Q, Xu L, Jie S Y, et al. Polybutadiene vitrimers with tunable epoxy ratios: preparation and properties[J]. Polymers, 2021, 13(23): 4157. |

| 28 | Montoya-Ospina M C, Verhoogt H, Osswald T A. Processing and rheological behavior of cross-linked polyethylene containing disulfide bonds[J]. SPE Polymers, 2022, 3(1): 25-40. |

| 29 | Zhang G G, Zhou X X, Liang K, et al. Mechanically robust and recyclable EPDM rubber composites by a green cross-linking strategy[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(13): 11712-11720. |

| 30 | Kar G P, Saed M O, Terentjev E M. Scalable upcycling of thermoplastic polyolefins into vitrimers through transesterification[J]. Journal of Materials Chemistry A, 2020, 8(45): 24137-24147. |

| 31 | Wang S, Ma S Q, Qiu J F, et al. Upcycling of post-consumer polyolefin plastics to covalent adaptable networks via in situ continuous extrusion cross-linking[J]. Green Chemistry, 2021, 23(8): 2931-2937. |

| 32 | Caffy F, Nicolaÿ R. Transformation of polyethylene into a vitrimer by nitroxide radical coupling of a bis-dioxaborolane[J]. Polymer Chemistry, 2019, 10(23): 3107-3115. |

| 33 | Breuillac A, Caffy F, Vialon T, et al. Functionalization of polyisoprene and polystyrene via reactive processing using azidoformate grafting agents, and its application to the synthesis of dioxaborolane-based polyisoprene vitrimers[J]. Polymer Chemistry, 2020, 11(40): 6479-6491. |

| 34 | Chen Y, Tang Z H, Zhang X H, et al. Covalently cross-linked elastomers with self-healing and malleable abilities enabled by boronic ester bonds[J]. ACS Applied Materials & Interfaces, 2018, 10(28): 24224-24231. |

| 35 | Breuillac A, Kassalias A, Nicolaÿ R. Polybutadiene vitrimers based on dioxaborolane chemistry and dual networks with static and dynamic cross-links[J]. Macromolecules, 2019, 52(18): 7102-7113. |

| 36 | Röttger M, Domenech T, van der Weegen R, et al. High-performance vitrimers from commodity thermoplastics through dioxaborolane metathesis[J]. Science, 2017, 356(6333): 62-65. |

| 37 | Xiao Y K, Liu P W, Wang W J, et al. Dynamically cross-linked polyolefin elastomers with highly improved mechanical and thermal performance[J]. Macromolecules, 2021, 54(22): 10381-10387. |

| 38 | Wang W Y, Zha X J, Bao R Y, et al. Vitrimers of polyolefin elastomer with physically cross-linked network[J]. Journal of Polymer Research, 2021, 28(6): 210. |

| 39 | Yang F, Pan L, Ma Z, et al. Highly elastic, strong, and reprocessable cross-linked polyolefin elastomers enabled by boronic ester bonds[J]. Polymer Chemistry, 2020, 11(19): 3285-3295. |

| 40 | He Z K, Niu H, Liu L Y, et al. Elastomeric polyolefin vitrimer: dynamic imine bond cross-linked ethylene/propylene copolymer[J]. Polymer, 2021, 229: 124015. |

| 41 | Tan C, Zou C, Chen C L. Material properties of functional polyethylenes from transition-metal-catalyzed ethylene-polar monomer copolymerization[J]. Macromolecules, 2022, 55(6): 1910-1922. |

| 42 | Tan C, Zou C, Chen C L. An ionic cluster strategy for performance improvements and product morphology control in metal-catalyzed olefin-polar monomer copolymerization[J]. Journal of the American Chemical Society, 2022, 144(5): 2245-2254. |

| 43 | van Zee N J, Nicolaÿ R. Vitrimers: permanently crosslinked polymers with dynamic network topology[J]. Progress in Polymer Science, 2020, 104: 101233. |

| 44 | de Vito G, Lanzetta N, Maglio G, et al. Functionalization of an amorphous ethylene-propylene copolymer by free radical initiated grafting of unsaturated molecules[J]. Journal of Polymer Science A Polymer Chemistry, 1984, 22(6): 1335-1347. |

| 45 | He Z K, Niu H, Zheng N, et al. Poly(ethylene-co-propylene)/poly(ethylene glycol) elastomeric hydrogels with thermoreversibly cross-linked networks[J]. Polymer Chemistry, 2019, 10(35): 4789-4800. |

| 46 | Zhao Y S, Li J L, Ma Y Q, et al. One-step reactive processing of vitrimeric thermoplastic polyolefin elastomer with greatly improved thermo-mechanical property[J]. Polymer, 2023, 282: 126185. |

| 47 | Fenimore L M, Chen B J, Chen Y X, et al. Covalent adaptable networks and thermosets of multi-block ethylene/1-octene copolymers made by free-radical processing: effects of melt flow index and crystallinity on thermomechanical properties and reprocessability [J]. Eur. Polym. J., 2024, 202: 112661. |

| 48 | Tretbar C, Castro J, Yokoyama K, et al. Fluoride-catalyzed siloxane exchange as a robust dynamic chemistry for high-performance vitrimers[J]. Advanced Materials, 2023, 35(28): e2303280. |

| 49 | Ma Y W, Shen Y F, Liu Z Y, et al. Exploring multiple functions of diarylsemipinacol linked to the saturated ethylene-propylene elastomer: from the dynamic covalent networks to tailoring its macroscopic performance[J]. Polymer Chemistry, 2019, 10(45): 6157-6165. |

| 50 | Zhang C X, Liu Z Y, Shi Z X, et al. Versatile approach to building dynamic covalent polymer networks by stimulating the dormant groups[J]. ACS Macro Letters, 2018, 7(11): 1371-1375. |

| 51 | Briou B, Améduri B, Boutevin B. Trends in the Diels-Alder reaction in polymer chemistry[J]. Chemical Society Reviews, 2021, 50(19): 11055-11097. |

| 52 | Jia Z, Zhu S L, Chen Y J, et al. Recyclable and self-healing rubber composites based on thermorevesible dynamic covalent bonding[J]. Composites Part A—Applied Science and Manufacturing, 2020, 129: 105709. |

| 53 | Chen X X, Dam M A, Ono K, et al. A thermally re-mendable cross-linked polymeric material[J]. Science, 2002, 295(5560): 1698-1702. |

| 54 | Hong M, Liu S R, Li B X, et al. Application of thiol-ene click chemistry to preparation of functional polyethylene with high molecular weight and high polar group content: influence of thiol structure and vinyl type on reactivity[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2012, 50(12): 2499-2506. |

| 55 | Wu W J, Zeng X R, Li H Q, et al. Facile synthesis of polyhydroxylated polybutadiene derived from hydroxyl-terminated polybutadiene via thiol-ene click reaction[J]. Journal of Macromolecular Science, Part A, 2014, 51(3): 229-239. |

| 56 | Li L, Li S H, Cui D M. Chemo- and stereoselective polymerization of 3-methylenehepta-1, 6-diene and its thiol-ene modification[J]. Journal of Polymer Science A Polymer Chemistry, 2017, 55(6): 1031-1039. |

| 57 | Kumar G S, Moorthy S, Karmakar H, et al. Neosilyllithium-catalyzed hydroboration of alkynes and alkenes in the presence of pinacolborane (HBpin)[J]. European Journal of Inorganic Chemistry, 2022, 2022(2): e202100895. |

| 58 | Terao H, Ishii S, Mitani M, et al. Ethylene/polar monomer copolymerization behavior of bis(phenoxy-imine)Ti complexes: formation of polar monomer copolymers[J]. Journal of the American Chemical Society, 2008, 130(52): 17636-17637. |

| 59 | Sampson J, Bruening M, Akhtar M N, et al. Copolymerization of ethylene and long-chain functional α-olefins by dinuclear zirconium catalysts[J]. Organometallics, 2021, 40(12): 1854-1858. |

| 60 | Edeleva M, van Steenberge P H M, Sabbe M K, et al. Connecting gas-phase computational chemistry to condensed phase kinetic modeling: the state-of-the-art[J]. Polymers, 2021, 13(18): 3027. |

| 61 | Galimberti M, Giannini U, Albizzati E, et al. Functionalized polymers from Ziegler-Natta catalysts[J]. Journal of Molecular Catalysis A: Chemical, 1995, 101(1): 1-10. |

| 62 | Kitphaitun S, Yan Q, Nomura K. The effect of SiMe3 and SiEt3 para substituents for high activity and introduction of a hydroxy group in ethylene copolymerization catalyzed by phenoxide-modified half-titanocenes[J]. Angewandte Chemie International Edition, 2020, 59(51): 23072-23076. |

| 63 | Wang A H, Niu H, He Z K, et al. Thermoreversible cross-linking of ethylene/propylene copolymer rubbers[J]. Polymer Chemistry, 2017, 8(31): 4494-4502. |

| 64 | Liu S H, Liu X Y, He Z K, et al. Thermoreversible cross-linking of ethylene/propylene copolymers based on Diels-Alder chemistry: the cross-linking reaction kinetics[J]. Polymer Chemistry, 2020, 11(36): 5851-5860. |

| 65 | Ittel S D, Johnson L K, Brookhart M. Late-metal catalysts for ethylene homo- and copolymerization[J]. Chemical Reviews, 2000, 100(4): 1169-1204. |

| 66 | Wang W B, Chen M, Pang W M, et al. Palladium-catalyzed synthesis of norbornene-based polar-functionalized polyolefin elastomers[J]. Macromolecules, 2021, 54(7): 3197-3203. |

| 67 | Odenwald L, Wimmer F P, Mast N K, et al. Molecularly defined polyolefin vitrimers from catalytic insertion polymerization[J]. Journal of the American Chemical Society, 2022, 144(29): 13226-13233. |

| 68 | Zhong S H, Tan Y X, Zhong L, et al. Precision synthesis of ethylene and polar monomer copolymers by palladium-catalyzed living coordination copolymerization[J]. Macromolecules, 2017, 50(15): 5661-5669. |

| 69 | Guo L H, Dai S Y, Sui X L, et al. Palladium and nickel catalyzed chain walking olefin polymerization and copolymerization[J]. ACS Catal., 2016, 6(1): 428-41. |

| 70 | Xiao Y, Wang W J, Li B G, et al. High-performance olefin thermoplastic elastomer based on dynamically cross-linking crystalline macromers and elastic backbones[J]. Macromolecules, . |

| 71 | Xu Z, Liu Y B, Wei D W, et al. Configurational entropy regulation in polyolefin elastomer/paraffin wax vitrimers by thermally responsive liquid-solid transition for force storage[J]. ACS Applied Materials & Interfaces, 2023, 15(9): 12423-12433. |

| 72 | Ahmadi M, Hanifpour A, Ghiassinejad S, et al. Polyolefins vitrimers: design principles and applications[J]. Chemistry of Materials, 2022, 34(23): 10249-10271. |

| 73 | Luo J C, Demchuk Z, Zhao X, et al. Elastic vitrimers: beyond thermoplastic and thermoset elastomers[J]. Matter, 2022, 5(5): 1391-1422. |

| 74 | Wan B Q, Xiao M Y, Dong X D, et al. Dynamic covalent adaptable polyimide hybrid dielectric films with superior recyclability[J]. Advanced Materials, 2023: e2304175. |

| 75 | Zhu L Q, Xu L, Jie S Y, et al. Preparation of styrene-butadiene rubber vitrimers with high strength and toughness through imine and hydrogen bonds[J]. Industrial & Engineering Chemistry Research, 2023, 62(5): 2299-2308. |

| 76 | Zhu L Q, Xu L, Jie S Y, et al. Upgrade SBS into vitrimers with excellent mechanical and physical properties[J]. European Polymer Journal, 2022, 180: 111600. |

| 77 | Koenig J L. The chemical reactions of network structures in elastomers[J]. Accounts of Chemical Research, 1999, 32(1): 1-8. |

| 78 | Pire M, Lorthioir C, Oikonomou E K, et al. Imidazole-accelerated crosslinking of epoxidized natural rubber by dicarboxylic acids: a mechanistic investigation using NMR spectroscopy[J]. Polymer Chemistry, 2012, 3(4): 946-953. |

| 79 | Litvinov V M, Dias A A. Analysis of network structure of UV-cured acrylates by 1H NMR relaxation, 13C NMR spectroscopy, and dynamic mechanical experiments[J]. Macromolecules, 2001, 34(12): 4051-4060. |

| 80 | Orza R A, Magusin P C M M, Litvinov V M, et al. Solid-state 1H NMR study on chemical cross-links, chain entanglements, and network heterogeneity in peroxide-cured EPDM rubbers[J]. Macromolecules, 2007, 40(25): 8999-9008. |

| 81 | Paturej J, Sheiko S S, Panyukov S, et al. Molecular structure of bottlebrush polymers in melts[J]. Science Advances, 2016, 2(11): e1601478. |

| 82 | Ricarte R G, Tournilhac F, Cloître M, et al. Linear viscoelasticity and flow of self-assembled vitrimers: the case of a polyethylene/dioxaborolane system[J]. Macromolecules, 2020, 53(5): 1852-1866. |

| 83 | Fang H G, Gao X C, Zhang F, et al. Triblock elastomeric vitrimers: preparation, morphology, rheology, and applications[J]. Macromolecules, 2022, 55(24): 10900-10911. |

| 84 | Xie M J, Wang C C, Zhang R, et al. Length effect of crosslinkers on the mechanical properties and dimensional stability of vitrimer elastomers with inhomogeneous networks[J]. Polymer, 2024, 290: 126550. |

| 85 | Wang S, Hu Y X, Kouznetsova T B, et al. Facile mechanochemical cycloreversion of polymer cross-linkers enhances tear resistance[J]. Science, 2023, 380(6651): 1248-1252. |

| 86 | Xu G F, Xiao Y K, Wang W J, et al. Rheological and mechanical study of comb-branched polyolefin elastomers containing macromer residues[J]. Macromolecules, 2023, 56(8): 3064-3072. |

| 87 | Polgar L M, van Duin M, Broekhuis A A, et al. Use of Diels-Alder chemistry for thermoreversible cross-linking of rubbers: the next step toward recycling of rubber products?[J]. Macromolecules, 2015, 48(19): 7096-7105. |

| 88 | Chen M, Zhou L, Wu Y P, et al. Rapid stress relaxation and moderate temperature of malleability enabled by the synergy of disulfide metathesis and carboxylate transesterification in epoxy vitrimers[J]. ACS Macro Letters, 2019, 8(3): 255-260. |

| 89 | Yang Z H, Wang Q H, Wang T M. Dual-triggered and thermally reconfigurable shape memory graphene-vitrimer composites[J]. ACS Applied Materials & Interfaces, 2016, 8(33): 21691-21699. |

| 90 | Capelot M, Unterlass M M, Tournilhac F, et al. Catalytic control of the vitrimer glass transition[J]. ACS Macro Letters, 2012, 1(7): 789-792. |

| 91 | Yang Y, Zhang S, Zhang X Q, et al. Detecting topology freezing transition temperature of vitrimers by AIE luminogens[J]. Nature Communications, 2019, 10: 3165. |

| 92 | Fang H G, Ye W J, Ding Y S, et al. Rheology of the critical transition state of an epoxy vitrimer[J]. Macromolecules, 2020, 53(12): 4855-4862. |

| 93 | Yang Y X, Huang L Y, Wu R Y, et al. Self-strengthening, self-welding, shape memory, and recyclable polybutadiene-based material driven by dual-dynamic units[J]. ACS Applied Materials & Interfaces, 2022, 14(2): 3344-3355. |

| 94 | Montoya-Ospina M C, Verhoogt H, Ordner M, et al. Effect of cross-linking on the mechanical properties, degree of crystallinity and thermal stability of polyethylene vitrimers[J]. Polymer Engineering & Science, 2022, 62(12): 4203-4213. |

| 95 | Cromwell O R, Chung J, Guan Z B. Malleable and self-healing covalent polymer networks through tunable dynamic boronic ester bonds[J]. Journal of the American Chemical Society, 2015, 137(20): 6492-6495. |

| 96 | Ricarte R G, Tournilhac F, Leibler L. Phase separation and self-assembly in vitrimers: hierarchical morphology of molten and semicrystalline polyethylene/dioxaborolane maleimide systems[J]. Macromolecules, 2019, 52(2): 432-443. |

| 97 | Prathumrat P, Nikzad M, Hajizadeh E, et al. Shape memory elastomers: a review of synthesis, design, advanced manufacturing, and emerging applications[J]. Polymers for Advanced Technologies, 2022, 33(6): 1782-1808. |

| 98 | Gopinath S, Adarsh N N, Nair P R, et al. Recent trends in thermo‐responsive elastomeric shape memory polymer nanocomposites[J]. Polymer Composites, 2023, 44(8): 4433-4458. |

| 99 | Zheng N, Xu Y, Zhao Q, et al. Dynamic covalent polymer networks: a molecular platform for designing functions beyond chemical recycling and self-healing[J]. Chemical Reviews, 2021, 121(3): 1716-1745. |

| 100 | Gao Y, Liu W F, Zhu S P. Thermoplastic polyolefin elastomer blends for multiple and reversible shape memory polymers[J]. Industrial & Engineering Chemistry Research, 2019, 58(42): 19495-19502. |

| 101 | Gao Y, Liu W F, Zhu S P. Polyolefin thermoplastics for multiple shape and reversible shape memory[J]. ACS Applied Materials & Interfaces, 2017, 9(5): 4882-4889. |

| 102 | Gao Y, Liu W F, Zhu S P. Reversible shape memory polymer from semicrystalline poly(ethylene-co-vinyl acetate) with dynamic covalent polymer networks[J]. Macromolecules, 2018, 51(21): 8956-8963. |

| [1] | 丁相斐, 丘晓琳, 朱喜成, 张佳伟, 陈锦华. pH响应性气体渗透CNC/PBAT复合膜的制备与性能[J]. 化工学报, 2024, 75(3): 1040-1051. |

| [2] | 肖拥君, 时兆翀, 万仁, 宋璠, 彭昌军, 刘洪来. 反向传播神经网络用于预测离子液体的自扩散系数[J]. 化工学报, 2024, 75(2): 429-438. |

| [3] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [4] | 刘宇喆, 李成才, 李琳, 王少辉, 刘培慧, 王同华. 活性炭的微结构与超级电容器性能的构效关系[J]. 化工学报, 2022, 73(4): 1807-1816. |

| [5] | 刘鑫, 冯平丽, 侯文烁, 王振华, 孙克宁. 锂硫电池中间层的研究进展[J]. 化工学报, 2020, 71(9): 4031-4045. |

| [6] | 范炳芝, 王一鑫, 廉霄甜, 谢维松, 于洋, 梁建华. 三萜类化合物抗病毒的构效关系及其作用机制研究进展[J]. 化工学报, 2020, 71(9): 4071-4101. |

| [7] | 杨鑫宇, 吴杰, 张建庭, 吴纯鑫, 赵德明. 功能化磁性纳米复合材料Fe3O4-mPD/SP吸附Cr(Ⅵ)研究[J]. 化工学报, 2020, 71(3): 1060-1071. |

| [8] | 田璐瑶, 王梓豪, 粟杨, 文华强, 申威峰. 基于深度学习的溶剂定量构效关系建模研究进展[J]. 化工学报, 2020, 71(10): 4462-4472. |

| [9] | 肖俏欣, 林文俊, 李浩然, 王从敏. 含醚阴离子功能化离子液体高效捕集SO2[J]. 化工学报, 2020, 71(1): 361-367. |

| [10] | 邓晓霞, 龚磊, 刘小棒, 邓东顺. 咪唑类三元低共熔溶剂捕集低压SO2的实验研究[J]. 化工学报, 2020, 71(1): 368-375. |

| [11] | 刘亚敏, 彭蕾, 苏凤英, 王湘湘, 黄艺真, 林在春, 喻晓静, 裴义山. 多孔胺基化氧化石墨烯基材料对CO2的吸附性能研究[J]. 化工学报, 2019, 70(5): 2016-2024. |

| [12] | 马香成, 秦蔚, 陈清林, 张冰剑. 芳烃分子描述符的修正和沸点预测建模[J]. 化工学报, 2019, 70(11): 4306-4314. |

| [13] | 何凯武, 唐思扬, 刘长军, 岳海荣, 梁斌. 有机胺功能化介孔固体吸附剂吸附分离CO2性能研究[J]. 化工学报, 2018, 69(9): 3887-3895. |

| [14] | 牛立博, 刘辰, 马苑媛, 张慧玲, 白国义. 核壳结构镍基纳米催化剂的制备及其在肉桂醛加氢反应中的性能[J]. 化工学报, 2017, 68(11): 4161-4168. |

| [15] | 胡甜甜, 赵地顺, 武宇, 张拴力, 扈士海, 翟建华. 醚基功能化离子液体催化合成乙酸正丁酯[J]. 化工学报, 2017, 68(1): 136-145. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号