化工学报 ›› 2024, Vol. 75 ›› Issue (10): 3414-3423.DOI: 10.11949/0438-1157.20240521

收稿日期:2024-05-13

修回日期:2024-06-26

出版日期:2024-10-25

发布日期:2024-11-04

通讯作者:

崔颖晗

作者简介:王迪(1989—),男,博士,副教授,wd1989125@163.com

基金资助:

Di WANG1( ), Yinghan CUI1(

), Yinghan CUI1( ), Lingfang SUN1, Yunlong ZHOU2

), Lingfang SUN1, Yunlong ZHOU2

Received:2024-05-13

Revised:2024-06-26

Online:2024-10-25

Published:2024-11-04

Contact:

Yinghan CUI

摘要:

为了解决可再生能源的间歇性和不稳定性等问题,基于超临界压缩二氧化碳储能(supercritical compressed carbon dioxide energy storage,SC-CCES)系统,利用CO2基二元混合物作为循环工质,对系统进行热力学性能分析。研究不同混合工质在不同比例下的储能性能以及储能系统往返效率和储能密度的变化规律。结果表明:超临界CO2混合工质储能系统的往返效率随着混入氪气质量分数的增加而升高,且高于单一CO2工质的往返效率;随着混入异丁烷、R32、R134a、丙烷的质量分数的增加能够使储能密度逐渐增加。研究结果可对未来建设CO2混合工质储能循环工程应用奠定理论基础。

中图分类号:

王迪, 崔颖晗, 孙灵芳, 周云龙. 超临界二氧化碳混合工质储能系统热力学分析[J]. 化工学报, 2024, 75(10): 3414-3423.

Di WANG, Yinghan CUI, Lingfang SUN, Yunlong ZHOU. Thermodynamic analysis of supercritical carbon dioxide mixed working fluid energy storage system[J]. CIESC Journal, 2024, 75(10): 3414-3423.

| 参数 | 仿真值 | 参考值 | 相对误差/% |

|---|---|---|---|

| 主压缩机温度/K | 322.8 | 324 | 0.37 |

| 主压缩机压力/kPa | 13842 | 13840 | 0.01 |

| 再压缩机温度/K | 391.9 | 391 | 0.23 |

| 再压缩机压力/kPa | 13968 | 13731 | 1.73 |

| 透平温度/K | 747.8 | 750 | 0.29 |

| 透平压力/kPa | 7889 | 7890 | 0.01 |

| 低温回热器热端温度/K | 337.2 | 335 | 0.66 |

| 低温回热器热端压力/kPa | 7820 | 7760 | 0.77 |

| 低温回热器冷端温度/K | 391.3 | 389 | 0.59 |

| 低温回热器冷端压力/kPa | 13840 | 13730 | 0.8 |

| 高温回热器热端温度/K | 415 | 418 | 0.72 |

| 高温回热器热端压力/kPa | 7890 | 7820 | 0.9 |

| 高温回热器冷端温度/K | 695.7 | 698 | 0.33 |

| 高温回热器冷端压力/kPa | 13730 | 13610 | 0.88 |

表1 模型验证

Table 1 Verification of the model

| 参数 | 仿真值 | 参考值 | 相对误差/% |

|---|---|---|---|

| 主压缩机温度/K | 322.8 | 324 | 0.37 |

| 主压缩机压力/kPa | 13842 | 13840 | 0.01 |

| 再压缩机温度/K | 391.9 | 391 | 0.23 |

| 再压缩机压力/kPa | 13968 | 13731 | 1.73 |

| 透平温度/K | 747.8 | 750 | 0.29 |

| 透平压力/kPa | 7889 | 7890 | 0.01 |

| 低温回热器热端温度/K | 337.2 | 335 | 0.66 |

| 低温回热器热端压力/kPa | 7820 | 7760 | 0.77 |

| 低温回热器冷端温度/K | 391.3 | 389 | 0.59 |

| 低温回热器冷端压力/kPa | 13840 | 13730 | 0.8 |

| 高温回热器热端温度/K | 415 | 418 | 0.72 |

| 高温回热器热端压力/kPa | 7890 | 7820 | 0.9 |

| 高温回热器冷端温度/K | 695.7 | 698 | 0.33 |

| 高温回热器冷端压力/kPa | 13730 | 13610 | 0.88 |

| 参数 | 数值 |

|---|---|

| 储能时间/s | 660 |

| 释能时间/s | 480 |

| 储能阶段混合工质流量/(kg/s) | 70 |

| 释能阶段混合工质流量/(kg/s) | 80 |

| 压缩机等熵效率/% | 89 |

| 透平等熵效率/% | 90 |

| 储冷罐内导热油体积/m3 | 55 |

| 储热罐内导热油体积/m3 | 0 |

| 环境温度/K | 298.15 |

| 热源温度/K | 838.15 |

表2 系统设计参数

Table 2 System design parameter

| 参数 | 数值 |

|---|---|

| 储能时间/s | 660 |

| 释能时间/s | 480 |

| 储能阶段混合工质流量/(kg/s) | 70 |

| 释能阶段混合工质流量/(kg/s) | 80 |

| 压缩机等熵效率/% | 89 |

| 透平等熵效率/% | 90 |

| 储冷罐内导热油体积/m3 | 55 |

| 储热罐内导热油体积/m3 | 0 |

| 环境温度/K | 298.15 |

| 热源温度/K | 838.15 |

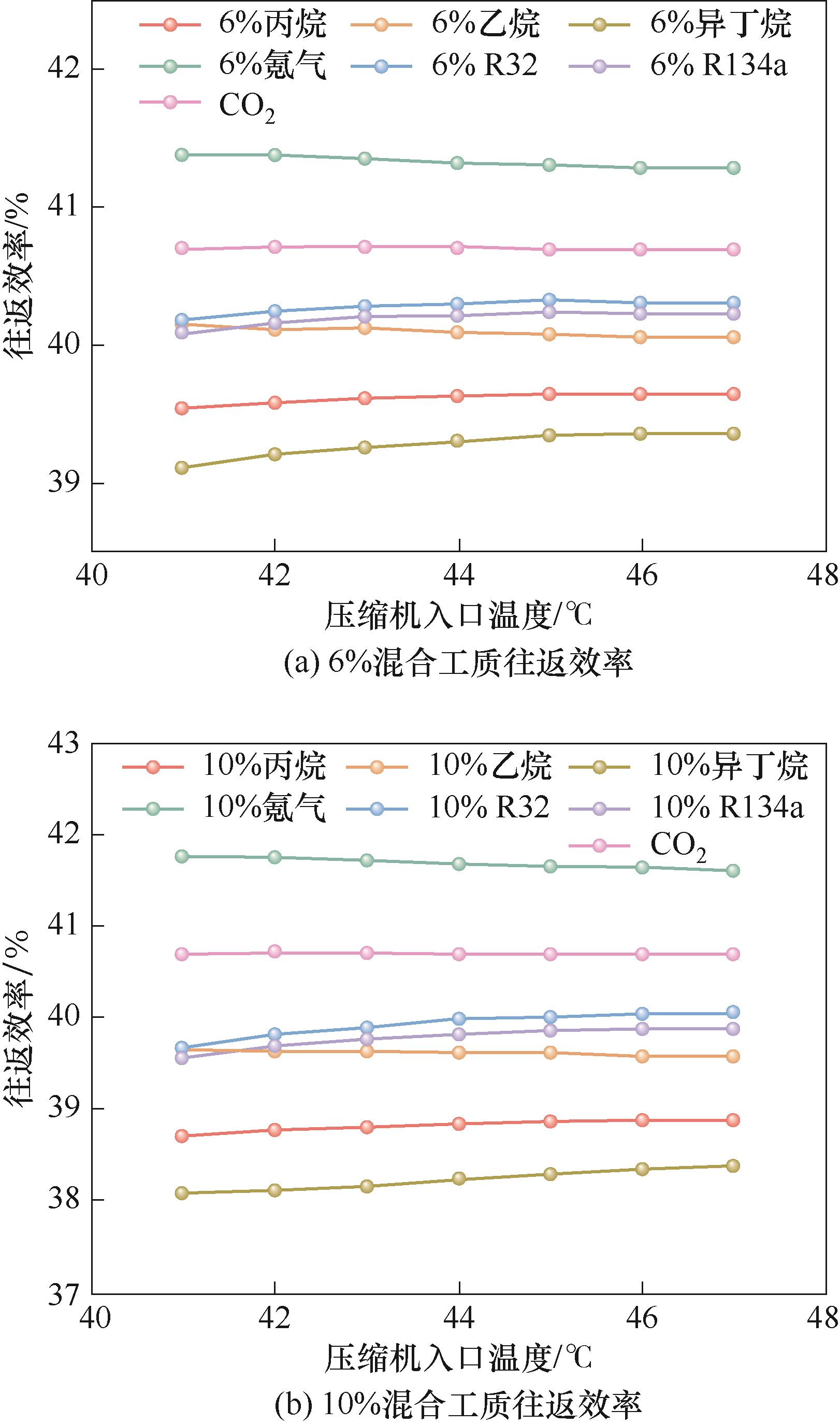

图5 压缩机入口温度变化下混合工质质量分数为6%、10%的往返效率

Fig.5 The round-trip efficiency with the mass fraction of the mixed working medium is 6% and 10% under the change of compressor inlet temperature

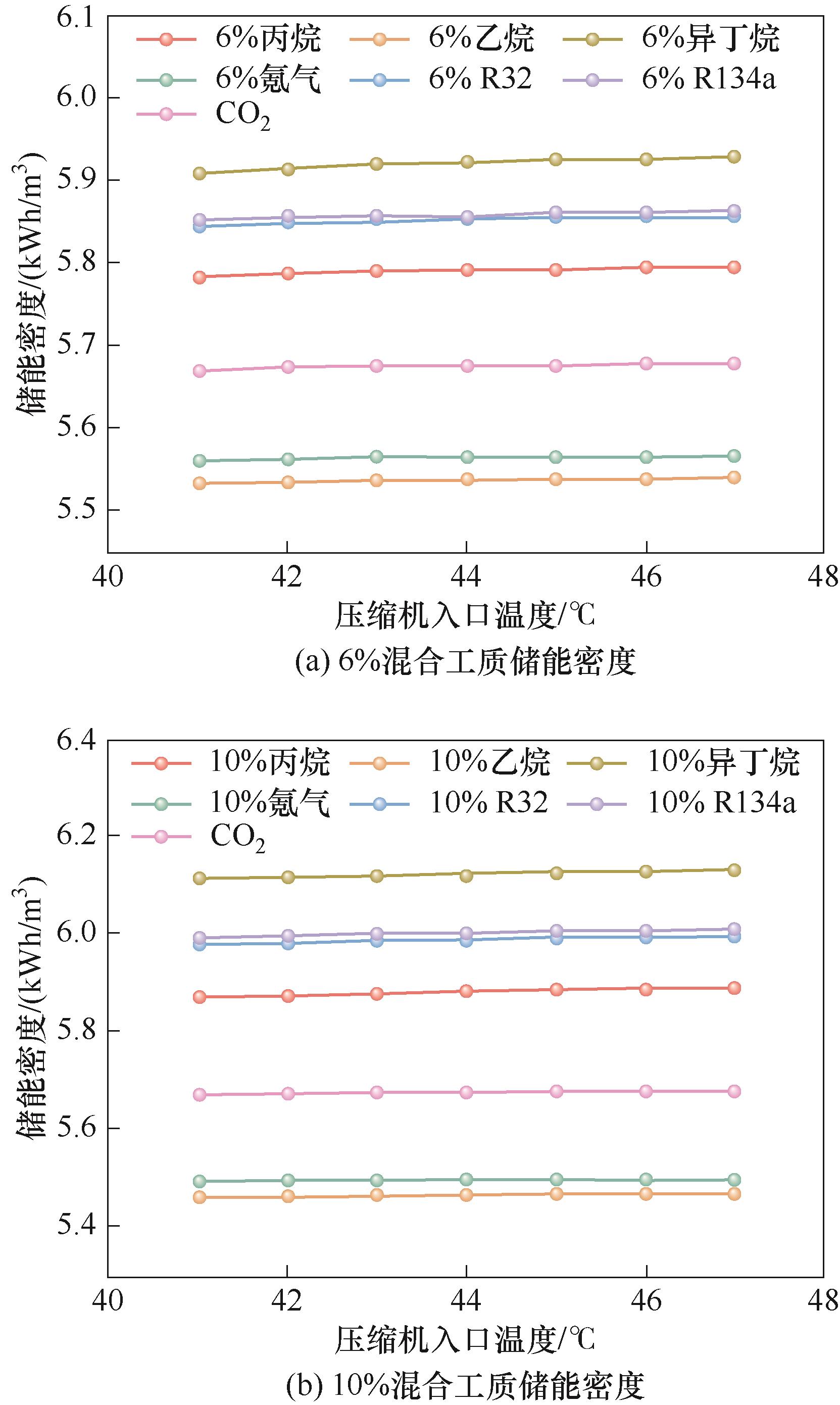

图6 压缩机入口温度变化下混合工质质量分数为6%、10%的储能密度

Fig. 6 The energy storage density with the mass fraction of the mixed working medium is 6% and 10% under the change of compressor inlet temperature

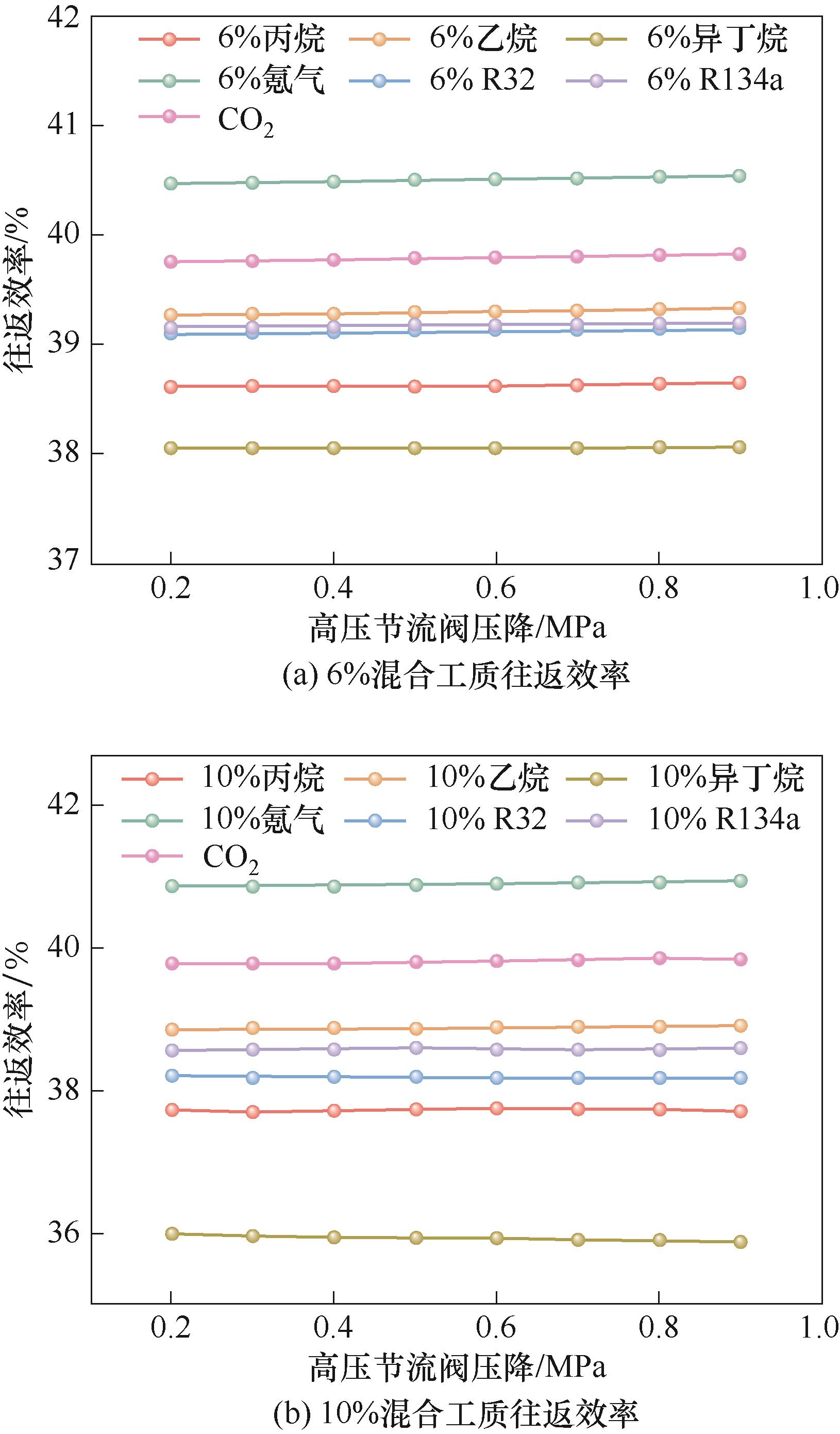

图7 高压节流阀压降变化下混合工质质量分数为6%、10%的往返效率

Fig. 7 The round-trip efficiency of the mass fraction of the mixed working medium is 6% and 10% under the pressure drop change of the throttle valve

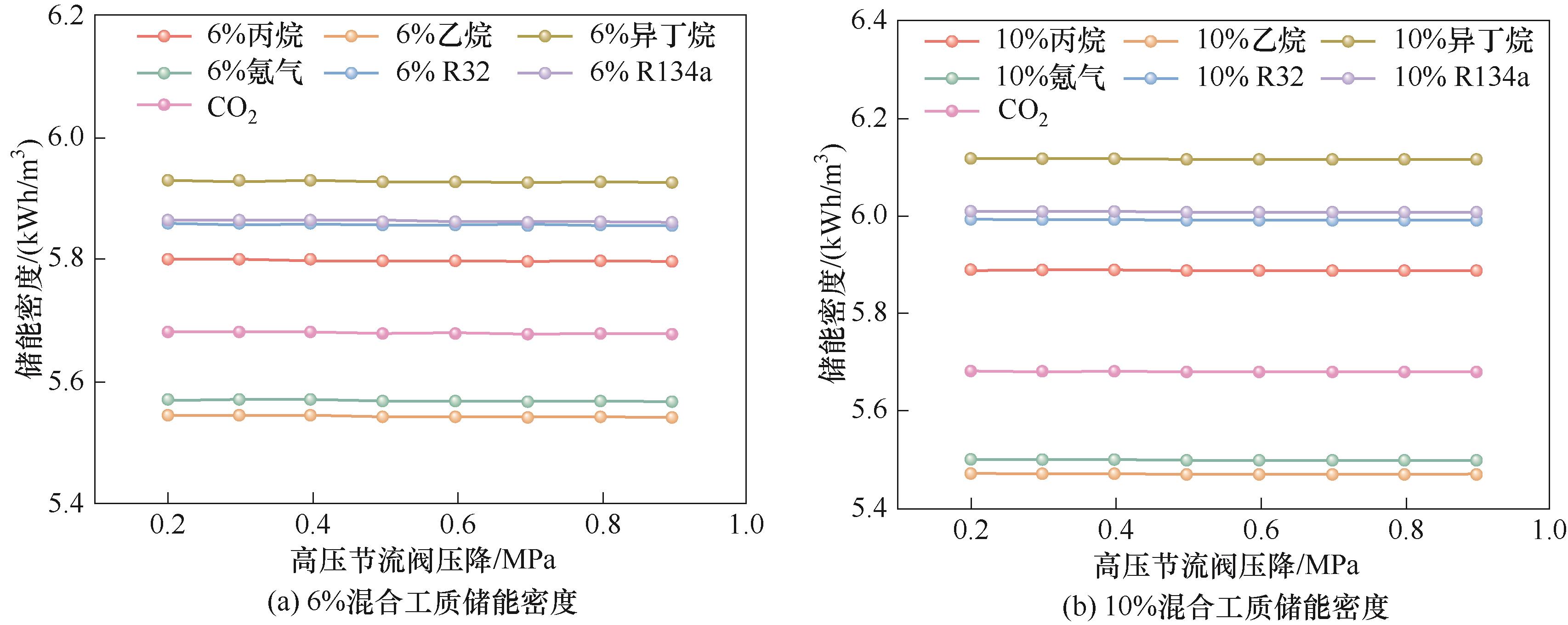

图8 高压节流阀压降变化下混合工质质量分数为6%、10%的储能密度

Fig. 8 The energy storage density with the mass fraction of the mixed working medium is 6% and 10% under the pressure drop change of the throttle valve

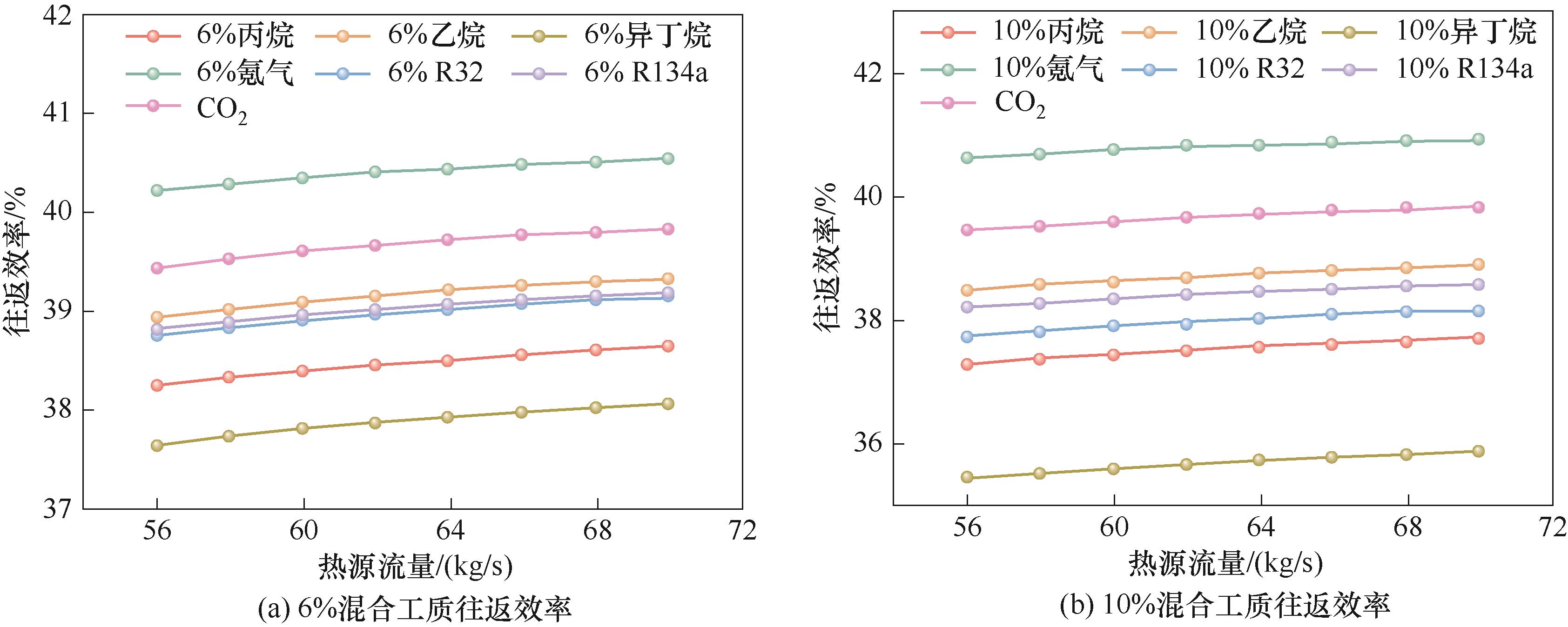

图9 热源流量变化下混合工质质量分数为6%、10%的往返效率

Fig. 9 The round-trip efficiency of the mass fraction of the mixed working medium is 6% and 10% under the change of heat source flow rate

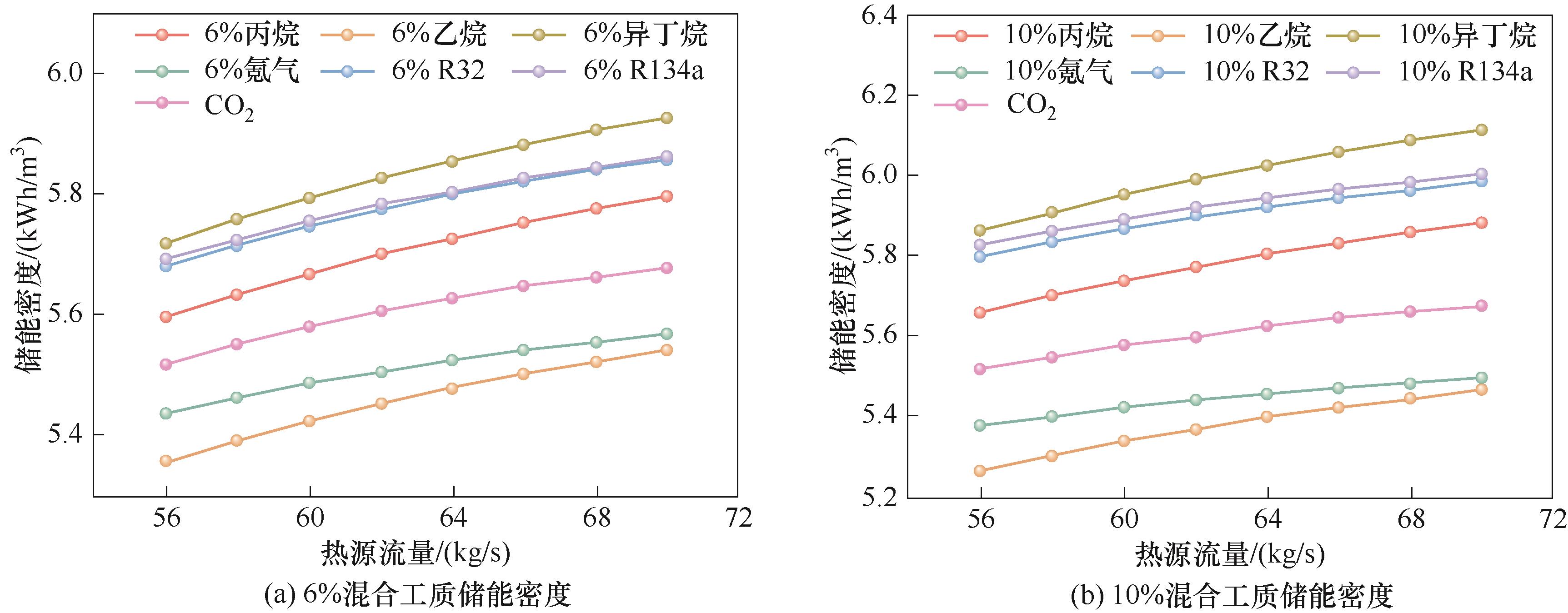

图10 热源流量变化下混合工质质量分数为6%、10%的储能密度

Fig. 10 The energy storage density of the mass fraction of the mixed working medium is 6% and 10% under the change of heat source flow rate

| 1 | 李晖, 刘栋, 姚丹阳. 面向碳达峰碳中和目标的我国电力系统发展研判[J]. 中国电机工程学报, 2021, 41(18): 6245-6259. |

| Li H, Liu D, Yao D Y. Analysis and reflection on the development of power system towards the goal of carbon emission peak and carbon neutrality[J]. Proceedings of the CSEE, 2021, 41(18): 6245-6259. | |

| 2 | Zhang Y, Shen X J, Tian Z, et al. A step towards dynamic: an investigation on a carbon dioxide binary mixtures based compressed gas energy storage system using energy and exergy analysis[J]. Energy, 2023, 282: 128415. |

| 3 | Zhang T H, Gao J M, Zhang Y, et al. Thermodynamic analysis of a novel adsorption-type trans-critical compressed carbon dioxide energy storage system[J]. Energy Conversion and Management, 2022, 270: 116268. |

| 4 | 李佳佳, 李兴朔, 魏凡超, 等. 耦合火电机组的新型压缩空气储能系统技术经济性评估研究[J]. 中国电机工程学报, 2023, 43(23): 9171-9183. |

| Li J J, Li X S, Wei F C, et al. Research on techno-economic evaluation of new type compressed air energy storage coupled with thermal power unit[J]. Proceedings of the CSEE, 2023, 43(23): 9171-9183. | |

| 5 | Shi X P, He Q, Liu Y X, et al. Thermodynamic and techno-economic analysis of a novel compressed air energy storage system coupled with coal-fired power unit[J]. Energy, 2024, 292: 130591. |

| 6 | Li F Y, Yu Y P, Shu Y, et al. Study on characteristics of photovoltaic and photothermal coupling compressed air energy storage system[J]. Process Safety and Environmental Protection, 2023, 178: 147-155. |

| 7 | Chen H, Wang H R, Li R X, et al. Thermo-dynamic and economic analysis of a novel pumped hydro-compressed air energy storage system combined with compressed air energy storage system as a spray system[J]. Energy, 2023, 280: 128134. |

| 8 | 李玉平, 徐玉杰, 李斌, 等. 跨临界二氧化碳储能系统研究[J]. 中国电机工程学报, 2018, 38(21): 6367-6374, 6499. |

| Li Y P, Xu Y J, Li B, et al. Research on transcritical carbon dioxide energy storage system[J]. Proceedings of the CSEE, 2018, 38(21): 6367-6374, 6499. | |

| 9 | 李玉平. 压缩二氧化碳储能系统的热力学性能分析[D]. 北京: 华北电力大学, 2018. |

| Li Y P. Thermal performance analysis of the compressed carbon dioxide energy storage system[D]. Beijing: North China Electric Power University, 2018. | |

| 10 | 高超, 段立强, 高统彤, 等. 集成塔式太阳能的新型超临界压缩二氧化碳储能系统性能分析[J]. 中国电机工程学报, 2024, 44(10): 3949-3962. |

| Gao C, Duan L Q, Gao T T, et al. Performance analysis of novel supercritical compressed carbon dioxide energy storage systems integrated with tower solar energy[J]. Proceedings of the CSEE, 2024, 44(10): 3949-3962. | |

| 11 | 郝银萍, 何青, 刘文毅. 多级回热式跨临界压缩二氧化碳储能系统热力性能分析[J]. 热能动力工程, 2020, 35(4): 16-23. |

| Hao Y P, He Q, Liu W Y. Thermal performance analysis of multi-stage regenerative transcritical compressed carbon dioxide energy storage system[J]. Journal of Engineering for Thermal Energy and Power, 2020, 35(4): 16-23. | |

| 12 | 章颢缤, 周宇, 刘琰, 等. 超临界二氧化碳-高温热泵联合储能发电系统设计及分析[J]. 热力发电, 2024, 53(4): 53-62. |

| Zhang H B, Zhou Y, Liu Y, et al. Design and analysis of a supercritical carbon dioxide and high-temperature heat pump combined energy storage and power generation system[J]. Thermal Power Generation, 2024, 53(4): 53-62. | |

| 13 | 刘辉. 超临界压缩二氧化碳储能系统热力学特性与热经济性研究[D]. 北京: 华北电力大学, 2017. |

| Liu H. Research on thermodynamic and thermoeconomic properties of super-critical compressed carbon dioxide energy storage[D]. Beijing: North China Electric Power University, 2017. | |

| 14 | 吴子睿, 孙瑞, 石凌峰, 等. CO2混合工质的气液相平衡的混合规则对比与预测研究[J]. 化工学报, 2022, 73(4): 1483-1492. |

| Wu Z R, Sun R, Shi L F, et al. A comparative and predictive study of the mixing rules for the vapor-liquid equilibria of CO2-based mixtures[J]. CIESC Journal, 2022, 73(4): 1483-1492. | |

| 15 | Niu X J, Ma N, Bu Z K, et al. Thermodynamic analysis of supercritical Brayton cycles using CO2-based binary mixtures for solar power tower system application[J]. Energy, 2022, 254: 124286. |

| 16 | 孙铭泽, 马宁, 李浩然, 等. 中低温超临界CO2及其混合工质布雷顿循环热力学分析[J]. 化工学报, 2022, 73(3): 1379-1388. |

| Sun M Z, Ma N, Li H R, et al. Thermodynamic analysis of Brayton cycle of medium and low temperature supercritical CO2 and its mixed working medium[J]. CIESC Journal, 2022, 73(3): 1379-1388. | |

| 17 | 刘旭, 杨绪青, 刘展. 一种新型的基于二氧化碳混合物的液体储能系统[J]. 储能科学与技术, 2021, 10(5): 1806-1814. |

| Liu X, Yang X Q, Liu Z. A novel liquid energy storage system based on a carbon dioxide mixture[J]. Energy Storage Science and Technology, 2021, 10(5): 1806-1814. | |

| 18 | Tang B, Sun L, Xie Y H. Design and performance evaluation of an energy storage system using CO2-based binary mixtures for thermal power plant under dry conditions[J]. Energy Conversion and Management, 2022, 268: 116043. |

| 19 | Yan X W, Zhao R J, Liu Z. Performance of a CO2-mixture cycled energy storage system: thermodynamic and economic analysis[J]. Applied Thermal Engineering, 2023, 226: 120280. |

| 20 | He Q, Liu H, Hao Y P, et al. Thermodynamic analysis of a novel supercritical compressed carbon dioxide energy storage system through advanced exergy analysis[J]. Renewable Energy, 2018, 127: 835-849. |

| 21 | 郭嘉琪, 王坤, 朱含慧, 等. 超临界CO2及其混合工质布雷顿循环热力学分析[J]. 工程热物理学报, 2017, 38(4): 695-702. |

| Guo J Q, Wang K, Zhu H H, et al. Thermodynamic analysis of Brayton cycles using supercritical carbon dioxide and its mixture as working fluid[J]. Journal of Engineering Thermophysics, 2017, 38(4): 695-702. | |

| 22 | 王瑞, 王轩, 蔡金文, 等. CO2混合工质动力循环系统的动态特性对比[J]. 工程热物理学报, 2020, 41(11): 2651-2657. |

| Wang R, Wang X, Cai J W, et al. Comparison of dynamic performance of CO2 mixture transcritical power cycle systems[J]. Journal of Engineering Thermophysics, 2020, 41(11): 2651-2657. | |

| 23 | 王迪, 司龙, 谢欣言, 等. 耦合超临界二氧化碳储能循环燃煤机组动态特性仿真[J]. 中国电机工程学报, 2023, 43(6): 2142-2153. |

| Wang D, Si L, Xie X Y, et al. Simulation of dynamic characteristics of coal-fired unit coupled with supercritical carbon dioxide energy storage cycle[J]. Proceedings of the CSEE, 2023, 43(6): 2142-2153. | |

| 24 | Hao Y P, He Q, Liu W Y, et al. Thermodynamic analysis of a novel fossil-fuel-free energy storage system with a trans-critical carbon dioxide cycle and heat pump[J]. International Journal of Energy Research, 2020, 44(10): 7924-7937. |

| 25 | Zhao P, Xu W P, Zhang S Q, et al. Components design and performance analysis of a novel compressed carbon dioxide energy storage system: a pathway towards realizability[J]. Energy Conversion and Management, 2021, 229: 113679. |

| 26 | Olumayegun O, Wang M H. Dynamic modelling and control of supercritical CO2 power cycle using waste heat from industrial processes[J]. Fuel, 2019, 249: 89-102. |

| 27 | Zhang Y, Yang K, Li X M, et al. Thermodynamic analysis of energy conversion and transfer in hybrid system consisting of wind turbine and advanced adiabatic compressed air energy storage[J]. Energy, 2014, 77: 460-477. |

| 28 | Li C, Wang D, Liu D, et al. Mathematical modelling of large-scale compressed air energy storage systems[C]//2019 25th International Conference on Automation and Computing (ICAC). Lancaster, UK: IEEE, 2019: 1-6. |

| 29 | Powell K M, Edgar T F. Modeling and control of a solar thermal power plant with thermal energy storage[J]. Chemical Engineering Science, 2012, 71: 138-145. |

| 30 | Fu H L, Shi J, Yuan J Q, et al. Thermodynamic analysis of photothermal-assisted liquid compressed CO2 energy storage system hybrid with closed-cycle drying[J]. Journal of Energy Storage, 2023, 66: 107415. |

| 31 | Deng T R, Li X H, Wang Q W, et al. Dynamic modelling and transient characteristics of supercritical CO2 recompression Brayton cycle[J]. Energy, 2019, 180: 292-302. |

| [1] | 曾港, 陈林, 杨董, 袁海专, 黄彦平. 矩形通道内超临界CO2局部热流场可视化实验[J]. 化工学报, 2024, 75(8): 2831-2839. |

| [2] | 李子扬, 郑楠, 方嘉宾, 魏进家. 再压缩S-CO2布雷顿循环性能分析及多目标优化[J]. 化工学报, 2024, 75(6): 2143-2156. |

| [3] | 王迪, 陈伟倩, 孙灵芳, 周云龙. 光热-跨临界压缩二氧化碳储能循环动态特性研究[J]. 化工学报, 2024, 75(5): 2047-2059. |

| [4] | 孙瑞, 田华, 吴子睿, 孙孝存, 舒歌群. 二氧化碳混合工质临界参数计算模型对比研究[J]. 化工学报, 2024, 75(2): 439-449. |

| [5] | 朱芝, 许恒杰, 陈维, 毛文元, 邓强国, 孙雪剑. 超临界二氧化碳螺旋槽干气密封热流耦合润滑临界阻塞特性研究[J]. 化工学报, 2024, 75(2): 604-615. |

| [6] | 邵明成, 潘玉贵, 王增丽, 赵强. CO2/CH4混合物理论跨临界增压过程的热力性能研究[J]. 化工学报, 2024, 75(10): 3742-3751. |

| [7] | 向腾龙, 王治红, 汪贵, 李龙. 液化天然气冷能梯级利用的多功能集成系统研究[J]. 化工学报, 2024, 75(10): 3401-3413. |

| [8] | 江澳翔, 陈源, 李运堂, 江锦波, 彭旭东, 章聪, 王冰清. 微间隙高速流体效应对箔片柱面气膜密封性能的影响[J]. 化工学报, 2024, 75(10): 3691-3704. |

| [9] | 张泽欣, 郑伟中, 徐益升, 胡冬冬, 卓欣宇, 宗原, 孙伟振, 赵玲. 超临界二氧化碳介质中晶圆清洗与选择性刻蚀研究进展[J]. 化工学报, 2024, 75(1): 110-119. |

| [10] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [11] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [12] | 朱兵国, 何吉祥, 徐进良, 彭斌. 冷却条件下渐扩/渐缩管内超临界压力二氧化碳的传热特性[J]. 化工学报, 2023, 74(3): 1062-1072. |

| [13] | 赫一凡, 于帅, 闫兴清, 喻健良. 基于特征线法的CO2减压波传播模型构建及止裂壁厚研究[J]. 化工学报, 2023, 74(12): 5038-5047. |

| [14] | 席国君, 刘子涵, 雷广平. FeTPPs-CuBTC协同强化低浓度煤层气吸附分离[J]. 化工学报, 2022, 73(9): 3940-3949. |

| [15] | 许婉婷, 许波, 王鑫, 陈振乾. 方形微通道内超临界CO2流动换热特性研究[J]. 化工学报, 2022, 73(4): 1534-1545. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号