化工学报 ›› 2025, Vol. 76 ›› Issue (2): 584-595.DOI: 10.11949/0438-1157.20240691

• 流体力学与传递现象 • 上一篇

收稿日期:2024-06-21

修回日期:2024-08-27

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

管小平,杨宁

作者简介:白谨豪(1996—),男,博士研究生,jhbai@ipe.ac.cn

基金资助:

Jinhao BAI( ), Xiaoping GUAN(

), Xiaoping GUAN( ), Ning YANG(

), Ning YANG( )

)

Received:2024-06-21

Revised:2024-08-27

Online:2025-03-25

Published:2025-03-10

Contact:

Xiaoping GUAN, Ning YANG

摘要:

电解水制氢是引领未来绿色能源发展的重要途径。压滤式水电解槽是常用的工业制氢装置,其中电解液分布的均匀性对提高电解效率和延长电极寿命至关重要。然而,传统的乳突板内流场分布均匀性差,导致电解效率变低,甚至出现局部温度过高,从而引发电极烧蚀等安全问题。为改善这一现象,提出“中心密,两侧疏”的凹凸单元分布策略,以改善极板内部的碱液流场分布。首先,搭建乳突板可视化实验平台,研究碱液停留时间分布,并用于数学模型验证。进而模拟了四组不同结构乳突板的单相流特性,并耦合颗粒追踪算法定量表征流动死区。结果表明,新的凹凸单元分布策略能使电解液在电解槽内的流场更加均匀,减少碱液的返混现象,降低流动死区的产生。此外,该方法还提高了系统的操作弹性,使其能够适应更广泛的流量条件。

中图分类号:

白谨豪, 管小平, 杨宁. 压滤式水电解槽乳突板内的流动特性分析与优化[J]. 化工学报, 2025, 76(2): 584-595.

Jinhao BAI, Xiaoping GUAN, Ning YANG. Analysis and optimization of flow characteristics in a filter-press water electrolyzer mastoid plate[J]. CIESC Journal, 2025, 76(2): 584-595.

| 参数 | 数值 |

|---|---|

| 进出口宽度 / mm | 10 |

| 进出口高度 / mm | 7.5 |

| 进出口深度 / mm | 20 |

| 凹单元个数 | 105 |

| 凸单元个数 | 112 |

| 凹凸单元直径 / mm | 15 |

| 流道直径 / mm | 380 |

表1 计算域结构参数

Table 1 Computational domain structural parameters

| 参数 | 数值 |

|---|---|

| 进出口宽度 / mm | 10 |

| 进出口高度 / mm | 7.5 |

| 进出口深度 / mm | 20 |

| 凹单元个数 | 105 |

| 凸单元个数 | 112 |

| 凹凸单元直径 / mm | 15 |

| 流道直径 / mm | 380 |

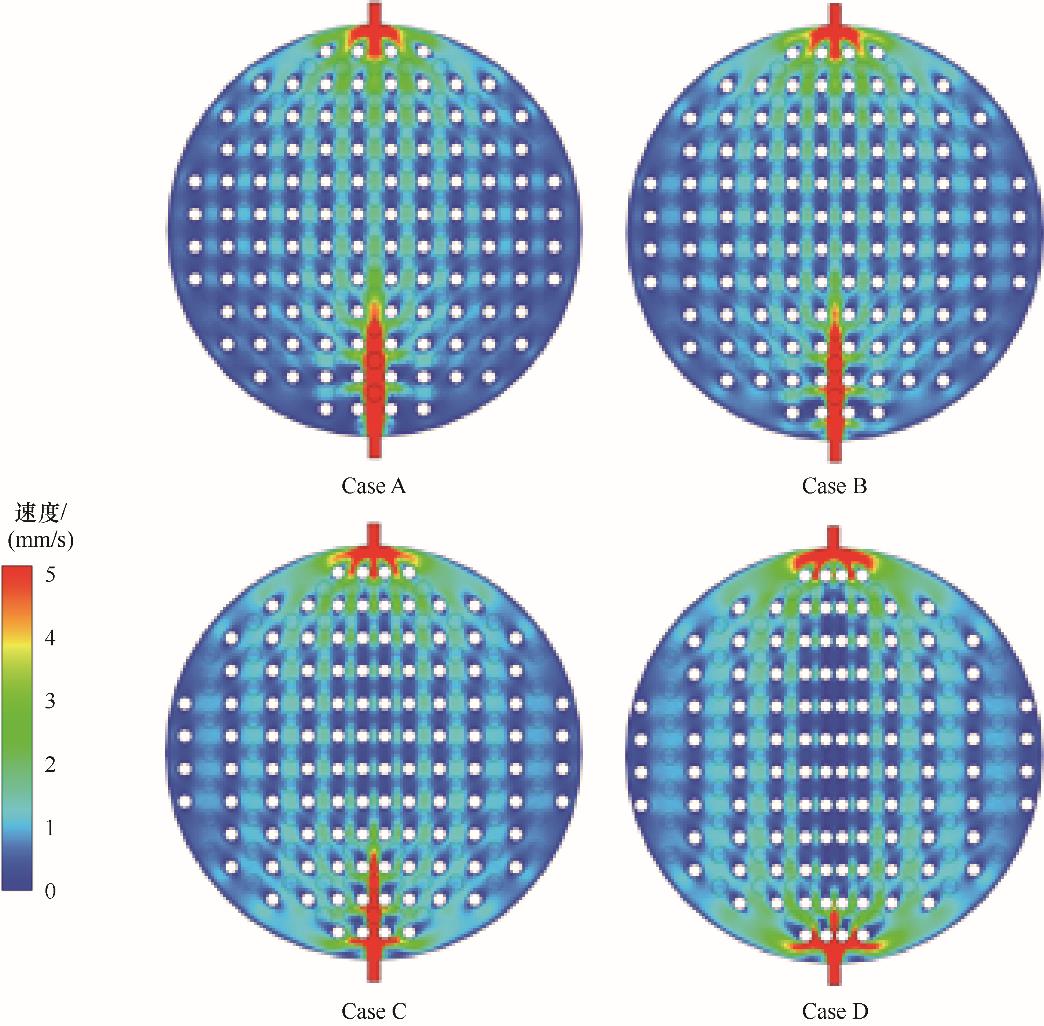

图7 不同结构截面在Z = 11.25 mm处的速度分布云图 (Q = 0.005 m3/h)

Fig.7 Velocity distribution contour plot at cross-section Z = 11.25 mm for different structures (Q = 0.005 m3/h)

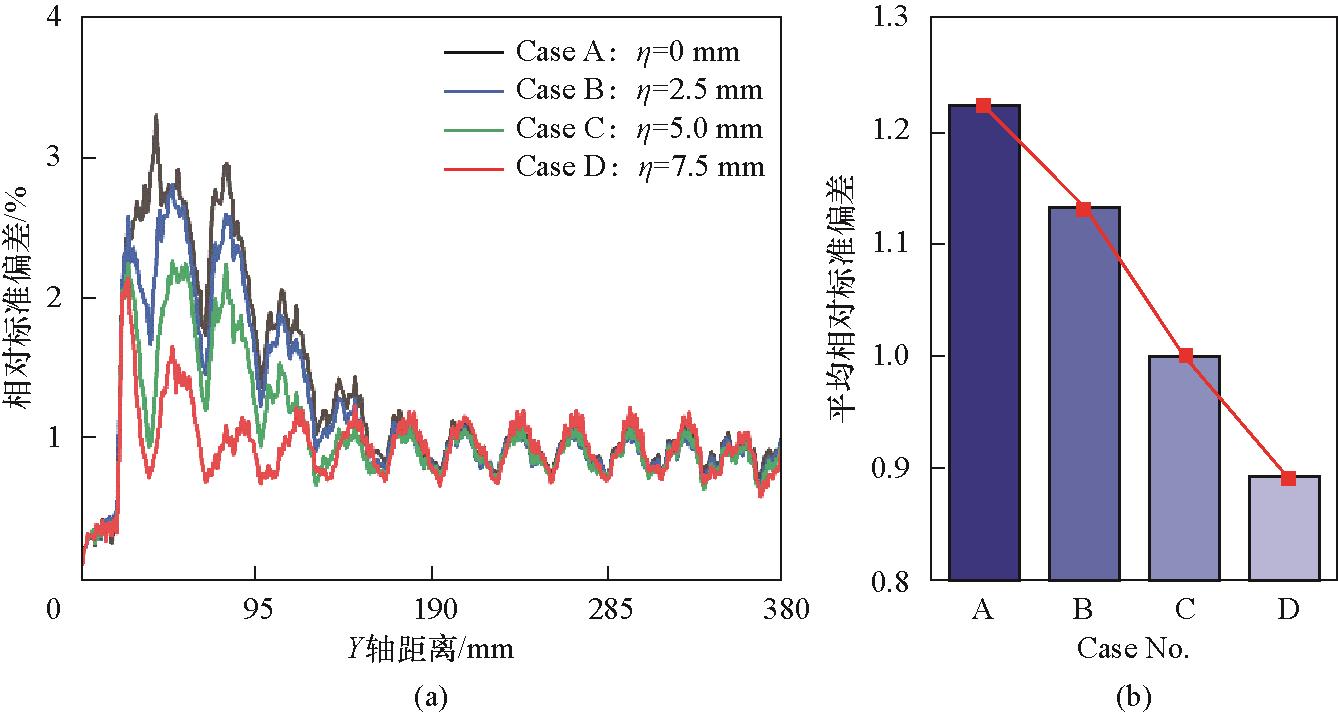

图9 (a) 不同结构不同Y截面处的速度相对标准偏差;(b) 速度相对标准偏差整体平均值

Fig.9 (a) Relative standard deviation of velocity at different Y cross-sections for different structures; (b) Overall average value of the relative standard deviation of velocity

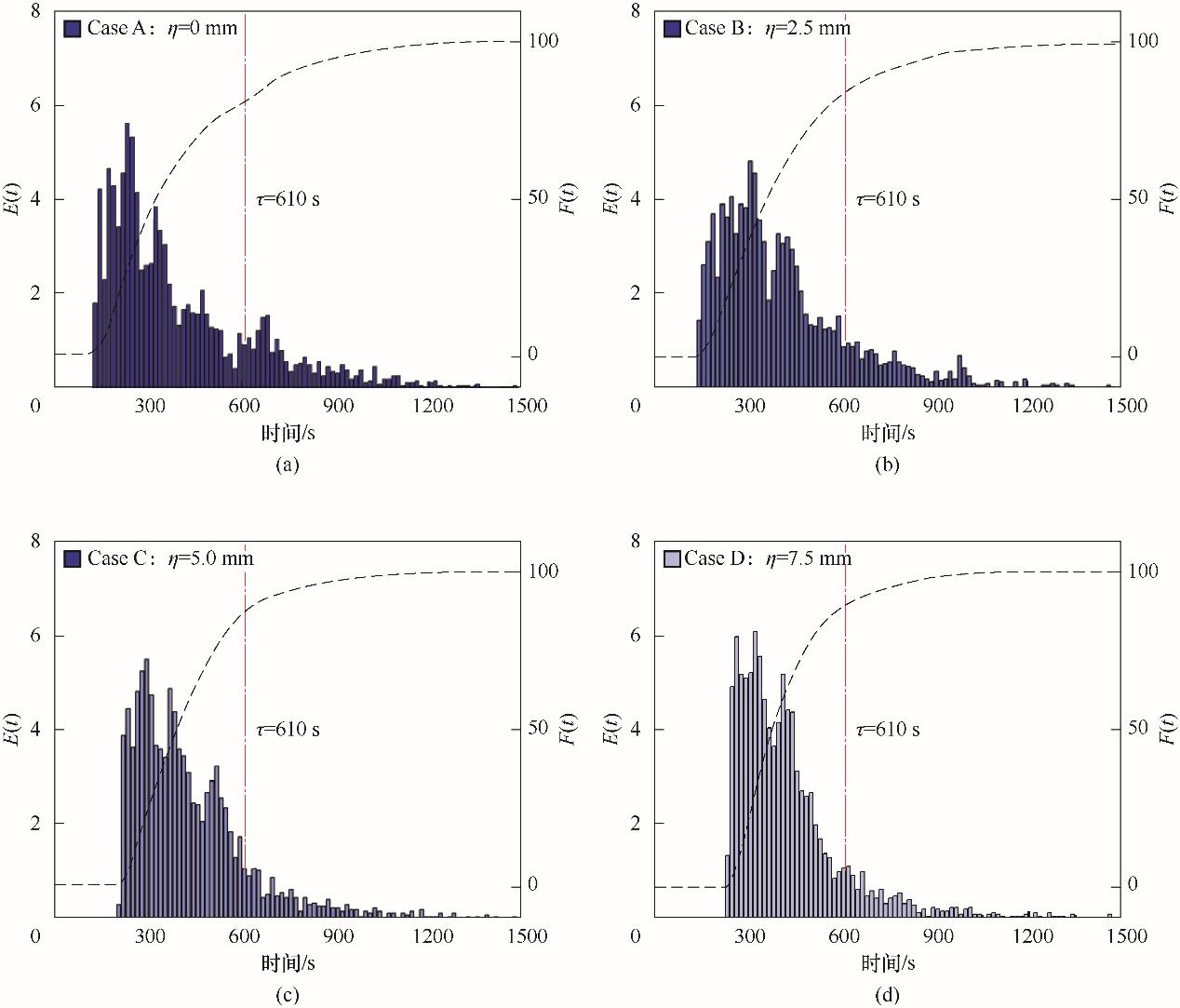

图10 不同结构下停留时间分布E(t)和累积分布函数F(t) (Q = 0.005 m3/h)

Fig.10 Comparison of residence time distribution E(t)and cumulative distribution function F(t) under different structures(Q = 0.005 m3/h)

| 1 | Zhang X Q. The development trend of and suggestions for China's hydrogen energy industry[J]. Engineering, 2021, 7(6): 719-721. |

| 2 | Yue M L, Lambert H, Pahon E, et al. Hydrogen energy systems: a critical review of technologies, applications, trends and challenges[J]. Renewable and Sustainable Energy Reviews, 2021, 146: 111180. |

| 3 | Maier M, Smith K, Dodwell J, et al. Mass transport in PEM water electrolysers: a review[J]. International Journal of Hydrogen Energy, 2022, 47(1): 30-56. |

| 4 | Hughes J P, Clipsham J, Chavushoglu H, et al. Polymer electrolyte electrolysis: a review of the activity and stability of non-precious metal hydrogen evolution reaction and oxygen evolution reaction catalysts[J]. Renewable and Sustainable Energy Reviews, 2021, 139: 110709. |

| 5 | Guan X P, Bai J H, Zhang J C, et al. Multiphase flow in PEM water electrolyzers: a mini-review[J]. Current Opinion in Chemical Engineering, 2023, 43:100988. |

| 6 | Zhang J C, Guan X P, Yang N. Lattice Boltzmann simulation of oxygen removal from anode porous transport layer in proton exchange membrane electrolyzer[J]. Chemical Engineering Science, 2024, 295: 120140. |

| 7 | 刘志鹏,赵长颖,吴睿,等. 基于水电解制氢的梯度多孔传输层中气液流动可视化实验研究[J]. 化工学报, 2024, 75(2): 520-530. |

| Liu Z P, Zhao C Y, Wu R, et al. Experimental study of gas-liquid flow visualization in gradient porous transport layers based on hydrogen production by water electrolysis[J]. CIESC Journal, 2024, 75(2): 520-530. | |

| 8 | Bai J H, Li Z F, Zhang J C, et al. Proton exchange membrane water electrolysis at high current densities: response time and gas-water distribution[J]. AIChE Journal, 2023, 69(12): e18223. |

| 9 | 蔡炽柳. 氢能及其应用前景分析[J]. 能源与环境, 2008(5): 39-41. |

| Cai C L. Analysis of hydrogen energy and its application prospect[J]. Energy and Environment, 2008(5): 39-41. | |

| 10 | Schalenbach M, Kasian O, Mayrhofer K J J. An alkaline water electrolyzer with nickel electrodes enables efficient high current density operation[J]. International Journal of Hydrogen Energy, 2018, 43(27): 11932-11938. |

| 11 | Xu W W, Lu Z Y, Wan P B, et al. High-performance water electrolysis system with double nanostructured superaerophobic electrodes[J]. Small, 2016, 12(18): 2492-2498. |

| 12 | Xiang C X, Papadantonakis K M, Lewis N S. Principles and implementations of electrolysis systems for water splitting[J]. Materials Horizons, 2016, 3(3): 169-173. |

| 13 | Rocha F, Delmelle R, Georgiadis C, et al. Effect of pore size and electrolyte flow rate on the bubble removal efficiency of 3D pure Ni foam electrodes during alkaline water electrolysis[J]. Journal of Environmental Chemical Engineering, 2022, 10(3): 107648. |

| 14 | Yang Y, De La Torre B, Stewart K, et al. The scheduling of alkaline water electrolysis for hydrogen production using hybrid energy sources[J]. Energy Conversion and Management, 2022, 257: 115408. |

| 15 | 李军. 压滤式电解槽电解单元内流动特性的模拟研究[D]. 北京: 中国石油大学(北京), 2020. |

| Li J. Simulation study on flow characteristics in electrolysis unit of filter-press electrolyzer[D]. Beijing: China University of Petroleum, 2020. | |

| 16 | Rao Y, Xu Y M, Wan C Y. An experimental and numerical study of flow and heat transfer in channels with pin fin-dimple and pin fin arrays[J]. Experimental Thermal and Fluid Science, 2012, 38: 237-247. |

| 17 | Xie G N, Liu J, Ligrani P M, et al. Numerical analysis of flow structure and heat transfer characteristics in square channels with different internal-protruded dimple geometrics[J]. International Journal of Heat and Mass Transfer, 2013, 67: 81-97. |

| 18 | De Haro Ruiz D, Sasmito A P, Shamim T. Numerical investigation of the high temperature PEM electrolyzer: effect of flow channel configurations[J]. ECS Transactions, 2013, 58(2): 99-112. |

| 19 | 李军, 王娟, 张佳, 等. 极板凹凸结构形状对电解槽内部流动特性的影响[J]. 过程工程学报, 2021, 21(3): 251-258. |

| Li J, Wang J, Zhang J, et al. Effects of pole plate's concave-convex shapes on flow characteristics in water electrolyzer[J]. The Chinese Journal of Process Engineering, 2021, 21(3): 251-258. | |

| 20 | Rao Y, Feng Y, Li B, et al. Experimental and numerical study of heat transfer and flow friction in channels with dimples of different shapes[J]. Journal of Heat Transfer, 2015, 137(3): 031901. |

| 21 | Elyyan M A, Rozati A, Tafti D K. Investigation of dimpled fins for heat transfer enhancement in compact heat exchangers[J]. International Journal of Heat and Mass Transfer, 2008, 51(11/12): 2950-2966. |

| 22 | Hwang S D, Kwon H G, Cho H H. Local heat transfer and thermal performance on periodically dimple-protrusion patterned walls for compact heat exchangers[J]. Energy, 2010, 35(12): 5357-5364. |

| 23 | Chen Y, Chew Y T, Khoo B C. Heat transfer and flow structure on periodically dimple–protrusion patterned walls in turbulent channel flow[J]. International Journal of Heat and Mass Transfer, 2014, 78: 871-882. |

| 24 | 王娟, 李军, 邹槊, 等. 压滤式水电解槽微通道内球凸-球凹结构绕流特性的模拟[J]. 过程工程学报, 2020, 20(3): 294-301. |

| Wang J, Li J, Zou S, et al. Simulation on flow characteristics of spherical convex–concave structure in microchannel of pressure-filtered water electrolyzer[J]. The Chinese Journal of Process Engineering, 2020, 20(3): 294-301. | |

| 25 | Wang T, Wang J Y, Wang P J, et al. Non-uniform liquid flow distribution in an alkaline water electrolyzer with concave-convex bipolar plate (CCBP): a numerical study[J]. International Journal of Hydrogen Energy, 2023, 48(33): 12200-12214. |

| 26 | Wang T, Wang J Y, Wang P J, et al. Plate structure design guideline for commercial alkaline water electrolyzers (AWEs) with improved liquid flow uniformity: multi-scale quantitative criteria and experimental validation[J]. International Journal of Hydrogen Energy, 2024, 49: 907-924. |

| 27 | Rodrigues A E. Residence time distribution (RTD) revisited[J]. Chemical Engineering Science, 2021, 230: 116188. |

| 28 | Gao Y J, Muzzio F J, Ierapetritou M G. A review of the residence time distribution (RTD) applications in solid unit operations[J]. Powder Technology, 2012, 228: 416-423. |

| 29 | Saravanathamizhan R, Paranthaman R, Balasubramanian N, et al. Residence time distribution in continuous stirred tank electrochemical reactor[J]. Chemical Engineering Journal, 2008, 142(2): 209-216. |

| 30 | Rivera F F, Pérez T, Castañeda L F, et al. Mathematical modeling and simulation of electrochemical reactors: a critical review[J]. Chemical Engineering Science, 2021, 239: 116622. |

| [1] | 卢飞, 鲁波娜, 许光文. 气固微型流化床反应分析仪的理想流型判据分析[J]. 化工学报, 2024, 75(6): 2201-2213. |

| [2] | 屠楠, 刘晓群, 王驰宇, 方嘉宾. 连续进出料鼓泡流化床停留时间分布的相似准则研究[J]. 化工学报, 2024, 75(2): 543-552. |

| [3] | 钟子豪, 刘塞尔, 商敏静, 苏远海. 基于磁力搅拌的微型CSTR流动特征及微观混合性能[J]. 化工学报, 2024, 75(11): 4217-4225. |

| [4] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [5] | 赵晶, 李伯耿, 卜志扬, 范宏. 微通道内低黏聚合物流体的停留时间分布研究[J]. 化工学报, 2021, 72(8): 4030-4038. |

| [6] | 胡丹丹, 耿素龙, 曾玺, 王芳, 岳君容, 许光文. 返混对气-固反应特性测试和活化能表征的影响[J]. 化工学报, 2021, 72(3): 1354-1363. |

| [7] | 黄正梁, 王超, 郭燕妮, 杨遥, 孙婧元, 王靖岱, 阳永荣. 基于停留时间分布的缠绕管内二次流研究[J]. 化工学报, 2021, 72(2): 921-927. |

| [8] | 兰斌, 徐骥, 刘志成, 王军武. 连续操作密相流化床颗粒停留时间分布特性模拟放大研究[J]. 化工学报, 2021, 72(1): 521-533. |

| [9] | 田凤国, 朱田, 孔德正, 雷鸣. 非均匀布风流化床内大颗粒停留时间特性[J]. 化工学报, 2020, 71(4): 1520-1527. |

| [10] | 姚东, 刘明言, 李翔南. 小型气-液-固流化床液相的停留时间分布[J]. 化工学报, 2018, 69(11): 4754-4762. |

| [11] | 周虹佳, 刘飞, 周明, 仲兆祥, 邢卫红. 双膜强化类Fenton工艺处理制浆废水的研究[J]. 化工学报, 2018, 69(1): 490-498. |

| [12] | 黄子宾, 朱闯杰, 黄岩, 程振民, 杨涛, 刘建锟, 方向晨. 沸腾床内液相的返混特性[J]. 化工学报, 2017, 68(2): 630-636. |

| [13] | 赵爱红, 鄂承林, 王芬芬, 卢春喜. 提升管CSVQS系统预汽提段颗粒速度和停留时间分布[J]. 化工学报, 2016, 67(8): 3276-3286. |

| [14] | 毛在砂, 杨超. 化学反应器宏观混合研究展望[J]. 化工学报, 2015, 66(8): 2795-2804. |

| [15] | 古新, 王珂, 郝建设, 刘敏珊, 潘国华. 帘式折流片换热器壳程流体流动死区[J]. 化工学报, 2014, 65(S1): 272-276. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号