化工学报 ›› 2025, Vol. 76 ›› Issue (2): 576-583.DOI: 10.11949/0438-1157.20240723

• 流体力学与传递现象 • 上一篇

魏攀攀1( ), 刘怿楠1, 朱春英1(

), 刘怿楠1, 朱春英1( ), 付涛涛1, 高习群2, 马友光1

), 付涛涛1, 高习群2, 马友光1

收稿日期:2024-06-28

修回日期:2024-07-25

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

朱春英

作者简介:魏攀攀(2001—),男,硕士研究生,weipanpan@tju.edu.cn

基金资助:

Panpan WEI1( ), Yinan LIU1, Chunying ZHU1(

), Yinan LIU1, Chunying ZHU1( ), Taotao FU1, Xiqun GAO2, Youguang MA1

), Taotao FU1, Xiqun GAO2, Youguang MA1

Received:2024-06-28

Revised:2024-07-25

Online:2025-03-25

Published:2025-03-10

Contact:

Chunying ZHU

摘要:

研究了改进的缩口T型微通道和毛细管嵌入阶梯式T型微通道内双水相液滴的制备,基于液滴尺寸对这两种微通道进行了比较。结果表明,其流型为喷射-弹状流和喷射-滴落流,流型的转变受到两相流率控制。而在毛细管嵌入阶梯式T型微通道内,液滴的生成范围和稳定程度明显优于缩口T型微通道。在两个微通道内液滴生成尺寸的变化规律是相似的,均随着连续相流率的增大而减小,随着分散相流率的增大而增大,但毛细管嵌入阶梯式T型微通道内生成的液滴尺寸相较于缩口T型微通道更小。建立了液滴尺寸的预测模型,对两种微通道均具有良好的预测效果。

中图分类号:

魏攀攀, 刘怿楠, 朱春英, 付涛涛, 高习群, 马友光. 改进的T型微通道内双水相液滴的制备[J]. 化工学报, 2025, 76(2): 576-583.

Panpan WEI, Yinan LIU, Chunying ZHU, Taotao FU, Xiqun GAO, Youguang MA. Preparation of aqueous two-phase droplets in improved T-shaped microchannel[J]. CIESC Journal, 2025, 76(2): 576-583.

| 初始浓度 | 相别 | 流体 | 密度ρ/(g/cm3) | 黏度μ/(mPa·s) | 表面张力σ/(mN/m) |

|---|---|---|---|---|---|

| 24%(质量分数) PEG | 连续相 | PEG富相溶液 | 1.066 | 40.968 | 0.48 |

| 24%(质量分数)TSC | 分散相 | TSC富相溶液 | 1.143 | 2.421 |

表1 所用流体的物理性质

Table 1 Physical properties of the fluids used

| 初始浓度 | 相别 | 流体 | 密度ρ/(g/cm3) | 黏度μ/(mPa·s) | 表面张力σ/(mN/m) |

|---|---|---|---|---|---|

| 24%(质量分数) PEG | 连续相 | PEG富相溶液 | 1.066 | 40.968 | 0.48 |

| 24%(质量分数)TSC | 分散相 | TSC富相溶液 | 1.143 | 2.421 |

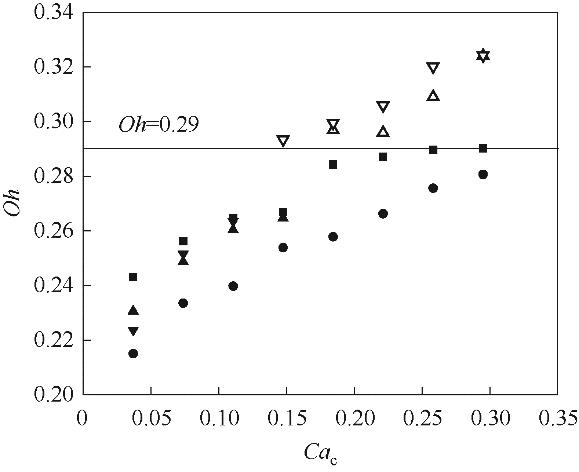

图7 Ohnesorge数对流型的影响■ 毛细管嵌入阶梯式T型微通道,Qd= 8 μl/min;● 毛细管嵌入阶梯式T型微通道,Qd= 12 μl/min;▲缩口T型微通道,Qd= 8 μl/min;▼ 缩口T型微通道,Qd= 10 μl/min;实心符号为稳定液滴,空心符号为不稳定液滴

Fig.7 Influence of Ohnesorge number on flow patterns

| 1 | Iqbal M, Tao Y F, Xie S Y, et al. Aqueous two-phase system (ATPS): an overview and advances in its applications[J]. Biological Procedures Online, 2016, 18: 18. |

| 2 | Mastiani M, Firoozi N, Petrozzi N, et al. Polymer-salt aqueous two-phase system (ATPS) micro-droplets for cell encapsulation[J]. Scientific Reports, 2019, 9: 15561. |

| 3 | Mastiani M, Seo S, Mosavati B, et al. High-throughput aqueous two-phase system droplet generation by oil-free passive microfluidics[J]. ACS Omega, 2018, 3(8): 9296-9302. |

| 4 | Song Y, Sauret A, Cheung Shum H. All-aqueous multiphase microfluidics[J]. Biomicrofluidics, 2013, 7(6): 61301 |

| 5 | Glyk A, Scheper T, Beutel S. PEG-salt aqueous two-phase systems: an attractive and versatile liquid-liquid extraction technology for the downstream processing of proteins and enzymes[J]. Applied Microbiology and Biotechnology, 2015, 99(16): 6599-6616. |

| 6 | Moon B U, Hwang D K, Tsai S S H. Shrinking, growing, and bursting: microfluidic equilibrium control of water-in-water droplets[J]. Lab on a Chip, 2016, 16(14): 2601-2608. |

| 7 | Daradmare S, Lee C S. Recent progress in the synthesis of all-aqueous two-phase droplets using microfluidic approaches[J]. Colloids and Surfaces B: Biointerfaces, 2022, 219: 112795. |

| 8 | Teixeira A G, Agarwal R, Ko K R, et al. Emerging biotechnology applications of aqueous two-phase systems[J]. Advanced Healthcare Materials, 2018, 7(6): 1701036. |

| 9 | Zhou C M, Zhu P G, Tian Y, et al. Progress in all-aqueous droplets generation with microfluidics: mechanisms of formation and stability improvements[J]. Biophysics Reviews, 2022, 3(2): 021301. |

| 10 | Elvira K S, Solvas X C I, Wootton R C R, et al. The past, present and potential for microfluidic reactor technology in chemical synthesis[J]. Nature Chemistry, 2013, 5(11): 905-915. |

| 11 | Chiu D T, DeMello A J, Di Carlo D, et al. Small but perfectly formed? Successes, challenges, and opportunities for microfluidics in the chemical and biological sciences[J]. Chem, 2017, 2(2): 201-223. |

| 12 | Maceiczyk R M, Bezinge L, DeMello A J. Kinetics of nanocrystal synthesis in a microfluidic reactor: theory and experiment[J]. Reaction Chemistry & Engineering, 2016, 1(3): 261-271. |

| 13 | Cui P, Wang S C. Application of microfluidic chip technology in pharmaceutical analysis: a review[J]. Journal of Pharmaceutical Analysis, 2019, 9(4): 238-247. |

| 14 | Berlanda S F, Breitfeld M, Dietsche C L, et al. Recent advances in microfluidic technology for bioanalysis and diagnostics[J]. Analytical Chemistry, 2021, 93(1): 311-331. |

| 15 | Zhou C, Chen Z J, Xie J, et al. Experimental study on rolling microchannel and nanochannel in chip materials by diamond[J]. Optics and Precision Engineering, 2023, 31(12): 1785-1792. |

| 16 | Sato R, Yahagi T, Tatami J, et al. Rapid manufacturing of complex-structured transparent silica glass materials through a hybridized approach of photo-curing and machining from interparticle photo-cross-linkable suspensions[J]. ACS Applied Materials & Interfaces, 2022, 14(14): 16445-16452. |

| 17 | Teh S Y, Lin R, Hung L H, et al. Droplet microfluidics[J]. Lab on a Chip, 2008, 8(2): 198. |

| 18 | Zhu P G, Wang L Q. Passive and active droplet generation with microfluidics: a review[J]. Lab on a Chip, 2017, 17(1): 34-75. |

| 19 | 张明慧, 恩溪弄, 冯博冉, 等. 基于微流控技术的液滴生成方法研究[J]. 印刷与数字媒体技术研究, 2024(1): 13-23, 30. |

| Zhang M H, En X N, Feng B R, et al. Study on droplet generation methods based on microfluidics technology[J]. Printing and Digital Media Technology Study, 2024(1): 13-23, 30. | |

| 20 | Thorsen T, Roberts R W, Arnold F H, et al. Dynamic pattern formation in a vesicle-generating microfluidic device[J]. Physical Review Letters, 2001, 86(18): 4163-4166. |

| 21 | Sheng L, Ma L, Chen Y C, et al. A comprehensive study of droplet formation in a capillary embedded step T-junction: from squeezing to jetting[J]. Chemical Engineering Journal, 2022, 427: 132067. |

| 22 | Wang K, Lu Y C, Xu J H, et al. Generation of micromonodispersed droplets and bubbles in the capillary embedded T-junction microfluidic devices[J]. AIChE Journal, 2011, 57(2): 299-306. |

| 23 | Nunes J K, Tsai S S H, Wan J, et al. Dripping and jetting in microfluidic multiphase flows applied to particle and fiber synthesis[J]. Journal of Physics D: Applied Physics, 2013, 46(11): 114002. |

| 24 | Husny J, Cooper-White J J. The effect of elasticity on drop creation in T-shaped microchannels[J]. Journal of Non-Newtonian Fluid Mechanics, 2006, 137(1/2/3): 121-136. |

| 25 | Mastiani M, Seo S, Jimenez S M, et al. Flow regime mapping of aqueous two-phase system droplets in flow-focusing geometries[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2017, 531: 111-120. |

| 26 | 翟小威, 潘湄蝶, 石盼, 等. 一步法高通量可控制备生物相容水/水微囊及其响应释放[J]. 高等学校化学学报, 2022, 43(12): 345-354. |

| Zhai X W, Pan M D, Shi P, et al. One-step high-throughput controlled preparation of biocompatible water/water microcapsules with triggered release[J]. Chem. J. Chinese Universities, 2022, 43(12): 345-354. | |

| 27 | Ma L, Cui Y J, Sheng L, et al. Determination of interfacial tension and viscosity under dripping flow in a step T-junction microdevice[J]. Chinese Journal of Chemical Engineering, 2022, 42: 210-218. |

| 28 | 石盼, 颜肖潇, 王行政, 等. 一步法制备生物相容油核微胶囊及其可控释放[J]. 化工学报, 2021, 72(1): 619-627. |

| Shi P, Yan X X, Wang X Z, et al. One-step fabrication of biocompatible oil-core microcapsules with controlled release[J]. CIESC Journal, 2021, 72(1): 619-627. | |

| 29 | Christopher G F, Noharuddin N N, Taylor J A, et al. Experimental observations of the squeezing-to-dripping transition in T-shaped microfluidic junctions[J]. Physical Review E: Statistical, Nonlinear, and Soft Matter Physics, 2008, 78(3 Pt 2): 036317. |

| 30 | Li X L, He L Q, He Y, et al. Numerical study of droplet formation in the ordinary and modified T-junctions[J]. Physics of Fluids, 2019, 31(8): 082101. |

| 31 | Glawdel T, Elbuken C, Ren C L. Droplet formation in microfluidic T-junction generators operating in the transitional regime(Ⅰ): Experimental observations[J]. Physical Review E: Statistical, Nonlinear, and Soft Matter Physics, 2012, 85(1 Pt 2): 016322. |

| 32 | Nisisako T, Torii T, Higuchi T. Droplet formation in a microchannel network[J]. Lab on a Chip, 2002, 2(1): 24-26. |

| 33 | Garstecki P, Fuerstman M J, Stone H A, et al. Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up[J]. Lab on a Chip, 2006, 6(3): 437-446. |

| 34 | Dong Y P, Zhu H W, Xiang X Y, et al. Formation of viscoelastic droplets in asymmetrical parallel microchannels[J]. Chemical Engineering Journal, 2023, 471: 144646. |

| 35 | Xu J H, Li S W, Tan J, et al. Correlations of droplet formation in T-junction microfluidic devices: from squeezing to dripping[J]. Microfluidics and Nanofluidics, 2008, 5(6): 711-717. |

| 36 | Jena S K, Bahga S S, Kondaraju S. Prediction of droplet sizes in a T-junction microchannel: effect of dispersed phase inertial forces[J]. Physics of Fluids, 2021, 33(3): 032120. |

| [1] | 张鑫源, 何呈祥, 李亚婷, 朱春英, 马友光, 付涛涛. 微通道内液液非均相传质的模拟和实验研究方法进展[J]. 化工学报, 2025, 76(2): 484-503. |

| [2] | 戴晓宇, 徐强, 杨晨宇, 苏筱斌, 郭烈锦. 多级混流式混输泵气液两相增压特性[J]. 化工学报, 2025, 76(2): 554-563. |

| [3] | 李彦, 郭红利, 苏国庆, 张建文. 加氢装置空冷器气液两相流动与冲刷腐蚀问题[J]. 化工学报, 2025, 76(1): 141-150. |

| [4] | 高羡明, 杨汶轩, 卢少辉, 任晓松, 卢方财. 双槽道结构对超疏水表面液滴合并弹跳的影响[J]. 化工学报, 2025, 76(1): 208-220. |

| [5] | 陈晗, 蔡畅, 刘红, 尹洪超. 正戊醇添加剂强化喷雾冷却传热实验研究[J]. 化工学报, 2025, 76(1): 131-140. |

| [6] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [7] | 陈森洋, 靳蒲航, 谭志明, 谢公南. 质子交换膜燃料电池中蛇形流道液滴运动数值仿真研究[J]. 化工学报, 2024, 75(S1): 183-194. |

| [8] | 赵振刚, 周梦瑶, 金典, 张大骋. 基于泡沫碳扩散层的直接甲醇燃料电池改性研究[J]. 化工学报, 2024, 75(S1): 259-266. |

| [9] | 徐英宇, 杨国强, 彭璟, 孙海宁, 张志炳. 微界面高级氧化处理煤化工废水的研究[J]. 化工学报, 2024, 75(S1): 283-291. |

| [10] | 李雨霜, 王兴成, 温伯尧, 骆政园, 白博峰. 多孔介质中乳状液驱油的两相流动过程及其影响因素[J]. 化工学报, 2024, 75(S1): 56-66. |

| [11] | 刘律, 刘洁茹, 范亮亮, 赵亮. 基于层流效应的被动式颗粒分离微流控方法研究[J]. 化工学报, 2024, 75(S1): 67-75. |

| [12] | 周文博, 殷姜维, 张丹, 杨越, 于佳豪, 赵冰超. 热辐射加热下NaCl水溶液液滴蒸发过程的实验研究[J]. 化工学报, 2024, 75(S1): 85-94. |

| [13] | 杜得辉, 冯威, 张江辉, 项燕龙, 乔高攀, 李蔚. 微型翅片疏水复合强化管管内流动沸腾换热预测模型[J]. 化工学报, 2024, 75(S1): 95-107. |

| [14] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [15] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号