化工学报 ›› 2025, Vol. 76 ›› Issue (3): 1312-1322.DOI: 10.11949/0438-1157.20240841

肖俊兵1( ), 钟湘宇1, 任建地1, 钟芳芳1, 刘昌会2(

), 钟湘宇1, 任建地1, 钟芳芳1, 刘昌会2( ), 贾传坤1

), 贾传坤1

收稿日期:2024-07-24

修回日期:2024-09-20

出版日期:2025-03-25

发布日期:2025-03-28

通讯作者:

肖俊兵,刘昌会

作者简介:肖俊兵(1988—),男,博士,讲师,xjb1th@163.com

基金资助:

Junbing XIAO1( ), Xiangyu ZHONG1, Jiandi REN1, Fangfang ZHONG1, Changhui LIU2(

), Xiangyu ZHONG1, Jiandi REN1, Fangfang ZHONG1, Changhui LIU2( ), Chuankun JIA1

), Chuankun JIA1

Received:2024-07-24

Revised:2024-09-20

Online:2025-03-25

Published:2025-03-28

Contact:

Junbing XIAO, Changhui LIU

摘要:

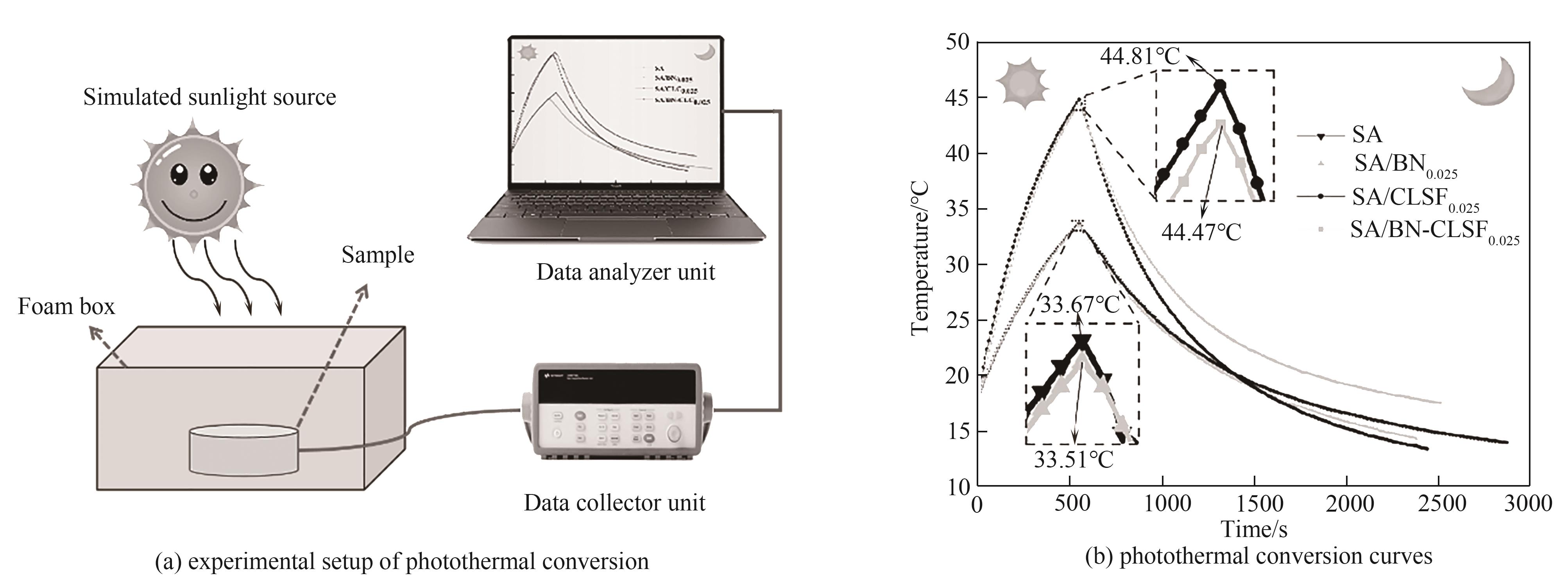

为改善硬脂酸(SA)相变储热性能,分别将氮化硼(BN)、丝瓜络碳(CLSF)以及BN-CLSF混合物作为添加剂加入SA制备复合材料,并研究不同添加剂对硬脂酸相变储热性能的影响。结果表明,当加入BN-CLSF的质量分数为2.5%时,复合材料的热导率最大可提高16.4%,对应的熔化潜热为153.04 J·g-1。相比于纯SA相变材料,复合材料的熔化时间最大缩短了72.3%,凝固时间最大缩短了33.3%。当光照时长为550 s时,复合材料SA/CLSF的表面温度较纯SA提高了11.14℃,表明添加CLSF有效提高了复合材料的光热转换能力。所制备基于丝瓜络碳材料的硬脂酸相变材料具有良好的热物理性能与光热转换能力,在太阳能光热利用、建筑节能、工业余热利用等领域具有广阔应用前景。

中图分类号:

肖俊兵, 钟湘宇, 任建地, 钟芳芳, 刘昌会, 贾传坤. 基于生物碳材料强化的硬脂酸相变材料储热性能研究[J]. 化工学报, 2025, 76(3): 1312-1322.

Junbing XIAO, Xiangyu ZHONG, Jiandi REN, Fangfang ZHONG, Changhui LIU, Chuankun JIA. Research on the heat storage properties of stearic acid phase change materials enhanced by bio-carbon materials[J]. CIESC Journal, 2025, 76(3): 1312-1322.

| Sample | Tm/℃ | hm/(J·g-1) | Sample | Tm/℃ | hm/(J·g-1) | Sample | Tm/℃ | hm/(J·g-1) |

|---|---|---|---|---|---|---|---|---|

| SA | 68.35 | 230.20 | — | — | — | — | — | — |

| SA/BN0.005 | 69.08 | 182.64 | SA/CLSF0.005 | 68.83 | 190.43 | SA/BN-CLSF0.005 | 70.08 | 203.16 |

| SA/BN0.010 | 69.25 | 168.59 | SA/CLSF0.010 | 68.80 | 184.80 | SA/BN-CLSF0.010 | 68.86 | 183.78 |

| SA/BN0.015 | 69.22 | 161.90 | SA/CLSF0.015 | 69.23 | 179.55 | SA/BN-CLSF0.015 | 69.02 | 175.51 |

| SA/BN0.020 | 69.25 | 159.45 | SA/CLSF0.020 | 69.07 | 174.67 | SA/BN-CLSF0.020 | 68.85 | 167.80 |

| SA/BN0.025 | 69.40 | 143.53 | SA/CLSF0.025 | 68.75 | 174.29 | SA/BN-CLSF0.025 | 69.46 | 153.04 |

表1 硬脂酸基复合材料熔化潜热以及相变温度

Table 1 Latent heat of melting and temperature of stearic acid based composite phase change materials

| Sample | Tm/℃ | hm/(J·g-1) | Sample | Tm/℃ | hm/(J·g-1) | Sample | Tm/℃ | hm/(J·g-1) |

|---|---|---|---|---|---|---|---|---|

| SA | 68.35 | 230.20 | — | — | — | — | — | — |

| SA/BN0.005 | 69.08 | 182.64 | SA/CLSF0.005 | 68.83 | 190.43 | SA/BN-CLSF0.005 | 70.08 | 203.16 |

| SA/BN0.010 | 69.25 | 168.59 | SA/CLSF0.010 | 68.80 | 184.80 | SA/BN-CLSF0.010 | 68.86 | 183.78 |

| SA/BN0.015 | 69.22 | 161.90 | SA/CLSF0.015 | 69.23 | 179.55 | SA/BN-CLSF0.015 | 69.02 | 175.51 |

| SA/BN0.020 | 69.25 | 159.45 | SA/CLSF0.020 | 69.07 | 174.67 | SA/BN-CLSF0.020 | 68.85 | 167.80 |

| SA/BN0.025 | 69.40 | 143.53 | SA/CLSF0.025 | 68.75 | 174.29 | SA/BN-CLSF0.025 | 69.46 | 153.04 |

| Sample | T1/℃ | T2/℃ |

|---|---|---|

| SA | 287.7 | 320.0 |

| SA/BN0.005 | 291.1 | 325.8 |

| SA/BN0.010 | 275.9 | 308.9 |

| SA/BN0.015 | 272.7 | 300.2 |

| SA/BN0.020 | 277.8 | 311.5 |

| SA/BN0.025 | 287.9 | 323.8 |

| SA/CLSF0.005 | 283.8 | 314.5 |

| SA/CLSF0.010 | 282.1 | 310.4 |

| SA/CLSF0.015 | 277.5 | 308.1 |

| SA/CLSF0.020 | 273.7 | 301.8 |

| SA/CLSF0.025 | 282.7 | 311.7 |

| SA/BN-CLSF0.005 | 270.5 | 302.7 |

| SA/BN-CLSF0.010 | 274.9 | 306.4 |

| SA/BN-CLSF0.015 | 277.2 | 310.9 |

| SA/BN-CLSF0.020 | 263.4 | 295.7 |

| SA/BN-CLSF0.025 | 268.8 | 301.1 |

表2 SA基复合材料的热重分析结果

Table 2 Thermogravimetric analysis of SA-based composite phase change materials

| Sample | T1/℃ | T2/℃ |

|---|---|---|

| SA | 287.7 | 320.0 |

| SA/BN0.005 | 291.1 | 325.8 |

| SA/BN0.010 | 275.9 | 308.9 |

| SA/BN0.015 | 272.7 | 300.2 |

| SA/BN0.020 | 277.8 | 311.5 |

| SA/BN0.025 | 287.9 | 323.8 |

| SA/CLSF0.005 | 283.8 | 314.5 |

| SA/CLSF0.010 | 282.1 | 310.4 |

| SA/CLSF0.015 | 277.5 | 308.1 |

| SA/CLSF0.020 | 273.7 | 301.8 |

| SA/CLSF0.025 | 282.7 | 311.7 |

| SA/BN-CLSF0.005 | 270.5 | 302.7 |

| SA/BN-CLSF0.010 | 274.9 | 306.4 |

| SA/BN-CLSF0.015 | 277.2 | 310.9 |

| SA/BN-CLSF0.020 | 263.4 | 295.7 |

| SA/BN-CLSF0.025 | 268.8 | 301.1 |

图7 SA基复合材料的光热转换实验装置示意图和光热转化曲线

Fig.7 Experimental setup of photothermal conversion and photothermal conversion curves of SA-based composite phase change materials

| 1 | Zhang H Q, Sun Q R, Yuan Y P, et al. A novel form-stable phase change composite with excellent thermal and electrical conductivities[J]. Chemical Engineering Journal, 2018, 336: 342-351. |

| 2 | 杨生, 邵雪峰, 范利武. 面向中温储热的D-半乳糖醇/肌糖醇二元共晶相变材料热稳定性研究[J]. 化工学报, 2020, 71(2): 864-870. |

| Yang S, Shao X F, Fan L W. Thermal endurance of binary eutectic phase change material D-dulcitol/inositol for medium temperature latent heat storage[J]. CIESC Journal, 2020, 71(2): 864-870. | |

| 3 | 吕培召, 徐一钧, 沈仕轩, 等. 多元低共熔材料热物性及电池热管理性能研究[J]. 工程热物理学报, 2021, 42(6): 1507-1515. |

| Lü P Z, Xu Y J, Shen S X, et al. The investigation on thermal properties and battery thermal management performance of polynary eutectic mixtures[J]. Journal of Engineering Thermophysics, 2021, 42(6): 1507-1515. | |

| 4 | 邹瀚影, 冯妍卉, 邱琳, 等. 十八烷酸热传导机制的尺度效应研究[J]. 化工学报, 2019, 70(S2): 155-160, 377. |

| Zou H Y, Feng Y H, Qiu L, et al. Size effect of heat conduction mechanism on stearic acid[J]. CIESC Journal, 2019, 70(S2): 155-160, 377. | |

| 5 | Zhang X L, Wang X, Zhong C H, et al. Ultrathin-wall mesoporous surface carbon foam stabilized stearic acid as a desirable phase change material for thermal energy storage[J]. Journal of Industrial and Engineering Chemistry, 2020, 85: 208-218. |

| 6 | 刘万强, 杨帆, 袁华, 等. 醇类有机物热传导的分子动力学模拟及微观机理研究[J]. 化工学报, 2020, 71(11): 5159-5168. |

| Liu W Q, Yang F, Yuan H, et al. Molecular dynamics simulation and mechanism study on thermal conductivity of alcohols[J]. CIESC Journal, 2020, 71(11): 5159-5168. | |

| 7 | Wu R Q, Gao W, Zhou Y H, et al. A novel three-dimensional network-based stearic acid/graphitized carbon foam composite as high-performance shape-stabilized phase change material for thermal energy storage[J]. Composites Part B: Engineering, 2021, 225: 109318. |

| 8 | He X Q, Zhang L, Li C Z. PEG-based polyurethane/paraffin@SiO2/boron nitride phase change composite with efficient thermal conductive pathways and superior mechanical property[J]. Composites Communications, 2021, 25: 100609. |

| 9 | Fu L Y, Wu Z X, Wu K Y, et al. A thermally induced flexible composite phase change material with boron nitride nanosheets/carbon nanotubes modified skeleton for battery thermal management[J]. Applied Energy, 2024, 373: 123899. |

| 10 | Wu L M, Liu Q X, Wang X L, et al. Preparation of two-dimensional nano montmorillonite/stearic acid energy storage composites with excellent stability and heat storage property[J]. Applied Clay Science, 2020, 191: 105614. |

| 11 | Pugalenthi S, Chellapandian M, Dharmaraj J J J, et al. Enhancing the thermal transport property of eutectic lauric-stearic acid based phase change material with silicon carbide nanoparticles for usage in battery thermal management system[J]. Journal of Energy Storage, 2024, 84: 110890. |

| 12 | Cheng P, Tang Z D, Chen X, et al. Advanced phase change hydrogel integrating metal-organic framework for self-powered thermal management[J]. Nano Energy, 2023, 105: 108009. |

| 13 | 吴婷婷, 胡艳鑫, 容惠强, 等. 基于膨胀石墨复合相变材料的传热性能研究[J]. 中南大学学报(自然科学版), 2021, 52(1): 200-209. |

| Wu T T, Hu Y X, Rong H Q, et al. Research on heat transfer performance of composite phase change materials based on expanded graphite[J]. Journal of Central South University(Science and Technology), 2021, 52(1): 200-209. | |

| 14 | Geng L, Wang J P, Yang X L, et al. Synergistic enhancement of phase change materials through three-dimensional porous layered covalent triazine framework/expanded graphite composites for solar energy storage and beyond[J]. Chemical Engineering Journal, 2024, 487: 150749. |

| 15 | Liang G Y, Zhang J W, An S H, et al. Phase change material filled hybrid 2D/3D graphene structure with ultra-high thermal effusivity for effective thermal management[J]. Carbon, 2021, 176: 11-20. |

| 16 | Wu S Y, Cao S, Xie H D, et al. Enhanced thermal performance of 3D hybrid graphene aerogel encapsulating paraffin for battery thermal management[J]. International Communications in Heat and Mass Transfer, 2024, 156: 107618. |

| 17 | Zhang M, Cheng H F, Wang C Y, et al. Kaolinite nanotube-stearic acid composite as a form-stable phase change material for thermal energy storage[J]. Applied Clay Science, 2021, 201: 105930. |

| 18 | Wen R L, Liu Y F, Yang C, et al. Enhanced thermal properties of stearic acid/carbonized maize straw composite phase change material for thermal energy storage in buildings[J]. Journal of Energy Storage, 2021, 36: 102420. |

| 19 | Sun M Y, Feng D L, Sun F Y, et al. Insights into effect of lignocellulosic biomass framework types on bio-based shape stable composite phase change materials[J]. Journal of Energy Storage, 2024, 91: 112103. |

| 20 | Jia X W, Li Q Y, Ao C H, et al. High thermal conductive shape-stabilized phase change materials of polyethylene glycol/boron nitride@chitosan composites for thermal energy storage[J]. Composites Part A: Applied Science and Manufacturing, 2020, 129: 105710. |

| 21 | Bin Shahid U, Abdala A. A critical review of phase change material composite performance through figure-of-merit analysis: graphene vs boron nitride[J]. Energy Storage Materials, 2021, 34: 365-387. |

| 22 | Xin S, Zhao Z W, Liu S X, et al. Study on the enhancement effect of synergy between multi-size functionalized boron nitride and graphene oxide on the thermal properties of phase change composites[J]. Molecules, 2023, 28(9): 3797. |

| 23 | Luo F B, He Y F, Cui W Q, et al. Shape-stabilized phase change materials with superior thermal conductivity for thermal energy harvesting[J]. ACS Applied Polymer Materials, 2022, 4(3): 2160-2168. |

| 24 | Jiang T Y, Zhang Y L, Olayiwola S, et al. Biomass-derived porous carbons support in phase change materials for building energy efficiency: a review[J]. Materials Today Energy, 2022, 23: 100905. |

| 25 | Hou Y J, Ma F, Fu Z, et al. Encapsulation of stearic-palmitic acid in alkali-activated coconut shell and corn cob biochar to optimize energy storage[J]. Journal of Energy Storage, 2023, 66: 107418. |

| 26 | Hekimoğlu G, Sarı A, Kar T, et al. Walnut shell derived bio-carbon/methyl palmitate as novel composite phase change material with enhanced thermal energy storage properties[J]. Journal of Energy Storage, 2021, 35: 102288. |

| 27 | An J Y, Yin M Q, Zhang Q, et al. Genome survey sequencing of Luffa cylindrica L. and microsatellite high resolution melting (SSR-HRM) analysis for genetic relationship of Luffa genotypes[J]. International Journal of Molecular Sciences, 2017, 18(9): 1942. |

| 28 | Su H X, Guo X, Chen G L, et al. A novel honeycomb-like porous carbon from loofah sponge for form-stable phase change materials with high encapsulation capacity and reliability[J]. Materials Letters, 2022, 308: 131118. |

| 29 | Song J Y, He H F, Wang Y B, et al. Shape-stabilized phase change composites supported by biomass loofah sponge-derived microtubular carbon scaffold toward thermal energy storage and electric-to-thermal conversion[J]. Journal of Energy Storage, 2022, 56: 105891. |

| 30 | Li L G, Song J Y, Wang Y B, et al. Fabrication and performance of shape-stable phase change composites supported by environment-friendly and economical loofah sponge fibers for thermal energy storage[J]. Energy & Fuels, 2022, 36(7): 3938-3946. |

| 31 | Xiao J, Zou B, Liu C H, et al. Carbonized loofah sponge fragments enhanced phase change thermal energy storage: preparation and thermophysical property analysis[J]. Applied Thermal Engineering, 2024, 242: 122505. |

| 32 | Li Y, Zheng N N, Ren Y, et al. Anisotropic and hierarchical porous boron nitride/graphene aerogels supported phase change materials for efficient solar-thermal energy conversion[J]. Ceramics International, 2024, 50(11): 18923-18931. |

| 33 | Dai Z F, Zhang G L, Xiao Y F, et al. High-directional thermally conductive stearic acid/expanded graphite—graphene films for efficient photothermal energy storage[J]. Chemical Engineering Journal, 2024, 484: 149203. |

| 34 | Ao C, Yan S Y, Zhao S T, et al. Stearic acid/expanded graphite composite phase change material with high thermal conductivity for thermal energy storage[J]. Energy Reports, 2022, 8: 4834-4843. |

| 35 | Li W, Dong Y, Zhang X, et al. Preparation and performance analysis of graphite additive/paraffin composite phase change materials[J]. Processes, 2019, 7(7): 447. |

| 36 | Wang C M, Chen K, Huang J, et al. Thermal behavior of polyethylene glycol based phase change materials for thermal energy storage with multiwall carbon nanotubes additives[J]. Energy, 2019, 180: 873-880. |

| 37 | Wang C M, Chen K, Huang Z, et al. Effect of polymer-derived silicon carbonitride on thermal performances of polyethylene glycol based composite phase change materials[J]. Solar Energy, 2020, 208: 282-288. |

| 38 | Liu Z P, He F F, Yang A S, et al. Double-skeleton based shape-stabilized phase change materials with excellent solar-thermal energy conversion and shape memory performance[J]. Thermochimica Acta, 2022, 717: 179360. |

| 39 | Liu S X, Zhang X, Zhu X Z, et al. A low-temperature phase change material based on capric-stearic acid/expanded graphite for thermal energy storage[J]. ACS Omega, 2021, 6(28): 17988-17998. |

| 40 | Bai K H, Li C C, Xie B S, et al. Emerging PEG/VO2 dual phase change materials for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2022, 239: 111686. |

| 41 | Feng B, Zhang Y H, Tu J, et al. Determination on the thermal conductivity and thermal contact resistance of thin composite phase change films as a thermal interfacial material[J]. Case Studies in Thermal Engineering, 2022, 33: 101979. |

| 42 | Cheng C L, Shalabh, Garg G. Coefficient of determination for multiple measurement error models[J]. Journal of Multivariate Analysis, 2014, 126: 137-152. |

| 43 | Ali Bhutto Y, Pandey A K, Saidur R, et al. Analyzing the thermal potential of binary 2D (h-BN/Gr) nanoparticles enhanced lauric acid phase change material for photovoltaic thermal system application[J]. Journal of Energy Storage, 2023, 73: 109116. |

| 44 | Zhang Y A, Wang J S, Qiu J J, et al. Ag-graphene/PEG composite phase change materials for enhancing solar-thermal energy conversion and storage capacity[J]. Applied Energy, 2019, 237: 83-90. |

| 45 | Liu Y N, Wang N N, Ding Y F. Preparation and properties of composite phase change material based on solar heat storage system[J]. Journal of Energy Storage, 2021, 40: 102805. |

| 46 | Hu Z C, Jiang M H, Zou Y J, et al. MoS2-decorated carbonized melamine foam/reduced graphene oxide network for constructing polyethylene-glycol-based multifunctional phase change materials toward multiple energy harvesting and microwave absorbing applications[J]. Chemical Engineering Journal, 2023, 461: 141923. |

| 47 | Gao M M, Zhu L L, Peh C K, et al. Solar absorber material and system designs for photothermal water vaporization towards clean water and energy production[J]. Energy & Environmental Science, 2019, 12(3): 841-864. |

| [1] | 刘彦贝, 王若名, 刘娟, Raza Taimoor, 陆玉正, Raza Rizwan, 朱斌, 李松波, 安胜利, 云斯宁. CeO2@La0.6Sr0.4Co0.2Fe0.8O3-δ 电解质的制备及半导体离子燃料电池性能研究[J]. 化工学报, 2025, 76(3): 1353-1362. |

| [2] | 齐珂, 王迪, 谢喆, 陈东升, 周云龙, 孙灵芳. 考虑多物理场耦合特性的固体氧化物燃料电池瞬态特性研究[J]. 化工学报, 2025, 76(3): 1264-1274. |

| [3] | 肖俊兵, 邹博, 任建地, 刘昌会, 贾传坤. 基于相图分析的氯化物复合熔盐储热性能研究[J]. 化工学报, 2025, 76(3): 963-974. |

| [4] | 李远华, 凌思棋, 封科军, 冯颖, 郭于菁, 谢世桓. 基于cMOFs的固定化脂肪酶微反应器的构筑及其扁桃酸催化应用[J]. 化工学报, 2025, 76(3): 1170-1179. |

| [5] | 李文宝, 胡锦鹏, 杜淼, 潘鹏举, 单国荣. 强韧P(SBMA-co-AAc)/SiO2复合水凝胶海洋防污减阻涂层[J]. 化工学报, 2025, 76(2): 787-796. |

| [6] | 吴德威, 汪郑鹏, 周玥, 李晓宁, 陈招, 李卓, 刘成伟, 李学刚, 肖文德. 固定床法制备锂离子电池硅碳负极材料及其储锂性能研究[J]. 化工学报, 2024, 75(S1): 300-308. |

| [7] | 唐溯, 郑子鏖, 魏翰泽, 许晓玲, 翟晓强. PMMA/PEG600/CNT复合定型相变材料制备与导热强化[J]. 化工学报, 2024, 75(S1): 309-320. |

| [8] | 吴学红, 韦新, 侯加文, 吕财, 刘勇, 刘鹤, 常志娟. 热解法制备碳纳米管及其在散热涂层中的应用研究[J]. 化工学报, 2024, 75(9): 3360-3368. |

| [9] | 王倩倩, 李冰, 郑伟波, 崔国民, 赵兵涛, 明平文. 氢燃料电池局部动态特征三维模型[J]. 化工学报, 2024, 75(8): 2812-2820. |

| [10] | 张林, 张子怡, 李勇, 童少平. Fe-MOF-74前体制备铁-碳/氮复合材料及其活化过硫酸盐性能[J]. 化工学报, 2024, 75(5): 1882-1889. |

| [11] | 丁相斐, 丘晓琳, 朱喜成, 张佳伟, 陈锦华. pH响应性气体渗透CNC/PBAT复合膜的制备与性能[J]. 化工学报, 2024, 75(3): 1040-1051. |

| [12] | 皮若冰, 周云龙. 直接Z型异质结体系光催化还原二氧化碳研究进展[J]. 化工学报, 2024, 75(10): 3379-3400. |

| [13] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [14] | 刘远超, 关斌, 钟建斌, 徐一帆, 蒋旭浩, 李耑. 单层XSe2(X=Zr/Hf)的热电输运特性研究[J]. 化工学报, 2023, 74(9): 3968-3978. |

| [15] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号