化工学报 ›› 2024, Vol. 75 ›› Issue (S1): 309-320.DOI: 10.11949/0438-1157.20240272

唐溯1( ), 郑子鏖1, 魏翰泽1, 许晓玲2, 翟晓强1(

), 郑子鏖1, 魏翰泽1, 许晓玲2, 翟晓强1( )

)

收稿日期:2024-03-06

修回日期:2024-04-12

出版日期:2024-12-25

发布日期:2024-12-17

通讯作者:

翟晓强

作者简介:唐溯(2000—),女,硕士研究生,Tangsu66@sjtu.edu.cn

基金资助:

Su TANG1( ), Zi'ao ZHENG1, Hanze WEI1, Xiaoling XU2, Xiaoqiang ZHAI1(

), Zi'ao ZHENG1, Hanze WEI1, Xiaoling XU2, Xiaoqiang ZHAI1( )

)

Received:2024-03-06

Revised:2024-04-12

Online:2024-12-25

Published:2024-12-17

Contact:

Xiaoqiang ZHAI

摘要:

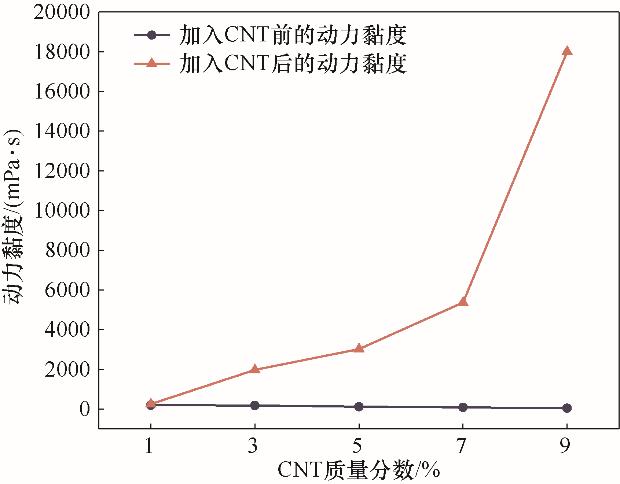

针对固-液相变复合材料由于碳材料分布不均引起的热导率低的问题,采用原位聚合法并结合官能化表面改性方式优化体系中CNT的分散,提出甲基丙烯酸甲酯聚合物(PMMA)/聚乙二醇(PEG600)/碳纳米管(CNT)的导热增强型复合相变材料。首先,确定以PMMA为基底封装相变材料PEG600的最佳质量配比为3∶7,此时材料兼具良好的封装性能和蓄热性能。其次,利用原位聚合法利于调控体系黏度的特性,在PMMA/PEG600体系中最大程度引入CNT至浓度阈值,极大提升了复合材料热导率。当CNT质量分数为7%时,复合材料的热导率为0.438 W/(m·K),约为未添加CNT时的3倍。最后,针对CNT进行羟基官能化表面改性进一步强化导热性能。当羟基化CNT质量分数为3%时,含CNT和羟基化CNT的三元复合材料较二元复合材料的热导率分别提升了8%和92%。

中图分类号:

唐溯, 郑子鏖, 魏翰泽, 许晓玲, 翟晓强. PMMA/PEG600/CNT复合定型相变材料制备与导热强化[J]. 化工学报, 2024, 75(S1): 309-320.

Su TANG, Zi'ao ZHENG, Hanze WEI, Xiaoling XU, Xiaoqiang ZHAI. Preparation and thermal conductivity reinforcement of PMMA/PEG600/CNT composite shaped phase change materials[J]. CIESC Journal, 2024, 75(S1): 309-320.

| 制备工艺 | 熔融共混法 | 原位聚合法 |

|---|---|---|

| 反应过程 | 物理共混 | 化学反应;物理共混 |

| 制备原理 | 高分子聚合物与相变材料物理熔融相结合 | 聚合物单体不断聚合为高分子材料,同时与相变材料物理熔融相结合 |

| 制备步骤 | 简单 | 烦琐 |

| 制备流程 | 熔融共混→倒入模具→冷却脱模 | 预聚合→恒温聚合→真空脱泡→高温固化→冷却成型 |

| 节能性 | 高温制备高耗能,200℃左右 | 低温制备更节能,80℃左右 |

| 安全性 | 高温,更危险 | 低温,更安全 |

| 导热性能优化程度 | 体系黏度不可控,碳团聚后难以均匀分布(阈值低) | 通过调控体系黏度抑制碳团聚,最大程度地引入碳材料(阈值高),并构建导热通路 |

| 高分子基底 | HDPE、PP、热塑性弹性体(SBS/SEBS/OBC) | PMMA、PDMS |

表1 熔融共混法和原位聚合法的制备工艺对比[12-20,35]

Table 1 Comparison of preparation processes by melt blending and in situ polymerization methods[12-20,35]

| 制备工艺 | 熔融共混法 | 原位聚合法 |

|---|---|---|

| 反应过程 | 物理共混 | 化学反应;物理共混 |

| 制备原理 | 高分子聚合物与相变材料物理熔融相结合 | 聚合物单体不断聚合为高分子材料,同时与相变材料物理熔融相结合 |

| 制备步骤 | 简单 | 烦琐 |

| 制备流程 | 熔融共混→倒入模具→冷却脱模 | 预聚合→恒温聚合→真空脱泡→高温固化→冷却成型 |

| 节能性 | 高温制备高耗能,200℃左右 | 低温制备更节能,80℃左右 |

| 安全性 | 高温,更危险 | 低温,更安全 |

| 导热性能优化程度 | 体系黏度不可控,碳团聚后难以均匀分布(阈值低) | 通过调控体系黏度抑制碳团聚,最大程度地引入碳材料(阈值高),并构建导热通路 |

| 高分子基底 | HDPE、PP、热塑性弹性体(SBS/SEBS/OBC) | PMMA、PDMS |

图1 基于原位聚合法的导热填料均匀分布三元高分子定型相变材料优化制备流程(1 cP=10-3 Pa·s)

Fig.1 Optimized preparation process of thermally conductive filler uniformly distributed ternary polymer stereotyped phase change materials based on in situ polymerization method

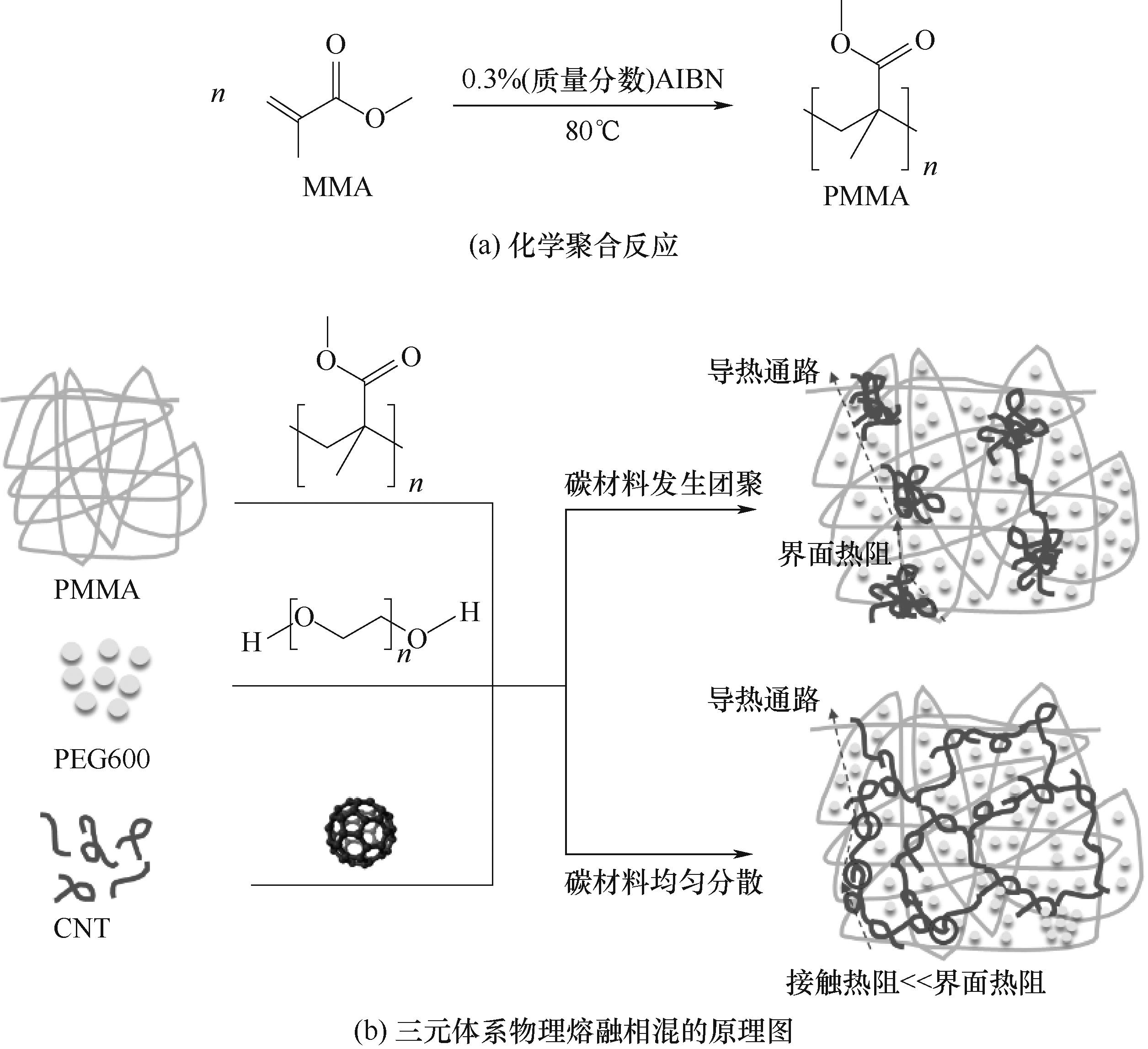

图2 基于原位聚合法制备PMMA/PEG600/CNT的化学和物理反应过程示意图

Fig.2 Schematic of the chemical and physical reaction process for the preparation of PMMA/PEG600/CNT based on in situ polymerization method

| 材料 | 熔化温度/℃ | 熔化峰值/℃ | 熔化焓/(J/g) | 凝固温度/℃ | 凝固峰值/℃ | 凝固焓/(J/g) |

|---|---|---|---|---|---|---|

| 纯PEG600 | 15.82 | 22.34 | 116.92 | 16.20 | 8.73 | 111.40 |

| 80%PEG600/20%PMMA | 13.82 | 18.95 | 82.21 | 16.83 | 13.42 | 74.40 |

| 70%PEG600/30%PMMA | 13.50 | 18.55 | 77.72 | 16.22 | 14.39 | 65.00 |

| 60%PEG600/40%PMMA | 13.38 | 18.47 | 55.44 | 16.81 | 10.42 | 52.09 |

| 50%PEG600/50%PMMA | 12.72 | 18.21 | 34.88 | 12.78 | 8.93 | 30.80 |

表2 PMMA/PEG600复合相变材料相变特性

Table 2 Phase change properties of PMMA/PEG600 composite phase change materials

| 材料 | 熔化温度/℃ | 熔化峰值/℃ | 熔化焓/(J/g) | 凝固温度/℃ | 凝固峰值/℃ | 凝固焓/(J/g) |

|---|---|---|---|---|---|---|

| 纯PEG600 | 15.82 | 22.34 | 116.92 | 16.20 | 8.73 | 111.40 |

| 80%PEG600/20%PMMA | 13.82 | 18.95 | 82.21 | 16.83 | 13.42 | 74.40 |

| 70%PEG600/30%PMMA | 13.50 | 18.55 | 77.72 | 16.22 | 14.39 | 65.00 |

| 60%PEG600/40%PMMA | 13.38 | 18.47 | 55.44 | 16.81 | 10.42 | 52.09 |

| 50%PEG600/50%PMMA | 12.72 | 18.21 | 34.88 | 12.78 | 8.93 | 30.80 |

| 材料 | 熔化温度/℃ | 熔化峰值/℃ | 熔化焓/(J/g) | 凝固温度/℃ | 凝固峰值/℃ | 凝固焓/(J/g) |

|---|---|---|---|---|---|---|

| 1%CNT/PEG600/PMMA | 13.12 | 19.41 | 71.24 | 15.98 | 14.53 | 45.60 |

| 3%CNT/PEG600/PMMA | 12.23 | 18.40 | 70.97 | 16.32 | 13.15 | 50.31 |

| 5%CNT/PEG600/PMMA | 11.54 | 17.91 | 64.94 | 16.44 | 12.84 | 56.64 |

| 7%CNT/PEG600/PMMA | 11.32 | 18.45 | 66.03 | 16.48 | 14.12 | 58.80 |

| 9%CNT/PEG600/PMMA | 11.23 | 18.50 | 63.02 | 16.72 | 14.33 | 55.99 |

表3 PMMA/PEG600/CNT复合相变材料的相变特性

Table 3 Phase transition properties of PMMA/PEG600/CNT composite phase change materials

| 材料 | 熔化温度/℃ | 熔化峰值/℃ | 熔化焓/(J/g) | 凝固温度/℃ | 凝固峰值/℃ | 凝固焓/(J/g) |

|---|---|---|---|---|---|---|

| 1%CNT/PEG600/PMMA | 13.12 | 19.41 | 71.24 | 15.98 | 14.53 | 45.60 |

| 3%CNT/PEG600/PMMA | 12.23 | 18.40 | 70.97 | 16.32 | 13.15 | 50.31 |

| 5%CNT/PEG600/PMMA | 11.54 | 17.91 | 64.94 | 16.44 | 12.84 | 56.64 |

| 7%CNT/PEG600/PMMA | 11.32 | 18.45 | 66.03 | 16.48 | 14.12 | 58.80 |

| 9%CNT/PEG600/PMMA | 11.23 | 18.50 | 63.02 | 16.72 | 14.33 | 55.99 |

图11 恒温聚合阶段在PEG600/PMMA中加入CNT前后的动力黏度对比

Fig.11 Comparison of kinetic viscosity before and after addition of CNT to PEG600/PMMA at constant temperature polymerization stage

| 材料 | 熔化温度/℃ | 熔化峰值/℃ | 熔化焓/(J/g) | 凝固温度/℃ | 凝固峰值/℃ | 凝固焓/(J/g) |

|---|---|---|---|---|---|---|

| 1%OH-CNT/PEG600/PMMA | 14.10 | 18.46 | 78.36 | 15.72 | 12.33 | 56.64 |

| 3%OH-CNT/PEG600/PMMA | 12.20 | 18.54 | 76.72 | 14.91 | 12.58 | 58.80 |

| 5%OH-CNT/PEG600/PMMA | 12.80 | 18.50 | 75.62 | 15.20 | 12.25 | 55.92 |

| 7%OH-CNT/PEG600/PMMA | 13.01 | 18.62 | 74.80 | 16.21 | 13.04 | 56.64 |

| 9%OH-CNT/PEG600/PMMA | 12.91 | 18.48 | 74.76 | 16.60 | 13.76 | 55.92 |

表4 PMMA/PEG600/OH-CNT复合相变材料的相变特性

Table 4 Phase transition properties of PMMA/PEG600/OH-CNT composite phase change materials

| 材料 | 熔化温度/℃ | 熔化峰值/℃ | 熔化焓/(J/g) | 凝固温度/℃ | 凝固峰值/℃ | 凝固焓/(J/g) |

|---|---|---|---|---|---|---|

| 1%OH-CNT/PEG600/PMMA | 14.10 | 18.46 | 78.36 | 15.72 | 12.33 | 56.64 |

| 3%OH-CNT/PEG600/PMMA | 12.20 | 18.54 | 76.72 | 14.91 | 12.58 | 58.80 |

| 5%OH-CNT/PEG600/PMMA | 12.80 | 18.50 | 75.62 | 15.20 | 12.25 | 55.92 |

| 7%OH-CNT/PEG600/PMMA | 13.01 | 18.62 | 74.80 | 16.21 | 13.04 | 56.64 |

| 9%OH-CNT/PEG600/PMMA | 12.91 | 18.48 | 74.76 | 16.60 | 13.76 | 55.92 |

| 1 | Chu S, Majumdar A. Opportunities and challenges for a sustainable energy future[J]. Nature, 2012, 488(7411): 294-303. |

| 2 | 张寅平, 刘真泉, 王馨, 等. 低温相变蓄冷材料蓄冷特性实验研究[J]. 暖通空调, 2005, 35(10): 114-117. |

| Zhang Y P, Liu Z Q, Wang X, et al. Experiment on cool storage performance of a low-temperature phase change material[J]. Hv & Ac, 2005, 35(10): 114-117. | |

| 3 | 刘业凤, 王雨晴, 余军. 复合相变材料应用于锂离子电池组散热的研究[J]. 制冷技术, 2021, 41(2): 49-55. |

| Liu Y F, Wang Y Q, Yu J. Research on application of composite phase change material in heat dissipation of lithium-ion battery pack[J]. Chinese Journal of Refrigeration Technology, 2021, 41(2): 49-55. | |

| 4 | 李帅帅, 李刚, 张俊永, 等. 基于相变蓄能的辐射式高效空气源热泵系统研究[J]. 制冷技术, 2022, 42(2): 32-38. |

| Li S S, Li G, Zhang J Y, et al. Research on radiant high efficiency air-source heat pump system based on phase change energy storage[J]. Chinese Journal of Refrigeration Technology, 2022, 42(2): 32-38. | |

| 5 | 周旭, 陈晨, 顾卫标, 等. 兼具低频磁屏蔽效能的印制板组件热沉制备与测试[J]. 制冷技术, 2021, 41(6): 40-45. |

| Zhou X, Chen C, Gu W B, et al. Preparation and test of printed circuit board assembly heat sink with low frequency magnetic shielding effectiveness[J]. Chinese Journal of Refrigeration Technology, 2021, 41(6): 40-45. | |

| 6 | 张小松, 夏燚, 金星. 相变蓄能建筑墙体研究进展[J]. 东南大学学报(自然科学版), 2015, 45(3): 612-618. |

| Zhang X S, Xia Y, Jin X. Review on phase change material building walls[J]. Journal of Southeast University (Natural Science Edition), 2015, 45(3): 612-618. | |

| 7 | Kenisarin M M, Kenisarina K M. Form-stable phase change materials for thermal energy storage[J]. Renewable and Sustainable Energy Reviews, 2012, 16(4): 1999-2040. |

| 8 | Cai Y B, Gao C T, Xu X L, et al. Electrospun ultrafine composite fibers consisting of lauric acid and polyamide 6 as form-stable phase change materials for storage and retrieval of solar thermal energy[J]. Solar Energy Materials and Solar Cells, 2012, 103: 53-61. |

| 9 | Mitran R A, Berger D, Munteanu C, et al. Evaluation of different mesoporous silica supports for energy storage in shape-stabilized phase change materials with dual thermal responses[J]. The Journal of Physical Chemistry C, 2015, 119(27): 15177-15184. |

| 10 | Wang C Y, Feng L L, Li W, et al. Shape-stabilized phase change materials based on polyethylene glycol/porous carbon composite: the influence of the pore structure of the carbon materials[J]. Solar Energy Materials and Solar Cells, 2012, 105: 21-26. |

| 11 | Gao H Y, Wang J J, Chen X, et al. Nanoconfinement effects on thermal properties of nanoporous shape-stabilized composite PCMs: a review[J]. Nano Energy, 2018, 53: 769-797. |

| 12 | Ye H, Ge X S. Preparation of polyethylene-paraffin compound as a form-stable solid-liquid phase change material[J]. Solar Energy Materials and Solar Cells, 2000, 64(1): 37-44. |

| 13 | Sarı A. Form-stable paraffin/high density polyethylene composites as solid-liquid phase change material for thermal energy storage: preparation and thermal properties[J]. Energy Conversion and Management, 2004, 45(13/14): 2033-2042. |

| 14 | Alkan C, Kaya K, Sarı A. Preparation, thermal properties and thermal reliability of form-stable paraffin/polypropylene composite for thermal energy storage[J]. Journal of Polymers and the Environment, 2009, 17(4): 254-258. |

| 15 | 陈雪芳, 门明燃, 李强, 等. 石蜡/聚丙烯定型相变储能材料的泄漏率和定型能力的研究[J]. 化工新型材料, 2022, 50(7): 137-141. |

| Chen X F, Men M R, Li Q, et al. Study on leakage rate and shaping ability of paraffin/PP FSPCMs for energy storage[J]. New Chemical Materials, 2022, 50(7): 137-141. | |

| 16 | Alkan C, Sari A. Fatty acid/poly(methyl methacrylate) (PMMA) blends as form-stable phase change materials for latent heat thermal energy storage[J]. Solar Energy, 2008, 82(2): 118-124. |

| 17 | Wang L J, Meng D. Fatty acid eutectic/polymethyl methacrylate composite as form-stable phase change material for thermal energy storage[J]. Applied Energy, 2010, 87(8): 2660-2665. |

| 18 | Zhang Q L, Zhao Y Q, Feng J C. Systematic investigation on shape stability of high-efficiency SEBS/paraffin form-stable phase change materials[J]. Solar Energy Materials and Solar Cells, 2013, 118: 54-60. |

| 19 | Xiao M, Feng B, Gong K C. Preparation and performance of shape stabilized phase change thermal storage materials with high thermal conductivity[J]. Energy Conversion and Management, 2002, 43(1): 103-108. |

| 20 | 何起帆, 吴闽强, 李廷贤, 等. 正十八烷/OBC/EG复合定型相变材料制备及热物性[J]. 化工学报, 2021, 72(S1): 539-545. |

| He Q F, Wu M Q, Li T X, et al. Preparation and thermophysical properties of octadecane/OBC/EG composite shaped phase change material[J]. CIESC Journal, 2021, 72(S1): 539-545. | |

| 21 | 李琳, 王宇, 张凯. 定形相变材料储热性能和强化传热研究进展[J]. 化工新型材料. DOI: 10.19817/j.cnki.issn1006-3536.2024.06.017 . |

| Li L, Wang Y, Zhang K. Advances in thermal storage properties and enhanced heat transfer of shaped phase change materials[J]. New Chemical Materials. DOI: 10.19817/j.cnki.issn1006-3536.2024.06.017 . | |

| 22 | 肖力光, 李冰, 王敬维. 氧化石墨烯改性无机水合盐三元定形相变材料的研究[J]. 化工新型材料, 2021, 49(1): 77-80, 85. |

| Xiao L G, Li B, Wang J W. Study on GO modified inorganic hydrate ternary shape-stabilized PCM[J]. New Chemical Materials, 2021, 49(1): 77-80, 85. | |

| 23 | 张云峰, 张璐, 刘鹏, 等. 纳米SiO2改性石蜡相变微胶囊涂料的制备及性能表征[J]. 涂料工业, 2021, 51(1): 34-39. |

| Zhang Y F, Zhang L, Liu P, et al. Preparation and characterization of nano SiO2 modified paraffin phase change microcapsule-based coatings[J]. Paint & Coatings Industry, 2021, 51(1): 34-39. | |

| 24 | 刘菁伟, 杨文彬, 田本强, 等. 石蜡/高密度聚乙烯/膨胀石墨导热增强型复合相变材料热导率的影响因素[J]. 高分子材料科学与工程, 2015, 31(5): 83-86, 92. |

| Liu J W, Yang W B, Tian B Q, et al. Thermal conductivity of paraffin/HDPE/expanded graphite phase change composite[J]. Polymer Materials Science & Engineering, 2015, 31(5): 83-86, 92. | |

| 25 | 汪向磊, 郭全贵, 王立勇, 等. 高导热定形聚乙烯/石蜡/膨胀石墨相变复合材料的研究[J]. 功能材料, 2013, 44(23): 3401-3404. |

| Wang X L, Guo Q G, Wang L Y, et al. Thermal conductivity enhancement of form-stable HDPE/paraffin by expanded graphite addition[J]. Journal of Functional Materials, 2013, 44(23): 3401-3404. | |

| 26 | Huang Q Q, Deng J, Li X X, et al. Experimental investigation on thermally induced aluminum nitride based flexible composite phase change material for battery thermal management[J]. Journal of Energy Storage, 2020, 32: 101755. |

| 27 | Mu M L, McNally T. The effect of multi-walled carbon nanotubes on the thermo-physical properties of shape stabilised phase change materials for buildings based on high density polyethylene and paraffin wax[J]. Journal of Energy Storage, 2022, 55: 105601. |

| 28 | Fredi G, Dorigato A, Fambri L, et al. Multifunctional epoxy/carbon fiber laminates for thermal energy storage and release[J]. Composites Science and Technology, 2018, 158: 101-111. |

| 29 | 谢晓倩, 赵天波, 马睿, 等. 苯乙烯-丁二烯-苯乙烯嵌段共聚物/石墨烯/石蜡定型相变材料的制备与性能研究[J]. 化工新型材料, 2022, 50(6): 80-85. |

| Xie X Q, Zhao T B, Ma R, et al. Preparation and property of SBS/MLG/PW shape-stabilized phase change materials[J]. New Chemical Materials, 2022, 50(6): 80-85. | |

| 30 | Wu M Q, Li T X, He Q F, et al. Thermally conductive and form-stable phase change composite for building thermal management[J]. Energy, 2022, 239: 121938. |

| 31 | Wu W X, Wu W, Wang S F. Form-stable and thermally induced flexible composite phase change material for thermal energy storage and thermal management applications[J]. Applied Energy, 2019, 236: 10-21. |

| 32 | 石优, 杨斌, 陆华阳, 等. 石墨烯纳米片填充HDPE/PEG相变复合材料的动态流变行为[J]. 高分子材料科学与工程, 2017, 33(10): 53-57. |

| Shi Y, Yang B, Lu H Y, et al. Dynamic rheological properties of GNFs-filled HDPE/PEG phase-change composites[J]. Polymer Materials Science & Engineering, 2017, 33(10): 53-57. | |

| 33 | Xiao X, Zhang P, Li M. Effective thermal conductivity of open-cell metal foams impregnated with pure paraffin for latent heat storage[J]. International Journal of Thermal Sciences, 2014, 81: 94-105. |

| 34 | Aftab W, Mahmood A, Guo W H, et al. Polyurethane-based flexible and conductive phase change composites for energy conversion and storage[J]. Energy Storage Materials, 2019, 20: 401-409. |

| 35 | Ye S, Zhang Q, Hu D, et al. Core-shell-like structured graphene aerogel encapsulating paraffin: shape-stable phase change material for thermal energy storage[J]. Journal of Materials Chemistry A, 2015, 3(7): 4018-4025. |

| 36 | Li T X, Wu M Q, Wu S, et al. Highly conductive phase change composites enabled by vertically-aligned reticulated graphite nanoplatelets for high-temperature solar photo/electro-thermal energy conversion, harvesting and storage[J]. Nano Energy, 2021, 89: 106338. |

| 37 | Saitō R, Dresselhaus G, Dresselhaus M S. Physical Properties of Carbon Nanotubes[M]. London: Imperial College Press, 1998. |

| 38 | Thostenson E T, Ren Z F, Chou T W. Advances in the science and technology of carbon nanotubes and their composites: a review[J]. Composites Science and Technology, 2001, 61(13): 1899-1912. |

| 39 | Allaoui A, Bai S, Cheng H M, et al. Mechanical and electrical properties of a MWNT/epoxy composite[J]. Composites Science and Technology, 2002, 62(15): 1993-1998. |

| 40 | Kwon S Y, Kwon I M, Kim Y G, et al. A large increase in the thermal conductivity of carbon nanotube/polymer composites produced by percolation phenomena[J]. Carbon, 2013, 55: 285-290. |

| 41 | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688, 2717. |

| Li Z, Zhang B, Wang L W. Development and properties of PEG-EG solid-solid phase change materials[J]. CIESC Journal, 2023, 74(6): 2680-2688, 2717. | |

| 42 | Ma C, Zhang W, Zhu Y F, et al. Alignment and dispersion of functionalized carbon nanotubes in polymer composites induced by an electric field[J]. Carbon, 2008, 46(4): 706-710. |

| 43 | Butala V, Stritih U. Experimental investigation of PCM cold storage[J]. Energy and Buildings, 2009, 41(3): 354-359. |

| [1] | 董新宇, 边龙飞, 杨怡怡, 张宇轩, 刘璐, 王腾. 冷却条件下倾斜上升管S-CO2流动与传热特性研究[J]. 化工学报, 2024, 75(S1): 195-205. |

| [2] | 吴德威, 汪郑鹏, 周玥, 李晓宁, 陈招, 李卓, 刘成伟, 李学刚, 肖文德. 固定床法制备锂离子电池硅碳负极材料及其储锂性能研究[J]. 化工学报, 2024, 75(S1): 300-308. |

| [3] | 汪张洲, 唐天琪, 夏嘉俊, 何玉荣. 基于复合相变材料的电池热管理性能模拟[J]. 化工学报, 2024, 75(S1): 329-338. |

| [4] | 秦思宇, 刘艺佳, 杨佳成, 佟薇, 金立文, 孟祥兆. 受限蒸汽腔内气液两相传热特性研究[J]. 化工学报, 2024, 75(S1): 47-55. |

| [5] | 胡俭, 姜静华, 范生军, 刘建浩, 邹海江, 蔡皖龙, 王沣浩. 中深层U型地埋管换热器取热特性研究[J]. 化工学报, 2024, 75(S1): 76-84. |

| [6] | 杜得辉, 冯威, 张江辉, 项燕龙, 乔高攀, 李蔚. 微型翅片疏水复合强化管管内流动沸腾换热预测模型[J]. 化工学报, 2024, 75(S1): 95-107. |

| [7] | 任冠宇, 张义飞, 李新泽, 杜文静. 翼型印刷电路板式换热器流动传热特性数值研究[J]. 化工学报, 2024, 75(S1): 108-117. |

| [8] | 李焱, 郑利军, 张恩勇, 王云飞. 深水海底管道软管内部流体渗透特性模型与试验研究[J]. 化工学报, 2024, 75(S1): 118-125. |

| [9] | 李新泽, 张双星, 任冠宇, 洪瑞, 杜文静. 大功率LED热管理用脉动热管热性能[J]. 化工学报, 2024, 75(S1): 126-134. |

| [10] | 陈超伟, 柳洋, 杜文静, 李金波, 史大阔, 辛公明. 局部热点下微肋通道流动传热特性[J]. 化工学报, 2024, 75(9): 3113-3121. |

| [11] | 吴学红, 韦新, 侯加文, 吕财, 刘勇, 刘鹤, 常志娟. 热解法制备碳纳米管及其在散热涂层中的应用研究[J]. 化工学报, 2024, 75(9): 3360-3368. |

| [12] | 朱子良, 王爽, 姜宇昂, 林梅, 王秋旺. 欧拉-拉格朗日迭代固-液相变算法[J]. 化工学报, 2024, 75(8): 2763-2776. |

| [13] | 王倩倩, 李冰, 郑伟波, 崔国民, 赵兵涛, 明平文. 氢燃料电池局部动态特征三维模型[J]. 化工学报, 2024, 75(8): 2812-2820. |

| [14] | 毛宇飞, 曹飞, 上官燕琴. 超临界压力流体管内湍流对流传热的计算方法[J]. 化工学报, 2024, 75(8): 2821-2830. |

| [15] | 曲玖哲, 杨鹏, 杨绪飞, 张伟, 宇波, 孙东亮, 王晓东. 硅基微柱簇阵列微通道流动沸腾实验研究[J]. 化工学报, 2024, 75(8): 2840-2851. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号