化工学报 ›› 2025, Vol. 76 ›› Issue (2): 596-611.DOI: 10.11949/0438-1157.20241102

• 流体力学与传递现象 • 上一篇

收稿日期:2024-09-30

修回日期:2024-11-11

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

付涛涛

作者简介:汪涵(2001—),男,博士研究生,wang_011012@tju.edu.cn

基金资助:

Han WANG( ), Chunying ZHU, Youguang MA, Taotao FU(

), Chunying ZHU, Youguang MA, Taotao FU( )

)

Received:2024-09-30

Revised:2024-11-11

Online:2025-03-25

Published:2025-03-10

Contact:

Taotao FU

摘要:

使用气体输送系统进行实验过程中时常会出现实际流量发生偏差的现象,并且不同入口压力和系统压差下其偏差值大小不同,一定情况下会影响实验结果的准确性,可通过误差预测对实验结果进行修正。以氮气输送系统为例,通过改变入口压力、压差和流量大小与范围并测量实际流量,进行误差分析和预测。研究结果表明,系统压差对流量控制的影响较小,而入口压力的增大需要配合背压阀的使用从而提高系统的精度,因此可以增加入口压力使偏差值更小。同时,根据理论推导和实验结果提出了普适的误差值与流量值的预测模型,可准确预测实际流量,为气体输送系统的误差分析与精准控制提供了新思路。

中图分类号:

汪涵, 朱春英, 马友光, 付涛涛. 入口压力及系统压差对气体输送系统流量的影响[J]. 化工学报, 2025, 76(2): 596-611.

Han WANG, Chunying ZHU, Youguang MA, Taotao FU. Effect of inlet pressure and differential pressure on flow rate of gas conveying system[J]. CIESC Journal, 2025, 76(2): 596-611.

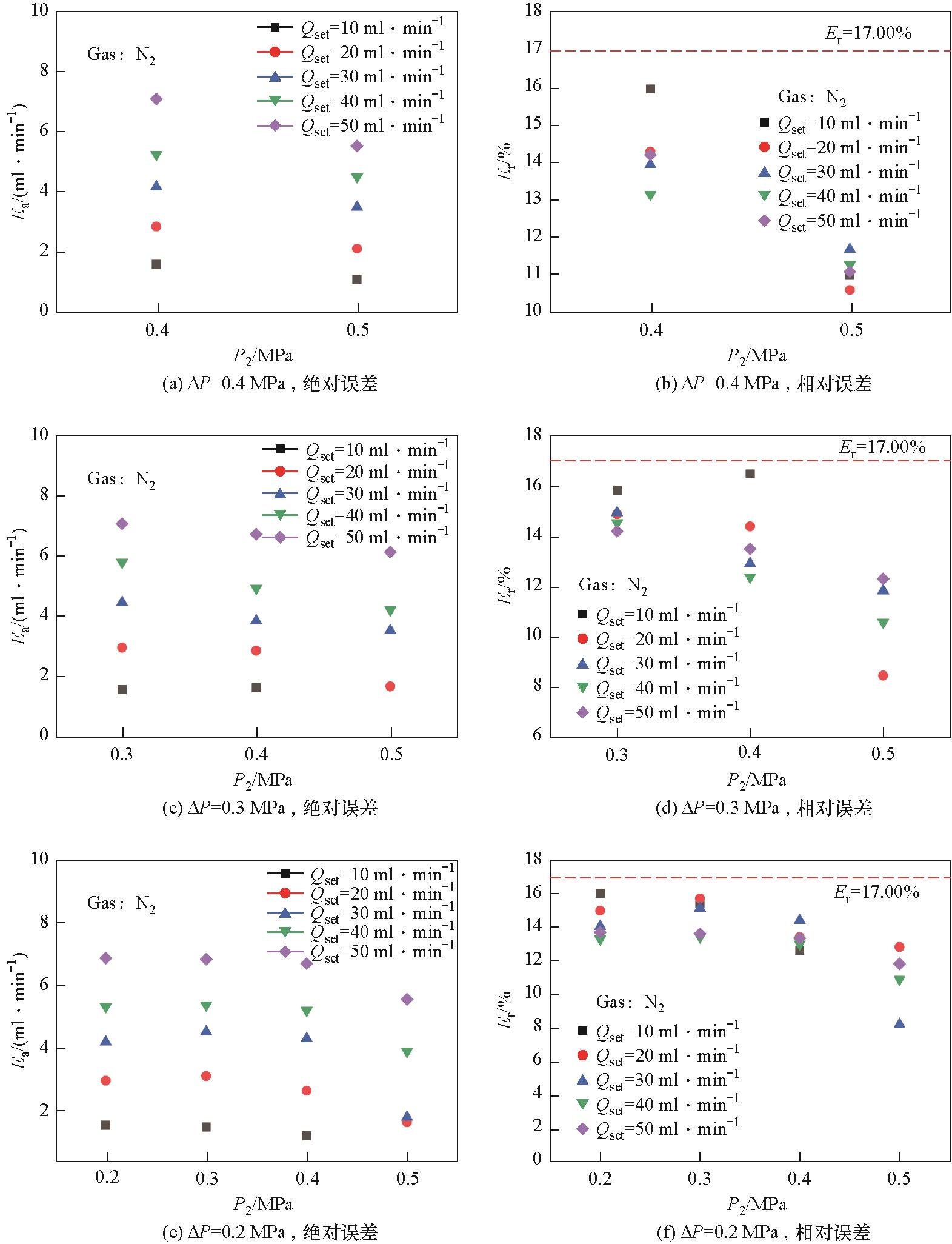

图10 MFC-1支路内绝对误差和相对误差随入口压力的变化规律(虚线代表17.00%)

Fig.10 Variation of absolute deviation and relative deviation with inlet pressure within the MFC-1 branch(the dashed line represents 17.00%)

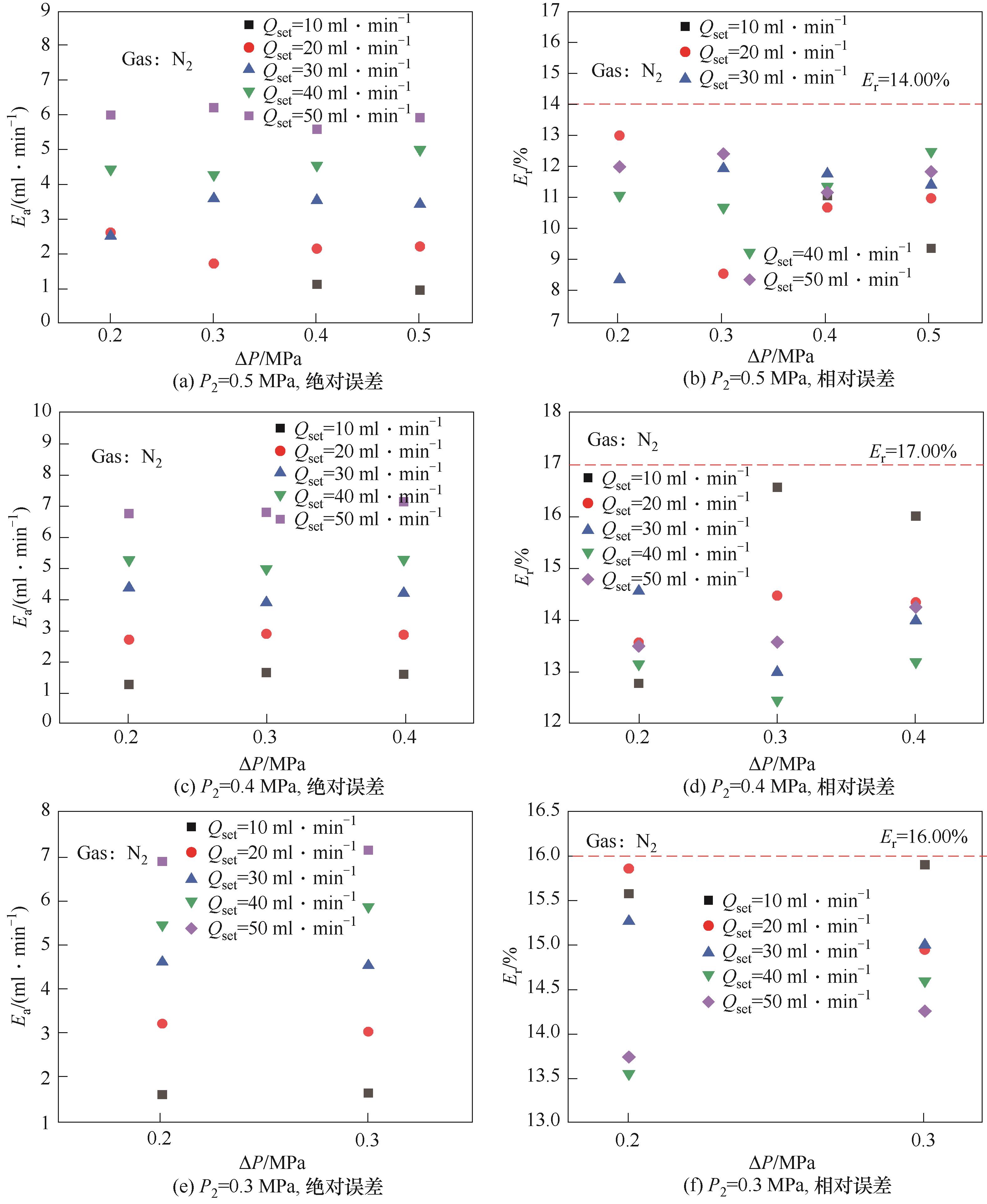

图11 MFC-1支路内绝对误差和相对误差随系统压差的变化规律

Fig.11 Variation of absolute deviation and relative deviation with system differential pressure within the MFC-1 branch

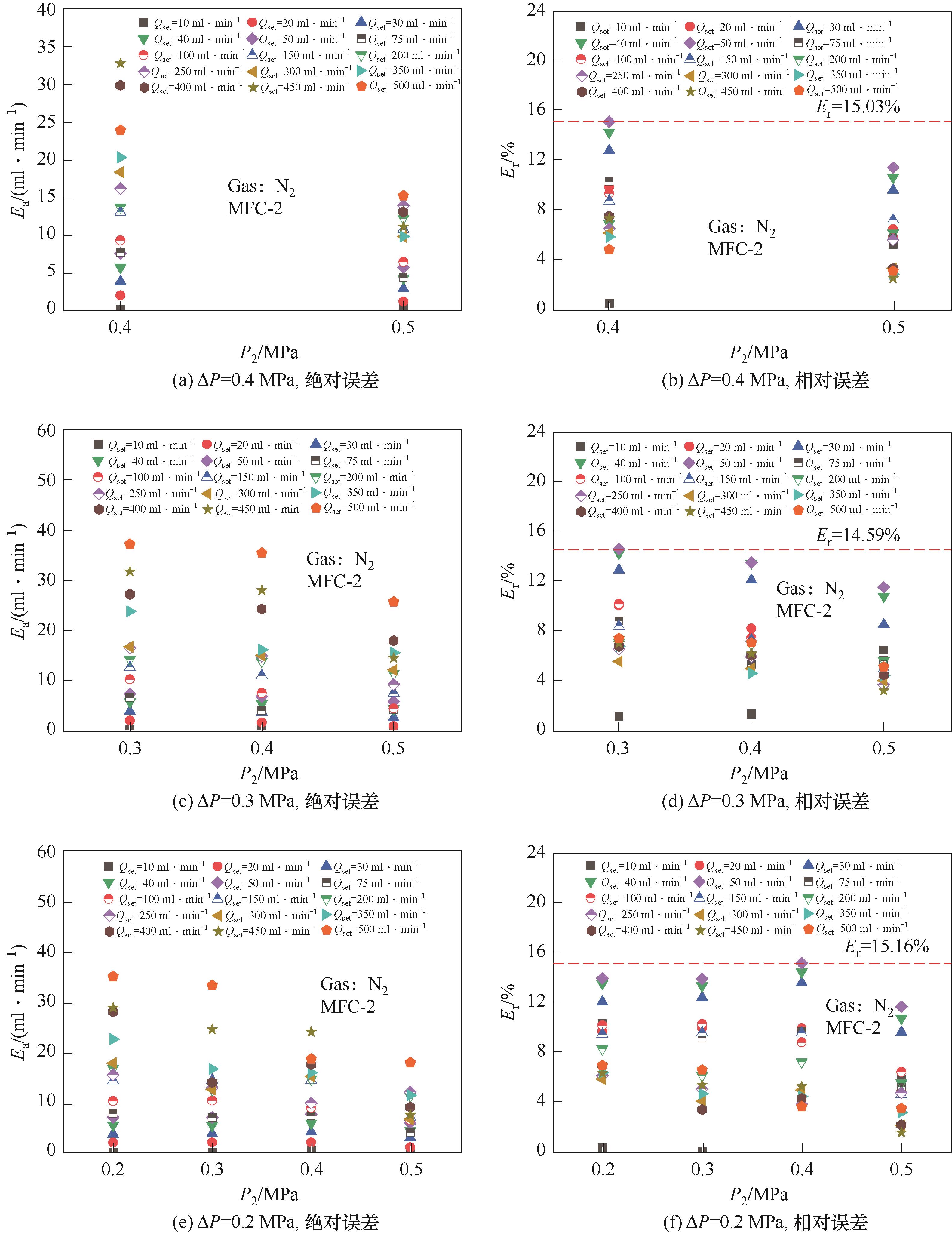

图14 MFC-2支路内绝对误差和相对误差随入口压力的变化规律[(b)、(d)、(f)中虚线分别代表15.03%、14.59%、15.16%]

Fig.14 Variation of absolute deviation and relative deviation with inlet pressure within the MFC-2 branch[the dashed lines in (b),(d),(f) represent 15.03%, 14.59%, and 15.16%, respectively]

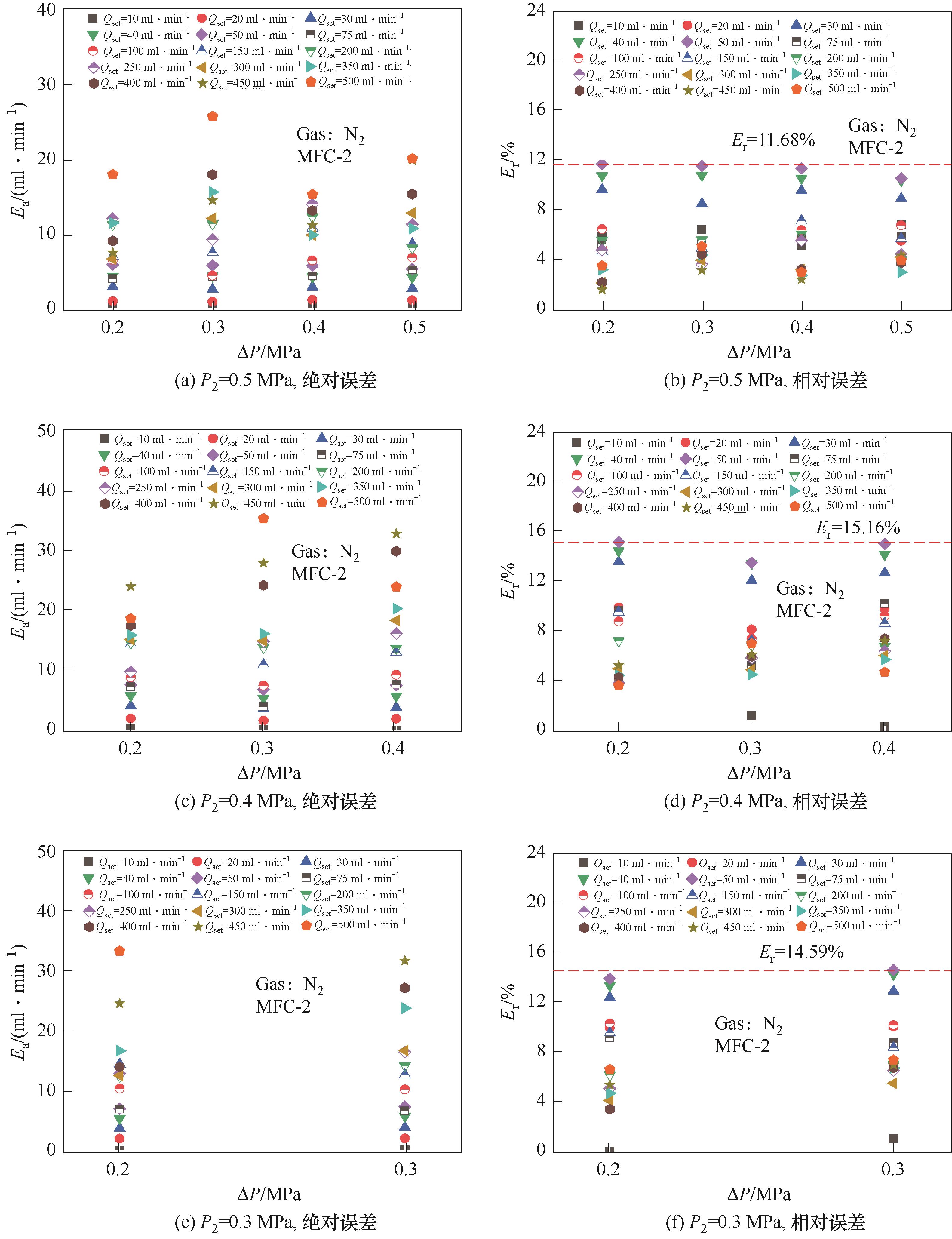

图15 MFC-2支路内绝对误差和相对误差随系统压差的变化规律

Fig.15 Variation of absolute deviation and relative deviation with system differential pressure within the MFC-2 branch

| 1 | Jiang J R, Feng X. Energy optimization of ammonia synthesis processes based on oxygen purity under different purification technologies[J]. Energy, 2019, 185: 819-828. |

| 2 | Eseva E A, Akopyan A V, Anisimov A V, et al. Oxidative desulfurization of hydrocarbon feedstock using oxygen as oxidizing agent (a review)[J]. Petroleum Chemistry, 2020, 60(9): 979-990. |

| 3 | Li S W, Wang W, Zhao J S. Highly effective oxidative desulfurization with magnetic MOF supported W-MoO3 catalyst under oxygen as oxidant[J]. Applied Catalysis B: Environmental, 2020, 277: 119224. |

| 4 | 张自生, 苏倩, 王伟文. 半导体光催化氮气还原合成氨的研究进展[J]. 青岛科技大学学报(自然科学版), 2024, 45(3): 17-30. |

| Zhang Z S, Su Q, Wang W W. Research progress of photocatalytic reduction of nitrogen to ammonia by semiconductors[J]. Journal of Qingdao University of Science and Technology (Natural Science Edition), 2024, 45(3): 17-30. | |

| 5 | Rizwan M, Gilani S R, Durrani A I, et al. Low temperature green extraction of Acer platanoides cellulose using nitrogen protected microwave assisted extraction (NPMAE) technique[J]. Carbohydrate Polymers, 2021, 272: 118465. |

| 6 | Reformatskaya I I, Begishev I R, Ascheulova I I, et al. Nitrogen protection as anticorrosion and fireproofing measure in the use of sour crude oil storage tanks[J]. Chemical and Petroleum Engineering, 2020, 56(7): 563-568. |

| 7 | Tang Z H, Wang Z R, Zhao K. Flame stabilization characteristics of turbulent hydrogen jet flame diluted by nitrogen[J]. Energy, 2023, 283: 129100. |

| 8 | Abhinavam Kailasanathan R K, Book E K, Fang T G, et al. Hydrocarbon species concentrations in nitrogen diluted ethylene-air laminar jet diffusion flames at elevated pressures[J]. Proceedings of the Combustion Institute, 2013, 34(1): 1035-1043. |

| 9 | Taylor C W, Bowden S A. What about nitrogen? Using nitrogen as a carrier gas during the analysis of petroleum biomarkers by gas chromatography mass spectrometry[J]. Journal of Chromatography A, 2023, 1697: 463989. |

| 10 | Fulton A C, Katilie C J, Giordano B C. Nitrogen carrier gas for the separation of trace explosives on CI-GC/MS[J]. Analytical Methods, 2023, 15(32): 4044-4048. |

| 11 | Ansari J A, Ismail M, Farid M. Investigation of nitrogen purging prior to UV treatment on quality of milk[J]. International Journal of Food Engineering, 2021, 17(3): 189-197. |

| 12 | 韩依飏. 二氧化碳的绿色资源化利用实现碳中和的研究进展[J]. 当代化工, 2023, 52(4): 973-976. |

| Han Y Y. Research progress in carbon neutralization by green resource utilization of carbon dioxide[J]. Contemporary Chemical Industry, 2023, 52(4): 973-976. | |

| 13 | 金伟, 李贵弘, 阮虹嘉, 等. 碳中和目标下二氧化碳捕集路径及技术研究进展[J]. 昆明理工大学学报(自然科学版), 2024, 49(3): 265-274. |

| Jin W, Li G H, Ruan H J, et al. Research progress on carbon dioxide capture pathways and technologies under carbon neutrality targets[J]. Journal of Kunming University of Science and Technology (Natural Science), 2024, 49(3): 265-274. | |

| 14 | 赵兴雷, 叶舣, 杨川箬. CO2制备高附加值材料的研究进展[J]. 现代化工, 2023, 43(6): 81-85. |

| Zhao X L, Ye Y, Yang C R. Research progress on CO2 conversion into highly value-added materials[J]. Modern Chemical Industry, 2023, 43(6): 81-85. | |

| 15 | Wang C L, Li F T, Qu H L, et al. Fabrication of three dimensional carbon nanotube foam by direct conversion carbon dioxide and its application in supercapacitor[J]. Electrochimica Acta, 2015, 158: 35-41. |

| 16 | Molina-Jirón C, Chellali M R, Kumar C N S, et al. Direct conversion of CO2 to multi-layer graphene using Cu-Pd alloys[J]. ChemSusChem, 2019, 12(15): 3509-3514. |

| 17 | Li B Y, Wang X F, Hopkinson D, et al. Amino acids react with carbon dioxide (CO2) and form nanofibers and nanoflowers: US10583388[P]. 2020-03-10. |

| 18 | Karimi M, Jodaei A, Khajvandi A, et al. In-situ capture and conversion of atmospheric CO2 into nano-CaCO3 using a novel pathway based on deep eutectic choline chloride-calcium chloride[J]. Journal of Environmental Management, 2018, 206: 516-522. |

| 19 | Bayat M, Lashkarbolooki M, Hezave A Z, et al. Investigation of gas injection flooding performance as enhanced oil recovery method[J]. Journal of Natural Gas Science and Engineering, 2016, 29: 37-45. |

| 20 | Jiang X, Nie X W, Guo X W, et al. Recent advances in carbon dioxide hydrogenation to methanol via heterogeneous catalysis[J]. Chemical Reviews, 2020, 120(15): 7984-8034. |

| 21 | Miralda C M, Macias E E, Zhu M Q, et al. Zeolitic imidazole framework-8 catalysts in the conversion of CO2 to chloropropene carbonate[J]. ACS Catalysis, 2012, 2(1): 180-183. |

| 22 | 刘凯, 陈勇江, 王世刚, 等. 电石灰气体输送系统中氮气的循环利用[J]. 聚氯乙烯, 2022, 50(9): 38-39. |

| Liu K, Chen Y J, Wang S G, et al. Recycling of nitrogen in lime gas conveying system[J]. Polyvinyl Chloride, 2022, 50(9): 38-39. | |

| 23 | 刘凯, 陈勇江, 王世刚, 等. 乙炔发生电石灰气体输送氮气循环利用技术[J]. 中国氯碱, 2020(4): 15-16. |

| Liu K, Chen Y J, Wang S G, et al. Technology of nitrogen recycling in the gas transportation of acetylene producing electric lime[J]. China Chlor-Alkali, 2020(4): 15-16. | |

| 24 | 赵长江. 天然气输送联动联锁安全控制研究应用[J]. 石化技术, 2022, 29(8): 200-202. |

| Zhao C J. Research and application of linkage interlocking safety control for natural gas transportation[J]. Petrochemical Industry Technology, 2022, 29(8): 200-202. | |

| 25 | Arnó J, Weston M H. Improving safety in dopant gas delivery systems[J]. MRS Advances, 2022, 7(36): 1421-1425. |

| 26 | 杨乃恒. 干式真空泵的原理、特征及其应用[J]. 真空, 2000, 37(3): 1-9. |

| Yang N H. Principle characteristics of dry vacuum pump and its applications[J]. Vacuum, 2000, 37(3): 1-9. | |

| 27 | 谢萍, 伍奕, 李长俊, 等. 混氢天然气管道输送技术研究进展[J]. 油气储运, 2021, 40(4): 361-370. |

| Xie P, Wu Y, Li C J, et al. Research progress on pipeline transportation technology of hydrogenmixed natural gas[J]. Oil & Gas Storage and Transportation, 2021, 40(4): 361-370. | |

| 28 | 童元梁, 陈玉乾, 杨涛. 压缩机的现状、发展及新型技术展望[J]. 化工管理, 2017(12): 145. |

| Tong Y L, Chen Y Q, Yang T. Present situation, development and new technology prospect of compressor[J]. Chemical Enterprise Management, 2017(12): 145. | |

| 29 | Kittiampon N, Kaewchada A, Jaree A. Carbon dioxide absorption using ammonia solution in a microchannel[J]. International Journal of Greenhouse Gas Control, 2017, 63: 431-441. |

| 30 | Jiang B, Jiang S K, Zhu C Y, et al. Effects of gas concentration on hydrodynamics of gas absorption in a microchannel[J]. AIChE Journal, 2022, 68(11): e17804. |

| 31 | 盛梅, 林西平, 肖建东, 等. 甲苯气相选择性氧化制苯甲醛: Fe-Mo-O/Al2O3催化剂研究[J]. 石油化工高等学校学报, 1999, 12(2): 6-10. |

| Sheng M, Lin X P, Xiao J D, et al. Catalytic vapor phase oxidation of toluene to benzaldehyde: study of Fe-Mo-O/Al2O3 catalysts[J]. Journal of Petrochemical Universities, 1999, 12(2): 6-10. | |

| 32 | Mi S, Weldetsadik N T, Hayat Z, et al. Effects of the gas feed on bubble formation in a microfluidic T-junction: constant-pressure versus constant-flow-rate injection[J]. Industrial & Engineering Chemistry Research, 2019, 58(23): 10092-10105. |

| 33 | Lignel S, Salsac A V, Drelich A, et al. Water-in-oil droplet formation in a flow-focusing microsystem using pressure- and flow rate-driven pumps[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2017, 531: 164-172. |

| 34 | Ward T, Faivre M, Abkarian M, et al. Microfluidic flow focusing: drop size and scaling in pressure versus flow-rate-driven pumping[J]. Electrophoresis, 2005, 26(19): 3716-3724. |

| 35 | Li D B, Gu Y K, Xue C T, et al. Experimental and numerical research on back pressure characteristics of a new structured back pressure valve[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2024, 46(9): 553. |

| 36 | 刘家旭, 徐英, 张涛, 等. 气体组分变化对热式质量流量计测量精度的影响[J]. 仪器仪表学报, 2020, 41(12): 32-38. |

| Liu J X, Xu Y, Zhang T, et al. Effect of gas composition change on the measurement accuracy of thermal mass flowmeter[J]. Chinese Journal of Scientific Instrument, 2020, 41(12): 32-38. | |

| 37 | Yu X L, Xu K J. Calculation and judgment of repeatability error affected by non-linearity correction based on flowmeter characteristic analysis[J]. Measurement, 2022, 196: 111251. |

| 38 | Popova M A, Ostapenko M S, Tveryakov A M. Application of the coefficient of influence in the calculation of the relative error of gas flow meters[J]. IOP Conference Series: Materials Science and Engineering, 2019, 666(1): 012035. |

| 39 | 黄延禄, 李初阳, 王庆标. 热式气体质量流量计的设计与计算[J]. 自动化与仪表, 2019, 34(5): 67-71. |

| Huang Y L, Li C Y, Wang Q B. Design and computation of a thermal gas mass flowmeter[J]. Automation & Instrumentation, 2019, 34(5): 67-71. | |

| 40 | 徐英, 姚云飞, 张涛, 等. 局部内热源热式传感器等效换热面积的影响[J]. 天津大学学报(自然科学与工程技术版), 2017, 50(5): 483-490. |

| Xu Y, Yao Y F, Zhang T, et al. Effect of equivalent heat exchange area on thermal sensor containing local internal heat source[J]. Journal of Tianjin University (Science and Technology), 2017, 50(5): 483-490. | |

| 41 | 徐静勇, 李斌, 时慧, 等. 基于FLUENT技术的热式质量流量计的仿真及实验的研究[J]. 科技传播, 2012, 4(4): 121-122, 66. |

| Xu J Y, Li B, Shi H, et al. Simulation and experimental study of thermal mass flowmeter based on FLUENT technology[J]. Public Communication of Science & Technology, 2012, 4(4): 121-122, 66. | |

| 42 | 于斌, 秦贞臻, 刘红. 热式质量流量计两种工作原理比较[J]. 中国高新技术企业, 2011(1): 175-176. |

| Yu B, Qin Z Z, Liu H. Comparison of two working principles of thermal mass flowmeter[J]. China High-Tech Enterprises, 2011(1): 175-176. | |

| 43 | Olin J G. Capillary Tube Thermal Mass Flow Meters & Controllers: A User's Guide[M]. Monterey: Sierra Instruments, Inc., 2013. |

| 44 | Rupnik K, Bajsić I, Kutin J. Modelling of a thermal dispersion mass flow meter[J]. Flow Measurement and Instrumentation, 2018, 59: 37-44. |

| [1] | 常斐, 师人博, 刘士花, 高文倩, 王一飞, 郑镔, 焦怡萱, 蓝兴英, 徐春明, 韩晔华. 石化行业产品生命周期碳足迹评价研究现状及展望[J]. 化工学报, 2025, 76(2): 419-437. |

| [2] | 李双喜, 刘安, 刘志远, 张江腾, 李世聪. 高速涡轮泵动静压混合式气体隔离密封扰动性能[J]. 化工学报, 2025, 76(1): 311-323. |

| [3] | 陈引, 赵霄, 杜王芳, 杨竹强, 李凯, 赵建福. 喷雾冷却液膜流动特性测试方案优化及传热规律分析[J]. 化工学报, 2024, 75(8): 2734-2743. |

| [4] | 曾港, 陈林, 杨董, 袁海专, 黄彦平. 矩形通道内超临界CO2局部热流场可视化实验[J]. 化工学报, 2024, 75(8): 2831-2839. |

| [5] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [6] | 吴邦汉, 林定标, 陆海峰, 郭晓镭, 刘海峰. 竖直管气动物流传输系统管道压降和传送瓶输送特性[J]. 化工学报, 2024, 75(7): 2465-2473. |

| [7] | 李沛奇, 陈雪娇, 武博翔, 蒋榕培, 杨超, 刘朝晖. 高参数石油基和煤基火箭煤油射线法密度测量实验研究[J]. 化工学报, 2024, 75(7): 2422-2432. |

| [8] | 马君霞, 李林涛, 熊伟丽. 基于Tri-training GPR的半监督软测量建模方法[J]. 化工学报, 2024, 75(7): 2613-2623. |

| [9] | 卢飞, 鲁波娜, 许光文. 气固微型流化床反应分析仪的理想流型判据分析[J]. 化工学报, 2024, 75(6): 2201-2213. |

| [10] | 黎宏陶, 王振雷, 王昕. 基于即时学习的改进条件高斯回归软测量[J]. 化工学报, 2024, 75(6): 2299-2312. |

| [11] | 张晗, 张淑宁, 刘珂, 邓冠龙. 基于慢特征分析与最小二乘支持向量回归集成的草酸钴合成过程粒度预报[J]. 化工学报, 2024, 75(6): 2313-2321. |

| [12] | 周辛梓, 李增辉, 孟现阳, 吴江涛. 低温下高纯空气黏度实验研究[J]. 化工学报, 2024, 75(3): 782-788. |

| [13] | 弓志超, 李双喜, 李方俊, 黄泽盛, 肖可应. 开启式艉轴唇形密封结构参数多目标优化及性能分析[J]. 化工学报, 2024, 75(12): 4689-4701. |

| [14] | 蒋琳, 张同旺, 刘荣正, 邵友林, 刘兵, 刘马林. 高密度颗粒流化行为测量的磁性颗粒示踪方法[J]. 化工学报, 2024, 75(12): 4453-4467. |

| [15] | 李文华, 叶洪涛, 罗文广, 刘乙奇. 基于MHSA-LSTM的软测量建模及其在化工过程中的应用[J]. 化工学报, 2024, 75(12): 4654-4665. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号