化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2262-2269.DOI: 10.11949/0438-1157.20241172

收稿日期:2024-10-22

修回日期:2024-11-26

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

刘蓓

作者简介:马瑞洁(2000—),女,博士研究生,mrj_0726@163.com

基金资助:

Ruijie MA( ), Zixuan HUANG, Xueqian GUAN, Guangjin CHEN, Bei LIU(

), Zixuan HUANG, Xueqian GUAN, Guangjin CHEN, Bei LIU( )

)

Received:2024-10-22

Revised:2024-11-26

Online:2025-05-25

Published:2025-06-13

Contact:

Bei LIU

摘要:

乙烷是石油化工生产中的重要原料,可用于生产乙烯等化学品。从天然气中分离出乙烷,可以实现资源的有效利用。采用吸收-吸附耦合分离法分离甲烷/乙烷混合气,通过将ZIF-8颗粒分散到N, N-二甲基丙烯基脲(DMPU)中形成悬浮浆液,以制备的浆液作为分离介质。研究结果表明,该浆液对乙烷的吸收容量明显高于甲烷;此外,该浆液的吸着速率快,乙烷在3~5 min即达到吸着平衡。283.15 K、初始气液比52.46左右时,ZIF-8/DMPU浆液体系对C2H6/CH4的分离因子可以达到9.26。在混合气动态穿透实验中,浆液也表现出出色的动力学分离性能。此外,该浆液的再生条件温和,回收的ZIF-8材料结构保持完整,可以实现C2H6/CH4的连续吸收-解吸循环分离。

中图分类号:

马瑞洁, 黄子轩, 关雪倩, 陈光进, 刘蓓. ZIF-8/DMPU浆液分离C2H6/ CH4混合气研究[J]. 化工学报, 2025, 76(5): 2262-2269.

Ruijie MA, Zixuan HUANG, Xueqian GUAN, Guangjin CHEN, Bei LIU. Efficient ethane and methane separation using ZIF-8/DMPU slurry[J]. CIESC Journal, 2025, 76(5): 2262-2269.

图1 实验装置原理图RTD—resistance thermocouple detector; DPT—differential pressure transducer; DAS—data acquisition system

Fig.1 Schematic diagram of the experimental device

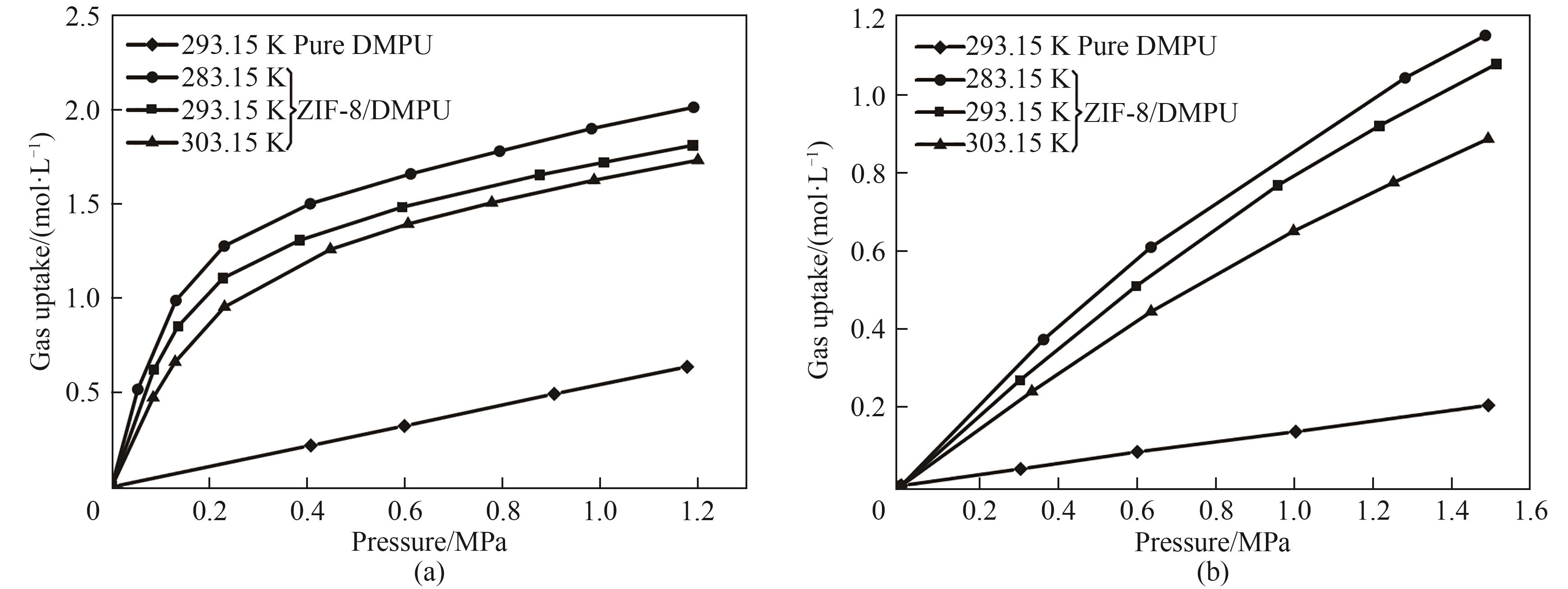

图4 (a) C2H6和(b) CH4在ZIF-8[30%(mass)]/DMPU浆液及纯DMPU溶剂中的吸着等温线

Fig.4 Sorption isotherms of (a) C2H6 and (b) CH4 in ZIF-8[30%(mass)]/DMPU slurry and pure DMPU solvent

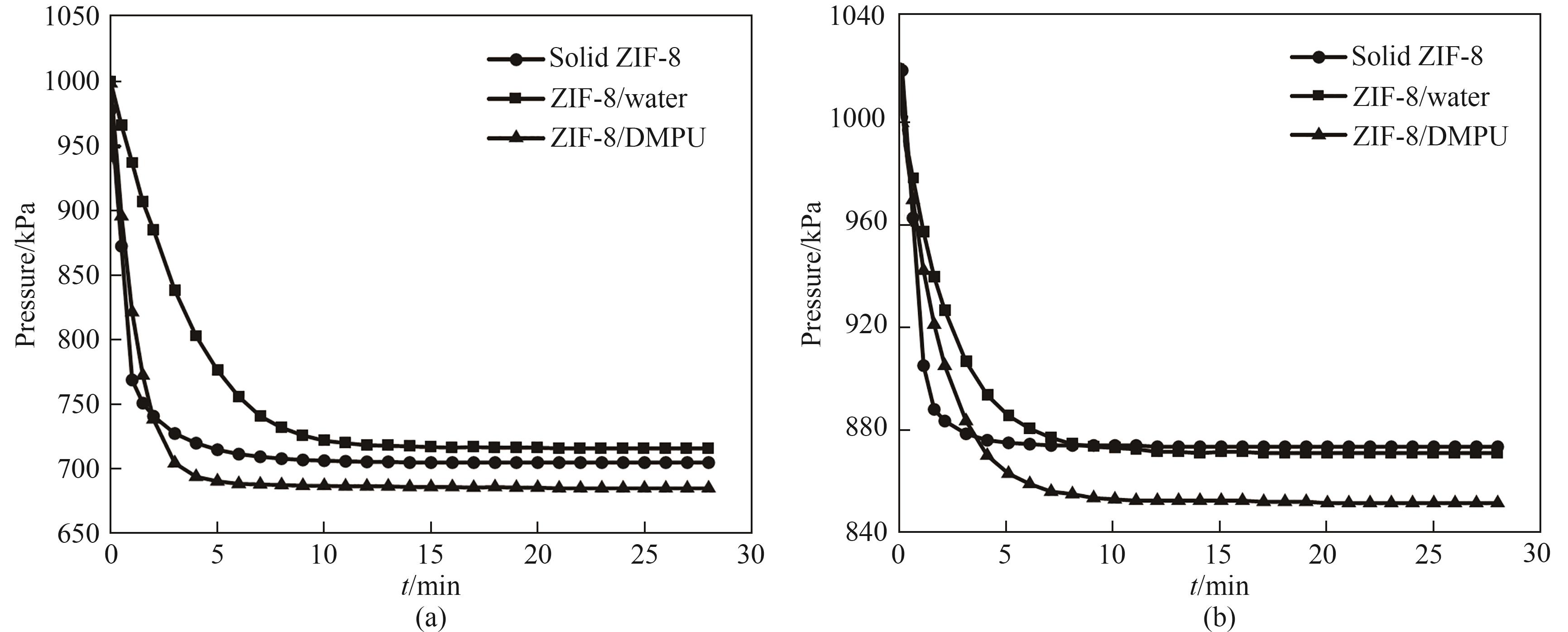

图5 293.15 K、初压约1 MPa的情况下(a) C2H6和(b) CH4在干ZIF-8、ZIF-8/水、ZIF-8/DMPU中的动力学曲线

Fig.5 Kinetic curves of (a) C2H6 and (b) CH4 in ZIF-8 powder, ZIF-8/water, and ZIF-8/DMPU at a temperature of 293.15 K and an initial pressure of ∼1 MPa.

| Gas mixtures | T/K | ϕ | PE/MPa | Sv1/(mol·L-1) | y1/%(mol) | x1/%(mol) | β | Sc1/(mol·L-1·MPa-1) |

|---|---|---|---|---|---|---|---|---|

| C2H6/CH4 | 283.15 | 52.46 | 0.43 | 0.09 | 2.20 | 17.24 | 9.26 | 9.3 |

| 293.15 | 53.50 | 0.47 | 0.09 | 2.45 | 17.49 | 8.44 | 7.4 | |

| 303.15 | 52.92 | 0.50 | 0.08 | 2.83 | 18.39 | 7.75 | 5.4 |

表1 不同温度下ZIF-8/DMPU浆液对C2H6 (1)/CH4 (2) [5.5/94.5(mol)]混合气的分离结果

Table 1 Separation results for C2H6 (1)/CH4 (2) [5.5/94.5(mol)] mixture by ZIF-8/DMPU slurry at various temperatures

| Gas mixtures | T/K | ϕ | PE/MPa | Sv1/(mol·L-1) | y1/%(mol) | x1/%(mol) | β | Sc1/(mol·L-1·MPa-1) |

|---|---|---|---|---|---|---|---|---|

| C2H6/CH4 | 283.15 | 52.46 | 0.43 | 0.09 | 2.20 | 17.24 | 9.26 | 9.3 |

| 293.15 | 53.50 | 0.47 | 0.09 | 2.45 | 17.49 | 8.44 | 7.4 | |

| 303.15 | 52.92 | 0.50 | 0.08 | 2.83 | 18.39 | 7.75 | 5.4 |

| Gas mixtures | ϕ | PE/MPa | Sv1/(mol·L-1) | y1/%(mol) | x1/%(mol) | β | Sc1/(mol·L-1·MPa-1) |

|---|---|---|---|---|---|---|---|

| C2H6/CH4 | 53.5 | 0.47 | 0.09 | 2.45 | 17.49 | 8.44 | 7.4 |

| 80.1 | 0.71 | 0.12 | 2.65 | 18.10 | 8.13 | 6.4 | |

| 111.3 | 1.00 | 0.16 | 2.83 | 18.52 | 7.81 | 5.6 | |

| 142.5 | 1.29 | 0.19 | 2.99 | 18.73 | 7.47 | 5.0 | |

| 217.5 | 1.99 | 0.26 | 3.32 | 19.41 | 7.01 | 3.9 |

表2 293.15 K下不同初始气液体积比下ZIF-8/DMPU浆液对C2H6 (1)/CH4 (2) [5.5/94.5(mol)]混合气的分离结果

Table 2 Separation results for C2H6 (1)/CH4 (2) [5.5/94.5(mol)] mixture by ZIF-8/DMPU slurry at 293.15 K and various initial gas-liquid volume ratios

| Gas mixtures | ϕ | PE/MPa | Sv1/(mol·L-1) | y1/%(mol) | x1/%(mol) | β | Sc1/(mol·L-1·MPa-1) |

|---|---|---|---|---|---|---|---|

| C2H6/CH4 | 53.5 | 0.47 | 0.09 | 2.45 | 17.49 | 8.44 | 7.4 |

| 80.1 | 0.71 | 0.12 | 2.65 | 18.10 | 8.13 | 6.4 | |

| 111.3 | 1.00 | 0.16 | 2.83 | 18.52 | 7.81 | 5.6 | |

| 142.5 | 1.29 | 0.19 | 2.99 | 18.73 | 7.47 | 5.0 | |

| 217.5 | 1.99 | 0.26 | 3.32 | 19.41 | 7.01 | 3.9 |

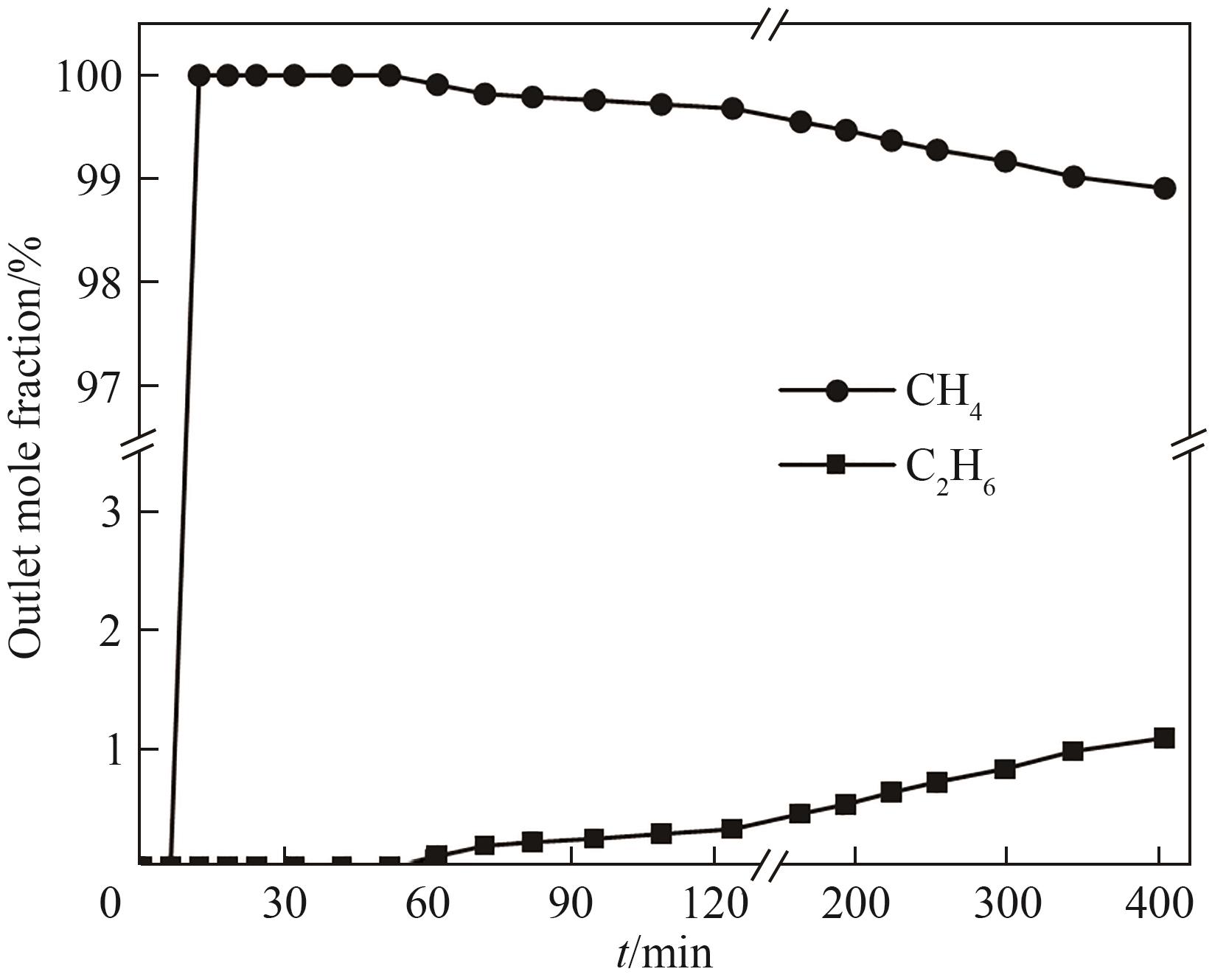

图6 在293.15 K、0.6 MPa、进气流量为49.5 ml/min时,C2H6/CH4[6.1/93.9(mol)]混合气在ZIF-8/DMPU浆液中的穿透曲线

Fig.6 Breakthrough curve for C2H6/CH4[6.1/93.9(mol)] mixture in ZIF-8 /DMPU slurry at 293.15 K, 0.6 MPa and 49.5 ml/min inlet flow rate

| Gas mixtures | Rused times | ϕ | PE/MPa | Sv1/(mol·L-1) | y1/%(mol) | x1/%(mol) | β |

|---|---|---|---|---|---|---|---|

| CH4/C2H6 | 0 | 53.50 | 0.47 | 0.09 | 2.45 | 17.49 | 8.44 |

| 41 | 53.34 | 0.47 | 0.08 | 2.52 | 17.79 | 8.37 | |

| 49 | 52.23 | 0.46 | 0.08 | 2.52 | 17.81 | 8.38 |

表3 293.15 K下再生浆液对C2H6 (1)/CH4 (2) [5.5/94.5 (mol)]混合气的分离结果

Table 3 Separation results for C2H6 (1)/CH4 (2) [5.5/94.5 (mol)] mixture using regenerated slurry at 293.15 K

| Gas mixtures | Rused times | ϕ | PE/MPa | Sv1/(mol·L-1) | y1/%(mol) | x1/%(mol) | β |

|---|---|---|---|---|---|---|---|

| CH4/C2H6 | 0 | 53.50 | 0.47 | 0.09 | 2.45 | 17.49 | 8.44 |

| 41 | 53.34 | 0.47 | 0.08 | 2.52 | 17.79 | 8.37 | |

| 49 | 52.23 | 0.46 | 0.08 | 2.52 | 17.81 | 8.38 |

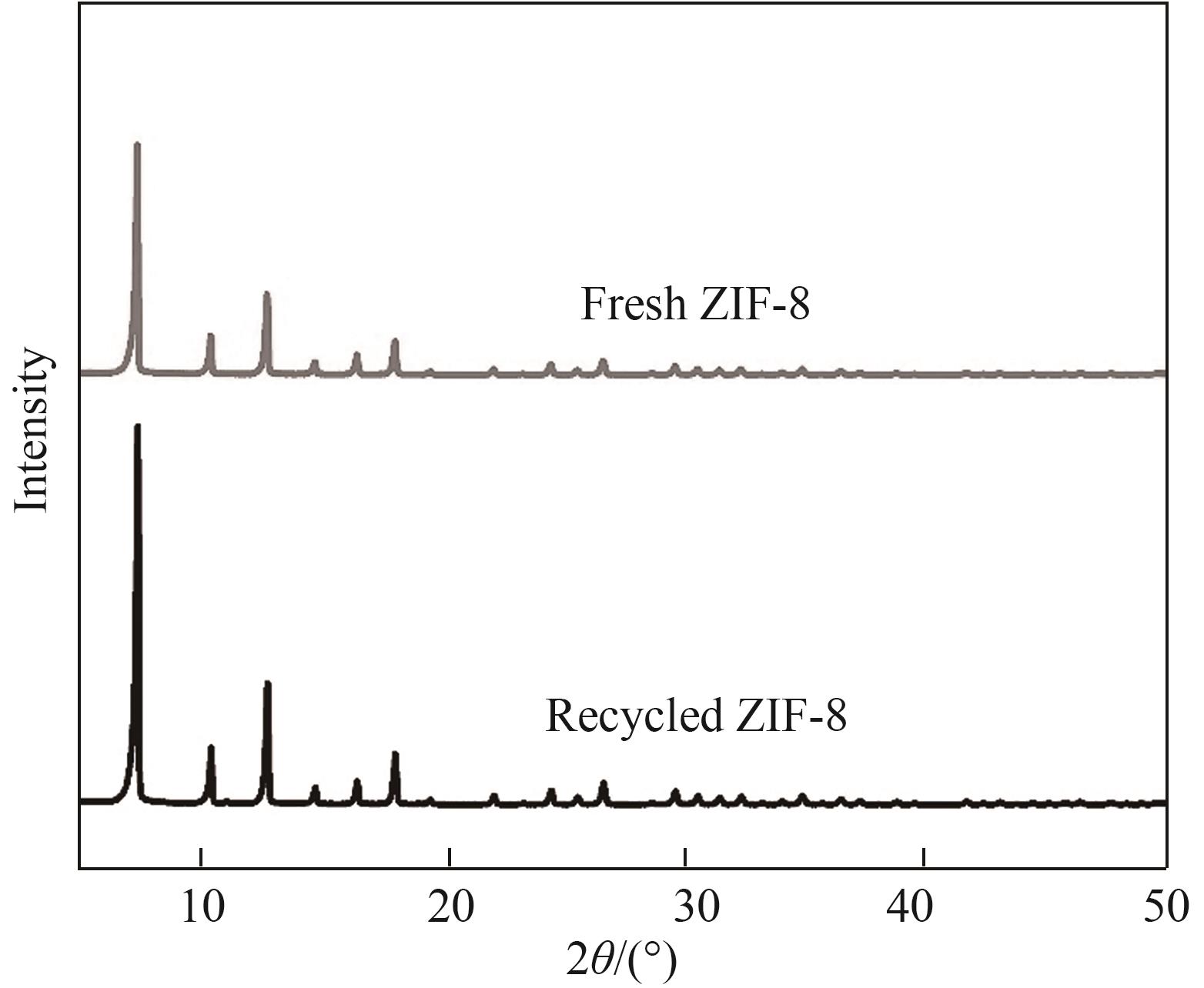

图7 新鲜的ZIF-8和从经过50次吸着-解吸循环实验的ZIF-8/DMPU浆液中回收的ZIF-8的XRD谱图

Fig.7 XRD patterns of fresh ZIF-8 and that recovered from ZIF-8/DMPU slurry after 50 cycle sorption-desorption experiments

| 1 | 李宇静, 梅相银. 对乙烯产能成为全球第一的思考[J]. 中国石油和化工产业观察, 2023(2): 36-39. |

| Li Y J, Mei X Y. Thoughts on ethylene production capacity becoming the first in the world[J]. China Petrochemical Industry Observer, 2023(2): 36-39. | |

| 2 | 冯国莉, 王勇, 庄妍, 等. 乙烯产业链产品价格影响因素及定价机制研究[J]. 炼油与化工, 2023, 34(6): 42-48. |

| Feng G L, Wang Y, Zhuang Y, et al. Study on influencing factors and pricing mechanism of products price in ethylene industry chain[J]. Refining and Chemical Industry, 2023, 34(6): 42-48. | |

| 3 | 王小强, 蔡小霞, 景媛媛, 等. 蒸汽裂解生产乙烯的原料优化选择与配置[J]. 石油与天然气化工, 2024, 53(1): 47-53. |

| Wang X Q, Cai X X, Jing Y Y, et al. Optimal selection and configuration of feedstock for ethylene by steam cracking[J]. Chemical Engineering of Oil & Gas, 2024, 53(1): 47-53. | |

| 4 | 赵百仁, 王振维, 盛在行. 乙烷逐步替代石脑油对乙烯装置的影响[J]. 乙烯工业, 2020, 32(3): 1-6, 73. |

| Zhao B R, Wang Z W, Sheng Z H. Influence of gradual replacement of naphtha with ethane on ethylene plant[J]. Ethylene Industry, 2020, 32(3): 1-6, 73. | |

| 5 | 李少林, 王磊, 贺江, 等. 美国天然气凝析液行业现状与展望[J]. 国际石油经济, 2015, 23(3): 30-40, 110. |

| Li S L, Wang L, He J, et al. Status and prospects of the natural gas liquids industry in the U.S.[J]. International Petroleum Economics, 2015, 23(3): 30-40, 110. | |

| 6 | 胡晓蓉. 天然气乙烷深冷回收工艺研究进展[J]. 中国矿业, 2022, 31(S1): 221-226. |

| Hu X R. Research progress of cryogenic natural gas recovery process[J]. China Mining Magazine, 2022, 31(S1): 221-226. | |

| 7 | Ghorbani B, Shirmohammadi R, Mehrpooya M. A novel energy efficient LNG/NGL recovery process using absorption and mixed refrigerant refrigeration cycles–Economic and exergy analyses[J]. Applied Thermal Engineering, 2018, 132: 283-295. |

| 8 | Yang M B, You F Q. Comparative techno-economic and environmental analysis of ethylene and propylene manufacturing from wet shale gas and naphtha[J]. Industrial & Engineering Chemistry Research, 2017, 56(14): 4038-4051. |

| 9 | Jokar S, Javanmardi J, Nasrifar K. Use of gas hydrate with propanone as the promoter for separation of gas mixtures methane + ethane[J]. Journal of Chemical & Engineering Data, 2019, 64(7): 3058-3067. |

| 10 | Naeiji P, Mottahedin M, Varaminian F. Separation of methane-ethane gas mixtures via gas hydrate formation[J]. Separation and Purification Technology, 2014, 123: 139-144. |

| 11 | Soltanimehr S, Javanmardi J, Nasrifar K. Liquid water-hydrate-vapor equilibrium for methane + ethane gas mixtures: application of gas hydrates for separation[J]. Journal of Chemical & Engineering Data, 2017, 62(7): 2143-2148. |

| 12 | Siddiqi K S, Thomas W J. The adsorption of methane-ethane mixtures on activated carbon[J]. Carbon, 1982, 20(6): 473-479. |

| 13 | Avila A M, Yang F, Shi M, et al. Extraction of ethane from natural gas at high pressure by adsorption on Na-ETS-10[J]. Chemical Engineering Science, 2011, 66(13): 2991-2996. |

| 14 | Yang Y X, Burke N, Ali S, et al. Experimental studies of hydrocarbon separation on zeolites, activated carbons and MOFs for applications in natural gas processing[J]. RSC Advances, 2017, 7(21): 12629-12638. |

| 15 | Hosseinpour S, Fatemi S, Mortazavi Y, et al. Performance of CaX zeolite for separation of C2H6, C2H4, and CH4 by adsorption process; capacity, selectivity, and dynamic adsorption measurements[J]. Separation Science and Technology, 2010, 46(2): 349-355. |

| 16 | Estupiñan Perez L, Avila A M, Sawada J A, et al. Process optimization-based adsorbent selection for ethane recovery from residue gas[J]. Separation and Purification Technology, 2016, 168: 19-31. |

| 17 | Lai Y J, Ji J Y, Wang H F, et al. Enhanced selectivity of alkane mixture gas on the N-oxide group decorated metal-organic framework[J]. Microporous and Mesoporous Materials, 2023, 359: 112670. |

| 18 | Altintas C, Keskin S. Molecular simulations of MOF membranes for separation of ethane/ethene and ethane/methane mixtures[J]. RSC Advances, 2017, 7(82): 52283-52295. |

| 19 | He Y B, Krishna R, Chen B L. Metal-organic frameworks with potential for energy-efficient adsorptive separation of light hydrocarbons[J]. Energy & Environmental Science, 2012, 5(10): 9107-9120. |

| 20 | Taheri M, Enge T G, Tsuzuki T. Water stability of cobalt doped ZIF-8: a quantitative study using optical analyses[J]. Materials Today Chemistry, 2020, 16: 100231. |

| 21 | Pan Y C, Liu Y Y, Zeng G F, et al. Rapid synthesis of zeolitic imidazolate framework-8 (ZIF-8) nanocrystals in an aqueous system[J]. Chemical Communications, 2011, 47(7): 2071-2073. |

| 22 | Li H, Chen W, Liu B, et al. A purely green approach to low-cost mass production of zeolitic imidazolate frameworks[J]. Green Energy & Environment, 2023, 8(3): 775-784. |

| 23 | 潘勇, 陈驰, 徐保明, 等. ZIF-8/乙二醇浆液连续捕集二氧化碳[J]. 化工进展, 2021, 40(10): 5812-5817. |

| Pan Y, Chen C, Xu B M, et al. Continuous capture of carbon dioxide by ZIF-8/ethylene glycol slurry[J]. Chemical Industry and Engineering Progress, 2021, 40(10): 5812-5817. | |

| 24 | Men'shchikov I E, Grekov D I, Pré P, et al. Influence of nanoporous carbon structures on high-pressure adsorption separation of light hydrocarbons[J]. Energy & Fuels, 2023, 37(10): 7539-7554. |

| 25 | Liu H, Liu B, Lin L C, et al. A hybrid absorption-adsorption method to efficiently capture carbon[J]. Nature Communications, 2014, 5: 5147. |

| 26 | Chen W, Zou E B, Zuo J Y, et al. Separation of ethane from natural gas using porous ZIF-8/water-glycol slurry[J]. Industrial & Engineering Chemistry Research, 2019, 58(23): 9997-10006. |

| 27 | 张瑞航, 曹潘, 杨锋, 等. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| Zhang R H, Cao P, Yang F, et al. Analysis of key parameters affecting product purity of natural gas ethane recovery process via ZIF-8 nanofluid[J]. CIESC Journal, 2023, 74(8): 3386-3393. | |

| 28 | Liu H, Yao D S, Li H S, et al. The experimental and theory research on the sorption kinetic of CH4 and C2H4 in ZIF-8/water-glycol slurry[J]. Microporous and Mesoporous Materials, 2022, 329: 111559. |

| 29 | 童雄师, 潘勇, 王慕宇, 等. 2-甲基咪唑/乙二醇体系常温脱除天然气中的二氧化碳[J]. 化工学报, 2016, 67(10): 4240-4245. |

| Tong X S, Pan Y, Wang M Y, et al. Removal of CO2 from natural gas by 2-methylimidazole/ethylene glycol system at room temperature[J]. CIESC Journal, 2016, 67(10): 4240-4245. | |

| 30 | Yang M K, Wang H S, Zuo J Y, et al. Efficient separation of butane isomers via ZIF-8 slurry on laboratory- and pilot-scale[J]. Nature Communications, 2022, 13(1): 4792. |

| [1] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| [2] | 唐磊, 王振菲, 李聪利, 杨佳辉, 郑浩, 石琪, 董晋湘. Co-MOF-74和Mg-MOF-74的CO工作吸附容量及操作条件[J]. 化工学报, 2025, 76(5): 2279-2293. |

| [3] | 花敬贤, 罗宇荣, 顾亚伟, 吴婷婷, 潘宜昌, 邢卫红. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| [4] | 李艳, 雷美丽, 李鑫钢. 基于分离性能的顺序式模拟移动床结构调控策略[J]. 化工学报, 2025, 76(5): 2219-2229. |

| [5] | 巴雅琪, 吴涛, 邸安頔, 陆安慧. 多孔炭材料用于低碳烃分离的研究进展[J]. 化工学报, 2025, 76(5): 2136-2157. |

| [6] | 谈朋, 李雪梅, 刘晓勤, 孙林兵. 基于柔性MOFs的磁响应复合材料及其丙烯吸附性能研究[J]. 化工学报, 2025, 76(5): 2230-2240. |

| [7] | 胡嘉朗, 姜明源, 金律铭, 张永刚, 胡鹏, 纪红兵. 机器学习辅助MOFs高通量计算筛选及气体分离研究进展[J]. 化工学报, 2025, 76(5): 1973-1996. |

| [8] | 齐昊, 王玉杰, 李申辉, 邹琦, 刘轶群, 赵之平. 双金属Co/Zn-ZIFs中C3H6和C3H8吸附和扩散行为分子模拟研究[J]. 化工学报, 2025, 76(5): 2313-2326. |

| [9] | 陶春珲, 李印辉, 傅钰, 段然, 赵泽一, 唐羽丰, 张罡, 马和平. 不同吸附剂对低浓度Kr气的选择性吸附与纯化[J]. 化工学报, 2025, 76(5): 2358-2366. |

| [10] | 陈建兵, 常昊, 高明, 邢兵, 张磊, 刘奇磊. 基于反应模板与分子动力学的胺基相变吸收剂分相预测方法[J]. 化工学报, 2025, 76(5): 2387-2396. |

| [11] | 张越, 刘佳鑫, 马敬, 刘毅. 金属有机骨架膜应用于海水提铀研究进展[J]. 化工学报, 2025, 76(5): 2087-2100. |

| [12] | 徐智超, 俞镇东, 吴昊峰, 吴沛文, 武洪翔, 巢艳红, 朱文帅, 刘植昌, 徐春明. 富酸位13X分子筛的制备及其超深度吸附脱除生物柴油中硫醇[J]. 化工学报, 2025, 76(5): 2198-2208. |

| [13] | 蔡天姿, 张海丰, 林海丹, 张子龙, 周鹏宇, 王柏林, 李小年. 硼掺杂氮基石墨烯检测变压器油中溶解气体CO和CO2的密度泛函理论研究[J]. 化工学报, 2025, 76(4): 1841-1851. |

| [14] | 赵俊德, 周爱国, 陈彦霖, 郑家乐, 葛天舒. 吸附法CO2直接空气捕集技术能耗现状[J]. 化工学报, 2025, 76(4): 1375-1390. |

| [15] | 张玮杰, 何甲文, 张一鸣, 李德立, 胡光亚, 蔡骁, 王金华, 黄佐华. 燃料分层对多级旋流甲烷燃烧流场和火焰结构影响研究[J]. 化工学报, 2025, 76(4): 1754-1764. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号