化工学报 ›› 2024, Vol. 75 ›› Issue (5): 1987-2000.DOI: 10.11949/0438-1157.20231297

刘礼豪1( ), 黄婷2, 雍宇3, 罗昕浩1, 赵泽明1, 宋尚飞1(

), 黄婷2, 雍宇3, 罗昕浩1, 赵泽明1, 宋尚飞1( ), 史博会1, 陈光进1, 宫敬1

), 史博会1, 陈光进1, 宫敬1

收稿日期:2023-12-05

修回日期:2024-03-28

出版日期:2024-05-25

发布日期:2024-06-25

通讯作者:

宋尚飞

作者简介:刘礼豪(1997—),男,博士研究生, liuliao72@163.com

基金资助:

Lihao LIU1( ), Ting HUANG2, Yu YONG3, Xinhao LUO1, Zeming ZHAO1, Shangfei SONG1(

), Ting HUANG2, Yu YONG3, Xinhao LUO1, Zeming ZHAO1, Shangfei SONG1( ), Bohui SHI1, Guangjin CHEN1, Jing GONG1

), Bohui SHI1, Guangjin CHEN1, Jing GONG1

Received:2023-12-05

Revised:2024-03-28

Online:2024-05-25

Published:2024-06-25

Contact:

Shangfei SONG

摘要:

管道中水合物再生与粉砂沉积堵塞是影响可燃冰开采的关键问题,而且管道中海水具有一定矿化度。利用高压环路开展了水-粉砂-NaCl-CH4体系水合物生成与水合物-粉砂沉积实验,揭示水合物生成到稳定固相沉积的四阶段演变过程。研究发现,在含有粉砂的盐水体系中甲烷水合物的诱导期相较于纯水体系可显著延长2~3倍,特别是在低含砂浓度(质量分数0.1%)和高流量(1600 kg/h)条件下,诱导期延长至3.3倍。分析认为NaCl和粉砂对水分子簇结构的扰乱是抑制水合物成核的关键机理,此外NaCl通过压缩颗粒双电层厚度削弱砂粒亲水性,通过纳米气泡桥接促使固相颗粒聚集并黏附于管壁,加速水合物-砂沉积层的形成。研究成果有助于保障可燃冰开发排采系统中多相流动的安全与稳定。

中图分类号:

刘礼豪, 黄婷, 雍宇, 罗昕浩, 赵泽明, 宋尚飞, 史博会, 陈光进, 宫敬. 含粉砂盐水体系甲烷水合物生成与固相沉积规律[J]. 化工学报, 2024, 75(5): 1987-2000.

Lihao LIU, Ting HUANG, Yu YONG, Xinhao LUO, Zeming ZHAO, Shangfei SONG, Bohui SHI, Guangjin CHEN, Jing GONG. CH4-hydrate formation and solid-phase deposition in salt-sand coexisting flow systems[J]. CIESC Journal, 2024, 75(5): 1987-2000.

| 实验编号 | 流量/(kg/h) | 粉砂浓度/%(质量分数) | 盐浓度/% (质量分数) | 压力/MPa |

|---|---|---|---|---|

| SY 1 | 1160 | 0 | 0 | 5.15 |

| SY 2 | 1160 | 0.1 | 3 | 5.15 |

| SY 3 | 1160 | 0.5 | 3 | 5.15 |

| SY 4 | 1160 | 1.5 | 3 | 5.15 |

| SY 5 | 1160 | 0.1 | 3 | 6.45 |

| SY 6 | 1160 | 0.5 | 3 | 6.45 |

| SY 7 | 1160 | 1.5 | 3 | 6.45 |

| SY 8 | 1600 | 0 | 0 | 5.15 |

| SY 9 | 1600 | 0.1 | 0 | 5.15 |

| SY 10 | 1600 | 0 | 3 | 5.15 |

| SY 11 | 1600 | 0.1 | 3 | 5.15 |

| SY 12 | 1600 | 0.5 | 3 | 5.15 |

| SY 13 | 1600 | 1.5 | 3 | 5.15 |

表1 实验条件汇总

Table 1 Summary of experimental conditions

| 实验编号 | 流量/(kg/h) | 粉砂浓度/%(质量分数) | 盐浓度/% (质量分数) | 压力/MPa |

|---|---|---|---|---|

| SY 1 | 1160 | 0 | 0 | 5.15 |

| SY 2 | 1160 | 0.1 | 3 | 5.15 |

| SY 3 | 1160 | 0.5 | 3 | 5.15 |

| SY 4 | 1160 | 1.5 | 3 | 5.15 |

| SY 5 | 1160 | 0.1 | 3 | 6.45 |

| SY 6 | 1160 | 0.5 | 3 | 6.45 |

| SY 7 | 1160 | 1.5 | 3 | 6.45 |

| SY 8 | 1600 | 0 | 0 | 5.15 |

| SY 9 | 1600 | 0.1 | 0 | 5.15 |

| SY 10 | 1600 | 0 | 3 | 5.15 |

| SY 11 | 1600 | 0.1 | 3 | 5.15 |

| SY 12 | 1600 | 0.5 | 3 | 5.15 |

| SY 13 | 1600 | 1.5 | 3 | 5.15 |

| 实验编号 | 体系 | 诱导期/min |

|---|---|---|

| SY8-1 | 纯水 | 10.8 |

| SY8-2 | 17.4 | |

| SY8-3 | 18.6 | |

| 平均诱导期 | 15.4±3.2 | |

| SY9-1 | 0.1%(质量分数)粉砂 | 21.00 |

| SY9-2 | 21.60 | |

| SY9-3 | 22.80 | |

| 平均诱导期 | 21.8±0.67 | |

| SY10-1 | 3%(质量分数) NaCl | 31.8 |

| SY10-2 | 19.8 | |

| SY10-3 | 25.2 | |

| 平均诱导期 | 25.6±4.13 | |

| SY11-1 | 3%(质量分数)NaCl+ 0.1%(质量分数)粉砂 | 67.2 |

| SY11-2 | 39 | |

| SY11-3 | 46.8 | |

| 平均诱导期 | 51±10.8 |

表2 相同初始压力与流量下不同体系水合物诱导期结果

Table 2 Hydrate induction time in different systems under the same flow conditions

| 实验编号 | 体系 | 诱导期/min |

|---|---|---|

| SY8-1 | 纯水 | 10.8 |

| SY8-2 | 17.4 | |

| SY8-3 | 18.6 | |

| 平均诱导期 | 15.4±3.2 | |

| SY9-1 | 0.1%(质量分数)粉砂 | 21.00 |

| SY9-2 | 21.60 | |

| SY9-3 | 22.80 | |

| 平均诱导期 | 21.8±0.67 | |

| SY10-1 | 3%(质量分数) NaCl | 31.8 |

| SY10-2 | 19.8 | |

| SY10-3 | 25.2 | |

| 平均诱导期 | 25.6±4.13 | |

| SY11-1 | 3%(质量分数)NaCl+ 0.1%(质量分数)粉砂 | 67.2 |

| SY11-2 | 39 | |

| SY11-3 | 46.8 | |

| 平均诱导期 | 51±10.8 |

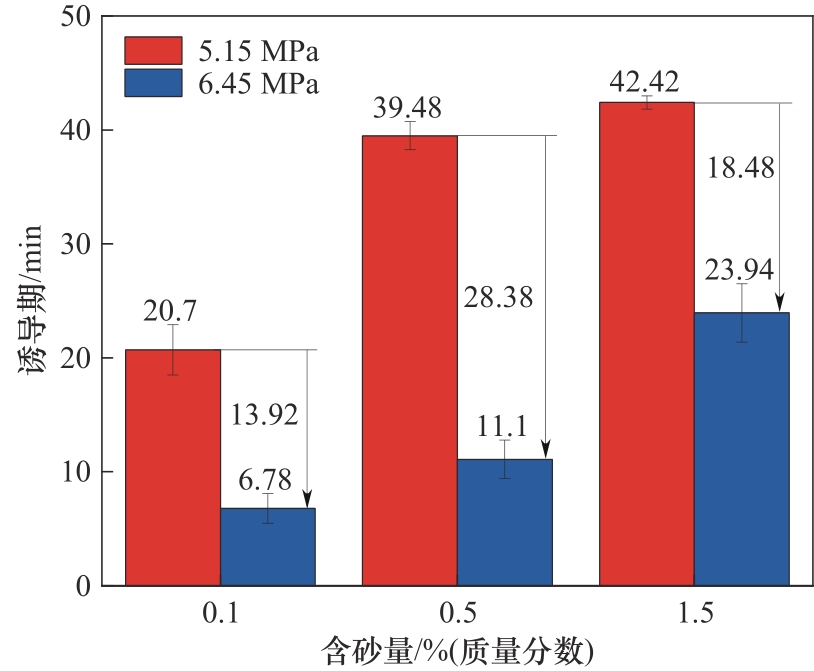

图11 低流量条件下含粉砂浓度对于水合物诱导期的影响(1160 kg/h,实验SY2~SY7)

Fig.11 Effect of sand concentration on hydrate induction time under low flow conditions (1160 kg/h, SY2—SY7)

| 1 | Sloan E D, Koh C A. Clathrate Hydrates of Natural Gases[M]. 3rd ed. Boca Raton, FL: CRC Press, 2007. |

| 2 | Makogon Y F. Natural gas hydrates-a promising source of energy[J]. Journal of Natural Gas Science and Engineering, 2010, 2(1): 49-59. |

| 3 | 高大统. 可燃冰的工业化开采前景[J]. 油气储运, 2017, 36(10): 1223-1226. |

| Gao D T. Industrialized exploitation prospect of combustible ice[J]. Oil & Gas Storage and Transportation, 2017, 36(10): 1223-1226. | |

| 4 | 周守为, 李清平, 吕鑫, 等. 天然气水合物开发研究方向的思考与建议[J]. 中国海上油气, 2019, 31(4): 1-8. |

| Zhou S W, Li Q P, Lyu X, et al. Thinking and suggestions on research direction of natural gas hydrate development[J]. China Offshore Oil and Gas, 2019, 31(4): 1-8. | |

| 5 | 李淑霞, 于笑, 李爽, 等. 神狐水合物藏降压开采产气量预测及增产措施研究[J]. 中国海上油气, 2020, 32(6): 122-127. |

| Li S X, Yu X, Li S, et al. Prediction of gas production of Shenhu hydrate reservoir by depressurization and its stimulation treatment[J]. China Offshore Oil and Gas, 2020, 32(6): 122-127. | |

| 6 | 韩笑, 刘姝, 万青翠, 等. 热激法开采天然气水合物研究进展[J]. 油气储运, 2019, 38(8): 849-855. |

| Han X, Liu S, Wan Q C, et al. Research progress on the exploitation of natural gas hydrate by thermal stimulation method[J]. Oil & Gas Storage and Transportation, 2019, 38(8): 849-855. | |

| 7 | Zhang L, Zou H, Han B, et al. Hydrate formation and deposition behaviors with kinetic inhibitors under pseudo multiphase flow[J]. Fuel, 2024, 360: 130612. |

| 8 | Wang J G, Meng Y, Han B Y, et al. Hydrate blockage in subsea oil/gas flowlines: prediction, prevention, and remediation[J]. Chemical Engineering Journal, 2023, 461: 142020. |

| 9 | Wang J G, Zhang Q, Jin R, et al. Identification and prediction of hydrate–slug flow to improve safety and efficiency of deepwater hydrocarbon transportation[J]. Journal of Cleaner Production, 2023, 430: 139632. |

| 10 | Kurihara M. Mallik 2002 gas hydrate production research well program: numerical simulation studies for analyzing the mechanism of gas production from methane hydrate reservoirs[J]. Journal of the Japan Institute of Energy, 2005, 84:112-118. |

| 11 | Fujii T, Noguchi S, Takayama T, et al. Site selection and formation evaluation at the 1st offshore methane hydrate production test site in the eastern Nankai trough, Japan[C]//75th EAGE Conference and Exhibition Incorporating SPE EUROPEC 2013. London, UK, 2013. |

| 12 | 周守为, 陈伟, 李清平, 等. 深水浅层非成岩天然气水合物固态流化试采技术研究及进展[J]. 中国海上油气, 2017, 29(4): 1-8. |

| Zhou S W, Chen W, Li Q P, et al. Research on the solid fluidization well testing and production for shallow non-diagenetic natural gas hydrate in deep water area[J]. China Offshore Oil and Gas, 2017, 29(4): 1-8. | |

| 13 | 叶建良, 秦绪文, 谢文卫, 等. 中国南海天然气水合物第二次试采主要进展[J]. 中国地质, 2020, 47(3): 557-568. |

| Ye J L, Qin X W, Xie W W, et al. Main progress of the second gas hydrate trial production in the South China Sea[J]. Geology in China, 2020, 47(3): 557-568. | |

| 14 | 刘翔, 王武昌, 张佳璐, 等. 管道内天然气水合物沉积演化进程数值模拟[J]. 油气储运, 2022, 41(2): 211-218. |

| Liu X, Wang W C, Zhang J L, et al. Numerical simulation on deposition evolution of natural gas hydrate in pipeline[J]. Oil & Gas Storage and Transportation, 2022, 41(2): 211-218. | |

| 15 | 李文庆, 王君傲, 段旭, 等. 基于CFD-DEM耦合方法的水合物堵塞模拟[J]. 油气储运, 2020, 39(12): 1379-1385. |

| Li W Q, Wang J A, Duan X, et al. Hydrate blockage simulation based on CFD-DEM coupling method[J]. Oil & Gas Storage and Transportation, 2020, 39(12): 1379-1385. | |

| 16 | Arjmandi M, Tohidi B, Danesh A, et al. Is subcooling the right driving force for testing low-dosage hydrate inhibitors?[J]. Chemical Engineering Science, 2005, 60(5): 1313-1321. |

| 17 | Li K, Fan S S. Effect of magnetization of water on induction time and growth period of natural gas hydrate[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(s1):81-85. |

| 18 | Jiang H, Jordan K D. Comparison of the properties of xenon, methane, and carbon dioxide hydrates from equilibrium and nonequilibrium molecular dynamics simulations[J]. Journal of Physical Chemistry C, 2010, 114(12): 5555-5564. |

| 19 | Linga P, Daraboina N, Ripmeester J A, et al. Enhanced rate of gas hydrate formation in a fixed bed column filled with sand compared to a stirred vessel[J]. Chemical Engineering Science, 2012, 68(1): 617-623. |

| 20 | Zhang C S, Fan S S, Liang D Q, et al. Effect of additives on formation of natural gas hydrate[J]. Fuel, 2004, 83(16): 2115-2121. |

| 21 | 孙始财, 业渝光, 刘昌岭, 等. 甲烷水合物在石英砂中生成过程研究[J]. 石油与天然气化工, 2011, 40(2): 123-127, 98. |

| Sun S C, Ye Y G, Liu C L, et al. Research of methane hydrate formation process in quartz sand[J]. Chemical Engineering of Oil & Gas, 2011, 40(2): 123-127, 98. | |

| 22 | Gao Q, Zhao J Z, Yin Z Y, et al. Experimental study on methane hydrate formation in quartz sand under tri-axial condition[J]. Journal of Natural Gas Science and Engineering, 2021, 85: 103707. |

| 23 | Englezos P, Hall S. Phase equilibrium data on carbon dioxide hydrate in the presence of electrolytes, water soluble polymers and montmorillonite[J]. Canadian Journal of Chemical Engineering, 1994, 72(5): 887-893. |

| 24 | Turner D J, Cherry R S, Sloan E D. Sensitivity of methane hydrate phase equilibria to sediment pore size[J]. Fluid Phase Equilibria, 2005, 228/229: 505-510. |

| 25 | Park S S, An E J, Lee S B, et al. Characteristics of methane hydrate formation in carbon nanofluids[J]. Journal of Industrial and Engineering Chemistry, 2012, 18(1): 443-448. |

| 26 | Zhang L, Xu S D, Li X, et al. Reaction kinetic characteristics and model of methane hydrate formation in porous media[J]. Energy & Fuels, 2017, 31(8): 8548-8559. |

| 27 | Zeng H, Zhang Y, Zhang L, et al. Effects of the NaCl concentration and montmorillonite content on formation kinetics of methane hydrate[J]. Journal of Marine Science and Engineering, 2022, 10(4): 548. |

| 28 | Constant Agnissan A C, Guimpier C, Terzariol M, et al. Influence of clay-containing sediments on methane hydrate formation: impacts on kinetic behavior and gas storage capacity[J]. Journal of Geophysical Research: Solid Earth, 2023, 128(9): 2023JB027333. |

| 29 | 柳扬. 蜡与水合物共存W/O体系流动及沉积规律研究[D]. 北京: 中国石油大学 (北京), 2019. |

| Liu Y. Study on the flow and deposition mechanisms of W/O systems containing wax and hydrates[D].Beijing: China University of Petroleum, 2019. | |

| 30 | Brown E P, Turner D, Grasso G, et al. Effect of wax/anti-agglomerant interactions on hydrate depositing systems[J]. Fuel, 2020, 264: 116573. |

| 31 | Wang W, Huang Q Y, Hu S J, et al. Influence of wax on cyclopentane clathrate hydrate cohesive forces and interfacial properties[J]. Energy & Fuels, 2020, 34(2): 1482-1491. |

| 32 | Liu Z M, Geng X, Gao Y, et al. Effect of wax crystal on the kinetic and morphology of gas hydrate deposition in water-in-oil emulsions[J]. Fuel, 2022, 330: 125501. |

| 33 | 陈玉川. 微米级颗粒分散体系内水合物生成与流动规律研究[D]. 北京: 中国石油大学 (北京), 2021. |

| Chen Y C. Study on hydrate formation and slurry flow properties in the dispersed systems with micron-sized particles[D].Beijing: China University of Petroleum, 2021. | |

| 34 | Shi B H, Chen Y C, Wang X F, et al. Flowloop investigation into hydrate formation and slurry flow in the presence of micron-sized sand particles[J]. Journal of Petroleum Science and Engineering, 2022, 212: 110251. |

| 35 | 丁麟. 多相混输管路天然气水合物浆液流动稳定性研究[D]. 北京: 中国石油大学 (北京), 2019. |

| Ding L. Study on the stability of natural gas hydrate slurry flow in a multiphase transportation pipeline [D]. Beijing: China University of Petroleum, 2019. | |

| 36 | Liu Y, Lv X F, Shi B H, et al. Rheological study of low wax content hydrate slurries considering phase interactions[J]. Journal of Natural Gas Science and Engineering, 2021, 94: 104106. |

| 37 | 王韧. 钻井液中纳米SiO2和水合物抑制剂对水合物形成影响研究[D]. 武汉: 中国地质大学, 2017. |

| Wang R. Study on the effects of nano-SiO2 and hydrate inhibitors on hydrate formation in drilling fluid[D].Wuhan: China University of Geosciences, 2017. | |

| 38 | Hua Z, Li M, Lin M, et al. Characterization of sandstone surface wettability by surface potential[J]. Journal of China University of Petroleum Edition of Natrual Science, 2015, 39(2):142-50. |

| 39 | Si S X, Yan Z, Gong Z B, et al. Pilot study of oilfield wastewater treatment by micro-flocculation filtration process[J]. Water Science and Technology, 2018, 77(1): 101-107. |

| 40 | 戴彩丽, 曹梦娇, 吴一宁, 等. 微纳孔隙油-水-岩石微观界面相互作用研究进展[J]. 深圳大学学报 (理工版), 2021, 38(6): 551-562. |

| Dai C L, Cao M J, Wu Y N, et al. Research progress on oil-water-rock interface interaction in micro-nano porous medium[J]. Journal of Shenzhen University (Science and Engineering), 2021, 38(6): 551-562. | |

| 41 | Demir C, Abramov A A, Çelik M S. Flotation separation of Na-feldspar from K-feldspar by monovalent salts[J]. Minerals Engineering, 2001, 14(7): 733-740 |

| 42 | Liu L H, Liu S Y, Peng H L, et al. Surface charge of mesoporous calcium silicate and its adsorption characteristics for heavy metal ions[J]. Solid State Sciences, 2020, 99: 106072. |

| 43 | Gupta R, Pathak D D. Surface functionalization of mesoporous silica with maltodextrin for efficient adsorption of selective heavy metal ions from aqueous solution[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 631: 127695. |

| 44 | Lv X F, Shi B H, Wang Y, et al. Experimental Study on hydrate induction time of gas-saturated water-in-oil emulsion using a high-pressure flow loop[J]. Oil & Gas Science and Technology-Revue D’IFP Energies Nouvelles, 2015, 70(6): 1111-1124. |

| 45 | 骆庆群. 气体在疏水性表面的吸附和积聚现象及其作用研究[D]. 太原: 太原理工大学, 2016. |

| Luo Q Q. Gas adsorption and accumulation on hydrophobic surface and its effects[D].Taiyuan: Taiyuan University of Technology, 2016. | |

| 46 | Ishida N. Direct measurement of hydrophobic particle-bubble interactions in aqueous solutions by atomic force microscopy: effect of particle hydrophobicity[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2007, 300(3): 293-299. |

| 47 | Liu L H, Shi B H, Song S F, et al. Co-deposition characteristics of hydrates and sands in gas-salty water-sands flow system[J]. Fuel, 2023, 346: 128276. |

| [1] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [2] | 黄磊, 孔令学, 白进, 李怀柱, 郭振兴, 白宗庆, 李平, 李文. 油页岩添加对准东高钠煤灰熔融行为影响的研究[J]. 化工学报, 2023, 74(5): 2123-2135. |

| [3] | 欧阳萍, 张睿, 周剑, 刘海燕, 刘植昌, 徐春明, 孟祥海. 铜铝双金属复合离子液体的电化学行为及电沉积铜机理[J]. 化工学报, 2022, 73(7): 3212-3221. |

| [4] | 顾鋆鋆, 黎睿, 吴兴熠, 汤显强, 胡艳平. 电动导排孔隙水对泥-水界面氮释放通量的控制效果研究[J]. 化工学报, 2022, 73(11): 5118-5127. |

| [5] | 刘坐东, 王禹晨, 邢维维, 赵波, 徐志明. 复合改性表面抑制颗粒污垢积聚特性分析[J]. 化工学报, 2022, 73(11): 4928-4937. |

| [6] | 胡慧慧, 杨亮, 刘道平, 张柯. 低剂量超吸水树脂溶液微滴中甲烷水合物生成动力学[J]. 化工学报, 2022, 73(10): 4659-4667. |

| [7] | 向茂乔, 耿玉琦, 朱庆山. 氮化硅粉体制备技术及粉体质量研究进展[J]. 化工学报, 2022, 73(1): 73-84. |

| [8] | 从少领, 赵捷, 杨玉飞, 吴长清, 贺凡, 袁华, 汪晓芹, 熊善新, 吴燕, 周安宁. 煤基聚苯胺制掺N碳微纳米管的实验研究[J]. 化工学报, 2021, 72(9): 4950-4960. |

| [9] | 金默, 刘道银, 陈晓平. 基于离散元方法的高碱煤灰沉积过程数值模拟研究[J]. 化工学报, 2021, 72(4): 1939-1946. |

| [10] | 裴俊华, 杨亮, 汪鑫, 胡晗, 刘道平. 泡沫铜强化甲烷水合物生成动力学实验研究[J]. 化工学报, 2021, 72(11): 5751-5760. |

| [11] | 刘坐东, 李斯琪, 邢维维, 徐志明. 板式换热器Ni-P-TiO2复合纳米镀层微生物污垢特性[J]. 化工学报, 2020, 71(8): 3535-3544. |

| [12] | 张红, 唐留. p型掺杂剂Cp2Mg在MOCVD气相中的反应机理研究[J]. 化工学报, 2020, 71(7): 3000-3008. |

| [13] | 桑元, 向茂乔, 宋淼, 朱庆山. 流化床化学气相沉积法制备近化学计量比的TiN粉体[J]. 化工学报, 2020, 71(6): 2743-2751. |

| [14] | 詹飞龙, 丁国良, 庄大伟, 张浩, 武滔, 叶向阳. 析湿工况下翅片管式换热器表面粉尘沉积过程的数值模型[J]. 化工学报, 2020, 71(5): 1986-1994. |

| [15] | 赵少飞, 刘鹏, 李婉萍, 曾小红, 钟远红, 余林, 曾华强. 一步电沉积法制备硫化镍/泡沫镍材料及其赝电容性能研究[J]. 化工学报, 2020, 71(4): 1836-1843. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号