化工学报 ›› 2024, Vol. 75 ›› Issue (1): 268-278.DOI: 10.11949/0438-1157.20231132

周尧1( ), 杨小平2(

), 杨小平2( ), 倪一程2, 刘继平1, 魏进家2,3, 严俊杰3

), 倪一程2, 刘继平1, 魏进家2,3, 严俊杰3

收稿日期:2023-11-06

修回日期:2023-12-17

出版日期:2024-01-25

发布日期:2024-03-11

通讯作者:

杨小平

作者简介:周尧(1994—),男,博士研究生,foreverzy@stu.xjtu.edu.cn

基金资助:

Yao ZHOU1( ), Xiaoping YANG2(

), Xiaoping YANG2( ), Yicheng NI2, Jiping LIU1, Jinjia WEI2,3, Junjie YAN3

), Yicheng NI2, Jiping LIU1, Jinjia WEI2,3, Junjie YAN3

Received:2023-11-06

Revised:2023-12-17

Online:2024-01-25

Published:2024-03-11

Contact:

Xiaoping YANG

摘要:

环路热管是一种高效被动式相变传热装置,广泛应用于高热流电子器件散热等领域。前期研究发现将小型两相引射器与平板式环路热管耦合,可大幅提高传热性能。然而,小型两相引射器内部流动及传热机理尚不清晰,难以对新型环路热管进行正向设计与理论建模。通过数值模拟研究了汽水参数和混合腔结构对两相引射器性能及内部流场分布的影响。结果表明,喉部下游存在凝结激波,随着背压增加,其位置逐渐向喉部移动;其强度与背压、蒸汽产量、混合腔长度呈正相关,与水温呈负相关。引射器最大工作背压在40~125 kPa,与蒸汽产量和水温呈正相关,与混合腔长度呈负相关。通过大量模拟,得到了设计功率下水温和混合腔长度对引射器工作模式和压比的影响规律。

中图分类号:

周尧, 杨小平, 倪一程, 刘继平, 魏进家, 严俊杰. 应用于新型环路热管的两相引射器数值模拟[J]. 化工学报, 2024, 75(1): 268-278.

Yao ZHOU, Xiaoping YANG, Yicheng NI, Jiping LIU, Jinjia WEI, Junjie YAN. Numerical simulation of two-phase steam ejector applied in novel loop heat pipe[J]. CIESC Journal, 2024, 75(1): 268-278.

图1 耦合两相引射器的环路热管示意图1—蒸发器;2—蒸汽管路;3—两相引射器;4—液体管路Ⅰ;5—冷却器Ⅰ;6—液体管路Ⅱ;7—冷却器Ⅱ

Fig.1 Schematic diagram of novel LHP system coupled with two-phase steam ejector1—evaporator; 2—vapor line; 3—two-phase steam ejector; 4—liquid line Ⅰ; 5—cooler Ⅰ; 6—liquid line Ⅱ; 7—cooler Ⅱ

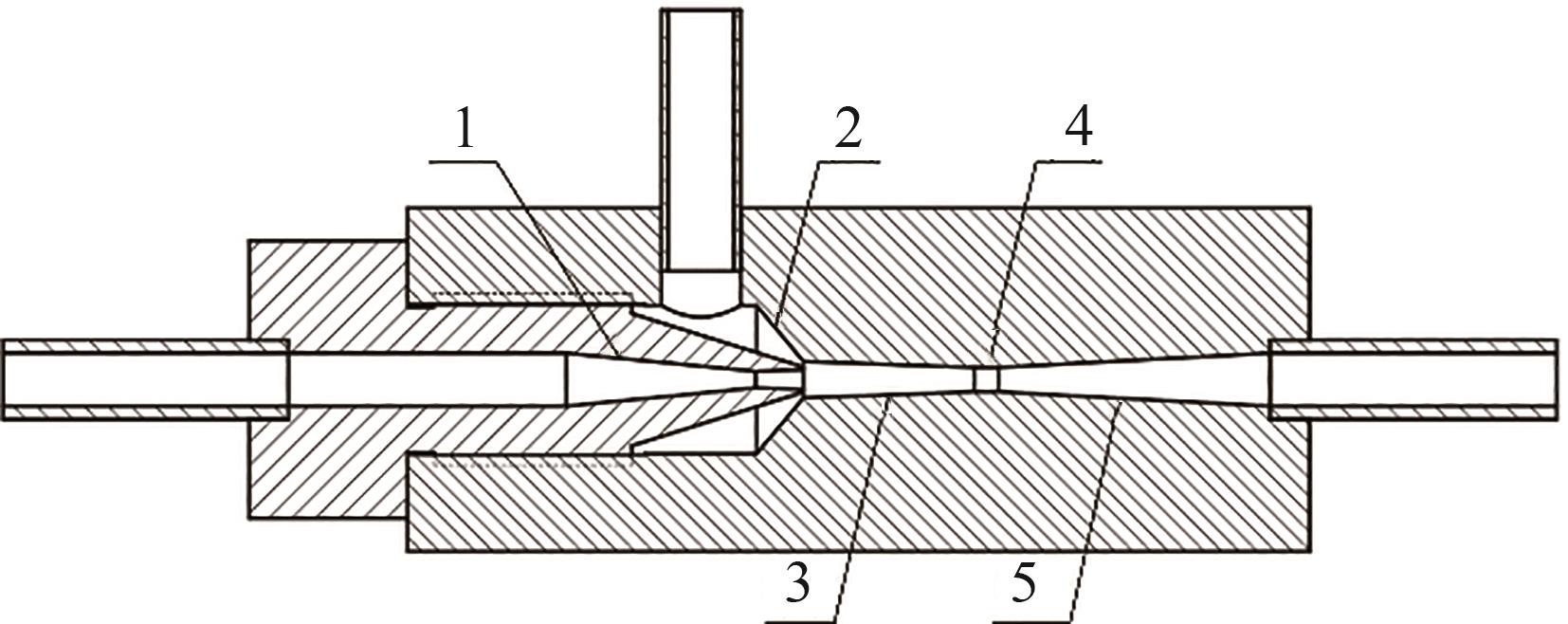

图2 两相引射器结构示意图1—蒸汽喷嘴;2—水喷嘴;3—混合腔;4—喉部;5—扩散器

Fig.2 Schematic diagram of two-phase steam ejector sturcture1—steam nozzle; 2—water nozzle; 3—mixing chamber; 4—throat; 5—diffuser

| 几何参数及边界条件 | 结构1 | 结构2 | 结构3 | 结构4 |

|---|---|---|---|---|

| 蒸汽喷嘴喉部直径, dst/mm | 1.24 | 1.24 | 1.24 | 1.24 |

| 蒸汽喷嘴出口直径, dso/mm | 1.5 | 1.5 | 1.5 | 1.5 |

| 混合腔入口直径, dmi/mm | 2.8 | 2.8 | 2.8 | 2.8 |

| 喉部直径, dm/mm | 1.8 | 1.8 | 1.8 | 1.8 |

| 混合腔长度, lm/mm | 13 | 11 | 9 | 7 |

| 喉部长度, lt/mm | 2 | 2 | 2 | 2 |

| 扩散段出口直径, dd/mm | 4 | 4 | 4 | 4 |

| 蒸汽喷嘴壁面厚度, δ/mm | 0.25 | 0.25 | 0.25 | 0.25 |

| 蒸汽入口压力, ps/kPa | 60~167 | 149 | 149 | 149 |

| 蒸汽喷嘴喉部质量流率, Gs/(kg/(m2·s)) | 95~257 | 232 | 232 | 232 |

| 蒸汽入口温度, Ts/℃ | 85.9~115 | 111 | 111 | 111 |

| 水喷嘴出口质量流率, Gw/(kg/(m2·s)) | 830~2238 | 2020 | 2020 | 2020 |

| 水喷嘴入口温度, Tw/℃ | 5~55 | 5~55 | 2~55 | 2~55 |

| 出口背压, pb/kPa | 40~129 | 79~114 | 89~113 | 91~105 |

表1 两相引射器的几何尺寸与边界条件

Table 1 Geometry dimensions and boundary conditions of two-phase steam ejector

| 几何参数及边界条件 | 结构1 | 结构2 | 结构3 | 结构4 |

|---|---|---|---|---|

| 蒸汽喷嘴喉部直径, dst/mm | 1.24 | 1.24 | 1.24 | 1.24 |

| 蒸汽喷嘴出口直径, dso/mm | 1.5 | 1.5 | 1.5 | 1.5 |

| 混合腔入口直径, dmi/mm | 2.8 | 2.8 | 2.8 | 2.8 |

| 喉部直径, dm/mm | 1.8 | 1.8 | 1.8 | 1.8 |

| 混合腔长度, lm/mm | 13 | 11 | 9 | 7 |

| 喉部长度, lt/mm | 2 | 2 | 2 | 2 |

| 扩散段出口直径, dd/mm | 4 | 4 | 4 | 4 |

| 蒸汽喷嘴壁面厚度, δ/mm | 0.25 | 0.25 | 0.25 | 0.25 |

| 蒸汽入口压力, ps/kPa | 60~167 | 149 | 149 | 149 |

| 蒸汽喷嘴喉部质量流率, Gs/(kg/(m2·s)) | 95~257 | 232 | 232 | 232 |

| 蒸汽入口温度, Ts/℃ | 85.9~115 | 111 | 111 | 111 |

| 水喷嘴出口质量流率, Gw/(kg/(m2·s)) | 830~2238 | 2020 | 2020 | 2020 |

| 水喷嘴入口温度, Tw/℃ | 5~55 | 5~55 | 2~55 | 2~55 |

| 出口背压, pb/kPa | 40~129 | 79~114 | 89~113 | 91~105 |

| 加热功率Q/W | 蒸发热量Qevap/W | 加热性能ΔT | 蒸汽入口压力ps | ||||

|---|---|---|---|---|---|---|---|

| 实验值/℃ | 模拟值/℃ | 相对误差/% | 实验值/kPa | 模拟值/ kPa | 相对误差/% | ||

| 450 | 343 | 31.0 | 30.1 | 0.32 | 69.9 | 71.3 | -2.0 |

| 550 | 430 | 37.7 | 35.7 | 0.64 | 87.7 | 89.5 | -2.1 |

表2 两相引射器数值模拟稳态数据与实验结果[16]对比

Table 2 Comparison of steady-state data between experiment[16] and numerical simulation in two-phase ejector

| 加热功率Q/W | 蒸发热量Qevap/W | 加热性能ΔT | 蒸汽入口压力ps | ||||

|---|---|---|---|---|---|---|---|

| 实验值/℃ | 模拟值/℃ | 相对误差/% | 实验值/kPa | 模拟值/ kPa | 相对误差/% | ||

| 450 | 343 | 31.0 | 30.1 | 0.32 | 69.9 | 71.3 | -2.0 |

| 550 | 430 | 37.7 | 35.7 | 0.64 | 87.7 | 89.5 | -2.1 |

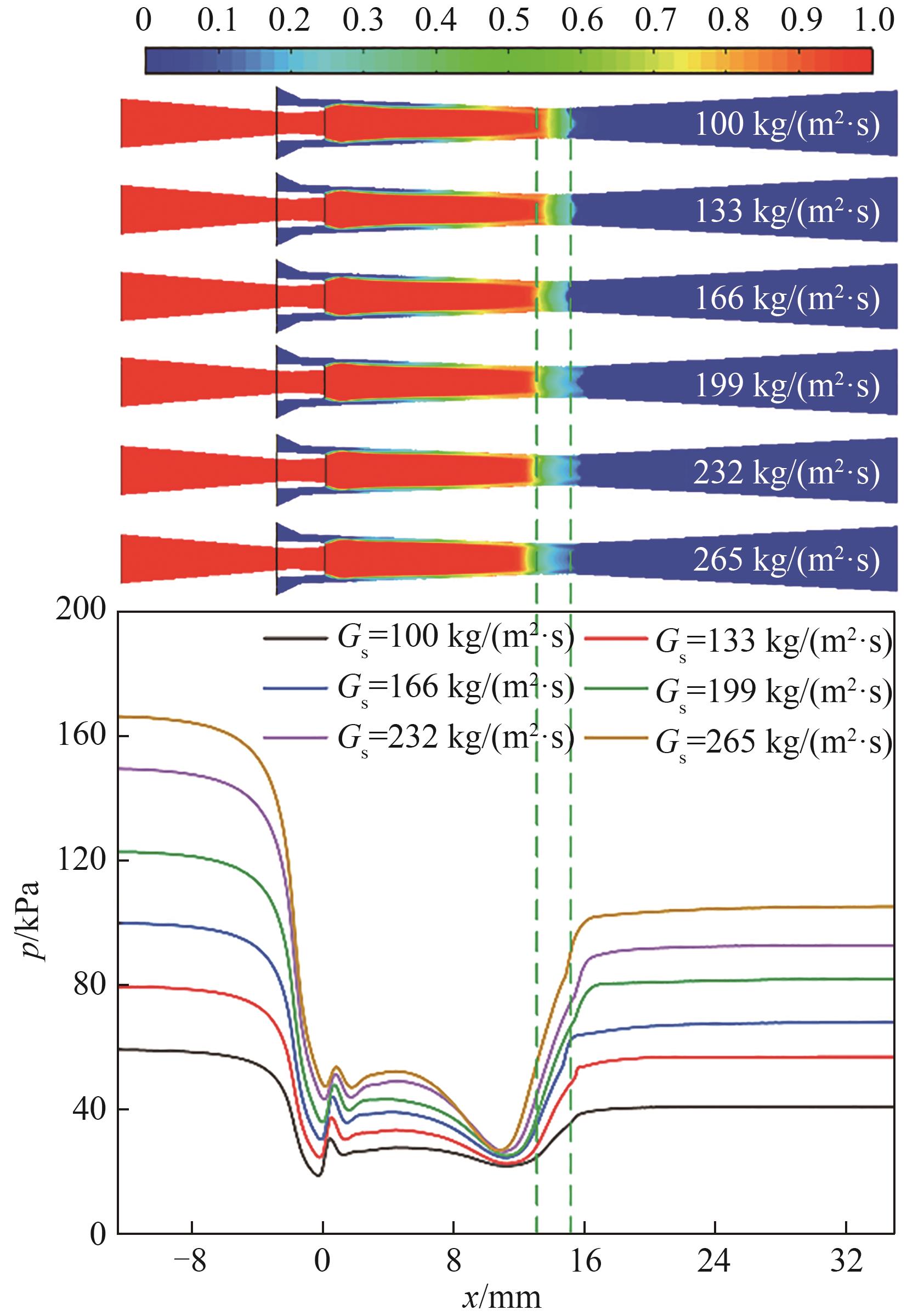

图8 不同蒸汽流量和最大出口背压下的含汽率云图及轴向压力分布

Fig.8 Contours of steam void fraction and axial pressure at maximum discharge pressure and different steam mass flow rates

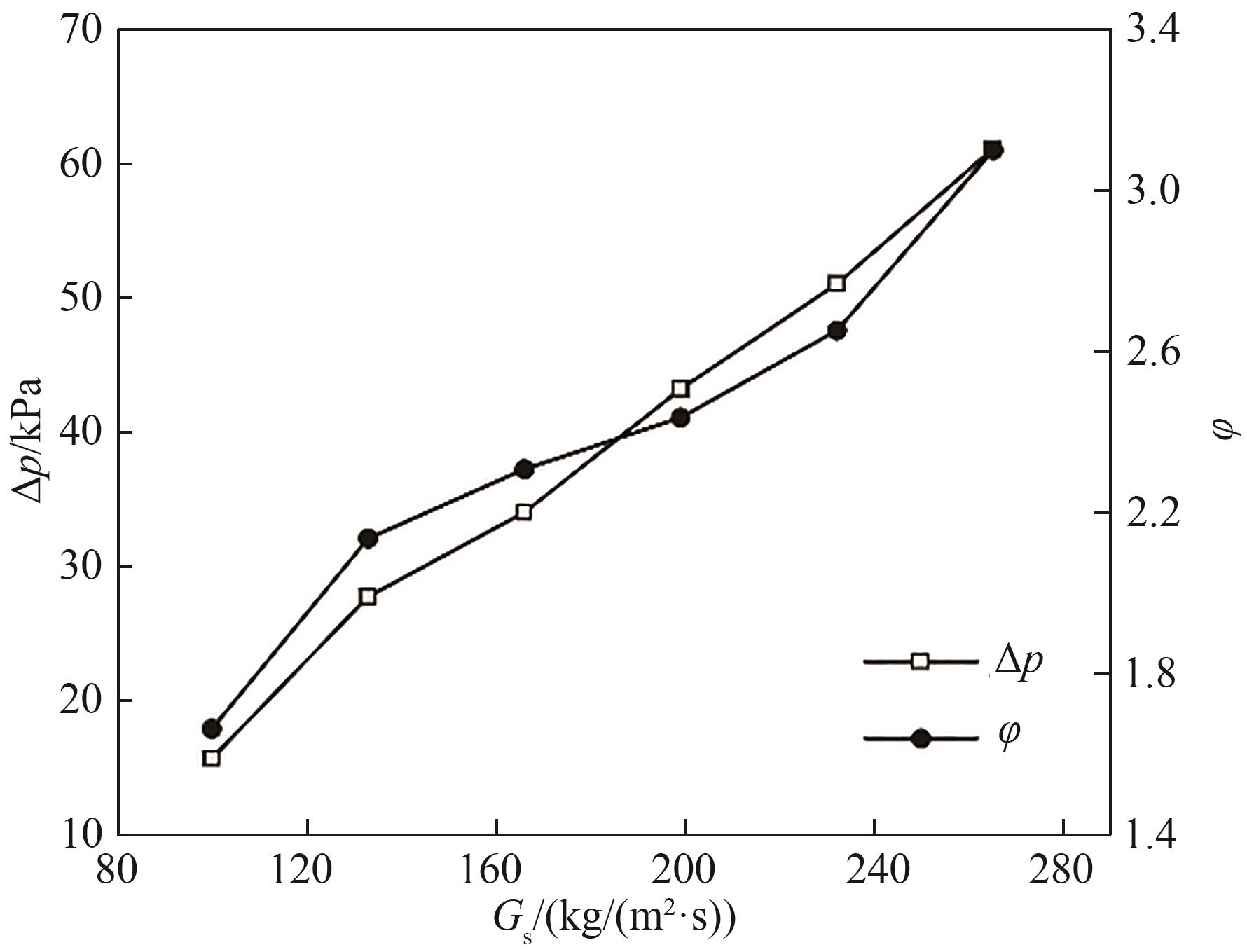

图13 不同最大出口背压和蒸汽流量下凝结激波前后的压差和压比

Fig.13 Pressure difference and pressure ratio between two sides of condensation shockwave at maximum discharge pressure and different steam mass flow rates

图14 不同最大出口背压和进水温度下凝结激波前后的压差和压比

Fig.14 Pressure difference and pressure ratio between two sides of condensation shockwave at maximum discharge pressure and different water temperature

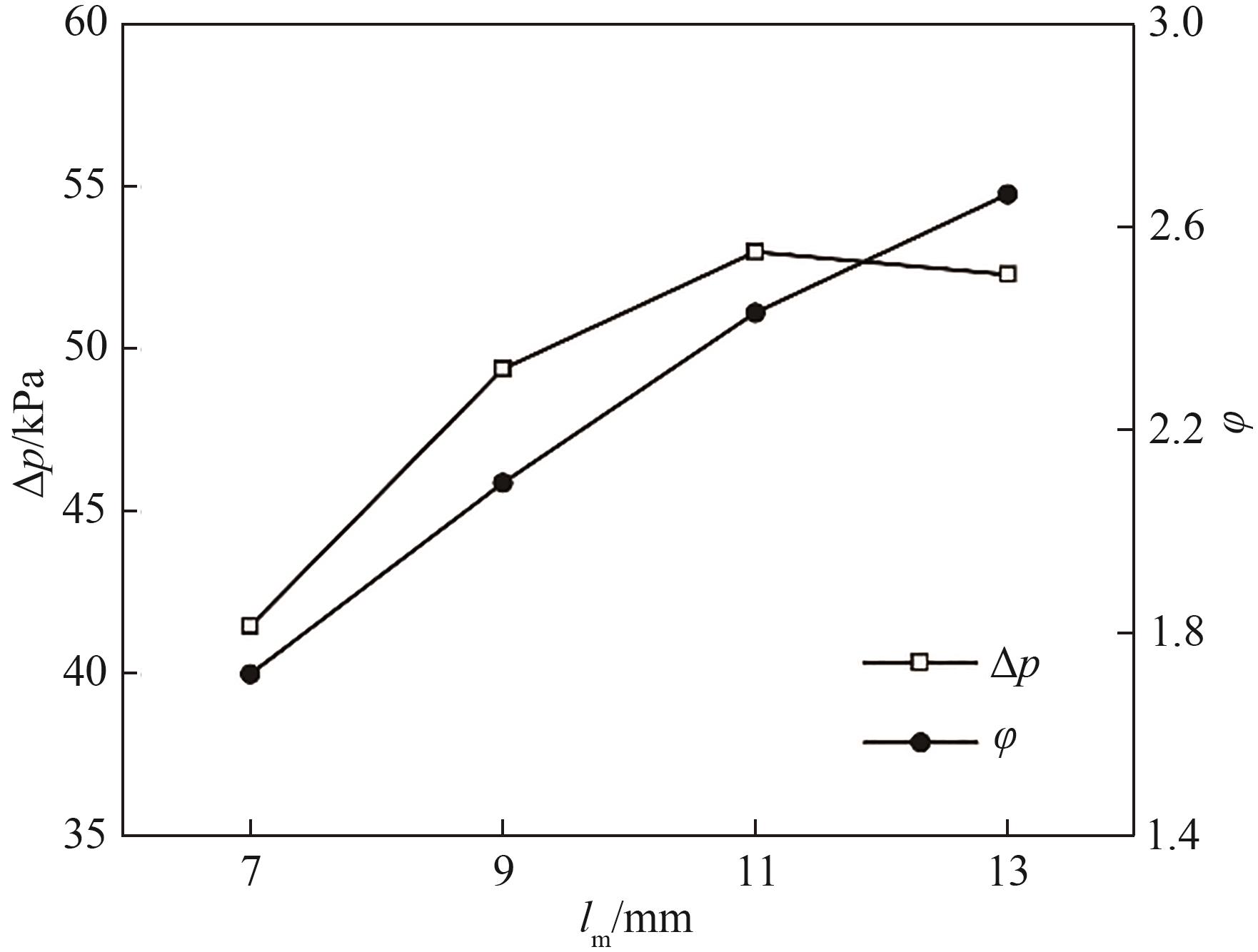

图15 不同最大出口背压和混合腔长度下凝结激波前后的压差和压比

Fig.15 Pressure difference and pressure ratio between two sides of condensation shockwave at maximum discharge pressure and different mixing chambers

| 1 | 魏进家, 刘蕾, 杨小平. 面向高热流电子器件散热的环路热管研究进展[J]. 化工学报, 2023, 74(1): 60-73. |

| Wei J J, Liu L, Yang X P. Research progress of loop heat pipes for heat dissipation of high-heat-flux electronic devices[J]. CIESC Journal, 2023, 74(1): 60-73. | |

| 2 | Su Q, Chang S N, Zhao Y Y, et al. A review of loop heat pipes for aircraft anti-icing applications[J]. Applied Thermal Engineering, 2018, 130: 528-540. |

| 3 | Beygzadeh V, Khalilarya S, Mirzaee I. Thermodynamic comparison of two novel combined systems based on solar loop heat pipe evaporator[J]. Energy, 2020, 206: 118145. |

| 4 | Mueller C, Tsvetkov P. A review of heat-pipe modeling and simulation approaches in nuclear systems design and analysis[J]. Annals of Nuclear Energy, 2021, 160: 108393. |

| 5 | Adachi T, Fujita K, Nagai H. Numerical study of temperature oscillation in loop heat pipe[J]. Applied Thermal Engineering, 2019, 163: 114281. |

| 6 | Bai L Z, Tao Y B, Guo Y D, et al. Startup characteristics of a dual compensation chamber loop heat pipe with an extended bayonet tube[J]. International Journal of Heat and Mass Transfer, 2020, 148: 119066. |

| 7 | Chen X T, Qi C, Wang W, et al. Heat transfer limit resulting from heat leak in a cryogenic loop heat pipe[J]. Applied Thermal Engineering, 2021, 184: 116280. |

| 8 | Ji X B, Wang Y, Xu J L, et al. Experimental study of heat transfer and start-up of loop heat pipe with multiscale porous wicks[J]. Applied Thermal Engineering, 2017, 117: 782-798. |

| 9 | 熊康宁, 吴伟, 汪双凤. 平板形蒸发器环路热管的研究进展[J]. 化工进展, 2021, 40(10): 5388-5402. |

| Xiong K N, Wu W, Wang S F. Research and development of loop heat pipe with flat evaporator[J]. Chemical Industry and Engineering Progress, 2021, 40(10): 5388-5402. | |

| 10 | 王野, 纪献兵, 郑晓欢, 等. 多尺度复合毛细芯环路热管的传热特性[J]. 化工学报, 2015, 66(6): 2055-2061. |

| Wang Y, Ji X B, Zheng X H, et al. Heat transfer characteristics of loop heat pipe with modulated composite porous wick[J]. CIESC Journal, 2015, 66(6): 2055-2061. | |

| 11 | Li X Q, Zhu K, Li H L, et al. Performance comparison regarding loop heat pipes with different evaporator structures[J]. International Journal of Thermal Sciences, 2019, 136: 86-95. |

| 12 | Setyawan I, Putra N, Hakim I I. Experimental investigation of the operating characteristics of a hybrid loop heat pipe using pump assistance[J]. Applied Thermal Engineering, 2018, 130: 10-16. |

| 13 | Zhang H, Jiang C, Zhang Z K, et al. A study on thermal performance of a pump-assisted loop heat pipe with ammonia as working fluid[J]. Applied Thermal Engineering, 2020, 175: 115342. |

| 14 | 莫冬传, 邹冠生, 丁楠, 等. 双通道平板型环路热管的传热特性[J]. 化工学报, 2012, 63(S1): 114-118. |

| Mo D C, Zou G S, Ding N, et al. Heat transfer characteristics of flat loop heat pipe with bi-transport loops[J]. CIESC Journal, 2012, 63(S1): 114-118. | |

| 15 | Boo J H, Jung E G. Bypass line assisted start-up of a loop heat pipe with a flat evaporator[J]. Journal of Mechanical Science and Technology, 2009, 23(6): 1613-1619. |

| 16 | Liu L, Yang X P, Yuan B, et al. Experimental study of a novel loop heat pipe with a vapor-driven jet injector[J]. International Journal of Heat and Mass Transfer, 2021, 164: 120518. |

| 17 | 刘蕾, 袁博, 崔晨乙, 等. 耦合引射器和沸腾池的环路热管传热特性研究[J]. 西安交通大学学报, 2022, 56(7): 19-26. |

| Liu L, Yuan B, Cui C Y, et al. Heat transfer characteristics of loop heat pipe with injector and boiling pool[J]. Journal of Xi'an Jiaotong University, 2022, 56(7): 19-26. | |

| 18 | Liu L, Yang X P, Yuan B, et al. Investigation of temperature oscillations in a novel loop heat pipe with a vapor-driven jet injector[J]. International Journal of Heat and Mass Transfer, 2021, 179: 121672. |

| 19 | Yan J J, Shao S F, Liu J P, et al. Experiment and analysis on performance of steam-driven jet injector for district-heating system[J]. Applied Thermal Engineering, 2005, 25(8/9): 1153-1167. |

| 20 | Takeya Y, Miwa S, Hibiki T, et al. Application of steam injector to improved safety of light water reactors[J]. Progress in Nuclear Energy, 2015, 78: 80-100. |

| 21 | Chen J Y, Jarall S, Havtun H, et al. A review on versatile ejector applications in refrigeration systems[J]. Renewable and Sustainable Energy Reviews, 2015, 49: 67-90. |

| 22 | Zhang Y, Qu X H, Zhang G M, et al. Effect of non-condensable gas on the performance of steam-water ejector in a trigeneration system for hydrogen production: an experimental and numerical study[J]. International Journal of Hydrogen Energy, 2020, 45(39): 20266-20281. |

| 23 | Cattadori G, Galbiati L, Mazzocchi L, et al. A single-stage high pressure steam injector for next generation reactors: test results and analysis[J]. International Journal of Multiphase Flow, 1995, 21(4): 591-606. |

| 24 | Kwidzinski R. Experimental investigation of condensation wave structure in steam-water injector[J]. International Journal of Heat and Mass Transfer, 2015, 91: 594-601. |

| 25 | Grolmes M. Steam-water condensing-injector performance analysis with supersonic inlet vapor and convergent condensing section[D]. Argonne, IL, USA: University of University of Notre Dame, 1968. |

| 26 | Miwa S, Endo H, Moribe T, et al. Investigation of the supersonic steam injector operation mode[J]. Nuclear Engineering and Design, 2018, 334: 57-65. |

| 27 | Miwa S, Xu Y F, Hibiki T, et al. Pressure elevation of high-performance steam-water condensing-injector[J]. International Journal of Heat and Mass Transfer, 2021, 170: 120971. |

| 28 | Narayanan J K, Roy A, Ghosh P. Computational fluid dynamics studies on unstable oscillatory direct contact condensation of subsonic steam jets in water cross-flow[J]. Journal of Heat Transfer, 2020, 142(5): 051601. |

| 29 | Končar B, Mavko B. Modelling of low-pressure subcooled flow boiling using the RELAP5 code[J]. Nuclear Engineering and Design, 2003, 220(3): 255-273. |

| 30 | Zhou Y, Yang X P, Fu P F, et al. Numerical investigation on submerged steam jet condensation in subcooled water flow in a restricted channel with the presence of non-condensable gas[J]. International Journal of Thermal Sciences, 2021, 170: 107122. |

| 31 | Zhou Y, Liu J P, Mo Y L, et al. Numerical simulation on the direct contact condensation in a steam-water two-phase ejector with non-condensable gas[J]. International Journal of Thermal Sciences, 2023, 185: 108030. |

| 32 | Chen X B, Tian M C, Qu X H, et al. Numerical investigation on the interfacial characteristics of steam jet condensation in subcooled water flow in a restricted channel[J]. International Journal of Heat and Mass Transfer, 2019, 137: 908-921. |

| 33 | Xu Q, Liang L, She Y L, et al. Numerical investigation on thermal hydraulic characteristics of steam jet condensation in subcooled water flow in pipes[J]. International Journal of Heat and Mass Transfer, 2022, 184: 122277. |

| 34 | Hughmark G A. Mass and heat transfer from rigid spheres[J]. AIChE Journal, 1967, 13(6): 1219-1221. |

| 35 | Lopez de Bertodano M A. Two fluid model for two-phase turbulent jets[J]. Nuclear Engineering and Design, 1998, 179(1): 65-74. |

| 36 | Shah A, Chughtai I R, Inayat M H. Experimental and numerical analysis of steam jet pump[J]. International Journal of Multiphase Flow, 2011, 37(10): 1305-1314. |

| 37 | Ma H J, Zhao H X, Wang L, et al. Modeling and investigation of a steam-water injector[J]. Energy Conversion and Management, 2017, 151: 170-178. |

| 38 | Radovskii I S. Speed of sound in two-phase vapor-liquid systems[J]. Journal of Applied Mechanics and Technical Physics, 1970, 11(5): 778-784. |

| 39 | Kieffer S W. Sound speed in liquid-gas mixtures: water-air and water-steam[J]. Journal of Geophysical Research, 1977, 82(20): 2895-2904. |

| [1] | 王俊男, 何呈祥, 王忠东, 朱春英, 马友光, 付涛涛. T型微混合器内均相混合的数值模拟[J]. 化工学报, 2024, 75(1): 242-254. |

| [2] | 李晓阳, 李东, 陶明磊, 周致富, 张灵怡, 苏力争, 张天宁, 李智, 陈斌. 多喷嘴喷雾冷却表面传热特性实验研究[J]. 化工学报, 2024, 75(1): 231-241. |

| [3] | 王义江, 孙莉, 刘梦涵, 杨金宏, 王国元. 基于响应面法的矿用翅片管空冷器参数优化[J]. 化工学报, 2024, 75(1): 279-291. |

| [4] | 崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| [5] | 赵碧丹, 代伊杨, 王军武, 张永民. CFD-DEM-IBM方法探究流化床倾斜挡板内构件受力特性[J]. 化工学报, 2024, 75(1): 255-267. |

| [6] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [7] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [8] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [9] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [10] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [11] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [12] | 苏伟, 马东旭, 金旭, 刘忠彦, 张小松. 表面润湿性对霜层传递特性影响可视化实验研究[J]. 化工学报, 2023, 74(S1): 122-131. |

| [13] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [14] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [15] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号