化工学报 ›› 2019, Vol. 70 ›› Issue (7): 2645-2659.DOI: 10.11949/j.issn.0438-1157.20190183

收稿日期:2019-03-04

修回日期:2019-04-07

出版日期:2019-07-05

发布日期:2019-07-05

通讯作者:

彭旭东

作者简介:沈伟(1993—),男,硕士研究生,<email>m15757174235@163.com</email>

基金资助:

Wei SHEN( ),Xudong PENG(

),Xudong PENG( ),Jinbo JIANG,Jiyun LI

),Jinbo JIANG,Jiyun LI

Received:2019-03-04

Revised:2019-04-07

Online:2019-07-05

Published:2019-07-05

Contact:

Xudong PENG

摘要:

超临界二氧化碳介质物性的特殊性使得高速超临界二氧化碳干气密封中的多种实际效应突显,忽略这些实际效应可能会给干气密封稳态性能求解带来较大误差。以螺旋槽干气密封为研究对象,推导了考虑惯性项和实际流态的膜压控制方程,采用有限差分法求得膜压分布,对比分析了基于实际修正模型与经典简化模型的高速超临界二氧化碳干气密封气膜刚度和泄漏率,分析了不同介质压力和速度条件下实际气体效应、惯性效应和湍流效应对气膜刚度和泄漏率的影响规律,揭示了三种效应对稳态性能的单独影响及交互影响机理。结果表明:在本文给定条件下,经典简化模型在速度较小时求得的泄漏率偏小,而在超高速时求得的气膜刚度和泄漏率都偏小;在超高速条件下,实际气体效应使气膜刚度和泄漏率都显著增大,湍流效应使气膜刚度增大,而使泄漏率减小,惯性效应对气膜刚度和泄漏率影响很弱;实际气体效应与湍流效应对稳态性能影响之间具有很强的交互影响关系。

中图分类号:

沈伟, 彭旭东, 江锦波, 李纪云. 高速超临界二氧化碳干气密封实际效应影响分析[J]. 化工学报, 2019, 70(7): 2645-2659.

Wei SHEN, Xudong PENG, Jinbo JIANG, Jiyun LI. Analysis on real effect of supercritical carbon dioxide dry gas seal at high speed[J]. CIESC Journal, 2019, 70(7): 2645-2659.

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 内径 ri/mm | 58.42 | 螺旋角β/(°) | 15 |

| 外径 ro/mm | 77.78 | 槽深 hg/μm | 5 |

| 内径压力 pi/MPa | 0.1 | 槽长比 α | 0.5 |

| 外径压力 po/MPa | 8/14 | 槽宽比 δ | 0.5 |

| 介质温度 T/K | 350 | 槽数 Ng | 12 |

| 非槽区膜厚 h0/μm | 3 |

表1 干密封环几何参数与工况参数

Table 1 Geometric parameter and operating condition parameter

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 内径 ri/mm | 58.42 | 螺旋角β/(°) | 15 |

| 外径 ro/mm | 77.78 | 槽深 hg/μm | 5 |

| 内径压力 pi/MPa | 0.1 | 槽长比 α | 0.5 |

| 外径压力 po/MPa | 8/14 | 槽宽比 δ | 0.5 |

| 介质温度 T/K | 350 | 槽数 Ng | 12 |

| 非槽区膜厚 h0/μm | 3 |

| 生产单位和应用场地 | 介质压力 po/MPa | 密封环线速度 v/(m·s-1) | 介质温度 T/K |

|---|---|---|---|

| Man Turbo, Beula, ND | 11.03 | 146.93 | 449.97 |

| Production Pump, Texas | 13.79 | 19.41 | 377.69 |

| Flowserve, NA | 15.17 | 17.76 | 324.87 |

| MHI, Japan | 21.50 | 65.25 | 477.77 |

| American Pump, Dallas | 17.24 | 23.59 | 310.97 |

表2 超临界CO2干气密封应用工况示例

Table 2 Examples of supercritical CO2 dry gas seal application conditions

| 生产单位和应用场地 | 介质压力 po/MPa | 密封环线速度 v/(m·s-1) | 介质温度 T/K |

|---|---|---|---|

| Man Turbo, Beula, ND | 11.03 | 146.93 | 449.97 |

| Production Pump, Texas | 13.79 | 19.41 | 377.69 |

| Flowserve, NA | 15.17 | 17.76 | 324.87 |

| MHI, Japan | 21.50 | 65.25 | 477.77 |

| American Pump, Dallas | 17.24 | 23.59 | 310.97 |

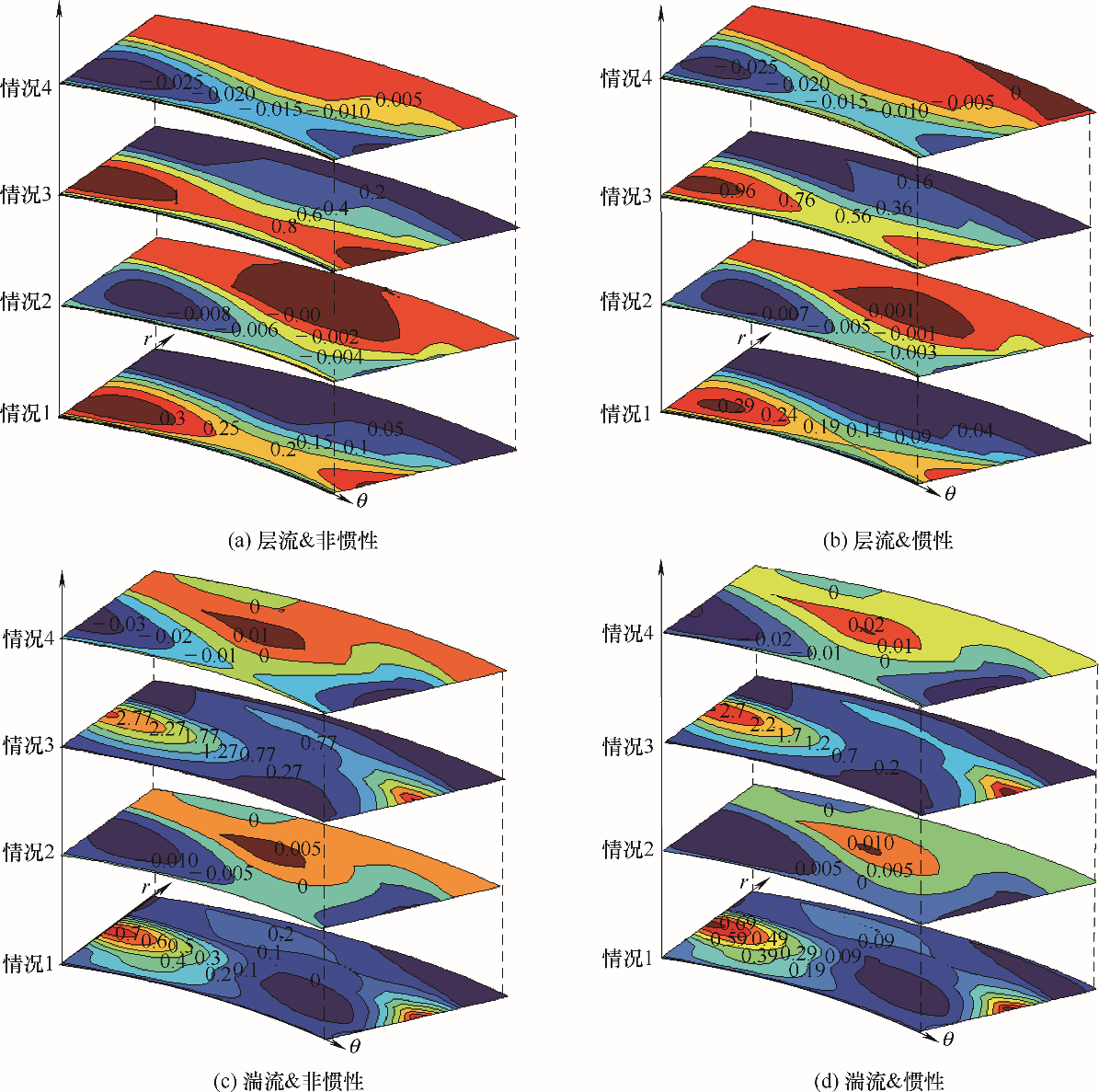

图6 不同压力和温度组合下实际气体超临界CO2干气密封膜压差值分布

Fig.6 Pressure differential distribution of supercritical CO2 dry gas seal for real gas compared with ideal gas at different combination of pressure and temperature

图9 不同计算模型计算所得超临界CO2干气密封径向平均膜压分布(po=14 MPa)

Fig.9 Average radial pressure distribution of supercritical CO2 dry gas seal obtained by different models (po=14 MPa)

| 压力 po/MPa | 线速度 v/(m·s-1) | 交互性能增量比/% | |||||

|---|---|---|---|---|---|---|---|

| 湍流对实际气体的影响 | 惯性对实际气体的影响 | 实际气体对湍流的影响 | 惯性对湍流的影响 | 实际气体对惯性的影响 | 湍流对惯性的影响 | ||

| 8 | 25 | 0.52 | 0.36 | 0.54 | 0.34 | 0.37 | 0.33 |

| 8 | 150 | 10.29 | -0.07 | 14.12 | 0.86 | -0.06 | 0.58 |

| 14 | 25 | 4.15 | 0.17 | 4.38 | 0.25 | 0.16 | 0.24 |

| 14 | 150 | 31.31 | -1.55 | 43.60 | 1.87 | -1.32 | 1.06 |

表3 不同工况条件下三种效应对超临界CO2干气密封气膜刚度的交互性能增量比

Table 3 Interactive increment ratio of film stiffness of supercritical CO2 dry gas seal of three effects at

| 压力 po/MPa | 线速度 v/(m·s-1) | 交互性能增量比/% | |||||

|---|---|---|---|---|---|---|---|

| 湍流对实际气体的影响 | 惯性对实际气体的影响 | 实际气体对湍流的影响 | 惯性对湍流的影响 | 实际气体对惯性的影响 | 湍流对惯性的影响 | ||

| 8 | 25 | 0.52 | 0.36 | 0.54 | 0.34 | 0.37 | 0.33 |

| 8 | 150 | 10.29 | -0.07 | 14.12 | 0.86 | -0.06 | 0.58 |

| 14 | 25 | 4.15 | 0.17 | 4.38 | 0.25 | 0.16 | 0.24 |

| 14 | 150 | 31.31 | -1.55 | 43.60 | 1.87 | -1.32 | 1.06 |

| 压力 po/MPa | 线速度 v/(m·s-1) | 交互性能增量比/% | |||||

|---|---|---|---|---|---|---|---|

| 湍流对实际气体的影响 | 惯性对实际气体的影响 | 实际气体对湍流的影响 | 惯性对湍流的影响 | 实际气体对惯性的影响 | 湍流对惯性的影响 | ||

| 8 | 25 | -0.21 | -0.39 | -0.17 | 0.32 | -0.32 | 0.32 |

| 8 | 150 | -5.98 | -0.89 | -4.35 | -1.32 | -0.70 | -1.44 |

| 14 | 25 | -2.36 | -0.47 | -1.55 | 0.71 | -0.31 | 0.72 |

| 14 | 150 | -24.37 | -2.14 | -12.83 | -0.37 | -1.46 | -0.50 |

表4 不同工况下三种效应对超临界CO2干气密封泄漏率的交互性能增量比

Table 4 Interactive increment ratio of leakage rate of supercritical CO2 dry gas seal of three effects at

| 压力 po/MPa | 线速度 v/(m·s-1) | 交互性能增量比/% | |||||

|---|---|---|---|---|---|---|---|

| 湍流对实际气体的影响 | 惯性对实际气体的影响 | 实际气体对湍流的影响 | 惯性对湍流的影响 | 实际气体对惯性的影响 | 湍流对惯性的影响 | ||

| 8 | 25 | -0.21 | -0.39 | -0.17 | 0.32 | -0.32 | 0.32 |

| 8 | 150 | -5.98 | -0.89 | -4.35 | -1.32 | -0.70 | -1.44 |

| 14 | 25 | -2.36 | -0.47 | -1.55 | 0.71 | -0.31 | 0.72 |

| 14 | 150 | -24.37 | -2.14 | -12.83 | -0.37 | -1.46 | -0.50 |

| 1 | DostalV. A supercritical carbon dioxide cycle for next generation nuclear reactors [D]. Massachusetts: Massachusetts Institute of Technology, 2004. |

| 2 | AhnY, BaeS J, KimM, et al. Review of supercritical CO2 power cycle technology and current status of research and development[J]. Nuclear Engineering & Technology, 2015, 47(6): 647-661. |

| 3 | ThatteA, DheeradhadaV. Coupled physical performance predictions and risk assessment for dry gas seal operating in MW-scale supercritical CO2 turbine [C]//Proceedings of ASME Turbo Expo 2016, Turbomachinery Technology Conference and Exposition, Seoul, South Korea 2016. |

| 4 | FairuzZ M, JahnI H J. Performance of supercritical CO2 dry gas seal near the critical point[C]// Proceedings of ASME Turbo Expo 2016, Turbomachinery Technology Conference and Exposition, Seoul, South Korea, 2016. |

| 5 | BaltadjievN D. An investigation of real gas effects in supercritical CO2 compressors[D]. Massachusetts: Massachusetts Institute of Technology, 2012. |

| 6 | JassimE, AbdiM A, MuzychkaY. Computational fluid dynamics study for flow of natural gas through high-pressure supersonic nozzles(part 1): Real gas effects and shockwave [J]. Petroleum Science & Technology, 2008, 26(15): 1757-1772. |

| 7 | MutoD, TsuboiN, TerashimaH. Numerical study of real gas effects on shock tube problems at supercritical conditions [J]. Transactions of the Japan Society for Aeronautical & Space Sciences Aerospace Technology Japan, 2014, 12(2): 39-44. |

| 8 | FairuzZ M, JahnI. The influence of real gas effects on the performance of supercritical CO2 dry gas seals [J]. Tribology International, 2016, 102: 333-347. |

| 9 | 许恒杰, 宋鹏云, 毛文元, 等. 层流状态下高压高转速二氧化碳干气密封的惯性效应分析[J]. 化工学报, 2018, 69(10): 4311-4323. |

| XuH J, SongP Y, MaoW Y, et al. Analysis on inertia effect of carbon dioxide dry gas seal at high speed and pressure under laminar condition[J]. CIESC Journal, 2018, 69(10): 4311-4323. | |

| 10 | DuQ W, GaoK K, ZhangD, et al. Effects of grooved ring rotation and working fluid on the performance of dry gas seal[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1323-1332. |

| 11 | 温建全. 超临界二氧化碳介质箔片轴承弹流耦合研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. |

| WenJ Q. The oretical study on characteristics of compliant foil bearings lubricated with supercritical carbon dioxide[D].Haerbin: Harbin Institute of Technology, 2017. | |

| 12 | ConboyT M. Real-gas effects in foil thrust bearings operating in the turbulent regime[J]. ASME Journal of Tribology, 2013, 135: 031703-1-031703-12. |

| 13 | ConstantinescuV N. Basic relationships in turbulent lubrication and their extension to include thermal effects[J]. ASME Journal of Lubrication Technology, 1973, 95(2): 147-154. |

| 14 | ConstantinescuV N, GaletuseS. On the possibilities of improving the accuracy of the evaluation of inertia forces in laminar and turbulent films[J]. ASME Journal of Tribology, 1974, 96(1): 69-77. |

| 15 | ConstantinescuV N. On the influence of inertia forces in turbulent and laminar self-acting films[J]. ASME Journal of Tribology, 1970, 92(3): 473-480. |

| 16 | NgC W, PanC H T. A linearized turbulent lubrication theory[J]. ASME Journal of Fluids Engineering, 1965, 87(3): 675-682. |

| 17 | NgC W. Fluid dynamic foundation of turbulent lubrication theory[J]. Tribology Transactions, 1964, 7(4): 311-321. |

| 18 | ElrodH G, NgC W. A theory for turbulent fluid films and its application to bearings[J]. ASME Journal of Lubrication Technology, 1967, 89(3): 346-362. |

| 19 | HirsG G. A bulk-flow theory for turbulence in lubricant films[J]. ASME Journal of Lubrication Technology, 1973, 95(2): 137-145. |

| 20 | WangJ K, KhonsariM M. Application of Hopf bifurcation theory to rotor-bearing systems with consideration of turbulent effects[J]. Tribology International, 2006, 39(7): 701-714. |

| 21 | LuanZ, KhonsariM M. Analysis of conjugate heat transfer and turbulent flow in mechanical seals[J]. Tribology International, 2009, 42(5): 762-769. |

| 22 | HashimotoH. The effects of fluid inertia forces on the static characteristics of sector-shaped, high-speed thrust bearings in turbulent flow regime[J]. Journal of Tribology, 1989, 111: 406-412. |

| 23 | HashimotoH. Performance characteristic analysis of sector-shaped pad thrust bearings in turbulent inertial flow regime under three types of lubrication conditions[J]. ASME Journal of Tribology, 1990, 112: 477-485. |

| 24 | ConboyT M. Real-gas effects in foil thrust bearings operating in the turbulent regime[J]. ASME Journal of Tribology, 2013, 135: 031703-1-12. |

| 25 | TaylorC M, DowsonD. Turbulent lubrication theory – application to design[J]. ASME Journal of Lubrication Technology, 1974, 96(1): 36-46. |

| 26 | 江锦波, 陈源, 赵文静, 等. 干气密封螺旋槽几何参数优选交互影响[J]. 化工学报, 2018, 69(4): 1518-1527. |

| JiangJ B, ChenY, ZhaoW J, et al. Interaction effect of optimized value of geometric parameters of spiral groove of dry gas seal[J]. CIESC Journal, 2018, 69(4): 1518-1527. | |

| 27 | 彭旭东, 江锦波, 白少先, 等. 中低压干气密封螺旋槽结构参数优化[J]. 化工学报, 2014, 65(11): 4536-4542. |

| PengX D, JiangJ B, BaiS X, et al. Structural parameter optimization of spiral groove dry gas seal under low or medium pressure[J]. CIESC Journal, 2014, 65(11): 4536-4542. | |

| 28 | 徐奇超, 江锦波, 彭旭东, 等. 基于遗传算法的干气密封双向槽统一模型与参数优化[J]. 化工学报, 2019, 70(3): 995-1005. |

| XuQ C, JiangJ B, PengX D, et al. Unified model and geometrical optimization of bi-directional groove of dry gas seal based on genetic algorithm[J]. CIESC Journal, 2019, 70(3): 995-1005. | |

| 29 | GlienickeJ, LaunertA, SchlumsH, et al. Non-contacting gas lubricated face seals for high PV values[J]. Seals Flow Code Development, 1994, 1: 367-378. |

| 30 | OchiaiM, HashimotoH. Static and dynamic characteristics of high-speed, stepped thrust gas-film bearings(Theoretical analysis considering fluid inertia forces)[J]. Procedia Environmental Sciences, 1997, 63(613): 3249-3256. |

| 31 | MarquardtJ T. Successful operational experience sealing supercritical CO2 [C]// Supercritical CO2 Power Cycle Symposium. Boulder, Colorado, USA:2015: 1-5. |

| 32 | 李沛剑, 郝小龙, 宋满存, 等. 超临界二氧化碳涡轮发电机的设计及应用探讨[J]. 船舶科学技术, 2017, 39(9): 111-116. |

| LiP J, HaoX L, SongM C, et al. The design and application of a supercritical carbon dioxide turbo-generator [J]. Ship Science and Technology, 2017, 39(9): 111-116. | |

| 33 | AhnY, BaeS J, KimM, et al. Review of supercritical CO2 power cycle technology and current status of research and developmnt[J]. Nuclear Engineering Technology, 2015, 47: 647-661. |

| [1] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [2] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [3] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [4] | 朱兵国, 何吉祥, 徐进良, 彭斌. 冷却条件下渐扩/渐缩管内超临界压力二氧化碳的传热特性[J]. 化工学报, 2023, 74(3): 1062-1072. |

| [5] | 许婉婷, 许波, 王鑫, 陈振乾. 方形微通道内超临界CO2流动换热特性研究[J]. 化工学报, 2022, 73(4): 1534-1545. |

| [6] | 汪森林, 李照志, 邵应娟, 钟文琪. 超临界二氧化碳垂直管内传热恶化数值模拟研究[J]. 化工学报, 2022, 73(3): 1072-1082. |

| [7] | 孙铭泽, 马宁, 李浩然, 姜海峰, 洪文鹏, 牛晓娟. 中低温超临界CO2及其混合工质布雷顿循环热力学分析[J]. 化工学报, 2022, 73(3): 1379-1388. |

| [8] | 颜建国, 郑书闽, 郭鹏程, 张博, 毛振凯. 基于GA-BP神经网络的超临界CO2传热特性预测研究[J]. 化工学报, 2021, 72(9): 4649-4657. |

| [9] | 严如奇, 丁雪兴, 徐洁, 洪先志, 包鑫. 基于湍流模型的S-CO2干气密封流场与稳态性能分析[J]. 化工学报, 2021, 72(8): 4292-4303. |

| [10] | 江鹏, 江锦波, 彭旭东, 孟祥铠, 马艺. 传热模型对近临界工况CO2干气密封温压分布和稳态性能影响[J]. 化工学报, 2021, 72(8): 4239-4254. |

| [11] | 孙雪剑, 宋鹏云, 毛文元, 邓强国, 许恒杰, 陈维. 考虑密封环材料属性和表面形貌干气密封启停阶段的动态接触特性分析[J]. 化工学报, 2021, 72(8): 4279-4291. |

| [12] | 洪燕珍, 王笛, 李卓昱, 徐亚南, 王宏涛, 苏玉忠, 彭丽, 李军. 超临界二氧化碳介入的α-松油醇催化合成1,8-桉叶素[J]. 化工学报, 2021, 72(7): 3680-3685. |

| [13] | 商浩, 陈源, 李孝禄, 王冰清, 李运堂, 彭旭东. 膜厚扰动下的非线性效应对干气密封性能影响研究[J]. 化工学报, 2021, 72(4): 2213-2222. |

| [14] | 江锦波, 滕黎明, 孟祥铠, 李纪云, 彭旭东. 基于多变量摄动的超临界CO2干气密封动态特性[J]. 化工学报, 2021, 72(4): 2190-2202. |

| [15] | 于辰,江锦波,赵文静,李纪云,彭旭东,王玉明. 基于微段组合的干气密封端面型槽结构模型及其参数影响[J]. 化工学报, 2021, 72(10): 5294-5309. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号