化工学报 ›› 2021, Vol. 72 ›› Issue (1): 619-627.DOI: 10.11949/0438-1157.20201000

• 材料化学工程与纳米技术 • 上一篇

收稿日期:2020-07-23

修回日期:2020-10-26

出版日期:2021-01-05

发布日期:2021-01-05

通讯作者:

陈东

作者简介:石盼(1997—),男,硕士研究生,基金资助:

SHI Pan1( ),YAN Xiaoxiao1,WANG Xingzheng1,FENG Leyun1,CHEN Dong1,2(

),YAN Xiaoxiao1,WANG Xingzheng1,FENG Leyun1,CHEN Dong1,2( )

)

Received:2020-07-23

Revised:2020-10-26

Online:2021-01-05

Published:2021-01-05

Contact:

CHEN Dong

摘要:

一步法可控制备生物相容油核微胶囊对工业制备微胶囊及其应用具有重要意义。通过设计微流控器件,成功实现一步法制备尺寸均一可控的生物相容油核微胶囊。利用玻璃毛细管管套管的方法制备了微流控器件。通过外相水凝胶相剪切内相油相得到油核液滴,同时油核液滴和外相水凝胶相在重力作用下脱离管口,形成油核微胶囊,再通过交联水凝胶壳层得到稳定的结构。系统研究了微流控器件结构、内相流速、外相流速等参数对油核微胶囊油核数量、微胶囊直径、壁厚等性质的影响规律。生物相容油核微胶囊作为活性物质的理想载体,可以实现pH改变触发的快速释放和壁厚调节的缓慢释放,为其实际应用奠定了基础。

中图分类号:

石盼, 颜肖潇, 王行政, 冯乐耘, 陈东. 一步法制备生物相容油核微胶囊及其可控释放[J]. 化工学报, 2021, 72(1): 619-627.

SHI Pan, YAN Xiaoxiao, WANG Xingzheng, FENG Leyun, CHEN Dong. One-step fabrication of biocompatible oil-core microcapsules with controlled release[J]. CIESC Journal, 2021, 72(1): 619-627.

| 密度/(g/ml) | 黏度/(mPa?s) | 表面张力/(mN/m) | |

|---|---|---|---|

| 内相 | 0.88 | 6 | 35.3 |

| 外相 | 1.00 | 300 | 70.2 |

表1 内外相流体物性参数

Table 1 Physical properties of inner or outer fluids

| 密度/(g/ml) | 黏度/(mPa?s) | 表面张力/(mN/m) | |

|---|---|---|---|

| 内相 | 0.88 | 6 | 35.3 |

| 外相 | 1.00 | 300 | 70.2 |

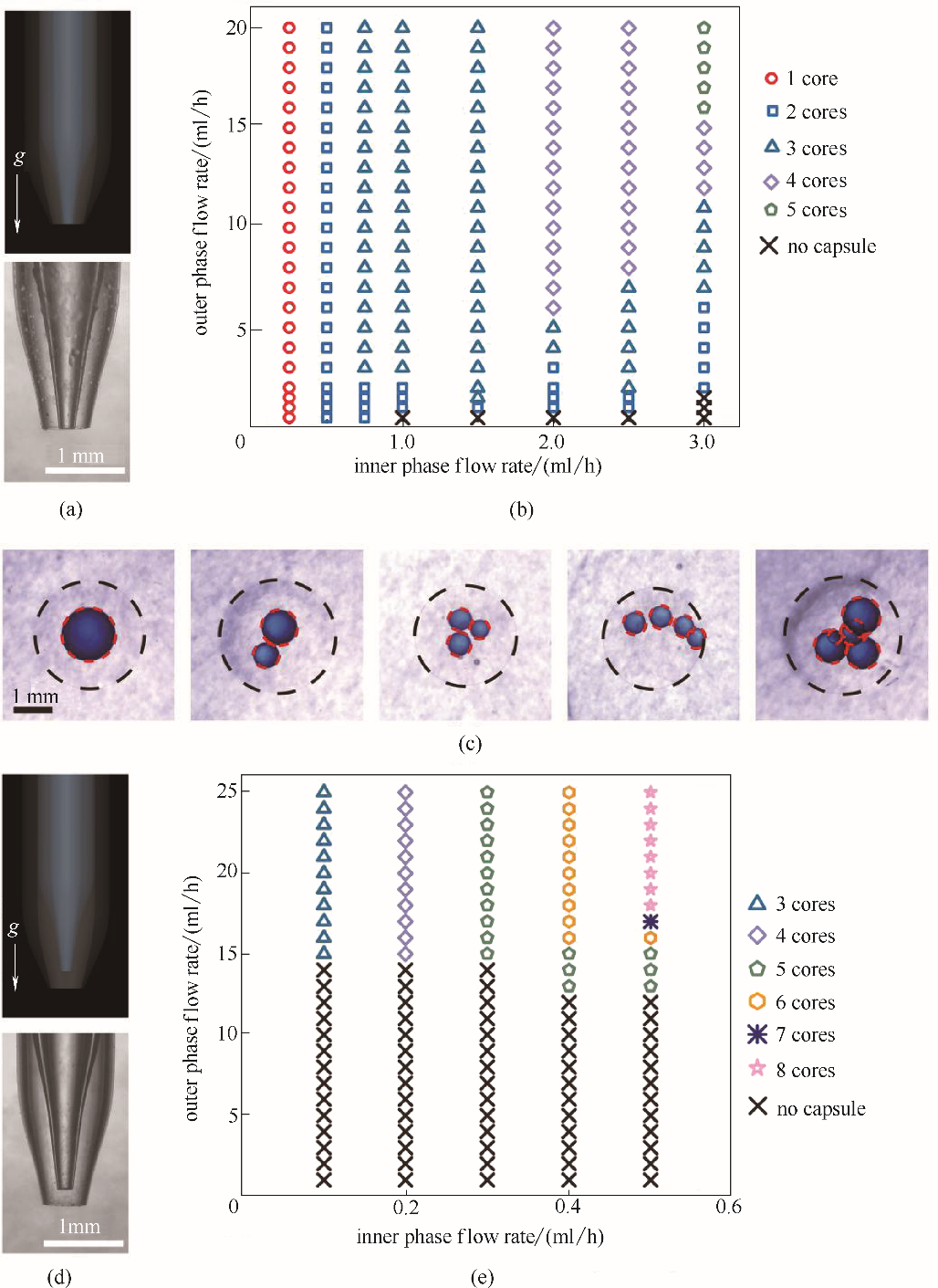

图1 玻璃毛细管微流控器件及其制备油核微胶囊:内管管口伸出外管管口的玻璃毛细管微流控器件(a);微胶囊生成过程(b);油核微胶囊(c);制备微胶囊的相图(红色圈表示可以形成单核微胶囊,黑色叉表示无法形成微胶囊)(d)

Fig.1 Preparation of oil-core microcapsules by glass-capillary microfluidic device. Glass capillary microfluidic device with inner nozzle extending from outer nozzle(a). Microcapsule formation process (b). Oil core microcapsules(c). Phase diagram of the prepared microcapsules, the red circle indicates that mononuclear microcapsules can be formed, and the black cross indicates that microcapsules cannot be formed (d)

图2 内相流速和外相流速对油核微胶囊直径和壁厚的影响:内相流速对微胶囊直径和壁厚的影响,外相流速保持10 ml/h不变(a);不同内相流速下生成的微胶囊实物图,外相流速保持10 ml/h不变(b);外相流速对微胶囊直径和壁厚的影响,内相流速保持0.5 ml/h不变(c);不同外相流速生成的微胶囊实物图,内相流速保持0.5 ml/h不变(d);高速相机拍摄的微胶囊形成过程(e)

Fig.2 Effect of inter phase flow rate and outer phase flow rate on the diameter and wall thickness of the oil-core microcapsules. Effect of inter phase flow rate on the diameter and wall thickness of the microcapsules, external phase flow rate remains constant at 10 ml/h (a). The physical map of the microcapsules generated at different inter phase flow rates, external phase flow rate remains constant at 10 ml/h (b). Effect of external phase flow rate on the diameter and wall thickness of the microcapsules, inter phase flow rate remains constant at 0.5 ml/h (c). The physical map of the microcapsules generated at different external phase flow rates, inter phase flow rate remains constant at 0.5 ml/h (d). The formation process of microcapsules captured by a high-speed camera (e)

图3 玻璃毛细管微流控器件结构对油核微胶囊的影响:内管管口与外管管口平齐的玻璃毛细管微流控器件(a); 管口平齐微流控器件制备微胶囊的相图(b);管口平齐微流控器件制备得到的多核微胶囊实物图(c);内管管口缩进外管管口的玻璃毛细管微流控器件(d);内管缩进外管微流控器件制备微胶囊的相图(e)

Fig.3 Effect of glass capillary microfluidic devices on the oil-core microcapsules. Glass capillary microfluidic device with inner tube orifice flush with outer tube orifice (a). Phase diagram of microcapsules prepared by microfluidic devices with flush nozzles (b). Physical image of multi-core microcapsules prepared by a flush nozzle microfluidic device (c). Glass capillary microfluidic device with inner tube orifice retracted into outer tube orifice (d). Phase diagram of microcapsules prepared by microfluidic device with inner tube retracted into outer tube (e)

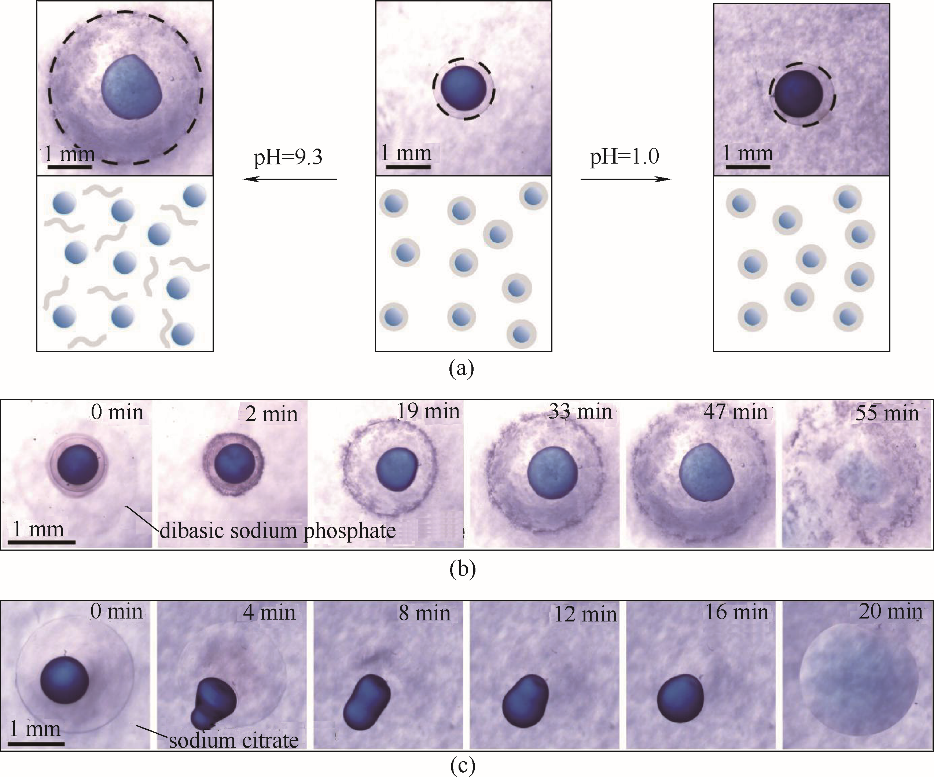

图4 生物相容油核微胶囊的pH响应和快速释放:油核微胶囊的pH响应(a);磷酸氢二钠激发油核微胶囊的快速释放(b);柠檬酸钠激发油核微胶囊的快速释放(c)

Fig.4 pH-triggered fast release of oil cores from biocompatible microcapsules. pH response of oil core microcapsules (a). Dibasic sodium phosphate stimulates rapid release of oil core microcapsules (b). Sodium citrate stimulates rapid release of oil core microcapsules (c)

图5 油核微胶囊的缓慢释放: 不同壁厚油核微胶囊中活性物质的缓慢释放曲线(a);不同壁厚油核微胶囊的实物图(b)

Fig.5 Sustained release of oil-core microcapsules. Sustained release curves of active substances in oil-core microcapsules with different wall thicknesses (a). Physical image of oil core microcapsules with different wall thicknesses (b)

| 1 | Amstad E. Capsules: their past and opportunities for their future[J]. ACS Macro Letters, 2017, 6(8): 841-847. |

| 2 | Zhang X P, Luo J, Zhang D X, et al. Porous microcapsules with tunable pore sizes provide easily controllable release and bioactivity[J]. Journal of Colloid and Interface Science, 2018, 517: 86-92. |

| 3 | Szczepanowicz K, Bazylińska U, Pietkiewicz J, et al. Biocompatible long-sustained release oil-core polyelectrolyte nanocarriers: from controlling physical state and stability to biological impact[J]. Advances in Colloid and Interface Science, 2015, 222: 678-691. |

| 4 | Dowding P J, Atkin R, Vincent B, et al. Oil core/polymer shell microcapsules by internal phase separation from emulsion droplets(Ⅱ): Controlling the release profile of active molecules[J]. Langmuir, 2005, 21(12): 5278-5284. |

| 5 | Kong L, Amstad E, Hai M, et al. Biocompatible microcapsules with a water core templated from single emulsions[J]. Chinese Chemical Letters, 2017, 28(9): 1897-1900. |

| 6 | Sun Z, Yang C J, Wang F, et al. Biocompatible and pH‐responsive colloidal surfactants with tunable shape for controlled interfacial curvature[J]. Angewandte Chemie International Edition, 2020, 59(24): 9365-9369. |

| 7 | Wagdare N A, Marcelis A T, Boom R M, et al. Microcapsules with a pH responsive polymer: influence of the encapsulated oil on the capsule morphology[J]. Colloids and Surfaces B: Biointerfaces, 2011, 88(1): 175-180. |

| 8 | Kong L L, Chen R, Wang X Z, et al. Controlled co-precipitation of biocompatible colorant-loaded nanoparticles by microfluidics for natural color drinks[J]. Lab on a Chip, 2019, 19(12): 2089-2095. |

| 9 | Ding T, Wang L, Zhang J, et al. Interfacially active polydopamine for nanoparticle stabilized nanocapsules in a one-pot assembly strategy toward efficient drug delivery [J]. Journal of Materials Chemistry B, 2018, 6(12): 1754-1763. |

| 10 | Song W, Das M, Xu Y, et al. Leveraging biomaterials for cancer immunotherapy: targeting pattern recognition receptors[J]. Materials Today Nano, 2019, 5: 100029. |

| 11 | Williams D F. Biocompatibility pathways in tissue-engineering templates[J]. Engineering, 2018, 4(2): 286-290. |

| 12 | Sun Z, Yang C, Eggersdorfer M, et al. A general strategy for one-step fabrication of biocompatible microcapsules with controlled active release[J]. Chinese Chemical Letters, 2020, 31(1): 249-252. |

| 13 | Lavanya M, Kathiravan T, Moses J, et al. Influence of spray-drying conditions on microencapsulation of fish oil and chia oil[J]. Drying Technology, 2020, 38(3): 279-292. |

| 14 | Wu B H, Yang C J, Li B, et al. Active encapsulation in biocompatible nanocapsules[J]. Small, 2020, 16(30): 2002716. |

| 15 | Mahdavi S A, Jafari S M, Ghorbani M, et al. Spray-drying microencapsulation of anthocyanins by natural biopolymers: a review[J]. Drying Technology, 2014, 32(5): 509-518. |

| 16 | Başyiğit B, Sağlam H, Ş Kandemir, et al. Microencapsulation of sour cherry oil by spray drying: evaluation of physical morphology, thermal properties, storage stability, and antimicrobial activity[J]. Powder Technology, 2020, 364: 654-663. |

| 17 | Wu L, Zhang M, Liu Y, et al. Characteristics and release of monosodium glutamate microcapsules obtained by spray drying[J]. Drying Technology, 2019, 37(11): 1340-1351. |

| 18 | 倪卓, 林煜豪, 黄苇颖, 等. 环氧树脂微胶囊合成及其反应动力学[J]. 化工学报, 2018, 69(4): 1790-1798. |

| Ni Z, Lin Y H, Huang W Y, et al, Preparation and reaction kinetics of epoxy resin microcapsules[J]. CIESC Journal, 2018, 69(4): 1790-1798. | |

| 19 | Sun Z, Wu B H, Ren Y X, et al. Diverse particle carriers prepared by co-precipitation and phase separation: formation and applications[J]. ChemPlusChem, 2020, 85: 1-11. |

| 20 | Abang S, Chan E S, Poncelet D. Effects of process variables on the encapsulation of oil in Ca-alginate capsules using an inverse gelation technique[J]. Journal of Microencapsulation, 2012, 29(5): 417-428. |

| 21 | Bremond N, Santanach-Carreras E, Chu L Y, et al. Formation of liquid-core capsules having a thin hydrogel membrane: liquid pearls[J]. Soft Matter, 2010, 6(11): 2484-2488. |

| 22 | Tsaur L S, Shen S, Aronson M P, et al. Compositions comprising capsule comprising oil surrounding hydrophobic or hydrophilic active and polymeric shell surrounding oil: US5441660[P]. 1995-08-15. |

| 23 | Samakradhamrongthai R S, Angeli P T, Kopermsub P, et al. Optimization of gelatin and gum arabic capsule infused with pandan flavor for multi-core flavor powder encapsulation[J]. Carbohydrate Polymers, 2019, 226: 115262. |

| 24 | Seiffert S. Microgel capsules tailored by droplet-based microfluidics[J]. ChemPhysChem, 2013, 14(2): 295-304. |

| 25 | Lensen D, Van Breukelen K, Vriezema D M, et al. Preparation of biodegradable liquid core PLLA microcapsules and hollow PLLA microcapsules using microfluidics[J]. Macromolecular Bioscience, 2010, 10(5): 475-480. |

| 26 | Liu C, Zheng W, Xie R, et al. Microfluidic fabrication of water-in-water droplets encapsulated in hydrogel microfibers[J]. Chinese Chemical Letters, 2019, 30(2): 457-460. |

| 27 | 蔡泉威, 巨晓洁, 谢锐, 等. 微流控技术可控制备异形微颗粒功能材料的研究进展[J]. 化工学报, 2019, 70(10): 3738-3747. |

| Cai Q W, Ju X J, Xie R, et al. Recent progress in controllable preparation of anisotropic microparticle functional materials based on microfluidics[J]. CIESC Journal, 2019, 70(10): 3738-3747. | |

| 28 | Zhao Y C, Chen G W, Yuan Q. Liquid-liquid two-phase flow patterns in a rectangular microchannel[J]. AIChE Journal, 2006, 52(12): 4052-4060. |

| 29 | Arriaga L, Amstad E, Weitz D. Scalable single-step microfluidic production of single-core double emulsions with ultra-thin shells[J]. Lab on a Chip, 2015, 15(16): 3335-3340. |

| 30 | Kong L L, Jin X Y, Hu D P, et al. Functional delivery vehicle of organic nanoparticles in inorganic crystals[J]. Chinese Chemical Letters, 2019, 30(12): 2351-2354. |

| 31 | Fang Z, Cao X R, Yu Y L, et al. Fabrication and characterization of microcapsule encapsulating EOR surfactants by microfluidic technique[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 570: 282-292. |

| 32 | Deng W, Guo H C, Li G A, et al. Fabrication of polymeric-laponite composite hollow microspheres via LBL assembly [J]. Chinese Chemical Letters, 2017, 28(2): 367-371. |

| 33 | Calvo P, Castaño Á L, Lozano M, et al. Influence of the microencapsulation on the quality parameters and shelf-life of extra-virgin olive oil encapsulated in the presence of BHT and different capsule wall components[J]. Food Research International, 2012, 45(1): 256-261. |

| 34 | Suryanarayana C, Rao K C, Kumar D. Preparation and characterization of microcapsules containing linseed oil and its use in self-healing coatings[J]. Progress in Organic Coatings, 2008, 63(1): 72-78. |

| 35 | Zhou T, Song Z, Sundmacher K. Big data creates new opportunities for materials research: a review on methods and applications of machine learning for materials design[J]. Engineering, 2019, 5(6): 1017-1026. |

| 36 | Chandran R, Chevva H, Zeng Z, et al. Solid-state synthesis of silver nanowires using biopolymer thin films[J]. Materials Today Nano, 2018, 1: 22-28. |

| 37 | Utada A S, Fernandez-Nieves A, Stone H A, et al. Dripping to jetting transitions in coflowing liquid streams[J]. Phys.Rev.Lett., 2007, 90(9):094502. |

| 38 | Geng Y, Ling S D, Huang J, et al. Multiphase microfluidics: fundamentals, fabrication, and functions[J]. Small, 2020, 16(6): 1906357. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 徐文杰, 贾献峰, 王际童, 乔文明, 凌立成, 王任平, 余子舰, 张寅旭. 有机硅/酚醛杂化气凝胶的制备和性能研究[J]. 化工学报, 2023, 74(8): 3572-3583. |

| [3] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [4] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [5] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [6] | 何宣志, 何永清, 闻桂叶, 焦凤. 磁液液滴颈部自相似破裂行为[J]. 化工学报, 2023, 74(7): 2889-2897. |

| [7] | 杨琴, 秦传鉴, 李明梓, 杨文晶, 赵卫杰, 刘虎. 用于柔性传感的双形状记忆MXene基水凝胶的制备及性能研究[J]. 化工学报, 2023, 74(6): 2699-2707. |

| [8] | 谢诗婷, 刘壮, 谢锐, 巨晓洁, 汪伟, 潘大伟, 褚良银. 聚(N-异丙基丙烯酰胺-共聚-烯丙基硫脲)智能微凝胶的制备及其Hg2+响应性能的研究[J]. 化工学报, 2023, 74(6): 2689-2698. |

| [9] | 范坤阳, 杨景兴, 许海波, 连兴容, 何凤梅, 陈聪慧, 李增耀. 遮光剂掺杂SiO2气凝胶传热的统一格子Boltzmann模型研究[J]. 化工学报, 2023, 74(5): 1974-1981. |

| [10] | 贾露凡, 王艺颖, 董钰漫, 李沁园, 谢鑫, 苑昊, 孟涛. 微流控双水相贴壁液滴流动强化酶促反应研究[J]. 化工学报, 2023, 74(3): 1239-1246. |

| [11] | 张雪婷, 胡激江, 赵晶, 李伯耿. 高分子量聚丙二醇在微通道反应器中的制备[J]. 化工学报, 2023, 74(3): 1343-1351. |

| [12] | 杨星宇, 马优, 朱春英, 付涛涛, 马友光. 梳状并行微通道内液液分布规律研究[J]. 化工学报, 2023, 74(2): 698-706. |

| [13] | 项星宇, 王忠东, 董艳鹏, 李守川, 朱春英, 马友光, 付涛涛. 微通道内屈服应力型流体的流变特性及多相流研究进展[J]. 化工学报, 2023, 74(2): 546-558. |

| [14] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [15] | 盛林, 昌宇, 邓建, 骆广生. 阶梯式T型微通道内有序气泡群的形成和流动特性研究[J]. 化工学报, 2023, 74(1): 416-427. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号