化工学报 ›› 2023, Vol. 74 ›› Issue (2): 690-697.DOI: 10.11949/0438-1157.20221061

何万媛1( ), 陈一宇1, 朱春英1, 付涛涛1, 高习群2, 马友光1(

), 陈一宇1, 朱春英1, 付涛涛1, 高习群2, 马友光1( )

)

收稿日期:2022-07-28

修回日期:2022-10-27

出版日期:2023-02-05

发布日期:2023-03-21

通讯作者:

马友光

作者简介:何万媛(1997—),女,硕士研究生,wanyuanhe@tju.edu.cn

基金资助:

Wanyuan HE1( ), Yiyu CHEN1, Chunying ZHU1, Taotao FU1, Xiqun GAO2, Youguang MA1(

), Yiyu CHEN1, Chunying ZHU1, Taotao FU1, Xiqun GAO2, Youguang MA1( )

)

Received:2022-07-28

Revised:2022-10-27

Online:2023-02-05

Published:2023-03-21

Contact:

Youguang MA

摘要:

研究了阵列凸起微通道内N-甲基二乙醇胺(MDEA)吸收CO2过程的气液两相传质特性。在弹状流型下,考察了气液两相流量、MDEA浓度对体积传质系数、CO2吸收效率、压力降以及能量损耗的影响。弹状气泡受到阵列凸起的挤压作用发生形变,促进了气液两相间的传质。与平滑通道相比,阵列凸起微通道在实验条件下具有更好CO2吸收效率。在相同的能量损耗时,阵列凸起微通道具有更大的体积传质系数。

中图分类号:

何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697.

Wanyuan HE, Yiyu CHEN, Chunying ZHU, Taotao FU, Xiqun GAO, Youguang MA. Study on gas-liquid mass transfer characteristics in microchannel with array bulges[J]. CIESC Journal, 2023, 74(2): 690-697.

| MDEA溶液浓度c/% | 密度 ρ/(kg·m-3) | 黏度 µ/(mPa·s) | 表面张力 σ / (mN·m-1) |

|---|---|---|---|

10 20 30 | 1005.4 1015.2 1025.0 | 1.290 1.941 3.092 | 59.30 55.20 53.00 |

表1 MDEA水溶液的物理性质

Table 1 Physical properties of MDEA aqueous solution

| MDEA溶液浓度c/% | 密度 ρ/(kg·m-3) | 黏度 µ/(mPa·s) | 表面张力 σ / (mN·m-1) |

|---|---|---|---|

10 20 30 | 1005.4 1015.2 1025.0 | 1.290 1.941 3.092 | 59.30 55.20 53.00 |

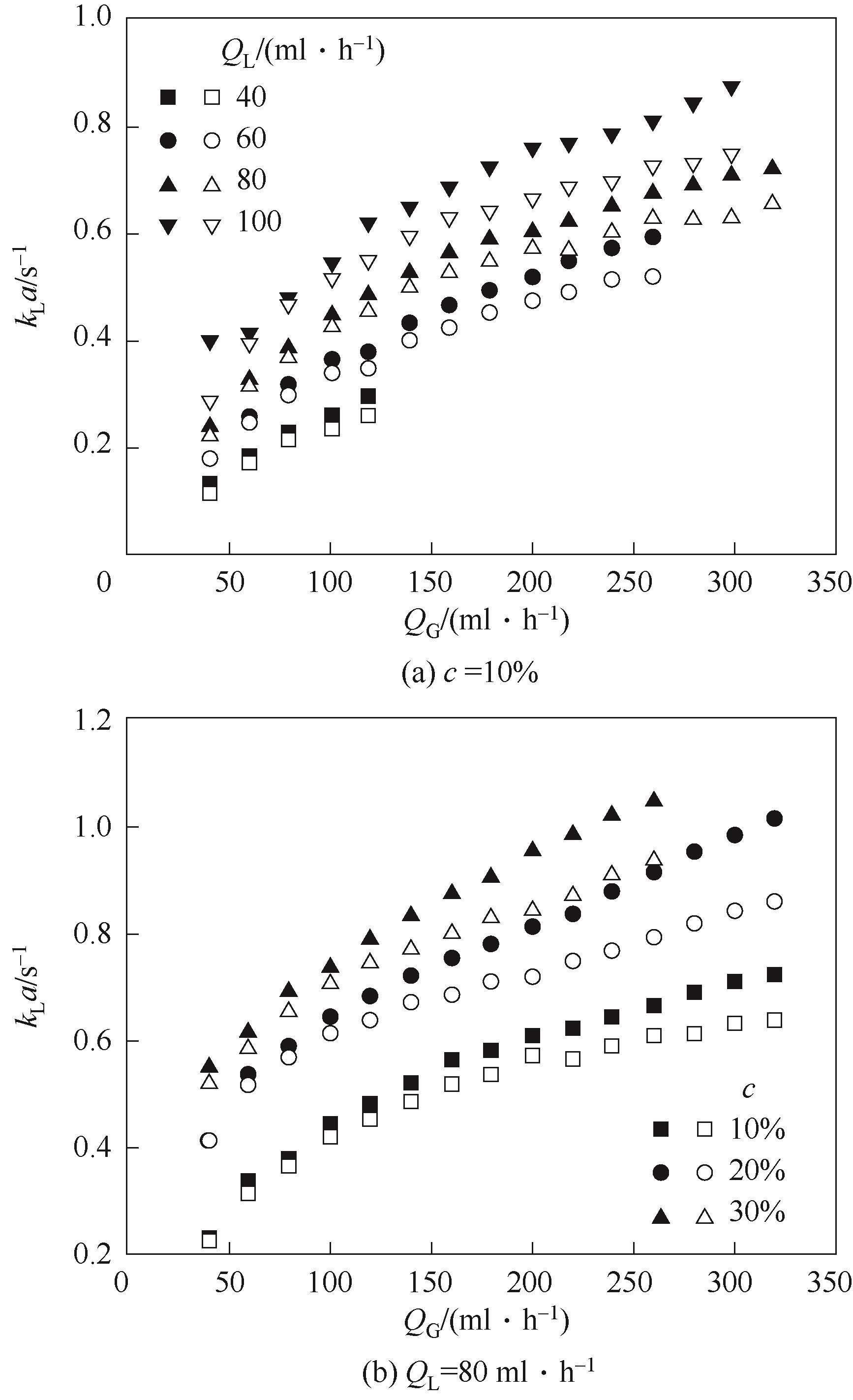

图4 气液相流量和MDEA浓度对液体体积传质系数kLa的影响 (实心符号表示阵列凸起的微通道,空心符号表示平滑通道)

Fig.4 Effects of gas and liquid flow rates and MDEA concentration on volumetric mass transfer coefficient kLa (solid symbols for the microchannel with array bulges, hollow symbols for non-array bulge microchannel)

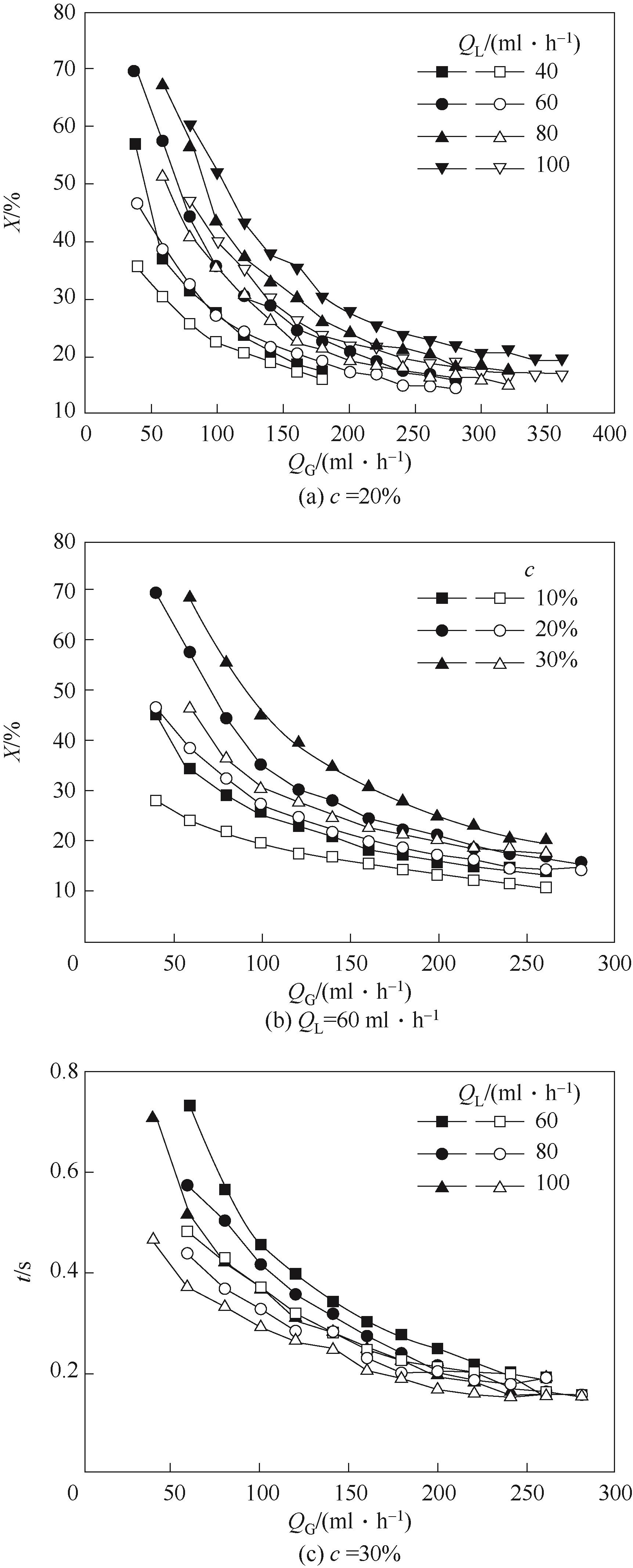

图5 气液相流量和MDEA浓度对CO2吸收效率的影响与气泡停留时间示意图 (实心符号表示阵列凸起的微通道,空心符号表示平滑通道)

Fig.5 The effect of gas and liquid flow rates and MDEA concentration on CO2 absorption efficiency and the bubble residence time (solid symbols for the microchannel with array bulges, hollow symbols for non-array bulge microchannel)

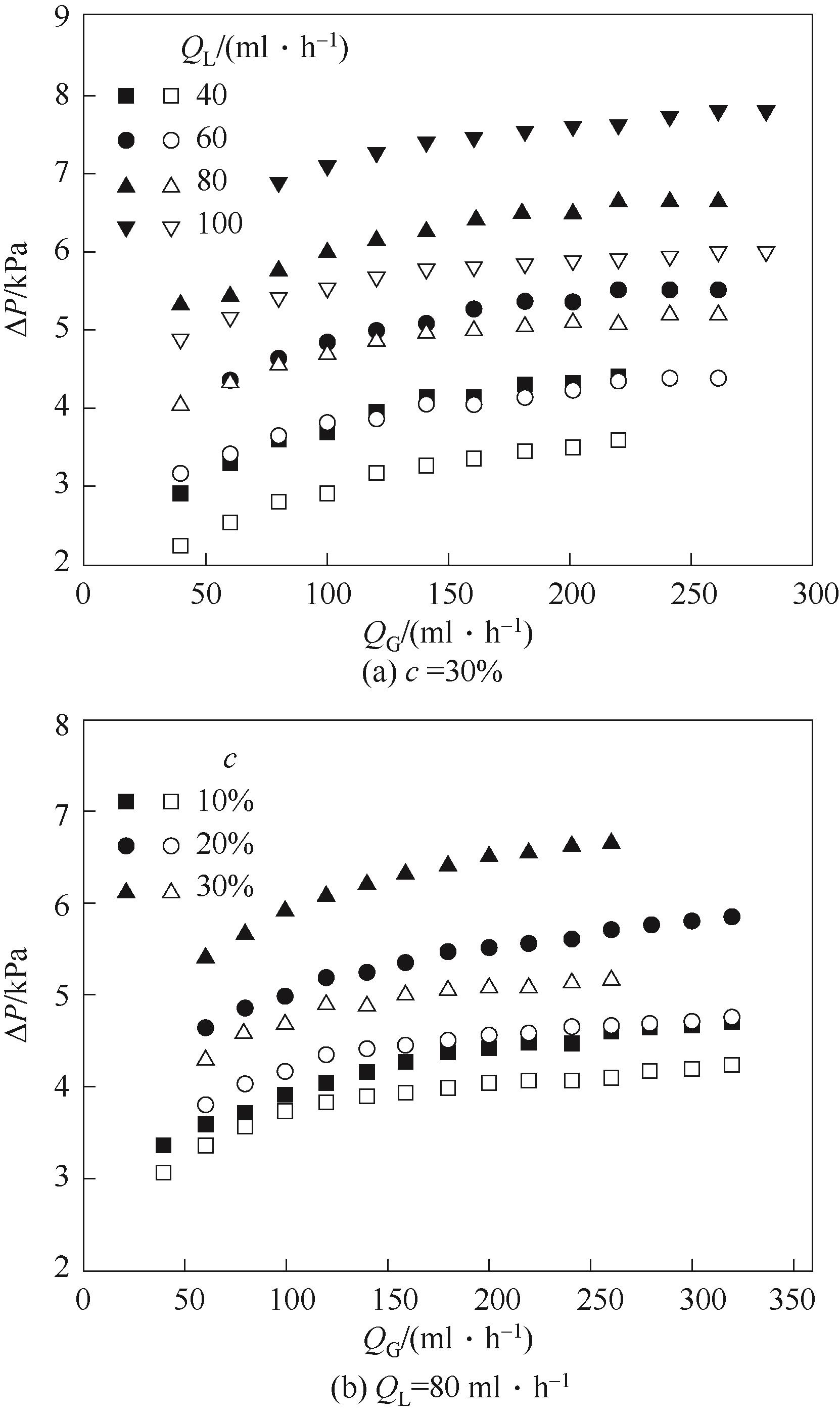

图6 气液相流量和MDEA浓度对压降ΔP的影响 (实心符号表示阵列凸起的微通道,空心符号表示平滑通道)

Fig.6 Effects of gas and liquid flow rates and MDEA concentration on pressure drop ΔP (solid symbols for the microchannel with array bulges, hollow symbols for non-array bulge microchannel)

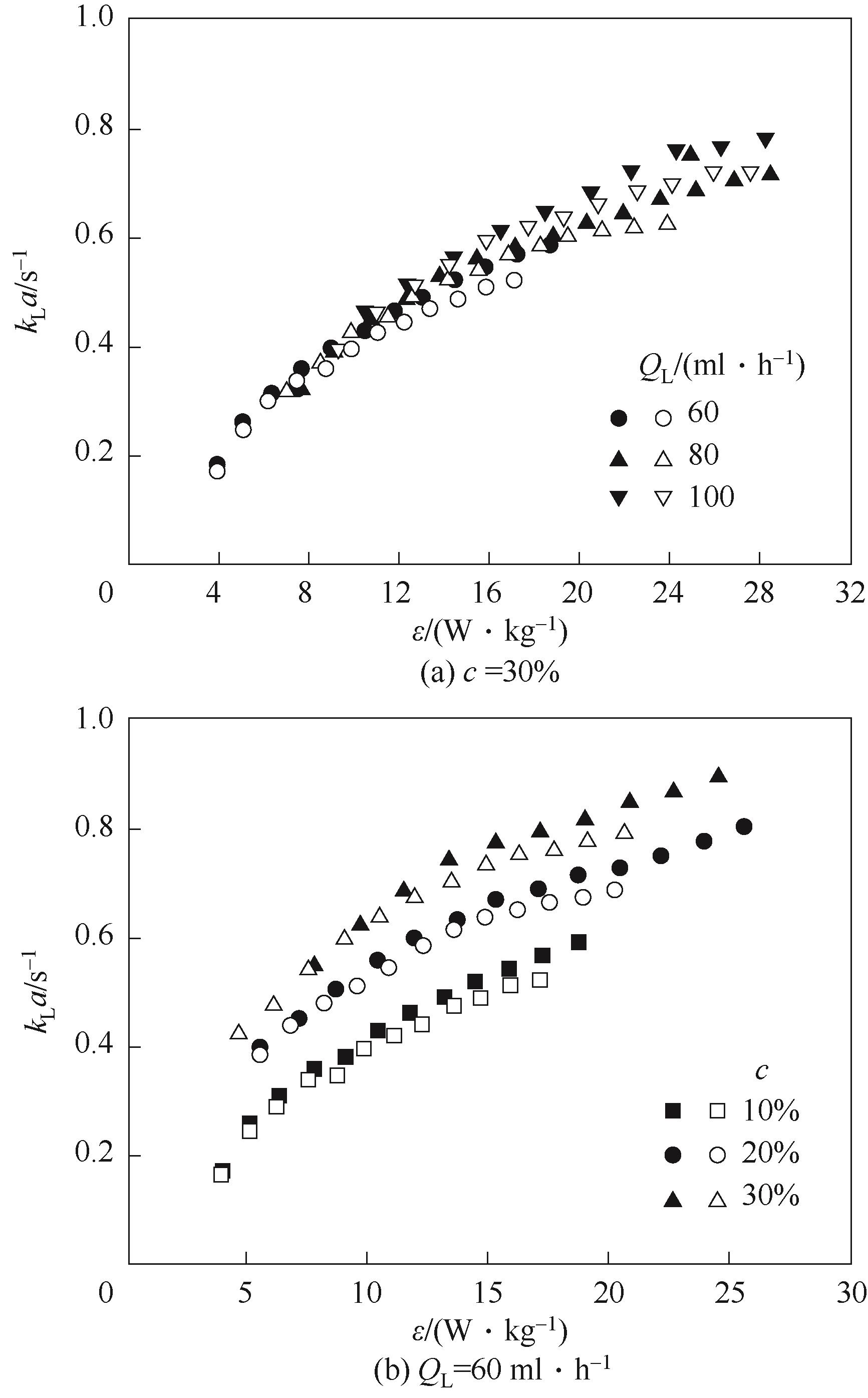

图7 液侧传质系数随能耗变化 (实心符号表示阵列凸起的微通道,空心符号表示平滑通道)

Fig.7 Relationship between liquid side volumetric mass transfer coefficient and energy consumption (solid symbols for the microchannel with array bulges, hollow symbols for non-array bulge microchannel)

| 1 | Abdollahi S A, Mokhtariyan N, Ameri E. Design of a solar reactor based on porous nanocomposite ceramics for removal of heavy metal ions from wastewater[J]. Solar Energy, 2022, 233: 61-70. |

| 2 | Dai L, Shan M J, Li J P, et al. Purification and reuse of carbon black wastewater of acetylene production from natural gas by microchannel filtration[J]. Process Safety and Environmental Protection, 2022, 162: 219-229. |

| 3 | Yao X J, Zhang Y, Du L Y, et al. Review of the applications of microreactors[J]. Renewable and Sustainable Energy Reviews, 2015, 47: 519-539. |

| 4 | Pan J, Zhang R, Lu Q B, et al. Experimental study on premixed methane-air catalytic combustion in rectangular micro channel[J]. Applied Thermal Engineering, 2017, 117: 1-7. |

| 5 | Chau J L H, Leung A Y L, Yeung K L. Zeolite micromembranes[J]. Lab on a Chip, 2003, 3(2): 53. |

| 6 | Kockmann N, Gottsponer M, Roberge D M. Scale-up concept of single-channel microreactors from process development to industrial production[J]. Chemical Engineering Journal, 2011, 167(2/3): 718-726. |

| 7 | Adamo A, Beingessner R L, Behnam M, et al. On-demand continuous-flow production of pharmaceuticals in a compact, reconfigurable system[J]. Science, 2016, 352(6281): 61-67. |

| 8 | Saber M, Commenge J M, Falk L. Microreactor numbering-up in multi-scale networks for industrial-scale applications: impact of flow maldistribution on the reactor performances[J]. Chemical Engineering Science, 2010, 65(1): 372-379. |

| 9 | Guo R W, Fu T T, Zhu C Y, et al. Flow distribution and mass transfer of gas-liquid flow in parallel microchannels with different tree-shaped distributors: halving-width versus constant-width[J]. Industrial & Engineering Chemistry Research, 2020, 59(3): 1327-1335. |

| 10 | Liu G T, Wang K, Lu Y C, et al. Liquid-liquid microflows and mass transfer performance in slit-like microchannels[J]. Chemical Engineering Journal, 2014, 258: 34-42. |

| 11 | Nieves-Remacha M J, Kulkarni A A, Jensen K F. OpenFOAM computational fluid dynamic simulations of single-phase flows in an advanced-flow reactor[J]. Industrial & Engineering Chemistry Research, 2015, 54(30): 7543-7553. |

| 12 | 王冠球, 林冠屹, 朱春英, 等. 微通道反应器的一维放大及气液传质特性[J]. 化工学报, 2021, 72(2): 937-944. |

| Wang G Q, Lin G Y, Zhu C Y, et al. One-dimensional amplification and gas-liquid mass transfer characteristics of microchannel reactor[J]. CIESC Journal, 2021, 72(2): 937-944. | |

| 13 | Wyss H M, Blair D L, Morris J F, et al. Mechanism for clogging of microchannels[J]. Physical Review E, 2007, 74(6): 061402. |

| 14 | Aubin J, Prat L, Xuereb C, et al. Effect of microchannel aspect ratio on residence time distributions and the axial dispersion coefficient[J]. Chemical Engineering and Processing: Process Intensification, 2009, 48(1): 554-559. |

| 15 | Liu Z D, Lu Y C, Wang J W, et al. Mixing characterization and scaling-up analysis of asymmetrical T-shaped micromixer: experiment and CFD simulation[J]. Chemical Engineering Journal, 2012, 181/182: 597-606. |

| 16 | Choi C W, Yu D I, Kim M H. Adiabatic two-phase flow in rectangular microchannels with different aspect ratios(part Ⅱ): Bubble behaviors and pressure drop in single bubble[J]. International Journal of Heat and Mass Transfer, 2010, 53(23/24): 5242-5249. |

| 17 | Hong S H, Tang Y L, Wang S F. Investigation on critical heat flux of flow boiling in parallel microchannels with large aspect ratio: experimental and theoretical analysis[J]. International Journal of Heat and Mass Transfer, 2018, 127: 55-66. |

| 18 | Wong H, Radke C J, Morris S. The motion of long bubbles in polygonal capillaries(part 2): Drag, fluid pressure and fluid flow[J]. Journal of Fluid Mechanics, 1995, 292: 95-110. |

| 19 | Jia H W, Zhang P. Investigation of the Taylor bubble under the effect of dissolution in microchannel[J]. Chemical Engineering Journal, 2016, 285: 252-263. |

| 20 | van Baten J M, Krishna R. CFD simulations of mass transfer from Taylor bubbles rising in circular capillaries[J]. Chemical Engineering Science, 2004, 59(12): 2535-2545. |

| 21 | 王宜飞, 王清强, 姬德生, 等. 微通道壁面浸润性对气-液两相流的影响规律研究[J]. 化工学报, 2022, 73(4): 1501-1514. |

| Wang Y F, Wang Q Q, Ji D S, et al. Effects of the wall wettability of microchannel on the gas-liquid two-phase flow hydrodynamics[J]. CIESC Journal, 2022, 73(4): 1501-1514. | |

| 22 | Seo H S, Kim Y J. A study on the mixing characteristics in a hybrid type microchannel with various obstacle configurations[J]. Materials Research Bulletin, 2012, 47(10): 2948-2951. |

| 23 | Yin Y R, Guo R W, Zhu C Y, et al. Enhancement of gas-liquid mass transfer in microchannels by rectangular baffles[J]. Separation and Purification Technology, 2020, 236: 116306. |

| 24 | Yang L, Shi Y X, Abolhasani M, et al. Characterization and modeling of multiphase flow in structured microreactors: a post microreactor case study[J]. Lab on a Chip, 2015, 15(15): 3232-3241. |

| 25 | Nieves-Remacha M J, Kulkarni A A, Jensen K F. Gas-liquid flow and mass transfer in an advanced-flow reactor[J]. Industrial & Engineering Chemistry Research, 2013, 52(26): 8996-9010. |

| 26 | Zhang S Z, Zhu C Y, Feng H S, et al. Intensification of gas-liquid two-phase flow and mass transfer in microchannels by sudden expansions[J]. Chemical Engineering Science, 2021, 229: 116040. |

| 27 | Naami A, Edali M, Sema T, et al. Mass transfer performance of CO2 absorption into aqueous solutions of 4-diethylamino-2-butanol, monoethanolamine, and N-methyldiethanolamine[J]. Industrial & Engineering Chemistry Research, 2012, 51(18): 6470-6479. |

| 28 | Mandal B P, Kundu M, Padhiyar N U, et al. Physical solubility and diffusivity of N2O and CO2 into aqueous solutions of (2-amino-2-methyl-1-propanol + diethanolamine) and (N-methyldiethanolamine + diethanolamine)[J]. Journal of Chemical & Engineering Data, 2004, 49(2): 264-270. |

| 29 | Haimour N, Sandall O C. Absorption of carbon dioxide into aqueous methyldiethanolamine[J]. Chemical Engineering Science, 1984, 39(12): 1791-1796. |

| 30 | Musterd M, van Steijn V, Kleijn C R, et al. Calculating the volume of elongated bubbles and droplets in microchannels from a top view image[J]. RSC Advances, 2015, 5(21): 16042-16049. |

| 31 | Jakiela S, Korczyk P M, Makulska S, et al. Discontinuous transition in a laminar fluid flow: a change of flow topology inside a droplet moving in a micron-size channel[J]. Physical Review Letters, 2012, 108(13): 134501. |

| 32 | Kreutzer M T, Kapteijn F, Moulijn J A, et al. Multiphase monolith reactors: chemical reaction engineering of segmented flow in microchannels[J]. Chemical Engineering Science, 2005, 60(22): 5895-5916. |

| 33 | Abiev R S. Modeling of pressure losses for the slug flow of a gas-liquid mixture in mini- and microchannels[J]. Theoretical Foundations of Chemical Engineering, 2011, 45(2): 156-163. |

| 34 | Abiev R S. Analysis of local pressure gradient inversion and form of bubbles in Taylor flow in microchannels[J]. Chemical Engineering Science, 2017, 174: 403-412. |

| 35 | Liu Z M, Zhang L X, Pang Y, et al. Micro-PIV investigation of the internal flow transitions inside droplets traveling in a rectangular microchannel[J]. Microfluidics and Nanofluidics, 2017, 21(12): 1-8. |

| 36 | Li S W, Xu J H, Wang Y J, et al. Liquid-liquid two-phase flow in pore array microstructured devices for scaling-up of nanoparticle preparation[J]. AIChE Journal, 2009, 55(12): 3041-3051. |

| 37 | Potdar A, Protasova L N, Thomassen L, et al. Designed porous milli-scale reactors with enhanced interfacial mass transfer in two-phase flows[J]. Reaction Chemistry & Engineering, 2017, 2(2): 137-148. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [3] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [4] | 代宝民, 王启龙, 刘圣春, 张佳宁, 李鑫海, 宗凡迪. 非共沸工质辅助过冷CO2冷热联供系统的热力学性能分析[J]. 化工学报, 2023, 74(S1): 64-73. |

| [5] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [6] | 杨天阳, 邹慧明, 周晖, 王春磊, 田长青. -30℃电动汽车补气式CO2热泵制热性能实验研究[J]. 化工学报, 2023, 74(S1): 272-279. |

| [7] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [8] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [9] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [10] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [11] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [12] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [13] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [14] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [15] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号