化工学报 ›› 2023, Vol. 74 ›› Issue (S1): 235-244.DOI: 10.11949/0438-1157.20221614

收稿日期:2022-11-15

修回日期:2022-12-25

出版日期:2023-06-05

发布日期:2023-09-27

通讯作者:

袁俊飞

作者简介:江河(1997—),男,硕士研究生,1031456669@qq.com

基金资助:

He JIANG( ), Junfei YUAN(

), Junfei YUAN( ), Lin WANG, Guyu XING

), Lin WANG, Guyu XING

Received:2022-11-15

Revised:2022-12-25

Online:2023-06-05

Published:2023-09-27

Contact:

Junfei YUAN

摘要:

以R134a制冷剂为工质,在质量流率为416~728 kg/(m2·s),基面热通量为36.7~242.6 kW/m2条件下,研究了方形均流腔和圆弧均流腔微细通道换热器内两相流型的变化规律以及不同条件下微通道的压降特性、压力波动特性与传热特性。结果表明:两种均流腔结构的微通道内流型过渡是相似的,在弹状流型时均观察到了流动逆转现象;相比于方形均流腔微通道,圆弧均流腔微通道的压降更低,压力波动幅度更小,且具有更高的传热系数。在热通量为242.6 kW/m2,质量流率为416 kg/(m2·s)条件下,压降降低了51%;在热通量为154.4 kW/m2,质量流率为416 kg/(m2·s)时,出口压力波动幅度降低了35%;当热通量为242.6 kW/m2,质量流率为728 kg/(m2·s) 时,微细流道末端的传热系数提高了9.7%。

中图分类号:

江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244.

He JIANG, Junfei YUAN, Lin WANG, Guyu XING. Experimental study on the effect of flow sharing cavity structure on phase change flow characteristics in microchannels[J]. CIESC Journal, 2023, 74(S1): 235-244.

| 均流腔结构 | Hch/μm | Wch/μm | Wf/μm | Nch/条 | Wb×Lb/mm | Wpl1/mm | Wpl2/mm | Wpl3/mm | R/mm |

|---|---|---|---|---|---|---|---|---|---|

| 方形均流腔 | 400 | 400 | 400 | 9 | 6.8×20 | 20 | 20 | 20 | — |

| 圆弧均流腔 | 400 | 400 | 400 | 9 | 6.8×20 | 20 | 10 | 6.8 | 10.9 |

表1 热沉几何尺寸

Table 1 Heat sink geometry size

| 均流腔结构 | Hch/μm | Wch/μm | Wf/μm | Nch/条 | Wb×Lb/mm | Wpl1/mm | Wpl2/mm | Wpl3/mm | R/mm |

|---|---|---|---|---|---|---|---|---|---|

| 方形均流腔 | 400 | 400 | 400 | 9 | 6.8×20 | 20 | 20 | 20 | — |

| 圆弧均流腔 | 400 | 400 | 400 | 9 | 6.8×20 | 20 | 10 | 6.8 | 10.9 |

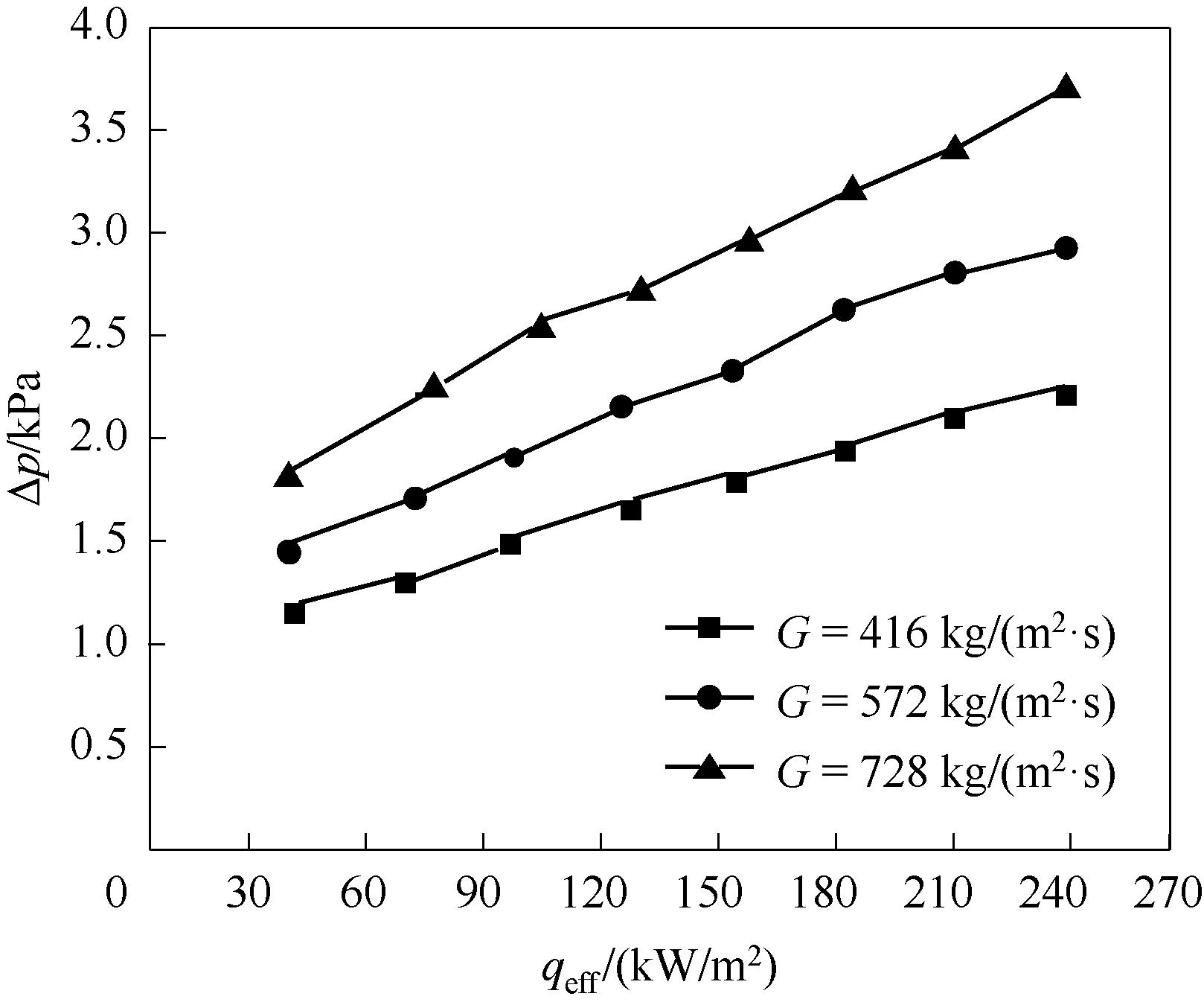

图7 不同质量流率下,圆弧均流腔微通道的压降随热通量的变化

Fig.7 Under different mass flow rates, the pressure drop of the microchannels in the circular-arc flow sharing cavity changes with the heat flux

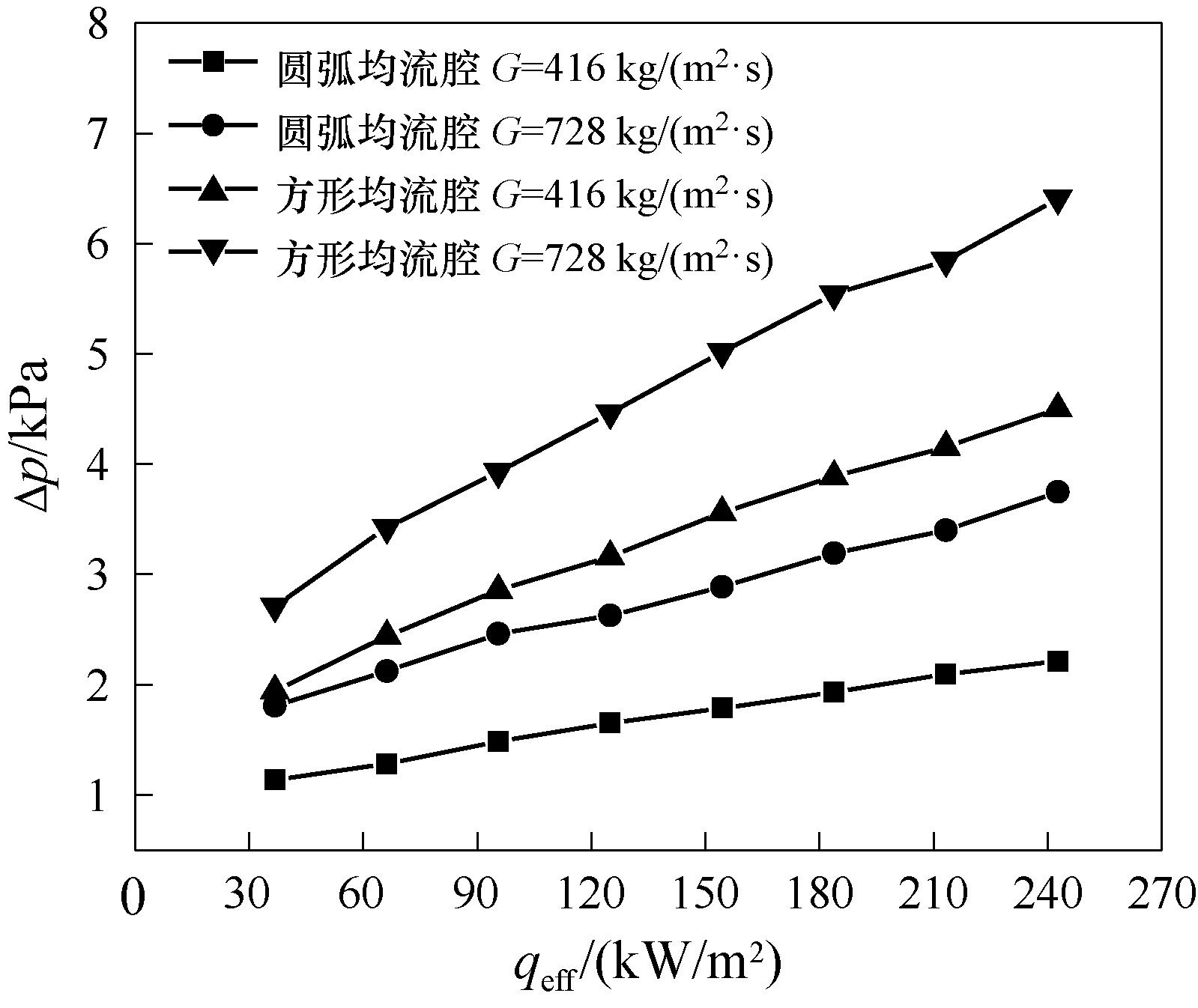

图8 不同质量流率下,圆弧均流腔微通道和方形均流腔微通道的压降随热通量的变化

Fig.8 Under different mass flow rates, the pressure drop of circular-arc and square flow sharing cavity microchannels varies with the heat flux

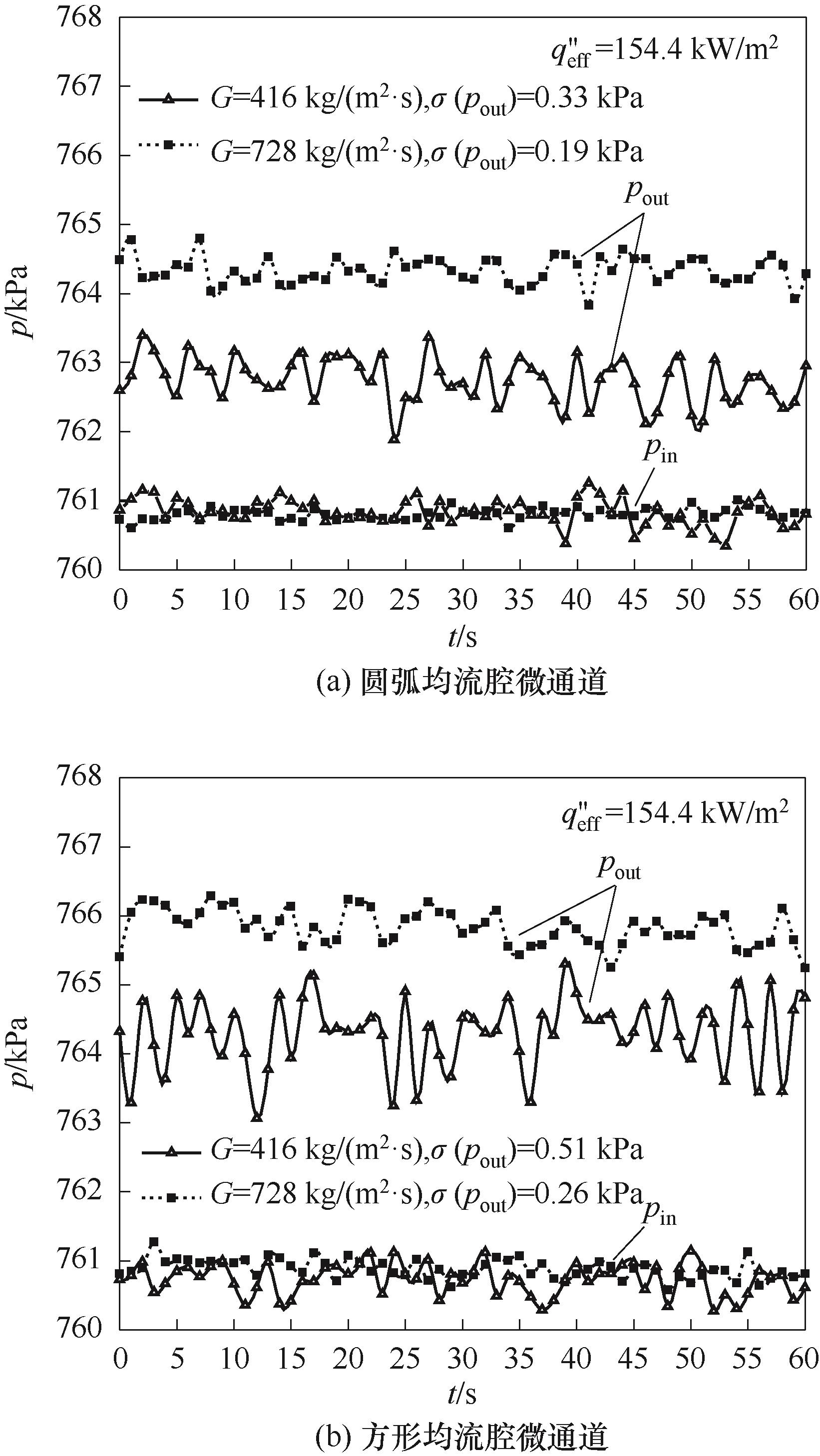

图9 热通量为154.4 kW/m2时,不同均流腔结构对通道进出口压力波动的影响

Fig.9 When the heat flux is 154.4 kW/m2, the influence of different flow sharing cavity structures on the pressure fluctuation at the inlet and outlet of the microchannels

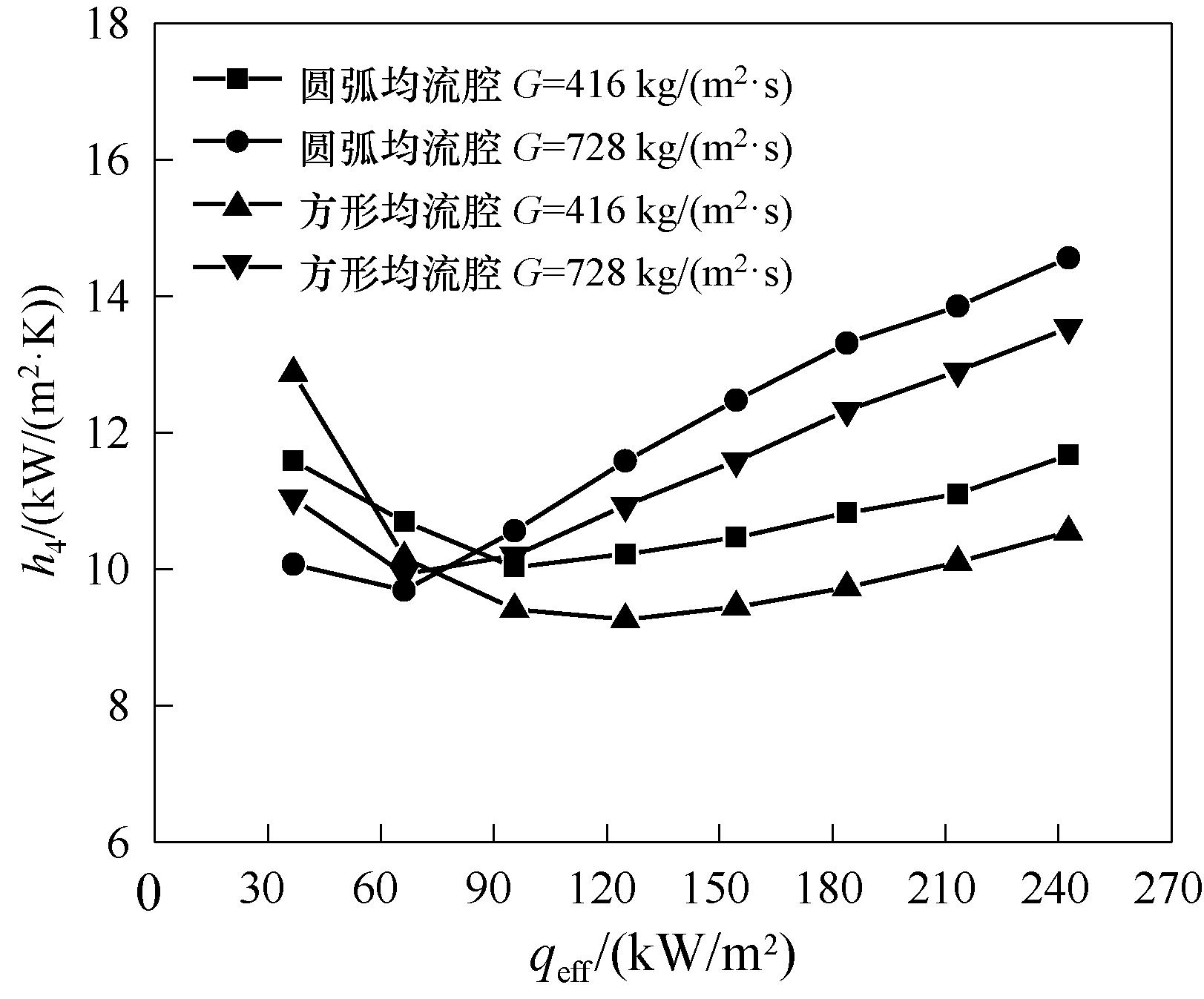

图10 不同质量流率下,圆弧均流腔微通道和方形均流腔微通道的传热系数随热通量的变化

Fig.10 Under different mass flow rates, the heat transfer coefficient of circular-arc and square flow sharing cavity microchannels varies with heat flux

| 1 | Deng D X, Zeng L, Sun W. A review on flow boiling enhancement and fabrication of enhanced microchannels of microchannel heat sinks[J]. International Journal of Heat and Mass Transfer, 2021, 175: 121332. |

| 2 | Prajapati Y K, Bhandari P. Flow boiling instabilities in microchannels and their promising solutions—a review[J]. Experimental Thermal and Fluid Science, 2017, 88: 576-593. |

| 3 | O'Neill L E, Mudawar I. Review of two-phase flow instabilities in macro- and micro-channel systems[J]. International Journal of Heat and Mass Transfer, 2020, 157: 119738. |

| 4 | Liu H D, Liu W, Chen D Q, et al. Experimental investigation on flow oscillation of boiling two-phase flow in a single rod channel[J]. Annals of Nuclear Energy, 2021, 158: 108281. |

| 5 | Kingston T A, Weibel J A, Garimella S V. High-frequency thermal-fluidic characterization of dynamic microchannel flow boiling instabilities(part 2): Impact of operating conditions on instability type and severity[J]. International Journal of Multiphase Flow, 2018, 106: 189-201. |

| 6 | Kuo C J, Peles Y. Pressure effects on flow boiling instabilities in parallel microchannels[J]. International Journal of Heat and Mass Transfer, 2009, 52(1/2): 271-280. |

| 7 | Chen S T, Chen X Y, Luo G Q, et al. Flow boiling instability of liquid nitrogen in horizontal mini channels[J]. Applied Thermal Engineering, 2018, 144: 812-824. |

| 8 | Zhang L, Wang Y F, Yu Z T. Experimental study of flow boiling instabilities in horizontal tubes under gas-liquid stratification condition: effects of heat flux and inlet subcooling degree[J]. International Journal of Heat and Mass Transfer, 2018, 118: 1040-1045. |

| 9 | Cheng K, Meng T, Tian C P, et al. Experimental investigation on flow characteristics of pressure drop oscillations in a closed natural circulation loop[J]. International Journal of Heat and Mass Transfer, 2018, 122: 1162-1171. |

| 10 | Qu W L, Mudawar I. Measurement and prediction of pressure drop in two-phase micro-channel heat sinks[J]. International Journal of Heat and Mass Transfer, 2003, 46(15): 2737-2753. |

| 11 | Oudah S K, Fang R, Tikadar A, et al. An experimental investigation of the effect of multiple inlet restrictors on the heat transfer and pressure drop in a flow boiling microchannel heat sink[J]. International Journal of Heat and Mass Transfer, 2020, 153: 119582. |

| 12 | Li Y F, Xia G D, Jia Y T, et al. Experimental investigation of flow boiling performance in microchannels with and without triangular cavities—a comparative study[J]. International Journal of Heat and Mass Transfer, 2017, 108: 1511-1526. |

| 13 | Zeng J, Zhang S W, Tang Y, et al. Flow boiling characteristics of micro-grooved channels with reentrant cavity array at different operational conditions[J]. International Journal of Heat and Mass Transfer, 2017, 114: 1001-1012. |

| 14 | Raj S, Shukla A, Pathak M, et al. A novel stepped microchannel for performance enhancement in flow boiling[J]. International Journal of Heat and Mass Transfer, 2019, 144: 118611. |

| 15 | Xia G D, Tang Y X, Zong L X, et al. Experimental investigation of flow boiling characteristics in microchannels with the sinusoidal wavy sidewall[J]. International Communications in Heat and Mass Transfer, 2019, 101: 89-102. |

| 16 | Prajapati Y K, Pathak M, Khan M K. Bubble dynamics and flow boiling characteristics in three different microchannel configurations[J]. International Journal of Thermal Sciences, 2017, 112: 371-382. |

| 17 | Zhang S W, Tang Y, Yuan W, et al. A comparative study of flow boiling performance in the interconnected microchannel net and rectangular microchannels[J]. International Journal of Heat and Mass Transfer, 2016, 98: 814-823. |

| 18 | Ma J X, Li W M, Ren C C, et al. Realizing highly coordinated, rapid and sustainable nucleate boiling in microchannels on HFE-7100[J]. International Journal of Heat and Mass Transfer, 2019, 133: 1219-1229. |

| 19 | Zong L X, Xia G D, Jia Y T, et al. Flow boiling instability characteristics in microchannels with porous-wall[J]. International Journal of Heat and Mass Transfer, 2020, 146: 118863. |

| 20 | Ghosh D P, Sharma D, Mohanty D, et al. Facile fabrication of nanostructured microchannels for flow boiling heat transfer enhancement[J]. Heat Transfer Engineering, 2019, 40(7): 537-548. |

| 21 | Yang F H, Dai X M, Peles Y, et al. Flow boiling phenomena in a single annular flow regime in microchannels (Ⅰ): Characterization of flow boiling heat transfer[J]. International Journal of Heat and Mass Transfer, 2014, 68: 703-715. |

| 22 | Alam T, Li W M, Chang W, et al. A comparative study of flow boiling HFE-7100 in silicon nanowire and plainwall microchannels[J]. International Journal of Heat and Mass Transfer, 2018, 124: 829-840. |

| 23 | Kandlikar S G, Kuan W K, Willistein D A, et al. Stabilization of flow boiling in microchannels using pressure drop elements and fabricated nucleation sites[J]. Journal of Heat Transfer, 2006, 128(4): 389-396. |

| 24 | Jones R J, Pate D T, Thiagarajan N, et al. Heat transfer and pressure drop characteristics in dielectric flow in surface-augmented microchannels[J]. Journal of Enhanced Heat Transfer, 2009, 16(3): 225-236. |

| 25 | Lin J Z, Yang H L. A review on the flow instability of nanofluids[J]. Applied Mathematics and Mechanics, 2019, 40(9): 1227-1238. |

| 26 | Liang G T, Mudawar I. Review of single-phase and two-phase nanofluid heat transfer in macro-channels and micro-channels[J]. International Journal of Heat and Mass Transfer, 2019, 136: 324-354. |

| 27 | Sharma D, Ghosh D P, Saha S K, et al. Thermohydraulic characterization of flow boiling in a nanostructured microchannel heat sink with vapor venting manifold[J]. International Journal of Heat and Mass Transfer, 2019, 130: 1249-1259. |

| 28 | Hedau G, Raj R, Saha S K. Effect of outlet plenum design on flow boiling heat transfer in microchannel heat sinks[J]. Thermal Science and Engineering Progress, 2021, 23: 100868. |

| 29 | Taitel Y, Barnea D, Dukler A E. Modelling flow pattern transitions for steady upward gas‐liquid flow in vertical tubes[J]. AIChE Journal, 1980, 26(3): 345-354. |

| 30 | Lee W H. Pressure iteration scheme for two-phase flow modeling[J]//Zn “Multiphase Trans Port: Fundamentals, Reactor Safety, Applications”, 1980, 1: 407-431. |

| [1] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [2] | 陈超伟, 柳洋, 杜文静, 李金波, 史大阔, 辛公明. 局部热点下微肋通道流动传热特性[J]. 化工学报, 2024, 75(9): 3113-3121. |

| [3] | 王皓宇, 杨杨, 荆文婕, 杨斌, 唐雨, 刘毅. 不同旋流器作用下气液螺旋环状流动特性研究[J]. 化工学报, 2024, 75(8): 2744-2755. |

| [4] | 朱子良, 王爽, 姜宇昂, 林梅, 王秋旺. 欧拉-拉格朗日迭代固-液相变算法[J]. 化工学报, 2024, 75(8): 2763-2776. |

| [5] | 赵亮, 李雨桥, 张德, 沈胜强. 螺旋喷嘴内外流场特性的实验研究[J]. 化工学报, 2024, 75(8): 2777-2786. |

| [6] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [7] | 曲玖哲, 杨鹏, 杨绪飞, 张伟, 宇波, 孙东亮, 王晓东. 硅基微柱簇阵列微通道流动沸腾实验研究[J]. 化工学报, 2024, 75(8): 2840-2851. |

| [8] | 李彦熹, 王晔春, 谢向东, 王进芝, 王江, 周煜, 潘盈秀, 丁文涛, 郭烈锦. 蜗壳式多通道气液旋流分离器结构优化及分离特性研究[J]. 化工学报, 2024, 75(8): 2875-2885. |

| [9] | 杨明军, 巩广军, 郑嘉男, 宋永臣. 泥质低渗水合物降压开采特性与模型研究[J]. 化工学报, 2024, 75(8): 2909-2916. |

| [10] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [11] | 董可豪, 周敬之, 周峰, 陈海家, 淮秀兰, 李栋. 超薄空间复杂边界条件下气体流动压降实验[J]. 化工学报, 2024, 75(7): 2505-2521. |

| [12] | 方立昌, 李梓龙, 陈博, 苏政, 贾莉斯, 王智彬, 陈颖. 基于相变微胶囊悬浮液的芯片阵列冷却特性研究[J]. 化工学报, 2024, 75(7): 2455-2464. |

| [13] | 吴邦汉, 林定标, 陆海峰, 郭晓镭, 刘海峰. 竖直管气动物流传输系统管道压降和传送瓶输送特性[J]. 化工学报, 2024, 75(7): 2465-2473. |

| [14] | 赵赫, 费滢洁, 朱春英, 付涛涛, 马友光. 高黏体系中纳米颗粒稳定气泡的形变及破裂行为[J]. 化工学报, 2024, 75(6): 2180-2189. |

| [15] | 李新泽, 张双星, 杨洪海, 杜文静. 基于电池冷却用新型脉动热管性能的实验研究[J]. 化工学报, 2024, 75(6): 2222-2232. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号