化工学报 ›› 2023, Vol. 74 ›› Issue (7): 3103-3115.DOI: 10.11949/0438-1157.20230320

吴文涛1( ), 褚良永1(

), 褚良永1( ), 张玲洁2, 谭伟民3, 沈丽明1, 暴宁钟1(

), 张玲洁2, 谭伟民3, 沈丽明1, 暴宁钟1( )

)

收稿日期:2023-04-04

修回日期:2023-07-05

出版日期:2023-07-05

发布日期:2023-08-31

通讯作者:

褚良永,暴宁钟

作者简介:吴文涛(1997—),男,硕士研究生,202061104097@njtech.edu.cn

基金资助:

Wentao WU1( ), Liangyong CHU1(

), Liangyong CHU1( ), Lingjie ZHANG2, Weimin TAN3, Liming SHEN1, Ningzhong BAO1(

), Lingjie ZHANG2, Weimin TAN3, Liming SHEN1, Ningzhong BAO1( )

)

Received:2023-04-04

Revised:2023-07-05

Online:2023-07-05

Published:2023-08-31

Contact:

Liangyong CHU, Ningzhong BAO

摘要:

生物基微胶囊的高效制备,对于生物基自愈合涂层的发展意义重大。针对传统石油基表面活性剂无法有效封装腰果酚基树脂及固化剂等愈合剂的难题,报道了以腰果酚基表面活性剂为乳化剂,通过溶剂蒸发法,高效制备聚甲基丙烯酸甲酯为外壳的生物基微胶囊的方法。结合溶剂蒸发法机理,提出了假说解释腰果酚基乳化剂的高效封装机制。通过SEM、TGA、粒径分析等表征方法研究了乳化剂浓度、芯壁比、转速、温度等工艺参数对微胶囊形貌、尺寸、稳定性的影响,确立粒径可控、单分散和规则球形的微胶囊制备工艺。研究表明蒸发温度40℃、芯壁比1∶1时制备的微胶囊具有较好的表面形貌,乳化剂浓度、转速与平均粒径之间存在规律性影响,并且埋植20%(质量)生物基微胶囊的自愈合涂层的愈合效率达到61.25%。报道的基于腰果酚基表面活性剂的生物基微胶囊的高效制备,对于生物基自愈合涂层的开发,推动生物基涂层对石油基的取代,具有指导意义。

中图分类号:

吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115.

Wentao WU, Liangyong CHU, Lingjie ZHANG, Weimin TAN, Liming SHEN, Ningzhong BAO. High-efficient preparation of cardanol-based self-healing microcapsules[J]. CIESC Journal, 2023, 74(7): 3103-3115.

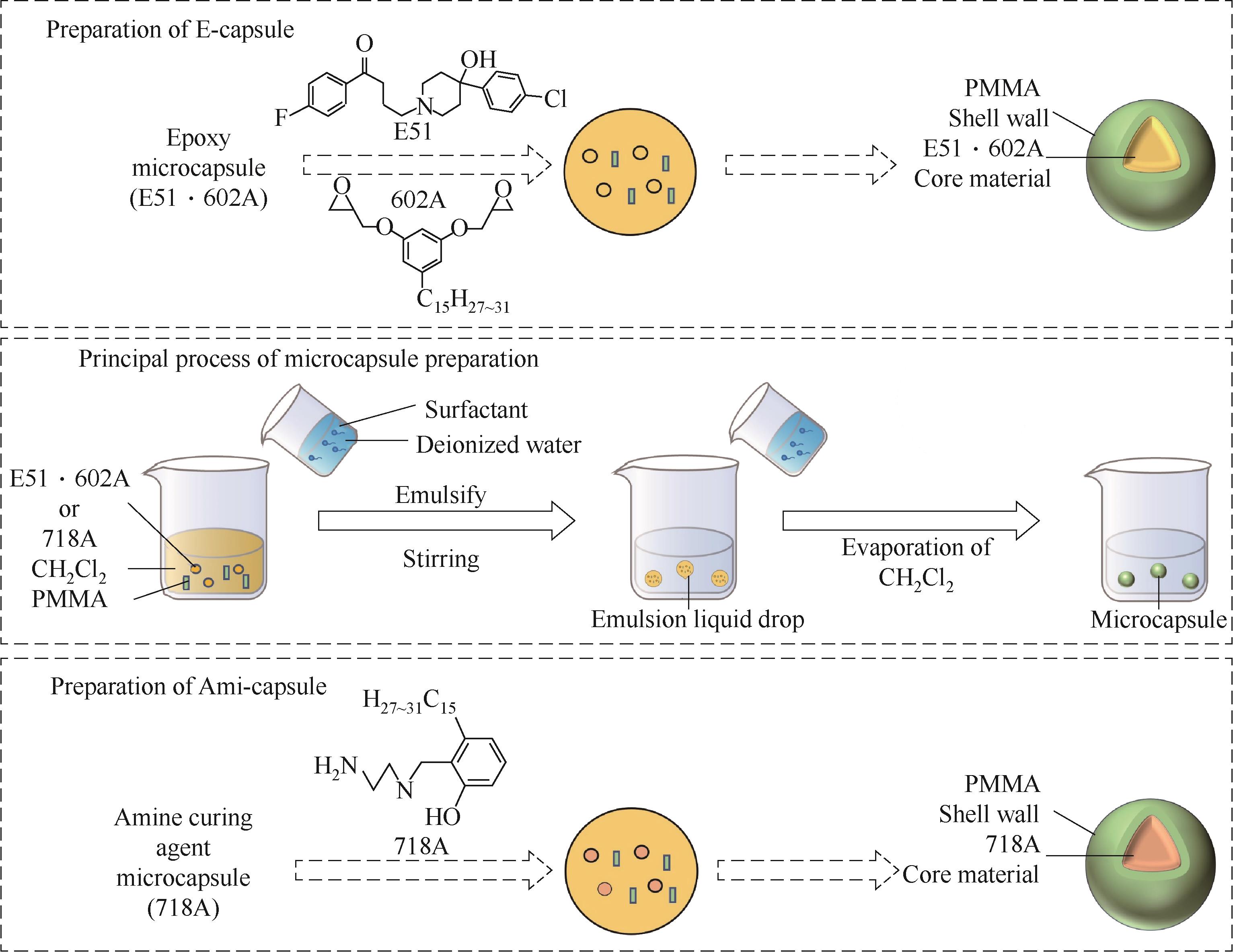

图1 生物基微胶囊E-capsule和Ami-capsule的合成工艺和结构示意图

Fig.1 Schematic diagram of the synthesis process and structure of bio-based microcapsules E-capsule and Ami-capsule

| 乳化剂 | 原材料类型 | HLB值 | pH |

|---|---|---|---|

| 聚乙烯醇(PVA) | 石油基 | 12.3 | 5.0~7.0 |

| 十二烷基硫酸钠(SDS) | 石油基 | 15 | 6.0~9.0 |

| 腰果酚基表面活性剂NSF3007C | 生物基 | 10.8 | 4.0~7.0 |

表1 乳化剂性质

Table 1 The properties of the emulsifier

| 乳化剂 | 原材料类型 | HLB值 | pH |

|---|---|---|---|

| 聚乙烯醇(PVA) | 石油基 | 12.3 | 5.0~7.0 |

| 十二烷基硫酸钠(SDS) | 石油基 | 15 | 6.0~9.0 |

| 腰果酚基表面活性剂NSF3007C | 生物基 | 10.8 | 4.0~7.0 |

| 序号 | 工艺参数 | 基础水平 | 最终水平 |

|---|---|---|---|

| 1 | 蒸发温度/℃ | 20 | 80 |

| 2 | 乳化剂浓度/%(质量) | 1 | 5 |

| 3 | 转速/(r/min) | 2000 | 3500 |

| 4 | 芯壁比 | 1∶2 | 3∶1 |

表2 影响微胶囊制备的工艺参数

Table 2 Process parameters affecting the preparation of microcapsules

| 序号 | 工艺参数 | 基础水平 | 最终水平 |

|---|---|---|---|

| 1 | 蒸发温度/℃ | 20 | 80 |

| 2 | 乳化剂浓度/%(质量) | 1 | 5 |

| 3 | 转速/(r/min) | 2000 | 3500 |

| 4 | 芯壁比 | 1∶2 | 3∶1 |

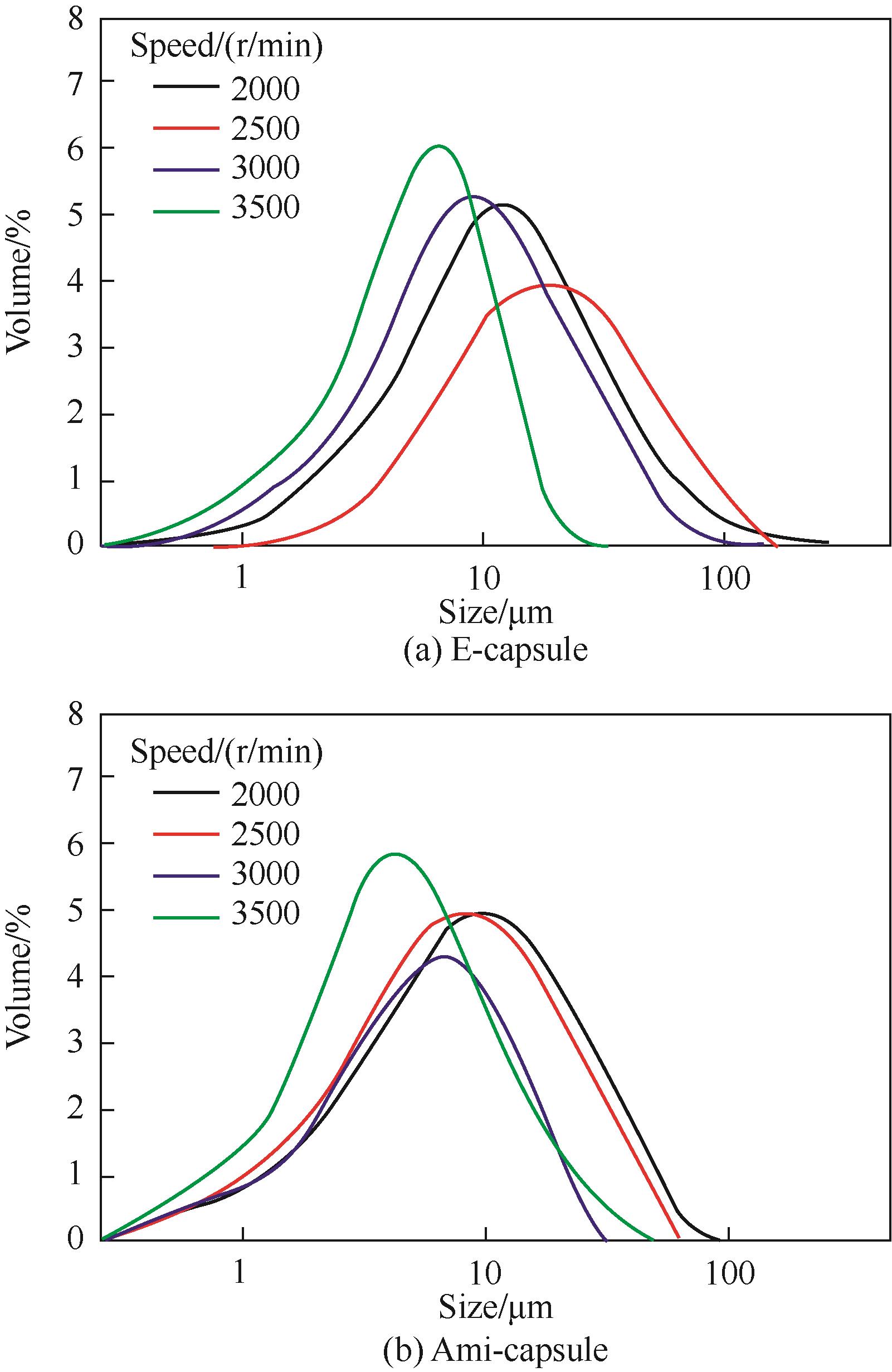

图9 不同搅拌速度下以NSF3007C为乳化剂制备的微胶囊的粒径分布

Fig.9 Particle size distribution of microcapsules prepared with NSF3007C as emulsifier at different stirring speeds

| 温度/℃ | 质量损失/% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 芯壁比 | 转速/(r/min) | 乳化剂浓度/%(质量) | |||||||||||

| 1∶2 | 1∶1 | 2∶1 | 3∶1 | 2000 | 2500 | 3000 | 3500 | 1 | 2 | 3 | 4 | 5 | |

| 60 | 1.7 | 0.8 | 1.4 | 0.6 | 1.1 | 0.8 | 0.4 | 1.7 | 1.4 | 0.8 | 0.8 | 6 | 0.7 |

| 80 | 1.8 | 1.3 | 2.2 | 4.6 | 1.6 | 1.3 | 4.1 | 2.2 | 1.5 | 1.3 | 1.0 | 11 | 0.9 |

| 100 | 2 | 1.9 | 4.7 | 5.4 | 3 | 1.9 | 4.9 | 3.4 | 2.4 | 1.9 | 1.4 | 12 | 1 |

| 120 | 4.5 | 5.7 | 5.6 | 7.1 | 5.3 | 5.7 | 5.8 | 7.3 | 5.7 | 2.8 | 2.1 | 14 | 5 |

表3 溶剂蒸发温度为40℃时不同工艺条件下制备的E-capsule储存12 h的质量损失

Table 3 Mass loss of E-capsule prepared under different process conditions at a solvent evaporation temperature of 40℃ after storage for 12 h

| 温度/℃ | 质量损失/% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 芯壁比 | 转速/(r/min) | 乳化剂浓度/%(质量) | |||||||||||

| 1∶2 | 1∶1 | 2∶1 | 3∶1 | 2000 | 2500 | 3000 | 3500 | 1 | 2 | 3 | 4 | 5 | |

| 60 | 1.7 | 0.8 | 1.4 | 0.6 | 1.1 | 0.8 | 0.4 | 1.7 | 1.4 | 0.8 | 0.8 | 6 | 0.7 |

| 80 | 1.8 | 1.3 | 2.2 | 4.6 | 1.6 | 1.3 | 4.1 | 2.2 | 1.5 | 1.3 | 1.0 | 11 | 0.9 |

| 100 | 2 | 1.9 | 4.7 | 5.4 | 3 | 1.9 | 4.9 | 3.4 | 2.4 | 1.9 | 1.4 | 12 | 1 |

| 120 | 4.5 | 5.7 | 5.6 | 7.1 | 5.3 | 5.7 | 5.8 | 7.3 | 5.7 | 2.8 | 2.1 | 14 | 5 |

| 温度/℃ | 质量损失/% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 芯壁比 | 转速/(r/min) | 乳化剂浓度/%(质量) | |||||||||||

| 1∶2 | 1∶1 | 2∶1 | 3∶1 | 2000 | 2500 | 3000 | 3500 | 1 | 2 | 3 | 4 | 5 | |

| 60 | 1.3 | 1.5 | 0.6 | 0.9 | 0.9 | 1.3 | 4.2 | 0.8 | 1.1 | 1.3 | 0.5 | 3.2 | 1.6 |

| 80 | 1.3 | 1.7 | 0.7 | 2.4 | 0.9 | 1.3 | 5 | 1 | 1.4 | 1.3 | 1 | 4.2 | 2.2 |

| 100 | 1.4 | 1.7 | 1.2 | 2.6 | 1.3 | 1.4 | 7.1 | 1.8 | 1.9 | 1.4 | 1.5 | 5.6 | 2.2 |

| 120 | 1.5 | 2 | 5. | 5.7 | 1.4 | 1.5 | 9 | 2.2 | 5.2 | 1.5 | 3 | 9.7 | 4 |

表4 溶剂蒸发温度为40℃时不同工艺条件下制备的Ami-capsule储存12 h的质量损失

Table 4 Mass loss of Ami-capsule prepared under different process conditions at a solvent evaporation temperature of 40℃ after storage for 12 h

| 温度/℃ | 质量损失/% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 芯壁比 | 转速/(r/min) | 乳化剂浓度/%(质量) | |||||||||||

| 1∶2 | 1∶1 | 2∶1 | 3∶1 | 2000 | 2500 | 3000 | 3500 | 1 | 2 | 3 | 4 | 5 | |

| 60 | 1.3 | 1.5 | 0.6 | 0.9 | 0.9 | 1.3 | 4.2 | 0.8 | 1.1 | 1.3 | 0.5 | 3.2 | 1.6 |

| 80 | 1.3 | 1.7 | 0.7 | 2.4 | 0.9 | 1.3 | 5 | 1 | 1.4 | 1.3 | 1 | 4.2 | 2.2 |

| 100 | 1.4 | 1.7 | 1.2 | 2.6 | 1.3 | 1.4 | 7.1 | 1.8 | 1.9 | 1.4 | 1.5 | 5.6 | 2.2 |

| 120 | 1.5 | 2 | 5. | 5.7 | 1.4 | 1.5 | 9 | 2.2 | 5.2 | 1.5 | 3 | 9.7 | 4 |

图13 (a)埋植生物基微胶囊的原始和愈合TDCB涂层样品的应力-应变曲线;(b)表面具有“X”划痕的自愈合涂层在3.5%(质量) NaCl溶液下浸泡的Bode曲线;(c)表面被划伤的自愈合涂层的SEM图;(d)表面被划伤的自愈合涂层愈合后的SEM图

Fig.13 (a) Stress-strain curves of original and healed TDCB coating samples embedded with bio-based microcapsules; (b) Bode curves of self-healing coating with “X” scratch on the surface immersed in 3.5%(mass) NaCl solution; (c) SEM image of self-healing coatings with scratched surface; (d) SEM image of the scratched self-healing coating after healing

| 1 | 唐二军, 姚蒙蒙, 郭晓峰, 等. 水性环氧丙烯酸酯乳液涂层成膜性能[J]. 化工学报, 2018, 69(S1): 143-147. |

| Tang E J, Yao M M, Guo X F, et al. Film formation for aqueous epoxy acrylate latex coatings[J]. CIESC Journal, 2018, 69(S1): 143-147. | |

| 2 | Xie L, Wang L, Fan X. The application of epoxy anticorrosive coating technology in metal corrosion prevention of chemical equipment[J]. Agro Food Industry Hi Tech, 2017, 28(1): 1345-1349. |

| 3 | Ou B L, Wang Y W, Lu Y. A review on fundamentals and strategy of epoxy-resin-based anticorrosive coating materials[J]. Polymer-Plastics Technology and Materials, 2021, 60(6): 601-625. |

| 4 | Bratychak M, Brostow W, Grynyshyn O, et al. Synthesis and characterization of petroleum resins with epoxy groups[J]. Materials Research Innovations, 2003, 7(3): 167-171. |

| 5 | Pradhan S, Pandey P, Mohanty S, et al. Insight on the chemistry of epoxy and its curing for coating applications: a detailed investigation and future perspectives[J]. Polymer-Plastics Technology and Engineering, 2016, 55(8): 862-877. |

| 6 | 何吉喆, 刘明言, 徐杨书函. 环氧豆油树脂涂层的防腐性能研究[J]. 化工学报, 2021, 72(2): 1067-1077. |

| He J Z, Liu M Y, Xu Y S H. Study on anticorrosive properties of epoxy soybean oil resin coating[J]. CIESC Journal, 2021, 72(2): 1067-1077. | |

| 7 | Zhen X, Li H W, Xu Z B, et al. Facile synthesis of lignin-based epoxy resins with excellent thermal-mechanical performance[J]. International Journal of Biological Macromolecules, 2021, 182: 276-285. |

| 8 | 郑杰元, 张先伟, 万金涛, 等. 丁香酚环氧有机硅树脂的制备及其固化动力学研究[J]. 化工学报, 2023, 74(2): 924-932. |

| Zheng J Y, Zhang X W, Wan J T, et al. Synthesis and curing kinetic analysis of eugenol-based siloxane epoxy resin[J]. CIESC Journal, 2023, 74(2): 924-932. | |

| 9 | Wu H, Liu C B, Cheng L, et al. Enhancing the mechanical and tribological properties of epoxy composites via incorporation of reactive bio-based epoxy functionalized graphene oxide[J]. RSC Advances, 2020, 10(66): 40148-40156. |

| 10 | Babahan-Bircan I, Demirkaya I, Hasan S O H, et al. Comparison of new bio-based epoxide-amine coatings with their nanocomposite coating derivatives (graphene, CNT, and fullerene) as replacements for BPA[J]. Progress in Organic Coatings, 2022, 165: 106714. |

| 11 | Ge C, Xu X B, Ma F, et al. Biomimetic modification of water-borne polymer coating with carnauba wax for controlled release of urea[J]. International Journal of Molecular Sciences, 2022, 23(13): 7422. |

| 12 | Nesterova T, Dam-Johansen K, Pedersen L T, et al. Microcapsule-based self-healing anticorrosive coatings: capsule size, coating formulation, and exposure testing[J]. Progress in Organic Coatings, 2012, 75(4): 309-318. |

| 13 | 张伦亮, 万里鹰, 黄军同, 等. 基于Diels-Alder动态共价键的含PEGDE片段自修复环氧树脂性能研究[J]. 化工学报, 2020, 71(6): 2871-2879. |

| Zhang L L, Wan L Y, Huang J T, et al. Properties of self-healing epoxy resin containing PEGDE segments based on Diels-Alder dynamic covalent bond[J]. CIESC Journal, 2020, 71(6): 2871-2879. | |

| 14 | Huang Y, Wang P J, Tan W M, et al. Photothermal and pH dual-responsive self-healing coating for smart corrosion protection[J]. Journal of Materials Science & Technology, 2022, 107: 34-42. |

| 15 | Ye K X, Bi Z X, Cui G, et al. External self-healing coatings in anticorrosion applications: a review[J]. Corrosion, 2020, 76(3): 279-298. |

| 16 | Christopher J E P, Sultan M T H, Selvan C P, et al. Manufacturing challenges in self-healing technology for polymer composites — a review[J]. Journal of Materials Research and Technology - JMR & T, 2020, 9(4): 7370-7379. |

| 17 | Schreiner C, Scharf S, Stenzel V, et al. Self-healing through microencapsulated agents for protective coatings[J]. Journal of Coatings Technology and Research, 2017, 14(4): 809-816. |

| 18 | Wu G, An J L, Sun D W, et al. Robust microcapsules with polyurea/silica hybrid shell for one-part self-healing anticorrosion coatings[J]. Journal of Materials Chemistry A, 2014, 2(30): 11614-11620. |

| 19 | Xu C Y, Chen Z, Wang C X, et al. Fabrication of dual self-healing multifunctional coating based on multicompartment microcapsules[J]. ACS Applied Materials & Interfaces, 2021, 13(49): 59298-59309. |

| 20 | Wang H R, Zhou Q X. Evaluation and failure analysis of linseed oil encapsulated self-healing anticorrosive coating[J]. Progress in Organic Coatings, 2018, 118: 108-115. |

| 21 | Farzi G, Davoodi A, Ahmadi A, et al. Encapsulation of cerium nitrate within poly(urea-formaldehyde) microcapsules for the development of self-healing epoxy-based coating[J]. ACS Omega, 2021, 6(46): 31147-31153. |

| 22 | White S R, Sottos N R, Geubelle P H, et al. Autonomic healing of polymer composites[J]. Nature, 2001, 409(6822): 794-797. |

| 23 | Song Y, Chen K F, Wang J J, et al. Synthesis of polyurethane/poly(urea-formaldehyde) double-shelled microcapsules for self-healing anticorrosion coatings[J]. Chinese Journal of Polymer Science, 2020, 38(1): 45-52. |

| 24 | 倪卓, 林煜豪, 黄苇颖, 等. 环氧树脂微胶囊合成及其反应动力学[J]. 化工学报, 2018, 69(4): 1790-1798. |

| Ni Z, Lin Y H, Huang W Y, et al. Preparation and reaction kinetics of epoxy resin microcapsules[J]. CIESC Journal, 2018, 69(4): 1790-1798. | |

| 25 | Chen Q, Zhang L Y, Zhang J L, et al. Bio-based polybenzoxazines coatings for efficient marine antifouling[J]. Progress in Organic Coatings, 2023, 174: 107298. |

| 26 | Parihar S, Gaur B. Thermo-reversible self-healing polymeric coatings derived from gum rosin[J]. Progress in Organic Coatings, 2022, 168: 106889. |

| 27 | Thakur T, Gaur B, Singha A S. Bio-based epoxy/imidoamine encapsulated microcapsules and their application for high performance self-healing coatings[J]. Progress in Organic Coatings, 2021, 159: 106436. |

| 28 | Shahabudin N, Yahya R, Gan S N. Microcapsules filled with a palm oil-based alkyd as healing agent for epoxy matrix[J]. Polymers, 2016, 8(4): 125. |

| 29 | Ataei S, Hassan A, Azari P, et al. Electrosprayed PMMA microcapsules containing green soybean oil-based acrylated epoxy and a thiol: a novel resin for smart self-healing coatings[J]. Smart Materials and Structures, 2020, 29(8): 085037. |

| 30 | Ahangaran F, Hayaty M, Navarchian A H, et al. Development of self-healing epoxy composites via incorporation of microencapsulated epoxy and mercaptan in poly(methyl methacrylate) shell[J]. Polymer Testing, 2019, 73: 395-403. |

| 31 | Lv K, Liu D, Li W, et al. Preparation and characterization of E7-PMMA microcapsules by solvent evaporation[J]. Molecular Crystals and Liquid Crystals, 2012, 557(1): 217-227. |

| 32 | Ahangaran F, Hayaty M, Navarchian A H. Morphological study of polymethyl methacrylate microcapsules filled with self-healing agents[J]. Applied Surface Science, 2017, 399: 721-731. |

| 33 | Xiao C D, Shen X C, Tao L. Modified emulsion solvent evaporation method for fabricating core-shell microspheres[J]. International Journal of Pharmaceutics, 2013, 452(1/2): 227-232. |

| 34 | Boumezgane O, Suriano R, Fedel M, et al. Self-healing epoxy coatings with microencapsulated ionic PDMS oligomers for corrosion protection based on supramolecular acid-base interactions[J]. Progress in Organic Coatings, 2022, 162: 106558. |

| 35 | Li Q, Mishra A K, Kim N H, et al. Effects of processing conditions of poly(methylmethacrylate) encapsulated liquid curing agent on the properties of self-healing composites[J]. Composites Part B: Engineering, 2013, 49: 6-15. |

| 36 | Cho S H, Andersson H M, White S R, et al. Polydimethylsiloxane-based self-healing materials[J]. Advanced Materials, 2006, 18(8): 997-1000. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [3] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [4] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [5] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [6] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [7] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [8] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [9] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [10] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [11] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [12] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [13] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [14] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [15] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号