化工学报 ›› 2023, Vol. 74 ›› Issue (5): 2170-2178.DOI: 10.11949/0438-1157.20230096

收稿日期:2023-02-10

修回日期:2023-04-03

出版日期:2023-05-05

发布日期:2023-06-29

通讯作者:

陈晓平

作者简介:陈宇豪(1999—),男,硕士研究生,cyh9982@163.com

基金资助:

Yuhao CHEN( ), Xiaoping CHEN(

), Xiaoping CHEN( ), Jiliang MA, Cai LIANG

), Jiliang MA, Cai LIANG

Received:2023-02-10

Revised:2023-04-03

Online:2023-05-05

Published:2023-06-29

Contact:

Xiaoping CHEN

摘要:

在回转窑炉实验台上进行了市政污泥焚烧的系列实验,研究了焚烧温度、污泥粒径、炉内停留时间及钙硫摩尔比等因素对污泥焚烧过程中气态污染物排放特性的影响规律。结果表明:随着焚烧温度的升高,SO2的排放浓度明显上升,但上升趋势随温度升高变缓;NO的排放浓度也随焚烧温度的升高而增加,但影响相对较小;随着污泥粒径的增加,SO2的排放浓度有明显下降,而NO的排放浓度变化较小;通过减小炉体倾角延长污泥在炉内的停留时间后,NO及SO2的排放总体均呈上升趋势,CO排放浓度则下降,但炉体倾角在1.5°~2.5°范围内变化时,各气态污染物的排放均无明显变化;污泥中掺混生石灰后,SO2的排放浓度明显下降,且随Ca/S(摩尔比)的增大逐渐降低,Ca/S超过4之后对SO2的减排影响变小;生石灰的加入也使NO的排放浓度降低,但随着Ca/S的提高,NO的排放浓度有所回升。

中图分类号:

陈宇豪, 陈晓平, 马吉亮, 梁财. 市政污泥回转窑焚烧气态污染物排放特性研究[J]. 化工学报, 2023, 74(5): 2170-2178.

Yuhao CHEN, Xiaoping CHEN, Jiliang MA, Cai LIANG. Gaseous pollutants emissions from rotary kiln combustion of municipal sewage sludge[J]. CIESC Journal, 2023, 74(5): 2170-2178.

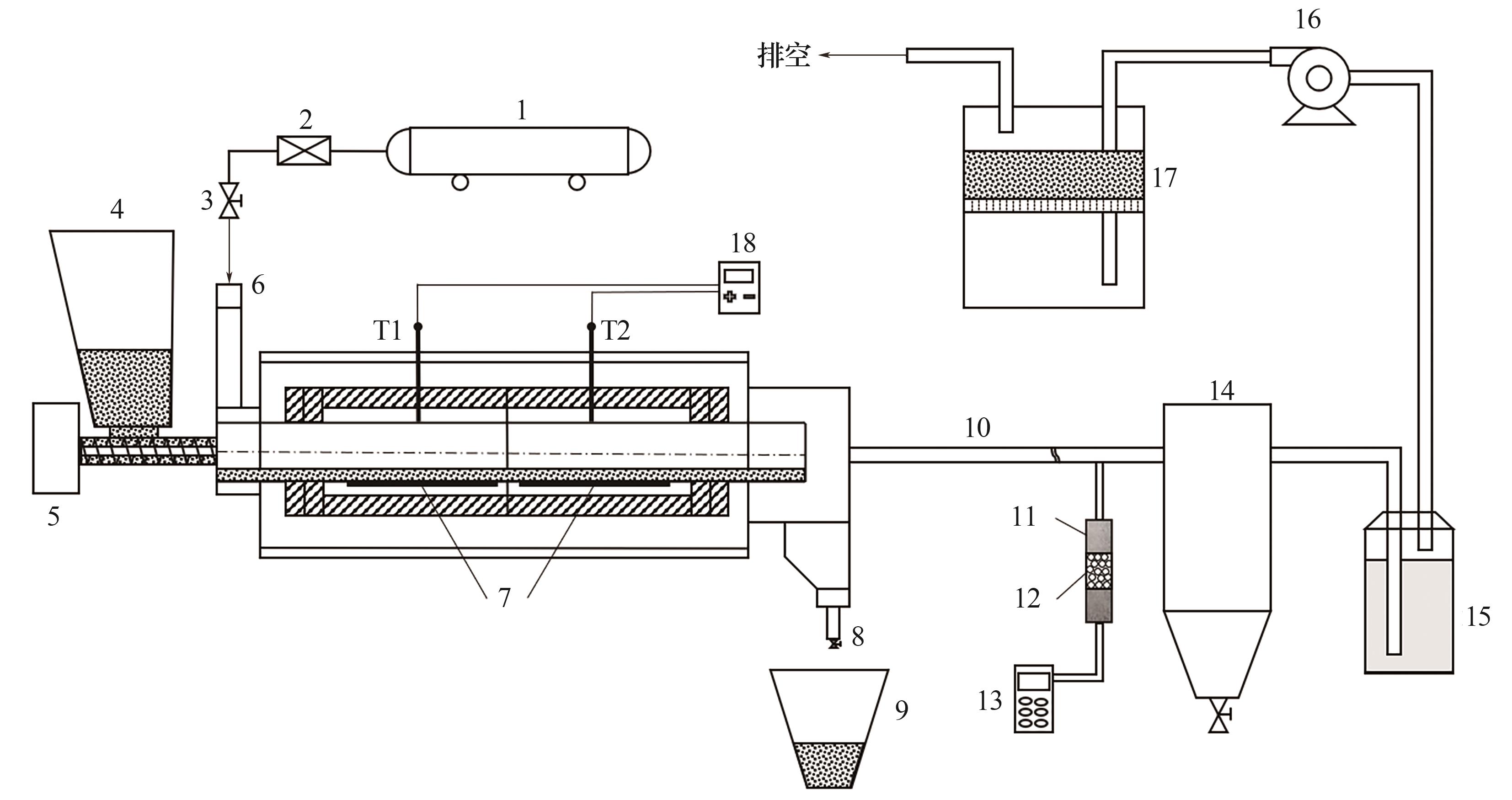

图1 回转窑实验台系统图1—空压机;2—流量计;3—阀门;4—料仓;5—螺旋给料器;6—进风口;7—电加热带;8—排渣口;9—炉渣收集装置;10—保温烟道;11—过滤棉(除尘);12—无水氯化钙(干燥);13—烟气分析仪;14—布袋除尘器;15—碱洗罐;16—引风机;17—活性炭;18—数显控制器

Fig.1 System diagram of rotary kiln test platform1—air compressor; 2—flowmeter; 3—valve; 4—stock bin; 5—worm feeder; 6—air inlet; 7—electrical heating; 8—slag discharge; 9—slag collection;10—insulation pipe; 11—filter cotton (dust removal); 12—anhydrous calcium chloride (desiccation); 13—flue gas analyzer; 14—bag-type dust remover;15—lye tank; 16—induced draft fan; 17—activated carbon; 18—digital display controller

| 试样 | 工业分析(空气干燥基)/% | 元素分析(干燥基)/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mt | Ad | Vd | FCd | C | H | O | N | S | ||

| 污泥 | 10.05 | 51.53 | 41.32 | 7.15 | 19.78 | 3.63 | 21.61 | 2.98 | 0.83 | |

表1 市政污泥的工业分析和元素分析结果

Table 1 Results of industrial and elemental analysis of municipal sludge

| 试样 | 工业分析(空气干燥基)/% | 元素分析(干燥基)/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mt | Ad | Vd | FCd | C | H | O | N | S | ||

| 污泥 | 10.05 | 51.53 | 41.32 | 7.15 | 19.78 | 3.63 | 21.61 | 2.98 | 0.83 | |

| 成分 | 含量/% |

|---|---|

| SiO2 | 41.78 |

| Al2O3 | 23.56 |

| Fe2O3 | 9.58 |

| CaO | 4.14 |

| MgO | 2.51 |

| SO3 | 1.65 |

| TiO2 | 0.75 |

| K2O | 1.77 |

| Na2O | 1.13 |

| MnO2 | 0.34 |

| P2O5 | 9.12 |

| 总量 | 96.33 |

表2 市政污泥的灰成分

Table 2 Ash component of municipal sludge

| 成分 | 含量/% |

|---|---|

| SiO2 | 41.78 |

| Al2O3 | 23.56 |

| Fe2O3 | 9.58 |

| CaO | 4.14 |

| MgO | 2.51 |

| SO3 | 1.65 |

| TiO2 | 0.75 |

| K2O | 1.77 |

| Na2O | 1.13 |

| MnO2 | 0.34 |

| P2O5 | 9.12 |

| 总量 | 96.33 |

| 炉体倾角/(°) | 物料停留时间/min | 质量流率/(g/s) |

|---|---|---|

| 3.0 | 8.0 | 1.00 |

| 2.5 | 9.0 | 0.90 |

| 2.0 | 10.5 | 0.85 |

| 1.5 | 11.5 | 0.78 |

| 1.0 | 12.5 | 0.64 |

表3 冷态下物料炉管内质量流率

Table 3 Mass flow rate inside the material furnace under cold condition

| 炉体倾角/(°) | 物料停留时间/min | 质量流率/(g/s) |

|---|---|---|

| 3.0 | 8.0 | 1.00 |

| 2.5 | 9.0 | 0.90 |

| 2.0 | 10.5 | 0.85 |

| 1.5 | 11.5 | 0.78 |

| 1.0 | 12.5 | 0.64 |

| 30 | 刘刚, 池涌, 蒋旭光, 等. 模拟危险废物颗粒回转窑内运动特性试验研究[J]. 工程热物理学报, 2005, 26(2): 343-346. |

| Liu G, Chi Y, Jiang X G, et al. Mass transfer of simulative hazardous waste particles in rotary kiln[J]. Journal of Engineering Thermophysics, 2005, 26(2): 343-346. | |

| 31 | 何丽娜. 村镇生活垃圾冷态回转窑运动规律研究[D]. 天津: 天津大学, 2017. |

| He L N. Study on movement law of cold rotary kiln for village domestic waste[D]. Tianjin: Tianjin University, 2017. | |

| 32 | Sullivan J D, Maier C G, Ralston O C. Passage of solid particles through rotary cylindrical kilns[EB/OL]//UNT Digital Library. United States: Government Printing Office, 1927[2023-03-14]. . |

| 33 | 张瑞宇, 张付申. 生物干化污泥混煤燃烧特性及污染物排放规律研究[J]. 环境科学与技术, 2015, 38(S2): 66-71. |

| Zhang R Y, Zhang F S. Co-combustion properties and typical pollutant emissions of biodried sludge with coal[J]. Environmental Science & Technology, 2015, 38(S2): 66-71. | |

| 34 | 侯祥松, 李金平, 张海, 等. 石灰石脱硫对循环流化床中N2O排放浓度的影响[J]. 电站系统工程, 2005, 21(3): 1-3. |

| Hou X S, Li J P, Zhang H, et al. Limestone effects on N2O emission in CFB combustors[J]. Power System Engineering, 2005, 21(3): 1-3. | |

| 35 | 柯希玮, 蔡润夏, 吕俊复, 等. 钙基脱硫剂对循环流化床NO x 排放影响研究进展[J]. 洁净煤技术, 2019, 25(1): 1-11. |

| Ke X W, Cai R X, Lyu J F, et al. Research progress of the effects of Ca-based sorbents on the NO x reaction in circulating fluidized bed boilers[J]. Clean Coal Technology, 2019, 25(1): 1-11. | |

| 36 | Fu S L, Song Q, Tang J S, et al. Effect of CaO on the selective non-catalytic reduction deNO x process: experimental and kinetic study[J]. Chemical Engineering Journal, 2014, 249: 252-259. |

| 37 | Schäfer S, Bonn B. Hydrolysis of HCN as an important step in nitrogen oxide formation in fluidised combustion (Ⅱ): Heterogeneous reactions involving limestone[J]. Fuel, 2002, 81(13): 1641-1646. |

| 38 | Shimizu T, Ishizu K, Kobayashi S, et al. Hydrolysis and oxidation of hydrogen cyanide over limestone under fluidized bed combustion conditions[J]. Energy & Fuels, 1993, 7(5): 645-647. |

| 39 | Elled A L, Åmand L E, Leckner B, et al. Influence of phosphorus on sulphur capture during co-firing of sewage sludge with wood or bark in a fluidised bed[J]. Fuel, 2006, 85(12/13): 1671-1678. |

| 1 | 2021年中国生态环境状况公报(摘录)[J]. 环境保护, 2022, 50(12): 61-74. |

| China ecological environment status bulletin 2021 (excerpt)[J]. Environmental Protection, 2022, 50(12): 61-74. | |

| 2 | 侯海盟. 城市下水污泥循环流化床焚烧及排放特性试验研究[D]. 北京: 中国科学院大学, 2013. |

| Hou H M. Experimental study on incineration and emission characteristics of municipal sewage sludge in circulating fluidized bed[D]. Beijing: University of Chinese Academy of Sciences, 2013. | |

| 3 | Werle S, Wilk R K. A review of methods for the thermal utilization of sewage sludge: the Polish perspective[J]. Renewable Energy, 2010, 35(9): 1914-1919. |

| 4 | Werther J, Ogada T. Sewage sludge combustion[J]. Progress in Energy and Combustion Science, 1999, 25(1): 55-116. |

| 5 | Vesilind A P, Ramsey T B. Effect of drying temperature on the fuel value of wastewater sludge[J]. Waste Management & Research, 1996, 14(2): 189-196. |

| 6 | 付少闯. 干化污泥焚烧及其污染物排放规律研究[D]. 郑州: 郑州大学, 2019. |

| Fu S C. Study on dry sludge incineration and pollutant discharge[D]. Zhengzhou: Zhengzhou University, 2019. | |

| 7 | Slim J, Wakefield R. The utilization of sewage-sludge in the manufacture of Clay Bricks[J]. Water Sa., 1991, 17(3): 197-202. |

| 8 | 陈汝超. 化工区危废污泥干化焚烧项目的工艺设计与运行[J]. 中国给水排水, 2017, 33(20): 50-52. |

| Chen R C. Process design and operation of hazardous waste sludge drying and incineration project in a chemical industry park[J]. China Water & Wastewater, 2017, 33(20): 50-52. | |

| 9 | Murakami T, Suzuki Y, Nagasawa H, et al. Combustion characteristics of sewage sludge in an incineration plant for energy recovery[J]. Fuel Processing Technology, 2009, 90(6): 778-783. |

| 10 | 俞伟伟. 污泥干化焚烧烟气脱硫工艺论证及优化研究[J]. 环境卫生工程, 2020, 28(3): 38-43. |

| Yu W W. Demonstration and optimization study on desulfurization process of flue gas from sludge drying and incineration[J]. Environmental Sanitation Engineering, 2020, 28(3): 38-43. | |

| 11 | 李春雨. 典型危险废物在两段式回转窑焚烧系统内的热处置和结渣特性研究及其应用[D]. 杭州: 浙江大学, 2011. |

| Li C Y. Studies and application on thermal disposal and slagging characteristics for typical hazardous waste in two-stage incineration system with rotary kiln[D]. Hangzhou: Zhejiang University, 2011. | |

| 12 | Ogada T, Werther J. Combustion characteristics of wet sludge in a fluidized bed: release and combustion of the volatiles[J]. Fuel, 1996, 75(5): 617-626. |

| 13 | Sun C L, Koziński J A. Ignition behaviour of pulp and paper combustible wastes[J]. Fuel, 2000, 79(13): 1587-1593. |

| 14 | Zha J R, Huang Y J, Clough P T, et al. Desulfurization using limestone during sludge incineration in a fluidized bed furnace: increased risk of particulate matter and heavy metal emissions[J]. Fuel, 2020, 273: 117614. |

| 15 | 马培东, 王里奥, 周在江, 等. 水泥旋窑并行处理城市污水厂污泥的污染物排放研究[J]. 环境工程学报, 2009, 3(9): 1683-1686. |

| Ma P D, Wang L A, Zhou Z J, et al. Study on pollutant emission from cement rotary kiln parallel treating municipal sludge[J]. Chinese Journal of Environmental Engineering, 2009, 3(9): 1683-1686. | |

| 16 | Yang D J, Ko J C, Kim J K, et al. Co-incineration characteristics of sewage sludge and industrial waste using the rotary kiln incinerator[J]. Journal of Korea Organic Resource Recycling Association, 2009, 17(3): 91-99. |

| 17 | Yang S Q, Kong Q F, Zeng D W, et al. Simulation research of a counter-flow rotary kiln hazardous waste incineration system[J]. International Journal of Coal Science & Technology, 2022, 9(1): 60. |

| 18 | 房点. 干化污泥在流化床内燃烧特性及污染物排放特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. |

| Fang D. Study on combustion characteristics and pollutants emission of dried sludge in fluidized bed[D]. Harbin: Harbin Institute of Technology, 2016. | |

| 19 | 刘志强, 刘青, 蒋文斌, 等. 循环流化床锅炉SO2和NO x 排放的影响规律研究[J]. 锅炉技术, 2013, 44(3): 23-27. |

| Liu Z Q, Liu Q, Jiang W B, et al. The effect of the emission in circulating fluidized bed boilers[J]. Boiler Technology, 2013, 44(3): 23-27. | |

| 20 | Kilpinen P, Hupa M. Homogeneous N2O chemistry at fluidized bed combustion conditions: a kinetic modeling study[J]. Combustion and Flame, 1991, 85(1/2): 94-104. |

| 21 | Aamand L E, Leckner B, Andersson S. Formation of nitrous oxide in circulating fluidized-bed boilers[J]. Energy & Fuels, 1991, 5(6): 815-823. |

| 22 | 江子箫, 陈晓平, 蒋志坚, 等. 城市污泥流化床燃烧过程中气态污染物排放特性[J]. 化工进展, 2018, 37(1): 368-374. |

| Jiang Z X, Chen X P, Jiang Z J, et al. Gaseous pollutants emissions from fluidized bed combustion of municipal sewage sludge[J]. Chemical Industry and Engineering Progress, 2018, 37(1): 368-374. | |

| 23 | Folgueras M B, Marı́a Dı́az R, Xiberta J. Sulphur retention during co-combustion of coal and sewage sludge[J]. Fuel, 2004, 83(10): 1315-1322. |

| 24 | 王勇强, 陆方, 周月桂. 粒径对贫煤空气分级NO x 排放特性影响的试验研究[J]. 动力工程学报, 2021, 41(11): 926-932. |

| Wang Y Q, Lu F, Zhou Y G. Experimental study on the effect of coal particle sizes on NO x emission characteristics of lean coal under air-staged combustion conditions[J]. Journal of Chinese Society of Power Engineering, 2021, 41(11): 926-932. | |

| 25 | 刘彦, 齐学义, 丁宁, 等. 煤粉再燃过程中NO均相与异相还原反应相对贡献的研究[J]. 动力工程, 2009, 29(10): 946-949, 955. |

| Liu Y, Qi X Y, Ding N, et al. Study on relative contributions of homogeneous and heterogeneous reaction during NO reduction in pulverized coal reburning[J]. Journal of Power Engineering, 2009, 29(10): 946-949, 955. | |

| 26 | 龚艳艳. 煤燃烧过程中燃料型NO x 生成及还原机理研究进展[J]. 煤质技术, 2022, 37(3): 9-23. |

| Gong Y Y. Research progress on formation and reduction mechanism of fuel-NO x during coal combustion[J]. Coal Quality Technology, 2022, 37(3): 9-23. | |

| 27 | 李爱民, 蔡九菊, 王志, 等. 固体废弃物在回转窑内混合特性的试验[J]. 东北大学学报, 2002, 23(2): 152-155. |

| Li A M, Cai J J, Wang Z, et al. Experimental research on the mixing characteristics of solid waste in rotary kiln[J]. Journal of Northeastern University, 2002, 23(2): 152-155. | |

| 28 | Boateng A A, Barr P V. Modelling of particle mixing and segregation in the transverse plane of a rotary kiln[J]. Chemical Engineering Science, 1996, 51(17): 4167-4181. |

| 29 | 李爱民, 李水清, 严建华, 等. 固体废弃物在回转窑内停留时间的试验研究[J]. 化学反应工程与工艺, 2002, 18(2): 152-157. |

| Li A M, Li S Q, Yan J H, et al. Experimental research on mean residence time of solid materials in rotary kiln[J]. Chemical Reaction Engineering and Technology, 2002, 18(2): 152-157. |

| [1] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [2] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [3] | 刘春雨, 周桓宇, 马跃, 岳长涛. CaO调质含油污泥干燥特性及数学模型[J]. 化工学报, 2023, 74(7): 3018-3027. |

| [4] | 屈园浩, 邓文义, 谢晓丹, 苏亚欣. 活性炭/石墨辅助污泥电渗脱水研究[J]. 化工学报, 2023, 74(7): 3038-3050. |

| [5] | 张兰河, 赖青燚, 王铁铮, 关潇卓, 张明爽, 程欣, 徐小惠, 贾艳萍. H2O2对SBR脱氮效率和污泥性能的影响[J]. 化工学报, 2023, 74(5): 2186-2196. |

| [6] | 白天昊, 王晓雯, 杨梦滋, 段新伟, 米杰, 武蒙蒙. 类水滑石衍生锌基氧化物高温煤气脱硫过程中COS释放行为及其抑制研究[J]. 化工学报, 2023, 74(4): 1772-1780. |

| [7] | 罗欣宜, 冯超, 刘晶, 乔瑜. 污泥不同热处理工艺产物磷的浸出回收实验研究[J]. 化工学报, 2022, 73(9): 4034-4044. |

| [8] | 王永倩, 王平, 程康, 毛晨林, 刘文锋, 尹智成, Ferrante Antonio. 氨气/甲烷贫预混旋转湍流火焰稳定性及NO生成[J]. 化工学报, 2022, 73(9): 4087-4094. |

| [9] | 沈嘉辉, 王侃宏, 郁达伟, 胡大洲, 魏源送. 游离氨调理污泥厌氧消化优化产甲烷过程与强化有机物释放[J]. 化工学报, 2022, 73(9): 4147-4155. |

| [10] | 张军, 胡升, 顾菁, 袁浩然, 陈勇. 甲醇体系电镀污泥衍生磁性多金属材料催化糠醛加氢转化[J]. 化工学报, 2022, 73(7): 2996-3006. |

| [11] | 陈冠益, 童图军, 李瑞, 王燕杉, 颜蓓蓓, 李宁, 侯立安. 热解时间对污泥生物炭活化过硫酸盐的影响研究[J]. 化工学报, 2022, 73(5): 2111-2119. |

| [12] | 白文轩, 陈锦湘, 刘芬, 张静淙, 谷志平, 熊成铭, 施王军, 余江. 非水相金属基离子液体湿法氧化脱硫工艺:发展与展望[J]. 化工学报, 2022, 73(5): 1847-1862. |

| [13] | 宋超宇, 熊亚选, 张金花, 金宇贺, 药晨华, 王辉祥, 丁玉龙. 污泥焚烧炉渣基定型复合相变储热材料的制备和性能[J]. 化工学报, 2022, 73(5): 2279-2287. |

| [14] | 杜智华, 杨娟, 戴俊, 冷冲冲, 张鸽. Ni2+取代对ZnTi-LDH选择性光氧化去除NO的性能增强[J]. 化工学报, 2022, 73(11): 4998-5010. |

| [15] | 杨晓阳, 王宝凤, 宋旭涛, 杨凤玲, 程芳琴. 污泥与高硫煤共水热碳化过程中硫氮形态转化规律[J]. 化工学报, 2022, 73(11): 5211-5219. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号