化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3426-3435.DOI: 10.11949/0438-1157.20241422

丁宏鑫1( ), 干文翔2, 赵雍洋1, 贾润泽1, 康子祺1, 赵玉隆1, 向勇1(

), 干文翔2, 赵雍洋1, 贾润泽1, 康子祺1, 赵玉隆1, 向勇1( )

)

收稿日期:2024-12-06

修回日期:2025-02-06

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

向勇

作者简介:丁宏鑫(1999—),男,博士研究生,1206492721@qq.com

基金资助:

Hongxin DING1( ), Wenxiang GAN2, Yongyang ZHAO1, Runze JIA1, Ziqi KANG1, Yulong ZHAO1, Yong XIANG1(

), Wenxiang GAN2, Yongyang ZHAO1, Runze JIA1, Ziqi KANG1, Yulong ZHAO1, Yong XIANG1( )

)

Received:2024-12-06

Revised:2025-02-06

Online:2025-07-25

Published:2025-08-13

Contact:

Yong XIANG

摘要:

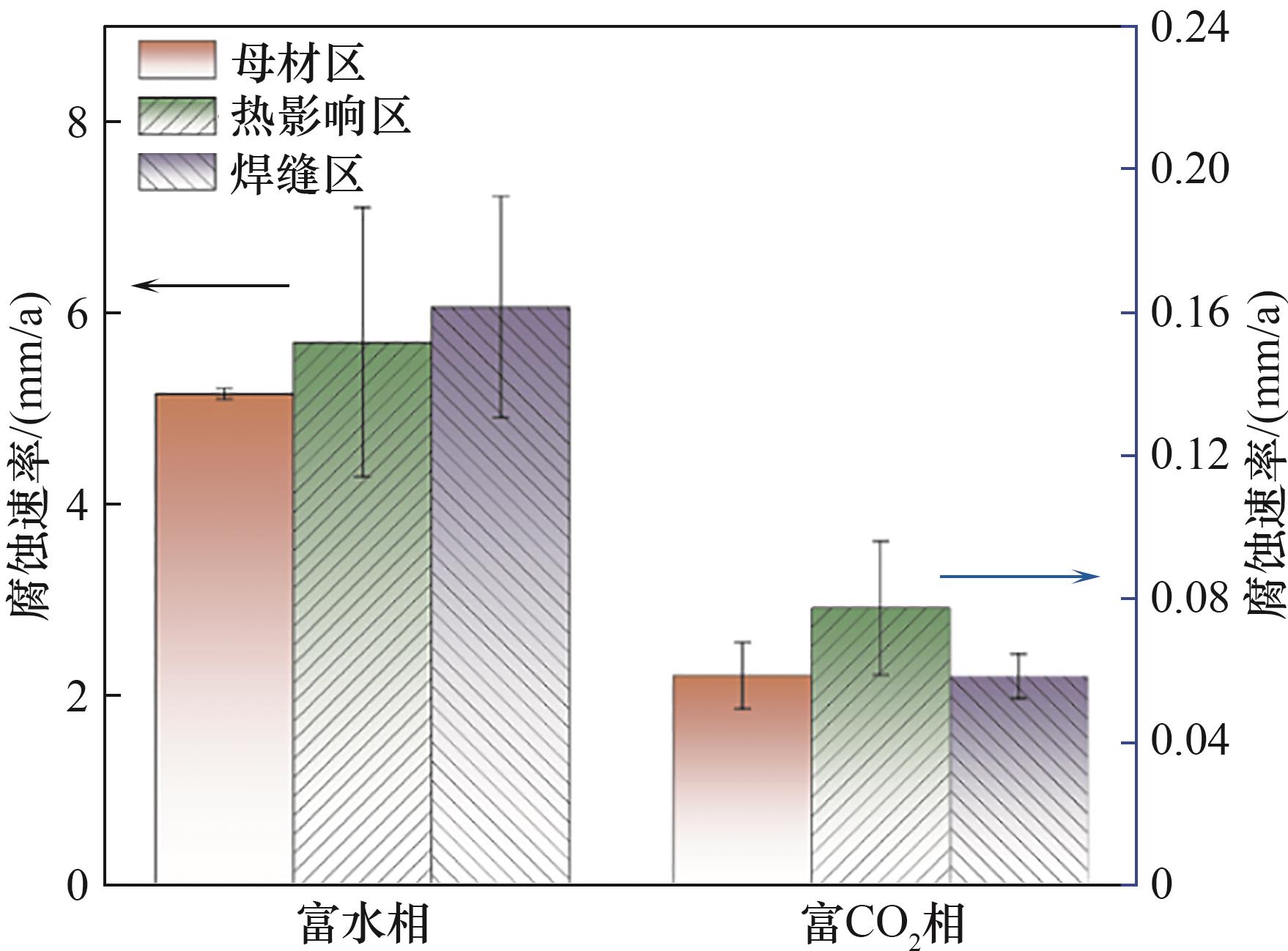

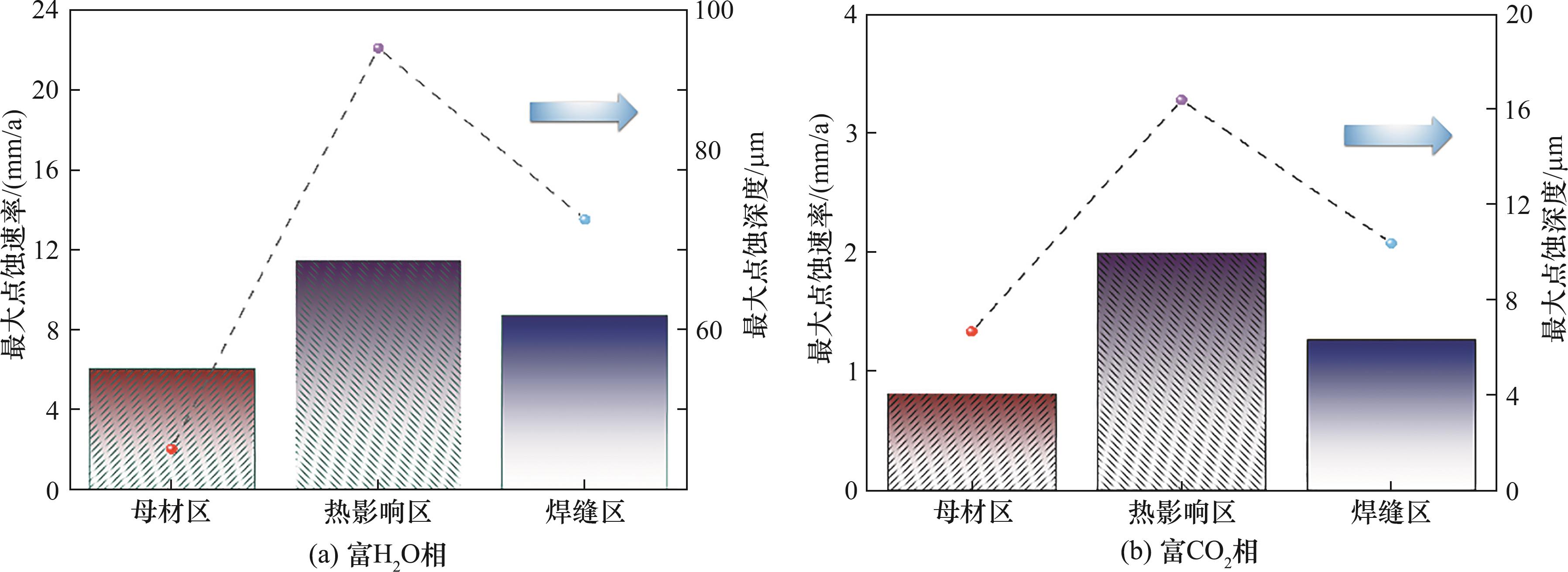

碳捕集、利用与封存(CCUS)技术对于实现国家双碳目标和减缓气候变化具有至关重要的作用。捕集得到的含H2O的CO2会对管输体系造成严重的腐蚀危害。本研究从输送体系可能的耐腐蚀薄弱环节焊接接头入手,研究X65管线钢焊接接头在富H2O相以及富CO2环境中,各区域的腐蚀行为与机理。结果表明,在富CO2相中,焊接接头各区域的均匀腐蚀速率均较低,这可能与生成了FeCO3产物膜有关;而在富H2O相中,焊接接头各区域均匀腐蚀速率显著升高,各区域均匀腐蚀差异并不明显,在热影响区出现了更为明显的点蚀深坑,且表面粗糙度较高。

中图分类号:

丁宏鑫, 干文翔, 赵雍洋, 贾润泽, 康子祺, 赵玉隆, 向勇. X65钢焊接接头在超临界CO2相及富H2O相中的腐蚀机理研究[J]. 化工学报, 2025, 76(7): 3426-3435.

Hongxin DING, Wenxiang GAN, Yongyang ZHAO, Runze JIA, Ziqi KANG, Yulong ZHAO, Yong XIANG. Corrosion mechanisms of X65 steel welded joints in supercritical CO2 and H2O-rich phases[J]. CIESC Journal, 2025, 76(7): 3426-3435.

| 元素 | 含量/%(质量分数) |

|---|---|

| C | 0.12 |

| Ni | 0.07 |

| Mo | 0.17 |

| Mn | 1.27 |

| Cr | 0.11 |

| V | 0.057 |

| Nb | 0.05 |

| Si | 0.18 |

| Cu | 0.12 |

| Sn | 0.008 |

| Al | 0.022 |

| B | 0.0005 |

| Ti | 0.001 |

| S | 0.002 |

| Fe | 余量 |

表1 X65管线钢元素成分

Table 1 Elemental composition of X65 pipeline steel

| 元素 | 含量/%(质量分数) |

|---|---|

| C | 0.12 |

| Ni | 0.07 |

| Mo | 0.17 |

| Mn | 1.27 |

| Cr | 0.11 |

| V | 0.057 |

| Nb | 0.05 |

| Si | 0.18 |

| Cu | 0.12 |

| Sn | 0.008 |

| Al | 0.022 |

| B | 0.0005 |

| Ti | 0.001 |

| S | 0.002 |

| Fe | 余量 |

图3 X65钢焊接接头各区域在富H2O相与富CO2相中72 h的腐蚀速率

Fig.3 Corrosion rate of different regions of X65 steel welded joints in water-rich and CO2-rich environments for 72 h

| 选取条件 | 质量分数/% | ||

|---|---|---|---|

| C | O | Fe | |

| A | 4.50 | 2.69 | 92.81 |

| B | 7.19 | 3.91 | 88.90 |

| C | 8.27 | 4.70 | 87.03 |

| D | 9.86 | 40.09 | 50.05 |

| E | 11.37 | 39.86 | 48.77 |

| F | 10.33 | 41.00 | 48.67 |

表2 管线钢焊接接头EDS元素分析

Table 2 EDS element analysis of pipeline steel welded joints

| 选取条件 | 质量分数/% | ||

|---|---|---|---|

| C | O | Fe | |

| A | 4.50 | 2.69 | 92.81 |

| B | 7.19 | 3.91 | 88.90 |

| C | 8.27 | 4.70 | 87.03 |

| D | 9.86 | 40.09 | 50.05 |

| E | 11.37 | 39.86 | 48.77 |

| F | 10.33 | 41.00 | 48.67 |

图9 X65管线钢焊接接头在不同工况下的最大点蚀速率及最大点蚀深度

Fig.9 The maximum pitting rate and maximum pitting depth of X65 pipeline steel welded joints under different working conditions

| 工况 | 表面粗糙度/μm |

|---|---|

| a | 1.276 |

| b | 9.462 |

| c | 1.986 |

| d | 1.178 |

| e | 2.289 |

| f | 2.072 |

表3 不同工况下表面粗糙度

Table 3 Surface roughness under different working conditions

| 工况 | 表面粗糙度/μm |

|---|---|

| a | 1.276 |

| b | 9.462 |

| c | 1.986 |

| d | 1.178 |

| e | 2.289 |

| f | 2.072 |

| [1] | Sim S, Cole I S, Choi Y S, et al. A review of the protection strategies against internal corrosion for the safe transport of supercritical CO2 via steel pipelines for CCS purposes[J]. International Journal of Greenhouse Gas Control, 2014, 29: 185-199. |

| [2] | Wang Z M, Song G L, Zhang J. Corrosion control in CO2 enhanced oil recovery from a perspective of multiphase fluids[J]. Frontiers in Materials, 2019, 6: 272. |

| [3] | 向勇, 原玉, 周佩, 等. 碳捕集利用与封存中的金属腐蚀问题研究:进展与挑战[J]. 中国工程科学, 2023, 25(3): 197-208. |

| Xiang Y, Yuan Y, Zhou P, et al. Metal corrosion in carbon capture, utilization, and storage: progress and challenges[J]. Strategic Study of CAE, 2023, 25(3): 197-208. | |

| [4] | Xiang Y, Li C, Hesitao W, et al. Understanding the pitting corrosion mechanism of pipeline steel in an impure supercritical CO2 environment[J]. The Journal of Supercritical Fluids, 2018, 138: 132-142. |

| [5] | Xiang Y, Wang Z, Xu C, et al. Impact of SO2 concentration on the corrosion rate of X70 steel and iron in water-saturated supercritical CO2 mixed with SO2 [J]. The Journal of Supercritical Fluids, 2011, 58(2): 286-294. |

| [6] | Li C, Xiang Y, Li W G. Initial corrosion mechanism for API 5L X80 steel in CO2/SO2-saturated aqueous solution within a CCUS system: inhibition effect of SO2 impurity[J]. Electrochimica Acta, 2019, 321: 134663. |

| [7] | Li C, Xiang Y, Wang R T, et al. Exploring the influence of flue gas impurities on the electrochemical corrosion mechanism of X80 steel in a supercritical CO2-saturated aqueous environment[J]. Corrosion Science, 2023, 211: 110899. |

| [8] | Li K Y, Zeng Y M. Long-term corrosion and stress corrosion cracking of X65 steel in H2O-saturated supercritical CO2 with SO2 and O2 impurities[J]. Construction and Building Materials, 2023, 362: 129746. |

| [9] | Zeng Y M, Li K Y. Influence of SO2 on the corrosion and stress corrosion cracking susceptibility of supercritical CO2 transportation pipelines[J]. Corrosion Science, 2020, 165: 108404. |

| [10] | Wei L, Pang X L, Gao K W. Corrosion of low alloy steel and stainless steel in supercritical CO2/H2O/H2S systems[J]. Corrosion Science, 2016, 111: 637-648. |

| [11] | 刘广瑜, 支树洁, 柳歆, 等. CCUS超临界/密相CO2管道内腐蚀研究进展[J]. 油气储运, 2024, 43(5): 510-523. |

| Liu G Y, Zhi S J, Liu X, et al. Research progress on internal corrosion of supercritical/dense-phase CO2 pipelines for CCUS[J]. Oil & Gas Storage and Transportation, 2024, 43(5): 510-523. | |

| [12] | Hua Y, Barker R, Neville A. Effect of temperature on the critical water content for general and localised corrosion of X65 carbon steel in the transport of supercritical CO2 [J]. International Journal of Greenhouse Gas Control, 2014, 31: 48-60. |

| [13] | 胡丽华, 衣华磊, 杨维健, 等. 水含量对超临界CO2输送管道腐蚀的影响[J]. 中国腐蚀与防护学报, 2024, 44(3): 576-584. |

| Hu L H, Yi H L, Yang W J, et al. Effect of water content on corrosion behavior of X65 pipeline steel in supercritical CO2 fluids[J]. Journal of Chinese Society for Corrosion and Protection, 2024, 44(3): 576-584. | |

| [14] | Xiang Y, Wang Z, Yang X X, et al. The upper limit of moisture content for supercritical CO2 pipeline transport[J]. The Journal of Supercritical Fluids, 2012, 67: 14-21. |

| [15] | Li C, Xiang Y, Song C C, et al. Assessing the corrosion product scale formation characteristics of X80 steel in supercritical CO2-H2O binary systems with flue gas and NaCl impurities relevant to CCUS technology[J]. The Journal of Supercritical Fluids, 2019, 146: 107-119. |

| [16] | Hong H, Ye T C, Zhang J, et al. Corrosion mitigation behavior of mild steel in supercritical CO2 environments with varying the solution volume[J]. Corrosion Science, 2024, 229: 111853. |

| [17] | Górka J, Jamrozik W, Kiel-Jamrozik M. The effect of TIG welding on the structure and hardness of butt joints made of Inconel 718[J]. Heliyon, 2023, 9(2): e13175. |

| [18] | Ralston K D, Birbilis N, Davies C H J. Revealing the relationship between grain size and corrosion rate of metals[J]. Scripta Materialia, 2010, 63(12): 1201-1204. |

| [19] | Khalaj G, Khalaj M J. Investigating the corrosion of the heat-affected zones (HAZs) of API-X70 pipeline steels in aerated carbonate solution by electrochemical methods[J]. International Journal of Pressure Vessels and Piping, 2016, 145: 1-12. |

| [20] | Alizadeh M, Bordbar S. The influence of microstructure on the protective properties of the corrosion product layer generated on the welded API X70 steel in chloride solution[J]. Corrosion Science, 2013, 70: 170-179. |

| [21] | Wang Q, Cao X M, Wu T Q, et al. Corrosion of X80 steel welded joint under disbonded coating in an acidic soil solution[J]. International Journal of Pressure Vessels and Piping, 2021, 194: 104508. |

| [22] | Chaves I A, Melchers R E. Pitting corrosion in pipeline steel weld zones[J]. Corrosion Science, 2011, 53(12): 4026-4032. |

| [23] | Deng H D, Cao X L, Yan Y B, et al. Effect of microstructure on corrosion of welded joints of X80 steel in water saturated supercritical CO2 [J]. Anti-Corrosion Methods and Materials, 2019, 66(4): 425-431. |

| [24] | Zhao Z P, Xu K, Xu P F, et al. CO2 corrosion behavior of simulated heat-affected zones for X80 pipeline steel[J]. Materials Characterization, 2021, 171: 110772. |

| [25] | Nordsveen M, Nešić S, Nyborg R, et al. A mechanistic model for carbon dioxide corrosion of mild steel in the presence of protective iron carbonate films (part 1): Theory and verification[J]. Corrosion, 2003, 59(5): 443-456. |

| [26] | Wang J Z, Wang J Q, Han E H. Influence of conductivity on corrosion behavior of 304 stainless steel in high temperature aqueous environment[J]. Journal of Materials Science & Technology, 2016, 32(4): 333-340. |

| [27] | Chin R J, Nobe K. Electrodissolution kinetics of iron in chloride solutions[J]. Journal of The Electrochemical Society, 1972, 119(11): 1457. |

| [28] | Foroulis Z A, Thubrikar M J. On the kinetics of the breakdown of passivity of preanodized aluminum by chloride ions[J]. Journal of the Electrochemical Society, 122(10): 1296-1301. |

| [29] | 韩晓龙, 王毅, 吴鑫, 等. CO2体系下X70天然气管线钢的电化学腐蚀行为研究[J]. 材料保护, 2024, 57(5): 83-89, 151. |

| Han X L, Wang Y, Wu X, et al. Study of electrochemical corrosion behavior on X70 natural gas pipeline steel under CO2 system[J]. Materials Protection, 2024, 57(5): 83-89, 151. | |

| [30] | Xiang Y, Song C C, Li C, et al. Characterization of 13Cr steel corrosion in simulated EOR-CCUS environment with flue gas impurities[J]. Process Safety and Environmental Protection, 2020, 140: 124-136. |

| [31] | 宋光铃, 曹楚南, 高卫红, 等. Cl-对铁在硫酸介质中致钝过程的影响[J]. 中国腐蚀与防护学报, 1994, 14(3): 175-183. |

| Song G L, Cao C N, Gao W H, et al. Effects of Cl- on passivation process of Fe in acidic media[J]. Journal of Chinese Society for Corrosion and Protection, 1994, 14(3): 175-183. | |

| [32] | Dugstad A, Hemmer H, Seiersten M. Effect of steel microstructure on corrosion rate and protective iron carbonate film formation[J]. Corrosion, 2001, 57(4): 369-378. |

| [33] | Lu Y X, Jing H Y, Han Y D, et al. Effect of welding heat input on the corrosion resistance of carbon steel weld metal[J]. Journal of Materials Engineering and Performance, 2016, 25(2): 565-576. |

| [34] | Ding H X, Xiang Y, Lu W P, et al. Selective adsorption and corrosion mechanism of SO2 and its hydrates on X65 welded joints steel in CO2-saturated aqueous solution[J]. Corrosion Science, 2024, 238: 112373. |

| [1] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [2] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [3] | 孙国庆, 李海波, 丁志阳, 郭文辉, 徐浩, 赵艳侠. 硅基负极材料的研究进展[J]. 化工学报, 2025, 76(7): 3197-3211. |

| [4] | 高凤凤, 程慧峰, 杨博, 郝晓刚. 电驱动NiFeMn LDH/CNTs/PVDF膜电极选择性提取钨酸根离子[J]. 化工学报, 2025, 76(7): 3350-3360. |

| [5] | 李姿睿, 齐凯, 王军, 夏国栋. 基于Janus纳米通道的脱盐过程分子动力学模拟研究[J]. 化工学报, 2025, 76(7): 3531-3538. |

| [6] | 王珺仪, 夏章讯, 景粉宁, 王素力. 基于重整气的高温聚合物电解质膜燃料电池电化学阻抗谱弛豫时间分布研究[J]. 化工学报, 2025, 76(7): 3509-3520. |

| [7] | 何昌秋, 田加猛, 陈义齐, 朱宇琛, 刘鑫, 王海, 王贞涛, 王军锋, 周致富, 陈斌. 电场-宏观结构表面协同强化薄液膜沸腾传热特性[J]. 化工学报, 2025, 76(6): 2589-2602. |

| [8] | 郭江悦, 常守金, 胡海涛. 水平管内甲醇流动冷凝数值模拟研究[J]. 化工学报, 2025, 76(6): 2580-2588. |

| [9] | 蒋敏, 邵翔宇, 郑立刚, 高建良, 雷刚. 膜片压力对氢-空气混合气体泄爆过程的影响[J]. 化工学报, 2025, 76(6): 2770-2780. |

| [10] | 康佳, 刘欢, 李海燕, 罗茂亮, 姚洪. 宽温区HCl/NaOH热介质中碳钢腐蚀行为及涂层性能研究[J]. 化工学报, 2025, 76(6): 2872-2885. |

| [11] | 梁碧麟, 余倩, 贾思琦, 李芳, 李其明. Ni-MOF-74金属有机框架膜的结构调变及气体分离性能研究[J]. 化工学报, 2025, 76(6): 2714-2721. |

| [12] | 孙文浩, 田君, 张锟, 刘娜, 曹宝森, 梁晓嫱. 锂离子电池用高热稳定性新型隔膜的研究新进展[J]. 化工学报, 2025, 76(6): 2524-2543. |

| [13] | 郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261. |

| [14] | 朱迪, 高守建, 方望熹, 靳健. 水蒸气诱导相分离构筑海绵孔结构超亲水聚醚砜膜及其油/水乳液分离性能研究[J]. 化工学报, 2025, 76(5): 2397-2409. |

| [15] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号