化工学报 ›› 2019, Vol. 70 ›› Issue (9): 3283-3290.DOI: 10.11949/0438-1157.20190133

侯中兰1,2( ),魏新利1,2(

),魏新利1,2( ),马新灵1,2,孟祥睿1,2

),马新灵1,2,孟祥睿1,2

收稿日期:2019-02-19

修回日期:2019-06-08

出版日期:2019-09-05

发布日期:2019-09-05

通讯作者:

魏新利

作者简介:侯中兰(1980—),女,博士研究生,高级工程师,基金资助:

Zhonglan HOU1,2( ),Xinli WEI1,2(

),Xinli WEI1,2( ),Xinling MA1,2,Xiangrui MENG1,2

),Xinling MA1,2,Xiangrui MENG1,2

Received:2019-02-19

Revised:2019-06-08

Online:2019-09-05

Published:2019-09-05

Contact:

Xinli WEI

摘要:

基于实验室3 kW有机朗肯循环(ORC)低温余热发电试验装置,参考石化行业能耗设计标准将循环水作为耗能工质,采用总能系统方法进行能耗分析,对比了不同热源温度下不同分析边界的系统及主要设备的热力学性能。结果显示:发电机输出功、膨胀机输出功、ORC子系统净输出功、ORC子系统热效率和?效率均随着热源温度和循环水流量的增加而增加;不同热源温度下,最大系统净输出功与最大系统?效率出现的工况一致。本试验在热源温度为120℃时取得最大系统净输出功0.731 kW和最大系统?效率11.81%,此时对应循环水流量为1.629 t·h-1。该研究为ORC余热发电系统性能与能耗分析提供了参考。

中图分类号:

侯中兰, 魏新利, 马新灵, 孟祥睿. 循环水流量对ORC余热发电系统性能影响的试验分析[J]. 化工学报, 2019, 70(9): 3283-3290.

Zhonglan HOU, Xinli WEI, Xinling MA, Xiangrui MENG. Experimental analysis of circulating water flow rate on performance of ORC waste heat power generation system[J]. CIESC Journal, 2019, 70(9): 3283-3290.

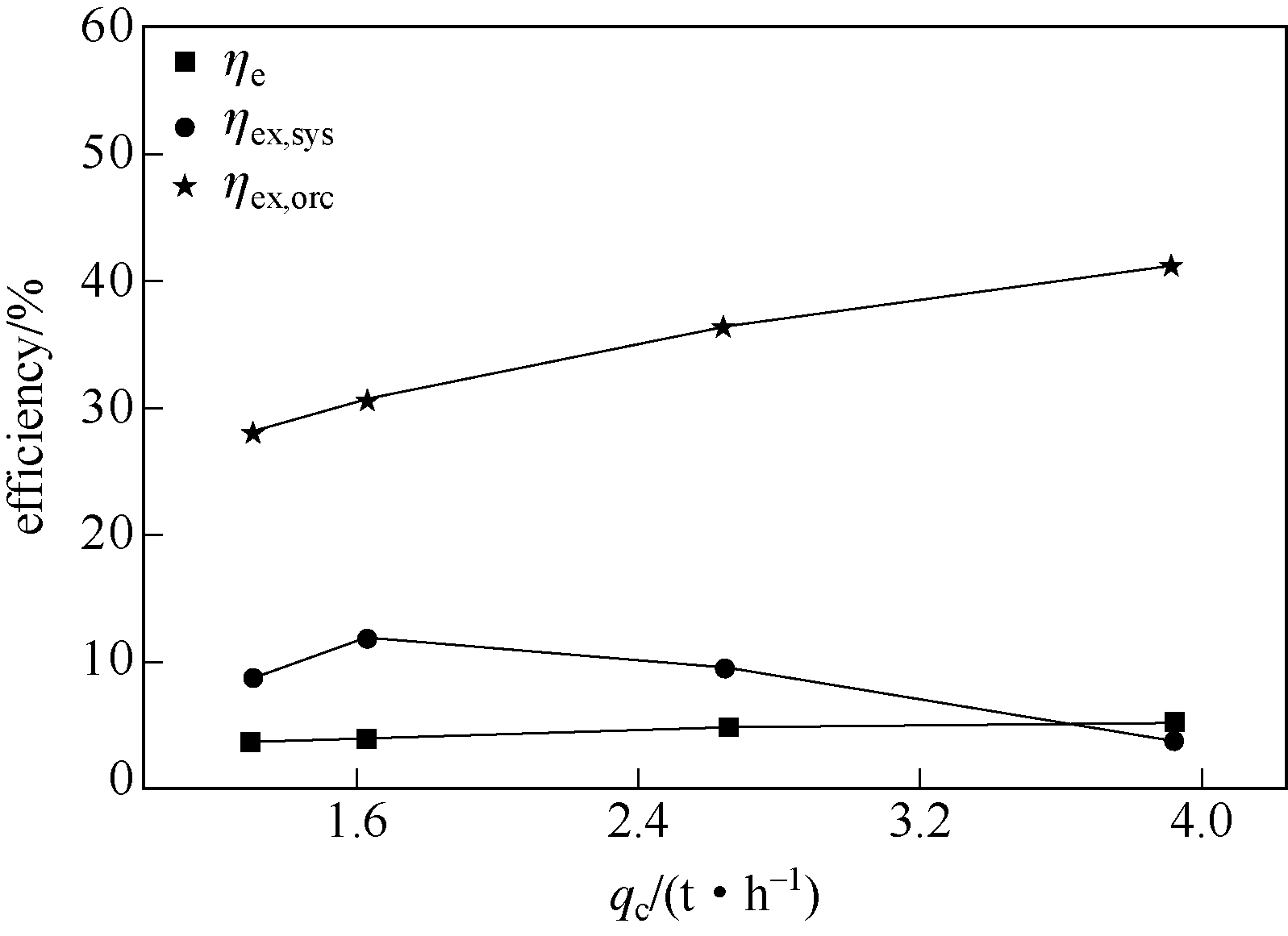

图7 热源温度为100℃时热效率和?效率随循环水流量的变化

Fig.7 Change of exergy efficiency and thermal efficiency along with flow rate of circulating water as heat source temperature is 100℃

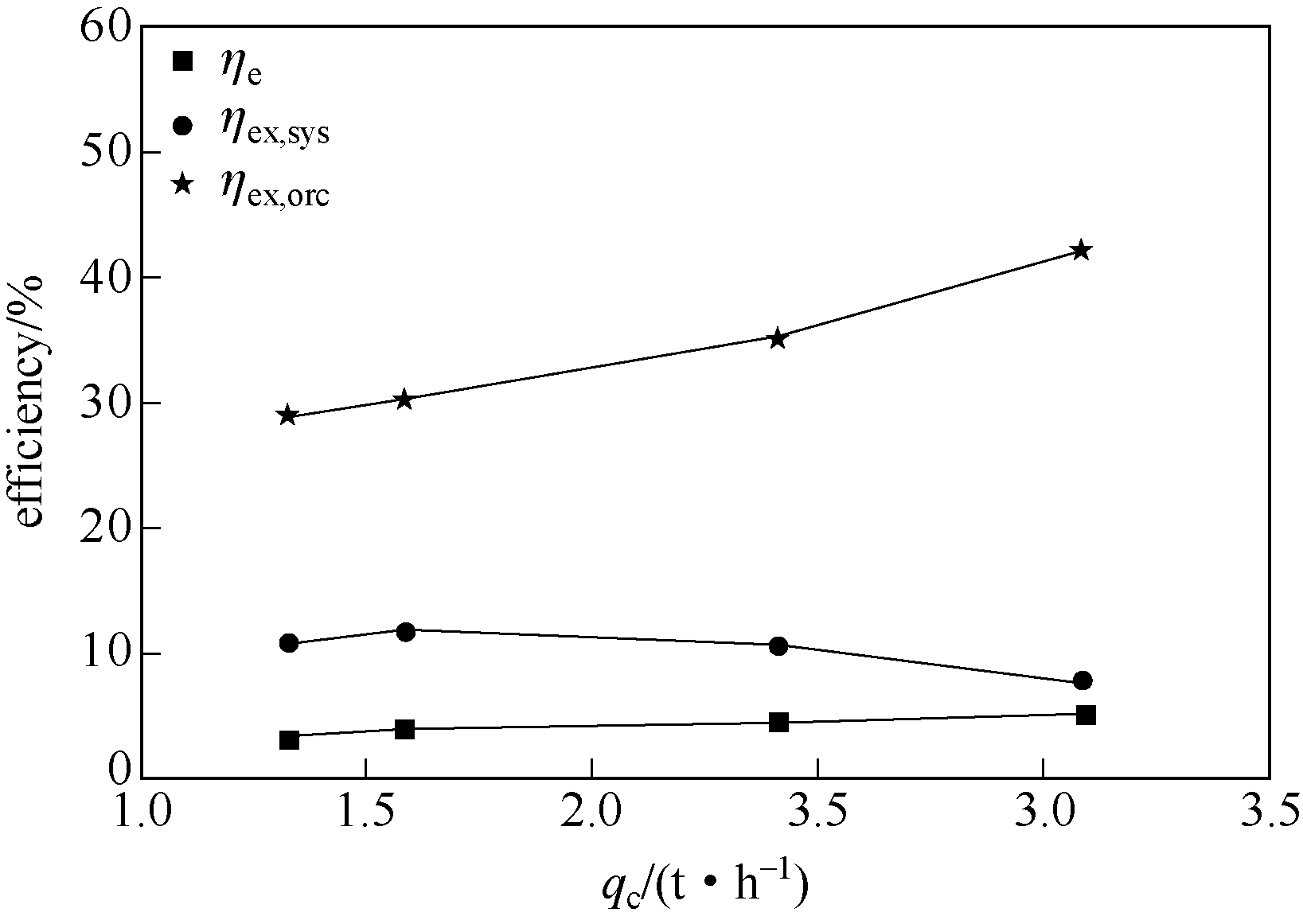

图8 热源温度为110℃时ORC子系统?效率和系统?效率及热效率随循环水流量的变化

Fig.8 Change of exergy efficiency and thermal efficiency along with flow rate of circulating water as heat source temperature is 110℃

图9 热源温度为120℃时ORC子系统?效率和系统?效率及热效率随循环水流量的变化

Fig.9 Change of exergy efficiency and thermal efficiency along with flow rate of circulating water as heat source temperature is 120℃

| T H /℃ | EQ / kW | | | q c/(t·h-1) |

|---|---|---|---|---|

| 100 | 5.527 | 0.645 | 11.68 | 1.546 |

| 110 | 5.826 | 0.686 | 11.78 | 1.581 |

| 120 | 6.194 | 0.731 | 11.81 | 1.629 |

表1 最大系统净输出功和最大系统?效率

Table 1 Maximum values of net output power and exergy efficiency of system

| T H /℃ | EQ / kW | | | q c/(t·h-1) |

|---|---|---|---|---|

| 100 | 5.527 | 0.645 | 11.68 | 1.546 |

| 110 | 5.826 | 0.686 | 11.78 | 1.581 |

| 120 | 6.194 | 0.731 | 11.81 | 1.629 |

| 1 | Bertrand F T , Lambrinos G , Frangoudakis A , et al . Low-grade heat conversion into power using organic Rankine cycles —a review of various applications[J]. Renewable and Sustainable Energy Reviews, 2011, 15: 3963-3979. |

| 2 | 刘强, 段远源, 万绪财 . 利用汽包锅炉连续排污余热的有机朗肯循环发电系统[J]. 中国电机工程学报, 2013, 33(35): 1-7. |

| Liu Q , Duan Y Y , Wan X C . Power generation systems using continuous blowdown waste heat from drum boilers driving an organic Rankine cycle[J]. Proceedings of the CSEE, 2013, 33(35): 1-7. | |

| 3 | Lee Y R , Liu L W , Chang Y Y , et al . Development and application of a 200 kW ORC generator system for energy recovery in chemical processes[J]. Energy Procedia, 2017, 129: 519-526. |

| 4 | Vikas R P , Vijay I B , Shreyas R , et al . Techno-economic comparison of solar organic Rankine cycle (ORC) and photovoltaic (PV) systems with energy storage[J]. Renewable Energy, 2017, 113: 1250-1260. |

| 5 | Pereira J S , Ribeiro J B , Ricardo M , et al . ORC based micro-cogeneration systems for residential application —a state of the art review and current challenges[J]. Renewable and Sustainable Energy Reviews, 2018, 92: 728-743. |

| 6 | 王华荣, 徐进良 . 采用BP-GA算法的有机朗肯循环多目标优化[J]. 中国电机工程学报, 2016 , 36(12): 3168- 3175. |

| Wang H R , Xu J L . Multi-objective optimization for organic Rankine cycle using BP-GA algorithm[J]. Proceedings of the CSEE, 2016, 36(12): 3168-3175. | |

| 7 | 马新灵, 孟祥睿, 魏新利, 等 . 有机朗肯循环低品位热能发电系统向心透平的设计与性能研究[J]. 中国电机工程学报, 2014, 34(14): 2289-2296. |

| Ma X L , Meng X R , Wei X L , et al . Design and performance study of radial inflow turbine used on organic Rankine cycle waste heat power generation system[J]. Proceedings of the CSEE, 2014, 34(14): 2289-2296. | |

| 8 | 郭贵奇, 罗向龙, 许俊俊, 等 . ORC换热设备结构与操作参数多目标同步优化[J]. 工程热物理学报, 2017, 38(8): 1619-1623. |

| Guo G Q , Luo X L , Xu J J , et al . Heat exchange equipment structure and operation parameter multi-objective optimization simultaneously of ORC[J]. Journal of Engineering Thermophysics, 2017, 38(8): 1619-1623. | |

| 9 | 张红光, 杨宇鑫, 孟凡骁, 等 . 有机朗肯循环系统中工质泵的运行性能[J]. 化工学报, 2017, 68(9): 3573-3579. |

| Zhang H G , Yang Y X , Meng F X , et al . Running performance of working fluid pump for organic Rankine cycle system [J]. CIESC Journal, 2017, 68(9): 3573-3579. | |

| 10 | Jan W , Dariusz M , Blanka J . Performance of the domestic micro ORC equipped with the shell-and-tube condenser with minichannels[J]. Energy, 2018, 157: 853-861. |

| 11 | Sun J , Liu Q , Duan Y Y . Effects of evaporator pinch point temperature difference on thermo-economic performance of geothermal organic Rankine cycle system[J]. Geothermics, 2018, 75: 249-258. |

| 12 | Song J , Gu C W , Ren X D . Parametric design and off-design analysis of organic Rankine cycle (ORC) system[J]. Energy Conversion and Management, 2016, 112: 157-165. |

| 13 | Shao L , Ma X L , Wei X L , et al . Design and experimental study of a small-sized organic Rankine cycle system under various cooling conditions[J]. Energy, 2017, 130: 236-245. |

| 14 | Liu Q , Duan Y Y , Yan Z . Effect of condensation temperature glide on the performance of organic Rankine cycles with zeotropic mixture working fluids[J]. Applied Energy, 2014, 115: 394-404. |

| 15 | 王慧, 马新灵, 孟祥睿, 等 . 工质流量对ORC低温余热发电系统性能的影响[J]. 化工学报, 2015, 66(10): 4185-4192. |

| Wang H , Ma X L , Meng X R , et al . Effect of mass flow rate on performance of organic Rankine cycle for power generation system with low-temperature waste heat[J]. CIESC Journal, 2015, 66(10): 4185-4192. | |

| 16 | 金红光 . 能的梯级利用与总能系统[J]. 科学通报, 2017, 62: 2589-2593. |

| Jin H G . Energy cascade utilization and total energy system[J]. Chinese Science Bulletin, 2017, 62: 2589-2593. | |

| 17 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会 . 综合能耗计算通则: GB/T2589—2008[S]. 北京: 中国标准出版社, 2008. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China . General principles for calculation of the comprehensive energy consumption: GB/T2589—2008[S]. Beijing: Standards Press of China, 2008. | |

| 18 | 中华人民共和国住房和城乡建设部, 中华人民共和国国家质量监督检验检疫总局 . 石油化工设计能耗计算标准: GB/T 50441—2016[S]. 北京: 中国计划出版社, 2016. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Ministry of Housing and Urban Rural Development of People’s Republic of China . Standard for calculation of energy consumption in petrochemical engineering design: GB/T50441—2016[S]. Beijing: China Planning Press, 2016. | |

| 19 | 徐海伦, 王少强, 邵远敬, 等 . 综合能耗计算过程中能源折标系数探讨[J]. 冶金能源, 2017, 36(3): 3-7. |

| Xu H L , Wang S Q , Shao Y J , et al . Study on energy conversion coefficient for comprehensive energy consumption calculation[J]. Energy for Metallurgical Industry, 2017, 36(3): 3-7. | |

| 20 | 杨勇平, 杨志平, 徐钢, 等 . 中国火力发电能耗状况及展望[J]. 中国电机工程学报, 2013, 33(23): 1-11. |

| Yang Y P , Yang Z P , Xu G , et al . Situation and prospect of energy consumption for China’s thermal power generation[J]. Proceedings of the CSEE, 2013, 33(23): 1-11. | |

| 21 | 吴玉庭, 赵英昆, 张超, 等 . 冷却系统对ORC性能影响的模拟研究[J]. 工程热物理学报, 2018, 39(7): 1412-1416. |

| Wu Y T , Zhao Y K , Zhang C , et al . Simulation study of cooling system on ORC performance[J]. Journal of Engineering Thermophysics, 2018, 39(7): 1412-1416. | |

| 22 | 吴玉庭, 赵英昆, 雷标, 等 . 冷却水流量对ORC系统性能影响的实验研究[J]. 化工学报, 2018, 69(6): 2639-2645. |

| Wu Y T , Zhao Y K , Lei B , et al . Effect of cooling water flow rate on power generation of organic Rankine cycle system[J]. CIESC Journal, 2018, 69(6): 2639-2645. | |

| 23 | Liu Q , Duan Y Y , Yang Z . Performance analyses of geothermal organic Rankine cycles with selected hydrocarbon working fluids[J]. Energy, 2013, 63: 123-132. |

| 24 | 曾丹苓, 敖越, 张新铭, 等 . 工程热力学 [M]. 3版. 北京: 高等教育出版社, 2004: 275. |

| Zeng D L , Ao Y , Zhang X M , et al . Engineering Thermodynamics [M]. 3rd ed. Beijing: Higher Education Press, 2004: 275. | |

| 25 | 穆永强, 张晓东 . 能量系统分析的热经济学方法概论[M]. 北京: 中国电力出版社, 2018: 102-104. |

| Mu Y Q , Zhang X D . An Overview of Thermoeconomic Methods for Energy System Analysis [M]. Beijing: China Electric Power Press, 2018: 102-104. | |

| 26 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会 . 能量系统㶲分析技术导则: GB/T 14909—2005[S]. 北京: 中国标准出版社, 2005. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China . Technical guides for exergy analysis in energy system:GB/T 14 909—2005[S]. Beijing: Standards Press of China, 2005. | |

| 27 | Qin X , Liu H D , Meng X R , et al . A study on the compressor frequency and optimal discharge pressure of the transcritical CO2 heat pump system[J]. International Journal of Refrigeration, 2019, 99: 101-113. |

| [1] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [2] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [3] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [4] | 卫雪岩, 钱勇. 微米级铁粉燃料中低温氧化反应特性及其动力学研究[J]. 化工学报, 2023, 74(6): 2624-2638. |

| [5] | 党玉荣, 莫春兰, 史科锐, 方颖聪, 张子杨, 李作顺. 综合评价模型联合遗传算法的混合工质ORC系统性能研究[J]. 化工学报, 2023, 74(5): 1884-1895. |

| [6] | 王昊成, 杨敬瑶, 董学强, 郭浩, 赵延兴, 公茂琼. 10 t/d级氢液化装置流程热力分析与优化[J]. 化工学报, 2022, 73(11): 5106-5117. |

| [7] | 顾潇, 邹慧明, 韩欣欣, 唐明生, 田长青. 基于余热回收的电动客车喷射补气热泵的制热性能[J]. 化工学报, 2021, 72(S1): 326-335. |

| [8] | 陈建业, 丁月, 吴钊, 禹云星, 邵双全. 带涡流管的新型加氢流程数值研究[J]. 化工学报, 2021, 72(S1): 461-466. |

| [9] | 崔运浩, 乔建新, 王晓涛, 宋斌, 阳朝辉, 戴巍, 李海冰. 普冷温区斯特林制冷机[J]. 化工学报, 2021, 72(S1): 390-397. |

| [10] | 李子航, 王占博, 苗政, 纪献兵. 亚临界有机朗肯循环系统工质筛选及热经济性分析[J]. 化工学报, 2021, 72(9): 4487-4495. |

| [11] | 曹健, 冯新, 吉晓燕, 陆小华. 基于混合工质的多级蒸发ORC理论极限性能研究[J]. 化工学报, 2021, 72(7): 3780-3787. |

| [12] | 荣杨一鸣, 吴巧仙, 周霞, 方松, 王凯, 邱利民, 植晓琴. 空分系统空气压缩余热自利用性能优化研究[J]. 化工学报, 2021, 72(3): 1654-1666. |

| [13] | 黄文博, 曹文炅, 李庭樑, 蒋方明. 干热岩热能重力热管采热系统数值模拟研究与经济性分析[J]. 化工学报, 2021, 72(3): 1302-1313. |

| [14] | 裴后举, 蒋彦龙, 施红, 崔永龙, 陈常栋, 钱晓辉. 基于M-L湍流模型的浮空器强迫对流换热[J]. 化工学报, 2020, 71(S1): 136-141. |

| [15] | 杨晓东, 庞丽萍, 阿嵘, 金亮. 高速飞行器燃油热管理系统飞行热航时[J]. 化工学报, 2020, 71(S1): 425-429. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号