化工学报 ›› 2020, Vol. 71 ›› Issue (8): 3652-3660.DOI: 10.11949/0438-1157.20200242

收稿日期:2020-03-09

修回日期:2020-05-21

出版日期:2020-08-05

发布日期:2020-08-05

通讯作者:

罗平

作者简介:周鑫(1993—),女,硕士研究生,基金资助:

Xin ZHUO1( ),Minghui QIU2,Ping LUO1(

),Minghui QIU2,Ping LUO1( )

)

Received:2020-03-09

Revised:2020-05-21

Online:2020-08-05

Published:2020-08-05

Contact:

Ping LUO

摘要:

针对选择性催化还原技术(SCR)存在装置大、运行费用高、催化剂中毒失活等问题,将平均孔径为100 nm的Al2O3陶瓷膜进行疏水改性并组装成膜接触器,以NaClO2水溶液为吸收液,开展陶瓷膜接触器在烟气脱硝领域的应用研究。考察了陶瓷膜接触器在化学吸收脱硝中的稳定性,以及气体流量、吸收液浓度、吸收液流量、吸收液pH等因素对NO脱除率和传质通量的影响,基于阻力串联模型,建立总传质系数方程。研究表明,陶瓷膜接触器在连续600 min运行过程中,NO的脱除效率及传质通量分别稳定在99%和0.038 mol·m-2·h-1左右。进气流量的增加会促进NO的吸收,吸收液pH=3时具有最高的氧化吸收性能,同时提高吸收液的浓度会增强NO的脱除效果。NO的传质过程同时受气、液、膜三相阻力控制,传质阻力分析结果表明,可以通过增加气体流速减小气相阻力,增加吸收液浓度同时降低pH减小液相阻力。本研究在烟气脱硝领域具有良好的应用前景。

中图分类号:

周鑫, 邱鸣慧, 罗平. 陶瓷膜接触器化学吸收氮氧化物的传质过程与阻力分析[J]. 化工学报, 2020, 71(8): 3652-3660.

Xin ZHUO, Minghui QIU, Ping LUO. Mass transfer performance and resistance analysis of chemical absorption of NOx based on ceramic membrane contactor[J]. CIESC Journal, 2020, 71(8): 3652-3660.

| 规格参数 | 参数值 |

|---|---|

| 膜组件尺寸(外径/内径)/mm | 25/22 |

| 膜尺寸(外径/内径)/mm | 12/8 |

| 膜有效长度/mm | 320 |

| 膜平均孔径/nm | 100 |

| 膜孔隙率/% | 40 |

| 膜管根数 | 1 |

表1 陶瓷膜接触器的规格参数

Table 1 Structure of Al2O3 ceramic membrane contactor

| 规格参数 | 参数值 |

|---|---|

| 膜组件尺寸(外径/内径)/mm | 25/22 |

| 膜尺寸(外径/内径)/mm | 12/8 |

| 膜有效长度/mm | 320 |

| 膜平均孔径/nm | 100 |

| 膜孔隙率/% | 40 |

| 膜管根数 | 1 |

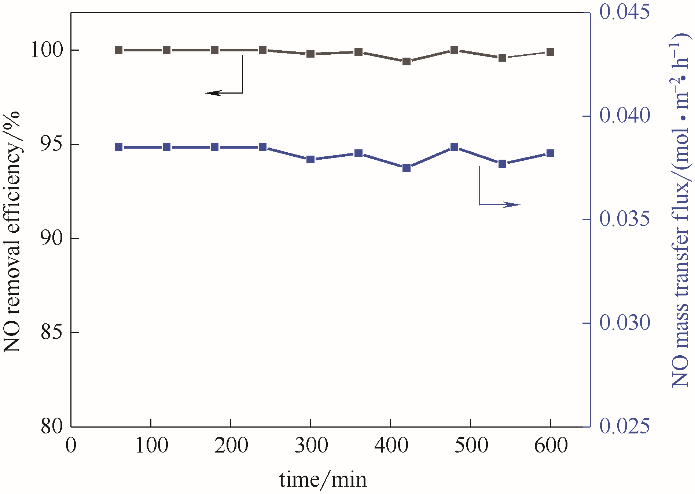

图5 疏水性陶瓷膜接触器的稳定性测试CNaClO2=0.02 mol·L-1, CNO=500 ml·m-3, Ql=30 ml·min-1, Qg=300 ml·min-1, T=293 K, pH=3

Fig.5 Stability performance of hydrophobic ceramic membrane contacor

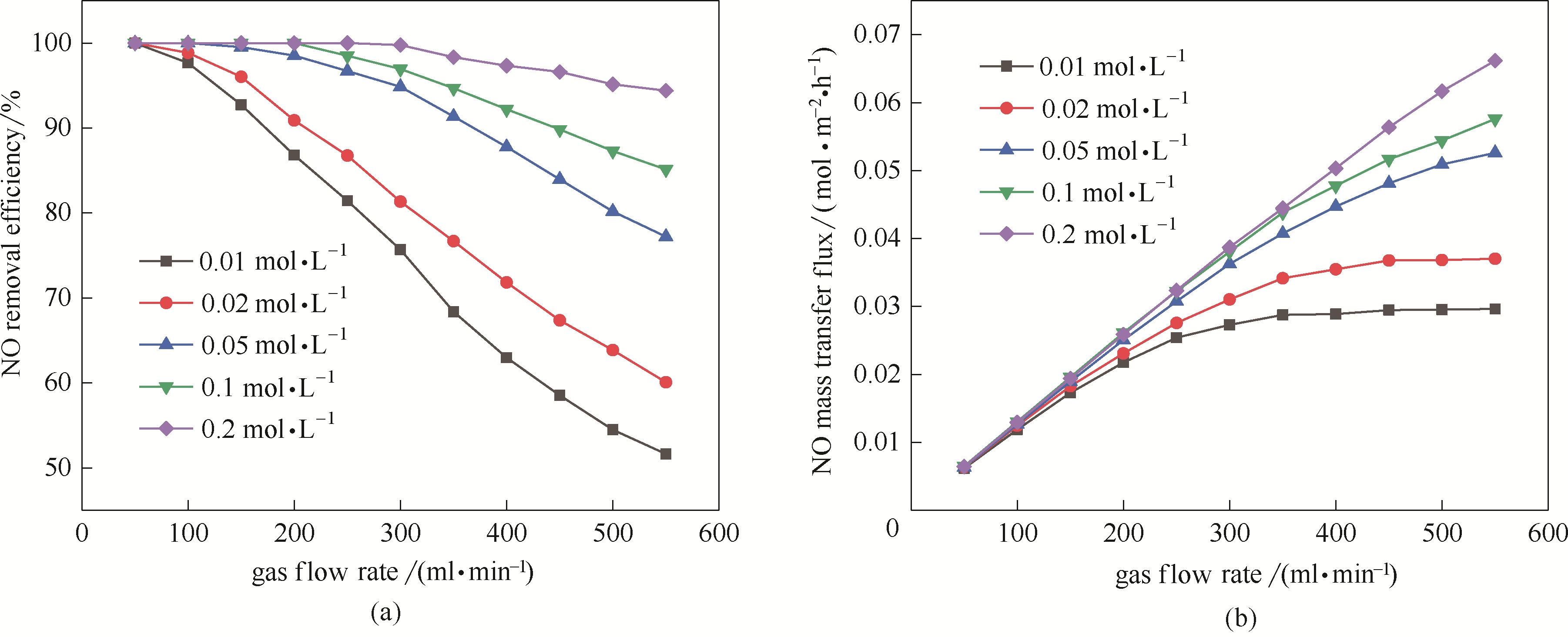

图6 进气流量对NO脱除率、传质通量的影响CNaClO2=0.01 mol·L-1, CNO=500ml·m-3, Ql=30 ml·min-1, T=293 K, pH=3

Fig.6 Effect of gas flow rate on NO removal efficiency and mass transfer flux

图8 吸收液pH对NO脱除率和传质通量的影响CNaClO2=0.01 mol·L-1, CNO=500 ml·m-3, Ql=30 ml·min-1, T=293 K

Fig.8 Effect of absorbent pH on NO removal efficiency and mass transfer flux

图9 吸收液浓度对NO脱除率和传质通量的影响CNO=500 ml·m-3, Ql=30 ml·min-1, pH=3, T=293 K

Fig.9 Effect of absorbent concentration on NO removal efficiency and mass transfer flux

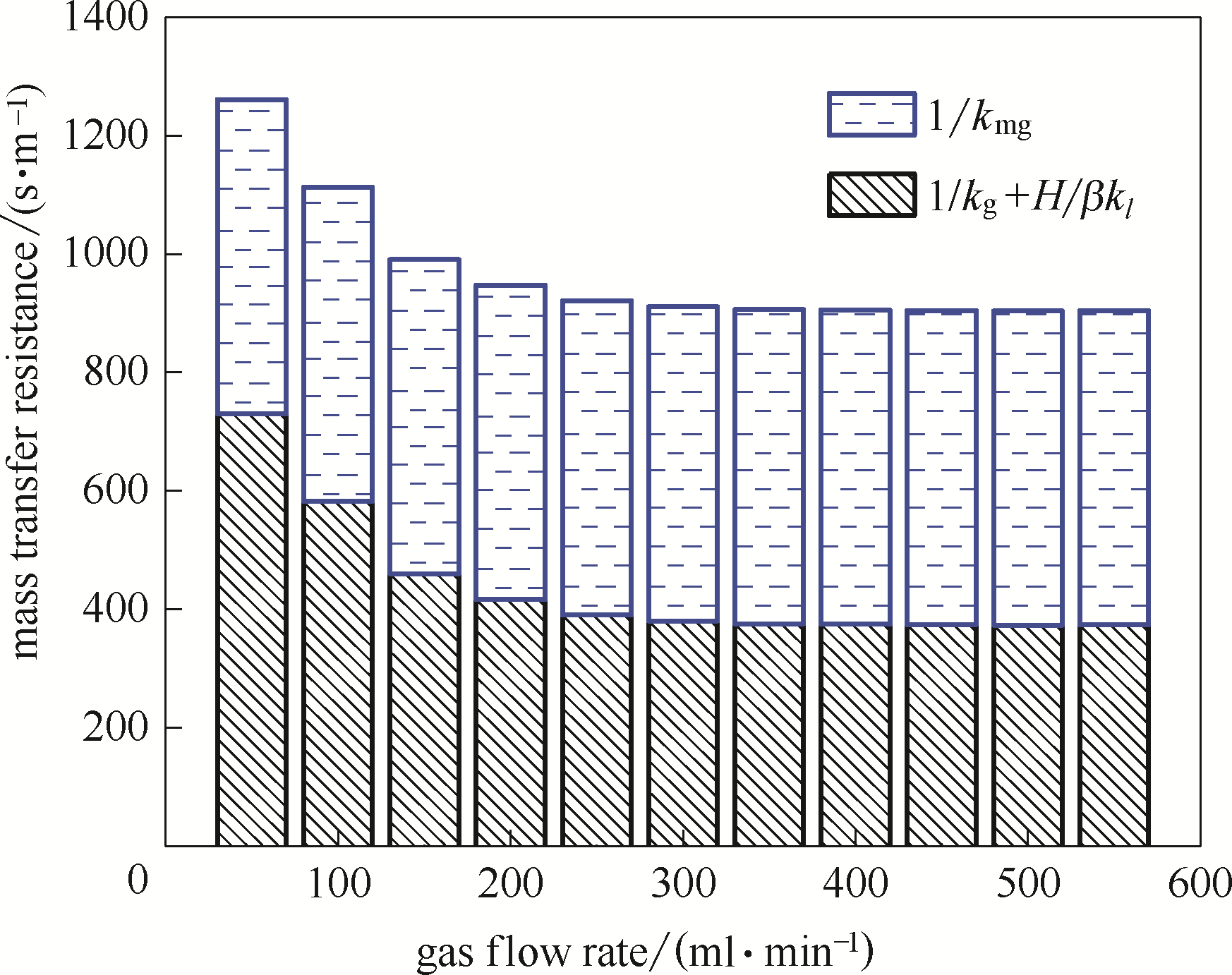

图10 气体流速与膜接触器总传质阻力的关系CNaClO2=0.01 mol·L-1, CNO=500 ml·m-3, Ql=30 ml·min-1,T=293 K, pH=3

Fig.10 Relationship between gas flow rate and membrane contactor mass transfer resistance

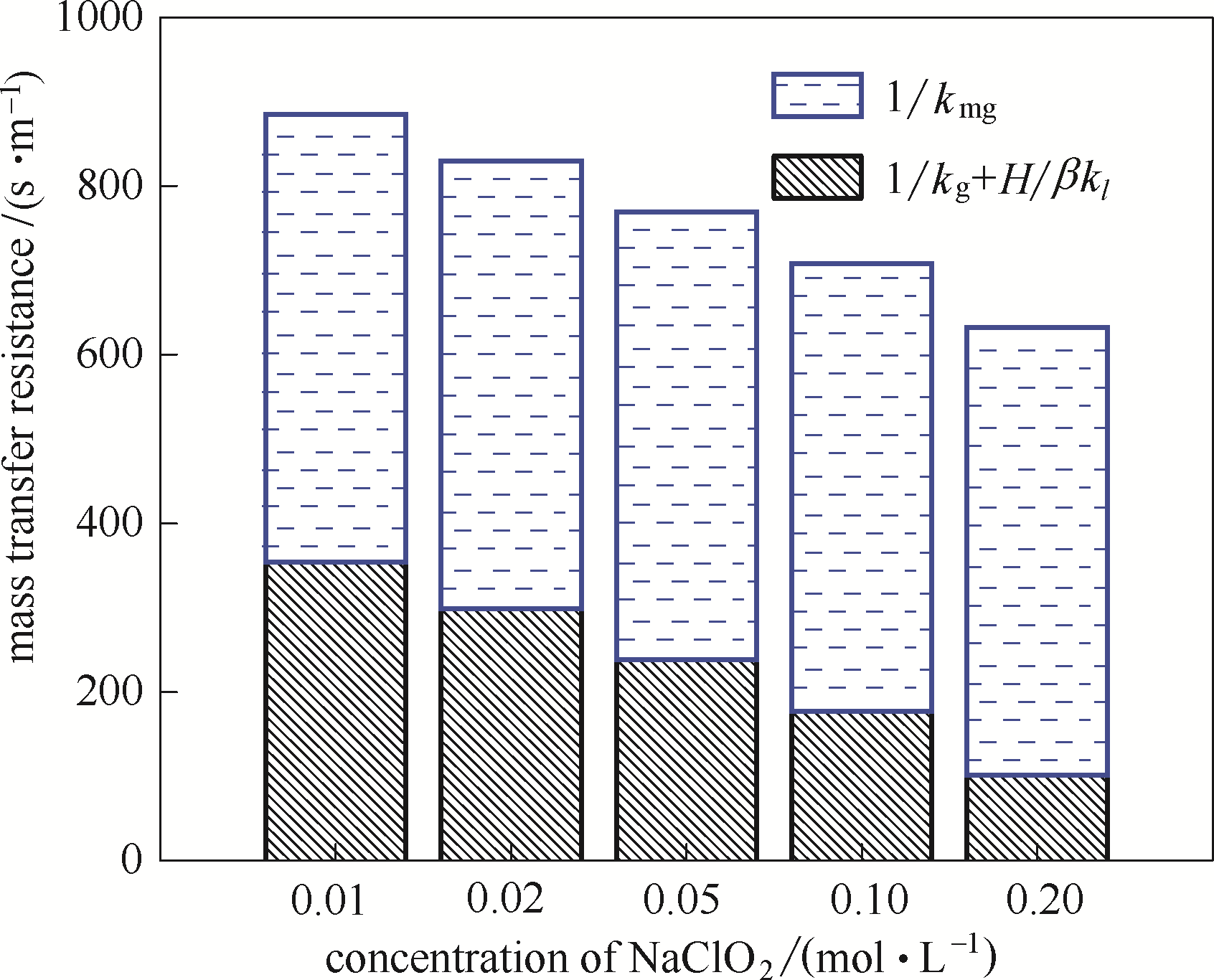

图11 吸收液浓度与膜接触器总传质阻力关系CNO=500 ml·m-3, Ql=30 ml·min-1, Qg=500 ml·min-1, T=293 K, pH=3

Fig.11 Relationship between absorption concentration and membrane contactor mass transfer resistance

| 1 | Asif M, Kim W S. Numerical study of NOx abatement using ozone injection integrated with wet absorption[J]. Ozone Science & Engineering, 2014, 36(5):472-484. |

| 2 | Guo L, Shu Y, Gao J. Present and future development of flue gas control technology of DeNOx in the world [J]. Energy Procedia, 2012, 17(part-A): 397-403. |

| 3 | Janssen F. Emission control from stationary sources[M]// Environmental Catalysis. World Scientific, 1999: 293-323. |

| 4 | 郑宴光. 新型船舶柴油机废气脱硝方法研究[D]. 大连: 大连海事大学, 2012. |

| Zheng Y G. Study on denitrification of marine diesel engine exhaust gas[D]. Dalian: Dalian Maritime University, 2012. | |

| 5 | Yang S L, Han Z T, Dong J M, et al. UV-enhanced NaClO oxidation of nitric oxide from simulated flue gas[J]. Journal of Chemistry, 2016, (2):1-8. |

| 6 | Deshwal B R, Lee S H, Jung J H, et al. Study on the removal of NOx from simulated flue gas using acidic NaClO2 solution[J]. Journal of Environmental Sciences, 2008, 20(1): 33-38. |

| 7 | Sreedhar I, Nahar T, Venugopal A, et al. Carbon capture by absorption-path covered and ahead[J]. Renewable and Sustainable Energy Reviews, 2017, 76: 1080-1107. |

| 8 | Mosadegh-Sedghi S, Rodrigue D, Brisson J, et al. Wetting phenomenon in membrane contactors — causes and prevention[J]. Journal of Membrane Science, 2014, 452: 332-353. |

| 9 | Lv Y X, Yu X H, Jia J J, et al. Fabrication and characterization of superhydrophobic polypropylene hollow fiber membranes for carbon dioxide absorption[J]. Applied Energy, 2012, 90(1): 167-174. |

| 10 | Sun X, Meng F, Yang F. Application of seawater to enhance SO2 removal from simulated flue gas through hollow fiber membrane contactor[J]. Journal of Membrane Science, 2008, 312(1/2): 6-14. |

| 11 | Mohebi S, Mousavi S M, Kiani S. Modeling and simulation of sour gas membrane-absorption system: influence of operational parameters on species removal[J]. Journal of Natural Gas Science & Engineering, 2009, 1(6):195-204. |

| 12 | 韩士贤, 高兴银, 符开云, 等. 疏水性单管陶瓷膜接触器在SO2吸收中的应用[J]. 化工学报, 2017, 68(6): 2415-2422. |

| Han S X, Gao X Y, Fu K Y, et al. Absorption of SO2 by single hydrophobic ceramic tubule-based membrane contactor[J]. Journal of Chemical Industry, 2017, 68(6): 2415-2422. | |

| 13 | Fang Z, Yu X, Tang W, et al. Denitration by oxidation-absorption with polypropylene hollow fiber membrane contactor[J]. Applied Energy, 2017, 206(15): 858-868. |

| 14 | 关毅鹏, 陈颖, 张召才, 等. 膜吸收法烟气同时脱硫脱硝试验研究[J]. 膜科学与技术, 2014, 34(1): 111-115. |

| Guan Y P, Chen Y, Zhang Z C, et al. Experimental study on simultaneous desulfurization and denitrification of flue gas by membrane absorption[J]. Membrane Science and Technology, 2014, 34(1): 111-115. | |

| 15 | 赵毅, 刘凤, 赵音, 等. 亚氯酸钠溶液同时脱硫脱硝的热力学研究[J]. 化学学报, 2008, 66(15): 1827-1832. |

| Zhao Y, Liu F, Zhao Y, et al. Simultaneous desulfurization and denitrification of sodium chlorite [J]. Acta Chemica Sinica, 2008, 66(15): 1827-1832. | |

| 16 | 赵静, 严金英, 邱婧伟, 等. NaClO2/NaClO 复合吸收液同时脱硫脱硝[J]. 环境工程学报, 2012, 6(10): 3684-3688. |

| Zhao J, Yan J Y, Qiu J W, et al. Simultaneous desulfurization and denitrification of NaClO2/NaClO composite absorbent[J]. Journal of Environmental Engineering, 2012, 6(10): 3684-3688. | |

| 17 | 郑德康, 韩志涛, 杨少龙,等. UV 辐射强化NaClO2溶液脱硝实验研究[J]. 化学工程, 2017, 45(2): 45-49, 67. |

| Zheng D K, Han Z T, Yang S L, et al. NO removal by wet scrubbing using UV-irradiated NaClO2 solution [J]. Chemical Engineering(China), 2017, 45(2): 45-49, 67. | |

| 18 | Gao J B, Wang S J, Zhao B, et al. Pilot-scale experimental study on the CO2 capture process with existing of SO2: degradation, reaction rate, and mass transfer[J]. Energy & Fuels, 2011, 25(12): 5802-5809. |

| 19 | Yang J, Yu X H, Yan J Y, et al. Effects of SO2 on CO2 capture using a hollow fiber membrane contactor[J]. Applied Energy, 2013, 112: 755-764. |

| 20 | Nanayakkara C E, Larish W A, Grassian V H. Titanium dioxide nanoparticle surface reactivity with atmospheric gases, CO2, SO2, and NO2: roles of surface hydroxyl groups and adsorbed water in the formation and stability of adsorbed products[J]. Journal of Physical Chemistry C, 2015, 118(40): 23011-23021. |

| 21 | Wu X, Zhao B, Liang W, et al. Hydrophobic PVDF/graphene hybrid membrane for CO2 absorption in membrane contactor[J]. Journal of Membrane Science, 2016, 520:120-129. |

| 22 | Koonaphaphapdeelert S, Li K. Preparation and characterization of hydrophobic ceramic hollow fibre membrane[J]. Journal of Membrane Science, 2007, 291(1/2): 70-76. |

| 23 | Gao N W, Li M, Jing W H, et al. Improving the filtration performance of ZrO2 membrane in non-polar organic solvents by surface hydrophobic modificaton[J]. Journal of Membrane Science, 2011, 375(1/2): 276-283. |

| 24 | 范益群, 邢卫红. 陶瓷膜表面性质研究进展[J]. 膜科学与技术, 2013, (5): 5-11. |

| Fan Y Q, Xing W H. Research progress on surface properties of ceramic membranes [J]. Membrane Science and Technology, 2013, (5): 5-11. | |

| 25 | 柯威, 高能文, 李梅, 等. 疏水性Al2O3膜表面的化学稳定性[J]. 南京工业大学学报(自然科学版), 2010, 32(6): 45-49. |

| Ke W, Gao N W, Li M, et al. Chemical stability of hydrophobic alumina membrane surface[J]. Journal of Nanjing University of Technology (Natural Science Edition), 2010, 32(6): 45-49. | |

| 26 | Sada E, Kumazawa H, Kudo I. Absorption of NO in aqueous mixed solutions of NaClO2 and NaOH[J]. Chemical Engineering Science, 1978, 33(3): 315-318. |

| 27 | 丁兆阳, 韩治洋, 石文荣, 等. 快速变压吸附制氧动态传质系数模拟分析[J]. 化工学报, 2018, 69(2): 759-768. |

| Ding Z Y, Han Z Y, Shi W R, et al. Simulation analysis of dynamic mass transfer coefficient of fast variable pressure adsorption oxygen production [J]. CIESC Journal, 2018, 69(2): 759-768. | |

| 28 | Mansourizadeh A, Ismail A F. Hollow fiber gas-liquid membrane contactors for acid gas capture: a review[J]. J. Hazard. Mater., 2009, 171(1/2/3): 38-53. |

| 29 | Rangwala H A. Absorption of carbon dioxide into aqueous solutions using hollow fiber membrane contactors[J]. Journal of Membrane Science, 1996, 112(20): 229-240. |

| [1] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [2] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [3] | 王思琪, 顾天宇, 陈献富, 王通, 李佳, 柯威, 李小锋, 范益群. 陶瓷膜用于杜仲叶提取液澄清的分离特性与膜污染机制研究[J]. 化工学报, 2023, 74(3): 1113-1125. |

| [4] | 陈献富, 王冬雨, 范益群, 邢卫红, 乔旭. 基于3D打印的多孔陶瓷膜研究进展[J]. 化工学报, 2023, 74(1): 105-115. |

| [5] | 马语峻, 刘向军. 多孔陶瓷膜烟气水分回收理论与模型研究[J]. 化工学报, 2022, 73(9): 4103-4112. |

| [6] | 季超, 刘炜, 漆虹. 基于空冷的疏水陶瓷膜冷凝器用于烟气脱湿过程强化的实验研究[J]. 化工学报, 2022, 73(5): 2174-2182. |

| [7] | 任盼锋, 海润泽, 李奇, 李文彬, 余国琮. 流化床液固两相传质过程的模拟研究进展[J]. 化工学报, 2022, 73(1): 1-17. |

| [8] | 杨林, 孟小谜, 姚露, 赖雨果, 蒋文举. 天然矿物共混活性焦联合低温脱硫脱硝[J]. 化工学报, 2021, 72(4): 2241-2248. |

| [9] | 谭卓伟, 杨留洋, 王振波, 豆肖辉, 张大磊, 张明阳, 金有海. 高剪切力流场下X80管线钢局部腐蚀深坑诱导局部湍流交互机理研究[J]. 化工学报, 2021, 72(4): 2203-2212. |

| [10] | 卿梦霞, 张鑫, 刘亮, 张巍, 王乐乐, 苏胜, 孔凡海, 向军. 燃煤烟气脱硝副产物硫酸氢铵/硫酸铵沉积与分解特性研究[J]. 化工学报, 2021, 72(2): 1132-1141. |

| [11] | 滕达, 李铁林, 李昂, 安连锁, 沈国清, 张世平. 单通道陶瓷膜管低压透水性能实验分析[J]. 化工学报, 2020, 71(S1): 261-271. |

| [12] | 汤常金,孙敬方,董林. 超低温(< 150℃)SCR脱硝技术研究进展[J]. 化工学报, 2020, 71(11): 4873-4884. |

| [13] | 张霄玲,鲍佳宁,李运甲,皇甫林,李文松,高士秋,许光文,李长明,余剑. 工业MnOx颗粒催化剂的制备及其低温脱硝应用研究[J]. 化工学报, 2020, 71(11): 5169-5177. |

| [14] | 李秀秀, 魏逸彬, 谢子萱, 漆虹. Al2O3和SiC微滤膜的疏水改性及其油固分离性能研究[J]. 化工学报, 2019, 70(7): 2737-2747. |

| [15] | 曹语, 王乐, 季超, 黄延召, 薛志磊, 陆剑鸣, 漆虹. 陶瓷膜冷凝器用于烟气脱白烟过程的中试研究[J]. 化工学报, 2019, 70(6): 2192-2201. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号