化工学报 ›› 2022, Vol. 73 ›› Issue (2): 712-721.DOI: 10.11949/0438-1157.20210987

苏畅1,2( ),冯晓博1,2(

),冯晓博1,2( ),张立云1,2,陈峰1,2,赵小燕1,2,曹景沛1,2(

),张立云1,2,陈峰1,2,赵小燕1,2,曹景沛1,2( )

)

收稿日期:2021-07-14

修回日期:2021-10-20

出版日期:2022-02-05

发布日期:2022-02-18

通讯作者:

冯晓博,曹景沛

作者简介:苏畅(1995—),男,硕士研究生,基金资助:

Chang SU1,2( ),Xiaobo FENG1,2(

),Xiaobo FENG1,2( ),Liyun ZHANG1,2,Feng CHEN1,2,Xiaoyan ZHAO1,2,Jingpei CAO1,2(

),Liyun ZHANG1,2,Feng CHEN1,2,Xiaoyan ZHAO1,2,Jingpei CAO1,2( )

)

Received:2021-07-14

Revised:2021-10-20

Online:2022-02-05

Published:2022-02-18

Contact:

Xiaobo FENG,Jingpei CAO

摘要:

合成气经二甲醚(DME)羰基化合成乙酸甲酯(MA),MA进一步加氢制备乙醇是一种新型高效的煤基合成气制备乙醇路线。采用温和的后处理方法改性DME羰基化分子筛,进一步提高DME羰基化效率,对其工业应用具有重要意义。本研究利用四乙基氢氧化铵(TEAOH)对HMOR分子筛改性处理,探讨了有机碱改性处理对HMOR分子筛的结构和DME羰基化催化性能的影响。研究发现,TEAOH浓度为0.3 mol/L时,HMOR分子筛介孔孔容增大约26%,外比表面积增大约10%,DME的转化率增幅达68%。TEAOH水解产生的OH-能够温和脱除HMOR分子筛中的骨架硅,获得介-微多级孔结构,提高DME羰基化反应过程中的传质速率。此外,水解的TEA+在分子筛表面富集,抑制了OH-的过度脱硅,保护分子筛基本骨架结构不被更深层次破坏。

中图分类号:

苏畅, 冯晓博, 张立云, 陈峰, 赵小燕, 曹景沛. 四乙基氢氧化铵改性对HMOR分子筛结构及二甲醚羰基化性能的影响[J]. 化工学报, 2022, 73(2): 712-721.

Chang SU, Xiaobo FENG, Liyun ZHANG, Feng CHEN, Xiaoyan ZHAO, Jingpei CAO. Effect of tetraethylammonium hydroxide treatment on the structure of HMOR zeolite and its catalytic performance in the carbonylation of dimethyl ether[J]. CIESC Journal, 2022, 73(2): 712-721.

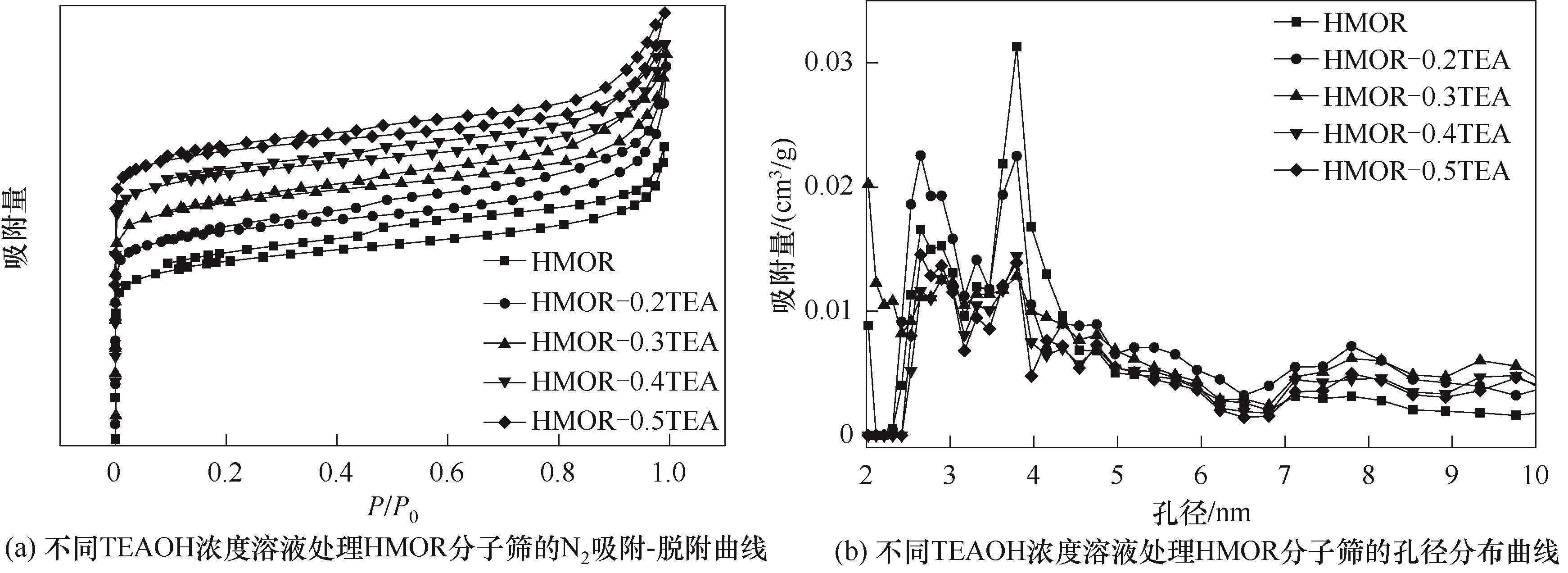

图3 不同TEAOH浓度溶液处理HMOR分子筛的N2吸附-脱附曲线(a)和孔径分布曲线(b)

Fig.3 N2 adsorption-desorption isotherms (a) and pore distribution (b) of HMOR zeolites treated by TEAOH solutions with different concentration

| HMOR zeolites | SBET①/(m2/g) | Smicro②/(m2/g) | Sext/(m2/g) | Vtotal③/(cm3/g) | Vmicro②/(cm3/g) | Vmeso④/(cm3/g) |

|---|---|---|---|---|---|---|

| HMOR | 506 | 449 | 57 | 0.308 | 0.181 | 0.127 |

| HMOR-0.2TEA | 516 | 456 | 60 | 0.357 | 0.183 | 0.174 |

| HMOR-0.3TEA | 548 | 484 | 64 | 0.351 | 0.191 | 0.160 |

| HMOR-0.4TEA | 533 | 474 | 59 | 0.331 | 0.190 | 0.141 |

| HMOR-0.5TEA | 524 | 467 | 56 | 0.335 | 0.188 | 0.147 |

表1 不同TEAOH浓度溶液处理HMOR分子筛的比表面积和孔结构

Table 1 Specific surface areas and pore properties of HMOR zeolites treated by TEAOH solutions with different concentration

| HMOR zeolites | SBET①/(m2/g) | Smicro②/(m2/g) | Sext/(m2/g) | Vtotal③/(cm3/g) | Vmicro②/(cm3/g) | Vmeso④/(cm3/g) |

|---|---|---|---|---|---|---|

| HMOR | 506 | 449 | 57 | 0.308 | 0.181 | 0.127 |

| HMOR-0.2TEA | 516 | 456 | 60 | 0.357 | 0.183 | 0.174 |

| HMOR-0.3TEA | 548 | 484 | 64 | 0.351 | 0.191 | 0.160 |

| HMOR-0.4TEA | 533 | 474 | 59 | 0.331 | 0.190 | 0.141 |

| HMOR-0.5TEA | 524 | 467 | 56 | 0.335 | 0.188 | 0.147 |

| 样品 | (B8-MR/B12-MR)/%① |

|---|---|

| HMOR | 13.6 |

| HMOR-0.2TEA | 15.5 |

| HMOR-0.3TEA | 16.7 |

| HMOR-0.4TEA | 14.8 |

| HMOR-0.5TEA | 13.5 |

表2 不同TEAOH浓度溶液处理HMOR分子筛的八元环B酸位点与十二元环B酸位点的比值

Table 2 B8-MR/B12-MR of HMOR zeolites treated by TEAOH solutions with different concentration

| 样品 | (B8-MR/B12-MR)/%① |

|---|---|

| HMOR | 13.6 |

| HMOR-0.2TEA | 15.5 |

| HMOR-0.3TEA | 16.7 |

| HMOR-0.4TEA | 14.8 |

| HMOR-0.5TEA | 13.5 |

图6 不同浓度TEAOH溶液处理的HMOR分子筛催化DME羰基化反应结果

Fig.6 DME conversion over HMOR zeolite treated by TEAOH solutions with different concentration(reaction conditions: 220℃, 1.5 MPa, DME∶CO∶Ar=4.32∶5.06∶90.62 (vol.), 1600 h-1)

图7 吡啶预处理HMOR分子筛催化DME羰基化反应结果

Fig.7 DME conversion over HMOR zeolites by pyridine treatment(reaction conditions: 220℃, 1.5 MPa, DME∶CO∶Ar=4.32∶5.06∶90.62 (vol.), 1600 h-1)

| 1 | Li Y, Sun Q, Huang S Y, et al. Dimethyl ether carbonylation over pyridine-modified MOR: enhanced stability influenced by acidity[J]. Catalysis Today, 2018, 311: 81-88. |

| 2 | 李振宇, 李顶杰, 黄格省, 等. 燃料乙醇发展现状及思考[J]. 化工进展, 2013, 32(7): 1457-1467. |

| Li Z Y, Li D J, Huang G S, et al. Insights on current development of fuel ethanol[J]. Chemical Industry and Engineering Progress, 2013, 32(7): 1457-1467. | |

| 3 | 黄守莹, 熊雄, 贺培, 等. 二甲醚羰基化丝光沸石成型催化剂黏结剂的研究[J]. 化工学报, 2020, 71(10): 4642-4651. |

| Huang S Y, Xiong X, He P, et al. Study on binder of extruded mordenite catalyst for dimethyl ether carbonylation[J]. CIESC Journal, 2020, 71(10): 4642-4651. | |

| 4 | Farrell A E, Plevin R J, Turner B T, et al. Ethanol can contribute to energy and environmental goals[J]. Science, 2006, 311(5760): 506-508. |

| 5 | 冯晓博, 刘天龙, 赵小燕, 等. 合成气与二甲醚为原料直接制乙醇催化反应研究进展[J]. 化工学报, 2021, 72(8): 3958-3967. |

| Feng X B, Liu T L, Zhao X Y, et al. Advance in ethanol synthesis from syngas via carbonylation of dimethyl ether and hydrogenation of methyl acetate[J]. CIESC Journal, 2021, 72(8): 3958-3967. | |

| 6 | Cleveland C J, Hall C A, Herendeen R A. Energy returns on ethanol production[J]. Science, 2006, 312(5781): 1746-1748. |

| 7 | 王鹏, 王宪贵, 郭战英, 等. 合成气合成乙醇的研究进展[J]. 洁净煤技术, 2010(1): 55-58. |

| Wang P, Wang X G, Guo Z Y, et al. Research progress in producer gas to ethanol technology [J]. Clean Coal Technology, 2010(1): 55-58. | |

| 8 | Choi Y, Liu P. Mechanism of ethanol synthesis from syngas on Rh(111)[J]. Journal of the American Chemical Society, 2009, 131(36): 13054-13061. |

| 9 | Portillo C M A, Villanueva P A L, Vidal-Barrero F, et al. Effects of methanol co-feeding in ethanol synthesis from syngas using alkali-doped MoS2 catalysts[J]. Fuel Processing Technology, 2015, 134: 270-274. |

| 10 | Mei D H, Rousseau R, Kathmann S M, et al. Ethanol synthesis from syngas over Rh-based/SiO2 catalysts: a combined experimental and theoretical modeling study[J]. Journal of Catalysis, 2010, 271(2): 325-342. |

| 11 | Lopez L, Montes V, Kušar H, et al. Syngas conversion to ethanol over a mesoporous Cu/MCM-41 catalyst: effect of K and Fe promoters[J]. Applied Catalysis A: General, 2016, 526: 77-83. |

| 12 | 赵娜, 牛君阳, 刘亚华, 等. 预处理条件及金属离子改性对H-MOR分子筛的DME羰基化性能影响[J]. 化工学报, 2015, 66(9): 3504-3510. |

| Zhao N, Niu J Y, Liu Y H, et al. Influence of pretreatment and metal cation modification of H-MOR zeolite on performance of DME carbonylation[J]. CIESC Journal, 2015, 66(9): 3504-3510. | |

| 13 | 黄守莹, 王悦, 吕静, 等. 合成气经二甲醚/乙酸甲酯制无水乙醇的研究进展[J]. 化工学报, 2016, 67(1): 240-247. |

| Huang S Y, Wang Y, Lü J, et al. Advances in indirect synthesis of ethanol from syngas via dimethyl ether/methyl acetate[J]. CIESC Journal, 2016, 67(1): 240-247. | |

| 14 | Cheung P, Bhan A, Sunley G J, et al. Selective carbonylation of dimethyl ether to methyl acetate catalyzed by acidic zeolites[J]. Angewandte Chemie, 2006, 118(10): 1647-1650. |

| 15 | Boronat M, Martínez-Sánchez C, Law D, et al. Enzyme-like specificity in zeolites: a unique site position in mordenite for selective carbonylation of methanol and dimethyl ether with CO[J]. Journal of the American Chemical Society, 2008, 130(48): 16316-16323. |

| 16 | Wang X S, Li R J, Yu C C, et al. Enhanced activity and stability over hierarchical porous mordenite (MOR) for carbonylation of dimethyl ether: influence of mesopores[J]. Journal of Fuel Chemistry and Technology, 2020, 48(8): 960-969. |

| 17 | Sheng H B, Qian W X, Zhang H T, et al. Synthesis of hierarchical porous H-mordenite zeolite for carbonylation of dimethyl ether[J]. Microporous and Mesoporous Materials, 2020, 295: 109950. |

| 18 | Yuan Y Y, Wang L Y, Liu H C, et al. Facile preparation of nanocrystal-assembled hierarchical mordenite zeolites with remarkable catalytic performance[J]. Chinese Journal of Catalysis, 2015, 36(11): 1910-1919. |

| 19 | Wang X S, Li R J, Yu C C, et al. Enhancing the dimethyl ether carbonylation performance over mordenite catalysts by simple alkaline treatment[J]. Fuel, 2019, 239: 794-803. |

| 20 | 韩海波, 王有和, 李康, 等. 超声波碱处理改性对丝光沸石结构、酸性质及其催化性能的影响[J]. 化工学报, 2018, 69(7): 3001-3008. |

| Han H B, Wang Y H, Li K, et al. Effect of ultrasonic alkali treatment on structural, acidic properties and performance of MOR catalyst[J]. CIESC Journal, 2018, 69(7): 3001-3008. | |

| 21 | 李莎, 李玉平, 狄春雨, 等. TPAOH/NaOH混合碱体系对ZSM-5沸石的改性及其催化性能研究[J]. 燃料化学学报, 2012, 40(5): 583-588. |

| Li S, Li Y P, Di C Y, et al. Modification and catalyst performance of ZSM-5 zeolite by treatment with TPAOH/NaOH mixed alkali[J]. Journal of Fuel Chemistry and Technology, 2012, 40(5): 583-588. | |

| 22 | 张云鹏, 李明罡, 王萍, 等. 四乙基氢氧化铵后晶化处理对ZSM-5分子筛结构及其甲醇制丙烯催化性能的影响[J]. 石油学报(石油加工), 2018, 34(4): 817-824. |

| Zhang Y P, Li M G, Wang P, et al. Enhancing the catalytic performance of ZSM-5 zeolite in methanol to propene reaction via recrystallization in the presence of tetraethylammonium hydroxide[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2018, 34(4): 817-824. | |

| 23 | Abelló S, Bonilla A, Pérez-Ramírez J. Mesoporous ZSM-5 zeolite catalysts prepared by desilication with organic hydroxides and comparison with NaOH leaching[J]. Applied Catalysis A: General, 2009, 364(1/2): 191-198. |

| 24 | Ravishankar R, Kirschhock C, Schoeman B J, et al. Physicochemical characterization of silicalite-1 nanophase material[J]. The Journal of Physical Chemistry B, 1998, 102(15): 2633-2639. |

| 25 | Bagnasco G. Improving the selectivity of NH3TPD measurements[J]. Journal of Catalysis, 1996, 159(1): 249-252. |

| 26 | Bai L Y, Xiong Z P, Zhan E S, et al. Piperazine as a versatile organic structure-directing agent for zeolite synthesis: effect of SiO2/Al2O3 ratio on phase selectivity[J]. Journal of Materials Science, 2019, 54(10): 7589-7602. |

| 27 | Xue H F, Huang X M, Zhan E S, et al. Selective dealumination of mordenite for enhancing its stability in dimethyl ether carbonylation[J]. Catalysis Communications, 2013, 37: 75-79. |

| 28 | Li Y, Huang S Y, Cheng Z Z, et al. Promoting the activity of Ce-incorporated MOR in dimethyl ether carbonylation through tailoring the distribution of Brønsted acids[J]. Applied Catalysis B: Environmental, 2019, 256: 117777. |

| 29 | Zhao N, Tian Y, Zhang L F, et al. Spacial hindrance induced recovery of over-poisoned active acid sites in pyridine-modified H-mordenite for dimethyl ether carbonylation[J]. Chinese Journal of Catalysis, 2019, 40(6): 895-904. |

| 30 | 王伟, 钱伟鑫, 马宏方, 等. 吡啶修饰H-MOR上二甲醚羰基化吸附-扩散理论研究[J]. 化工学报, 2021, 72(9): 4786-4795. |

| Wang W, Qian W X, Ma H F, et al. A theoretical study on adsorption-diffusion of dimethyl ether carbonylation on pyridine-modified H-MOR[J]. CIESC Journal, 2021, 72(9): 4786-4795. | |

| 31 | Xue H F, Huang X M, Ditzel E, et al. Coking on micrometer- and nanometer-sized mordenite during dimethyl ether carbonylation to methyl acetate[J]. Chinese Journal of Catalysis, 2013, 34(8): 1496-1503. |

| [1] | 何金峰, 李秀珍, 寇建耀, 陶庭杰, 余灿, 刘欢, 陈永元, 赵豪健, 江大好, 李小年. 乙醇制高级醇有序介孔氧化铝负载铜基催化剂研究[J]. 化工学报, 2023, 74(3): 1082-1091. |

| [2] | 项望凯, 刘园园, 郑映, 潘鹏举. 基于熔融/固相缩聚制备中高分子量聚乙醇酸[J]. 化工学报, 2023, 74(2): 933-940. |

| [3] | 王悦琳, 晁伟, 蓝晓程, 莫志朋, 佟淑环, 王铁峰. 合成气生物发酵法制乙醇的研究进展[J]. 化工学报, 2022, 73(8): 3448-3460. |

| [4] | 韦双明, 余明高, 裴蓓, 李世梁, 康亚祥, 徐梦娇, 郭佳琪. 三元混合气体燃料爆炸特性实验研究[J]. 化工学报, 2022, 73(1): 451-460. |

| [5] | 董桂霖, 罗祖伟, 曹约强, 周静红, 李伟, 周兴贵. 液相还原温度对草酸酯加氢制乙醇酸甲酯银硅催化剂性能的影响[J]. 化工学报, 2022, 73(1): 232-240. |

| [6] | 高帅涛, 刘雪珂, 张丽, 刘芬, 余江, 商剑锋, 欧天雄, 周政, 陈平文. Aspen Plus模拟高浓度H2S/CO2酸性气的选择性分离[J]. 化工学报, 2021, 72(S1): 413-420. |

| [7] | 何婷, 林文胜. 基于余热利用的活化MDEA法脱除CO2的天然气液化系统[J]. 化工学报, 2021, 72(S1): 453-460. |

| [8] | 陈晨, 王明明, 王志刚, 谭小耀. 镍基非对称中空纤维膜用于乙醇自热重整制氢[J]. 化工学报, 2021, 72(S1): 482-493. |

| [9] | 梁家豪, 张国强, 高源, 尹娇, 郑华艳, 李忠. 介孔构建对CuY甲醇氧化羰基化反应活性的影响[J]. 化工学报, 2021, 72(9): 4685-4697. |

| [10] | 丁婉月, 马晓华. 合成次数及硅铝比调控SAPO-34分子筛膜的乙醇脱水性能[J]. 化工学报, 2021, 72(8): 4410-4417. |

| [11] | 冯晓博, 刘天龙, 赵小燕, 曹景沛. 合成气与二甲醚为原料直接制乙醇催化反应研究进展[J]. 化工学报, 2021, 72(8): 3958-3967. |

| [12] | 郭海军, 张海荣, 丁帅, 黎海龙, 彭芬, 熊莲, 陈新德. 木质纤维素多元醇液化及液化产物提质的研究进展[J]. 化工学报, 2021, 72(6): 3228-3238. |

| [13] | 石敦峰, 甘云华, 罗燕来, 江政纬, 周毅. 乙醇浓度和应变率对扩散火焰特性的数值分析[J]. 化工学报, 2021, 72(5): 2801-2809. |

| [14] | 黄艳, 陈功, 王睿猛, 邵珊, 张正生, 杨东晓, 卢真保, 黄佳, 赵祯霞, 赵钟兴. MIL-100(Fe)中乙醇对低挥发性香兰素的协同脱附研究[J]. 化工学报, 2021, 72(5): 2697-2705. |

| [15] | 彭启, 贾力, 丁艺, 张永欣, 党超, 银了飞. 受限微结构对低表面张力液滴合并弹跳的影响[J]. 化工学报, 2021, 72(4): 1920-1929. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号