化工学报 ›› 2022, Vol. 73 ›› Issue (8): 3326-3337.DOI: 10.11949/0438-1157.20220699

收稿日期:2022-05-16

修回日期:2022-07-28

出版日期:2022-08-05

发布日期:2022-09-06

通讯作者:

王琪

作者简介:杨双桥(1990—),男,博士,副研究员,yangshuangqiao@scu.edu.cn

基金资助:

Shuangqiao YANG( ), Baojie WEI, Dawei XU, Li LI, Qi WANG(

), Baojie WEI, Dawei XU, Li LI, Qi WANG( )

)

Received:2022-05-16

Revised:2022-07-28

Online:2022-08-05

Published:2022-09-06

Contact:

Qi WANG

摘要:

包装是商品使用、储存、运输的重要保障,不可或缺。塑料包装轻质、易加工、性价比高,增长极快,成为现代社会主要的包装材料,其中铝塑复合包装通过材料优势互补,可满足阻隔性、抗菌性、力学性能和印刷性能等多功能要求,应用广泛,但即用即弃,废弃物难分离难回收利用,无法降解,也难焚烧处理,污染环境,浪费资源,亟待治理。本文综述了铝塑复合包装结构性能和应用,以及废弃物回收利用难点,重点介绍了本团队采用自主创新的固相剪切碾磨加工装备和技术,实现废弃铝塑复合包装的室温超细粉碎和均匀分散,改善加工性和力学性能,制备可拆卸物流包装箱及导热导电功能制品的研究工作。

中图分类号:

杨双桥, 韦宝杰, 徐大伟, 李莉, 王琪. 铝塑复合包装的应用及废弃物回收利用新技术[J]. 化工学报, 2022, 73(8): 3326-3337.

Shuangqiao YANG, Baojie WEI, Dawei XU, Li LI, Qi WANG. Application of aluminum-plastic packaging and new recycling technology of the waste[J]. CIESC Journal, 2022, 73(8): 3326-3337.

| Materials | Thickness/μm | Oxygen permeability/(cm3/(m2·d·(0.1 mPa))) | Water vapor permeability/ (g/(m2·d)) |

|---|---|---|---|

| PE | 50 | 2187.7 | 7.8 |

| BOPP | 50 | 582.5 | 3.0 |

| PET | 50 | 25.2 | 7.0 |

| PA | 15 | 41.2 | 290.6 |

| PET/PE | 50 | 88.7 | 5.6 |

| PET/CPP | 50 | 75.4 | 5.8 |

| PET/Al/PE | 60 | 0.13 | 0.48 |

| BOPA/Al/CPP | 60 | 0.07 | 0.51 |

| PET/Al/CPP | 60 | 0.12 | 0.45 |

表1 常见塑料包装氧气和水蒸气的透过率[5]

Table 1 Oxygen and moisture permeability of common plastic packaging[5]

| Materials | Thickness/μm | Oxygen permeability/(cm3/(m2·d·(0.1 mPa))) | Water vapor permeability/ (g/(m2·d)) |

|---|---|---|---|

| PE | 50 | 2187.7 | 7.8 |

| BOPP | 50 | 582.5 | 3.0 |

| PET | 50 | 25.2 | 7.0 |

| PA | 15 | 41.2 | 290.6 |

| PET/PE | 50 | 88.7 | 5.6 |

| PET/CPP | 50 | 75.4 | 5.8 |

| PET/Al/PE | 60 | 0.13 | 0.48 |

| BOPA/Al/CPP | 60 | 0.07 | 0.51 |

| PET/Al/CPP | 60 | 0.12 | 0.45 |

图1 磨盘盘面示意图(a),动磨盘和静磨盘剪切区示意图 (b),高分子材料在磨盘中的运动轨迹(c) [26]

Fig.1 Schematic diagram of mill pan (a), shear region of milling and static pan (b) and trajectory route of polymer during pan milling (c) [26]

| Polymer type | Particle size |

|---|---|

| PA6 | ~80 nm |

| PP, PS | 0.3—2 µm |

| PC, PPS | 10—50 µm |

| PES, PEEK | 1—10 µm |

| HDPE, waste rubber, SBS | micro-scale |

表2 固相剪切碾磨加工制备的聚合物微纳粉体极限粒径[21, 28-31]

Table 2 Particle size of micro/nano polymer powder prepared by solid-state shear milling [21, 28-31]

| Polymer type | Particle size |

|---|---|

| PA6 | ~80 nm |

| PP, PS | 0.3—2 µm |

| PC, PPS | 10—50 µm |

| PES, PEEK | 1—10 µm |

| HDPE, waste rubber, SBS | micro-scale |

图4 废弃铝塑复合包装初破碎照片(a),力化学研磨粉体照片(b),废弃铝塑复合包装超细粉体SEM形貌[(c)、(d)],不同碾磨次数铝元素示踪[1次(e),10次(f)]

Fig.4 Photos of pre-crushed aluminum plastic packaging waste (APPW) (a), powders prepared by solid-state shear milling technology (b), SEM morphology of APPW powders [(c),(d)] and the distribution of aluminum after 1 (e) and 10 (f) milling cycles

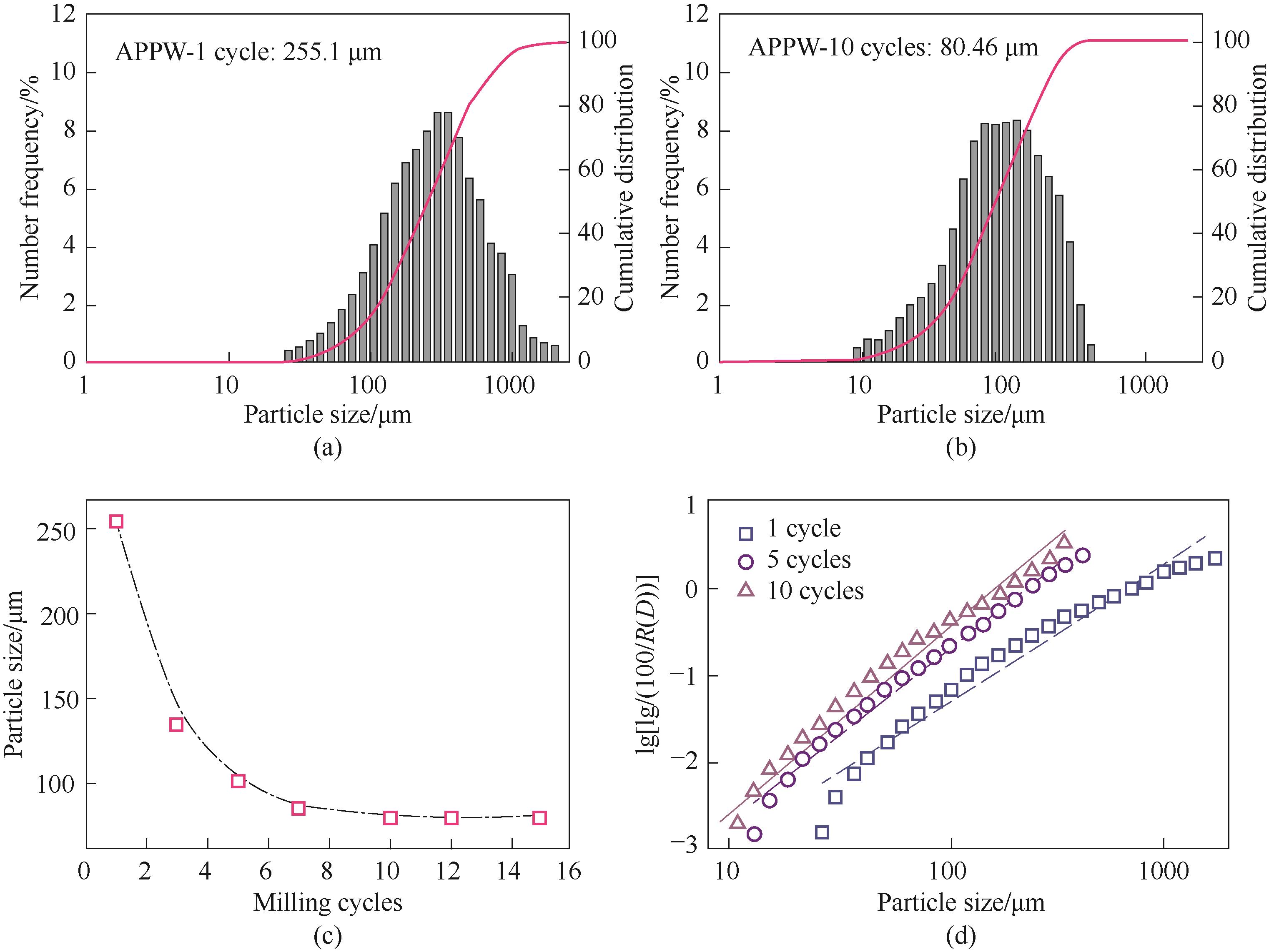

图5 废弃铝塑复合包装力化学研磨1次(a)和10次(b)粒径分布及平均粒径(c),粉体粒径Rosin-Rammler Bennet拟合曲线(d)

Fig.5 Particle size distribution of APPW after 1(a) and 10 (b) milling cycles, mean particle size (c) and Rosin-Rammler Bannet fitting curve of particle size (d)

| Parameter | 1 cycle | 5 cycles | 10 cycles |

|---|---|---|---|

| De/μm | 321 | 152 | 106 |

| b | 1.03×10-4 | 5.03×10-5 | 5.09×10-5 |

| n | 1.59 | 1.97 | 2.12 |

表3 固相剪切碾磨过程Rosin-Rammler Bennet系数的变化

Table 3 Development of Rosin-Rammler Bennet coefficient during the solid-state shear milling

| Parameter | 1 cycle | 5 cycles | 10 cycles |

|---|---|---|---|

| De/μm | 321 | 152 | 106 |

| b | 1.03×10-4 | 5.03×10-5 | 5.09×10-5 |

| n | 1.59 | 1.97 | 2.12 |

图6 研磨0次(a)、5次(b)和10次(c)后废弃铝塑复合包装粉体密炼加工数码照片,密炼加工过程转矩曲线(d),密炼加工平衡扭矩时间(e),熔体熔融指数(f)

Fig.6 Photos of APPW powders after 0 (a), 1 (b) and 10 (c) milling cycles during the mixing processing, torque curve (d), balance torque time (e) and melt index (f)

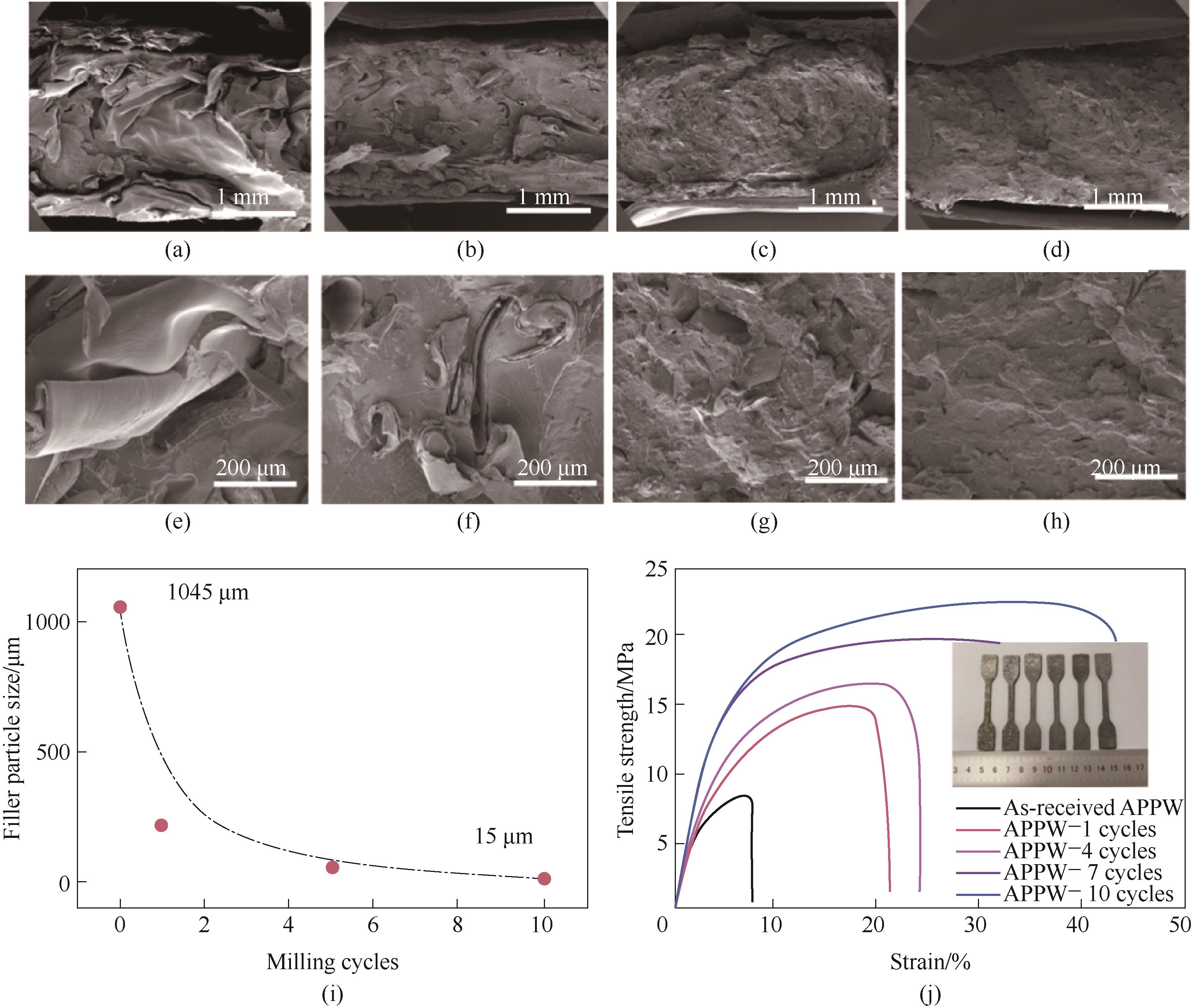

图7 废弃铝塑再生复合材料未研磨处理[(a)、(e)]、碾磨1次[(b)、(f)]、碾磨4次[(c)、(g)]和碾磨10次[(d)、(h)]SEM形貌,填料统计尺寸与碾磨次数的关系(i),拉伸性能(j)

Fig.7 SEM images of reused APPW composites with 0 cycle [(a),(e)], 1 cycle [(b),(f)], 4 cycles[(c),(g)], and 10 cycles [(d),(h)], relation between filler size and milling cycle (i) and tensile strength (j)

| Samples | Tensile strength /MPa | Elongation at break/% | Electrical conductivity/ (S/cm) | Thermal conductivity/ (W/(m∙K)) |

|---|---|---|---|---|

| after milling | 22.1 | 47.1 | 10-12 | 0.6 |

| without milling | 8.5 | 7.9 | 10-14 | — |

表4 废弃铝塑再生复合材料性能

Table 4 Properties of recycled APPW composites

| Samples | Tensile strength /MPa | Elongation at break/% | Electrical conductivity/ (S/cm) | Thermal conductivity/ (W/(m∙K)) |

|---|---|---|---|---|

| after milling | 22.1 | 47.1 | 10-12 | 0.6 |

| without milling | 8.5 | 7.9 | 10-14 | — |

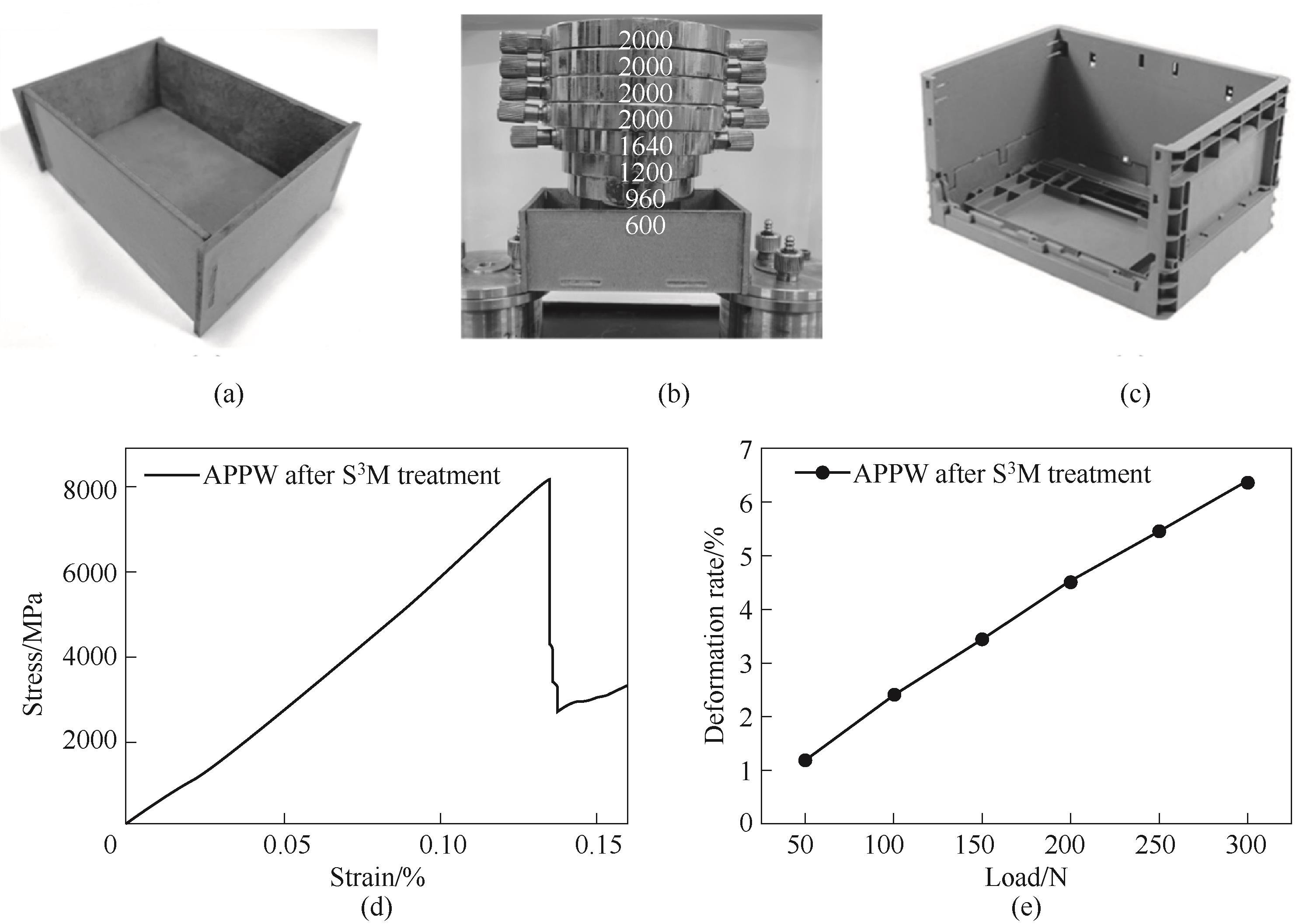

图8 废弃铝塑复合包装超细粉体模压制品(a),载荷加载试验(b),注塑制备工业可折叠物流箱(c),应力-应变曲线(d),形变率和载荷的关系(e)

Fig.8 Molded APPW part (a), load test (b), industrial detachable logistics packer prepared by injection molding (c), stress-strain cure (d) and relation between deformation rate and load (e)

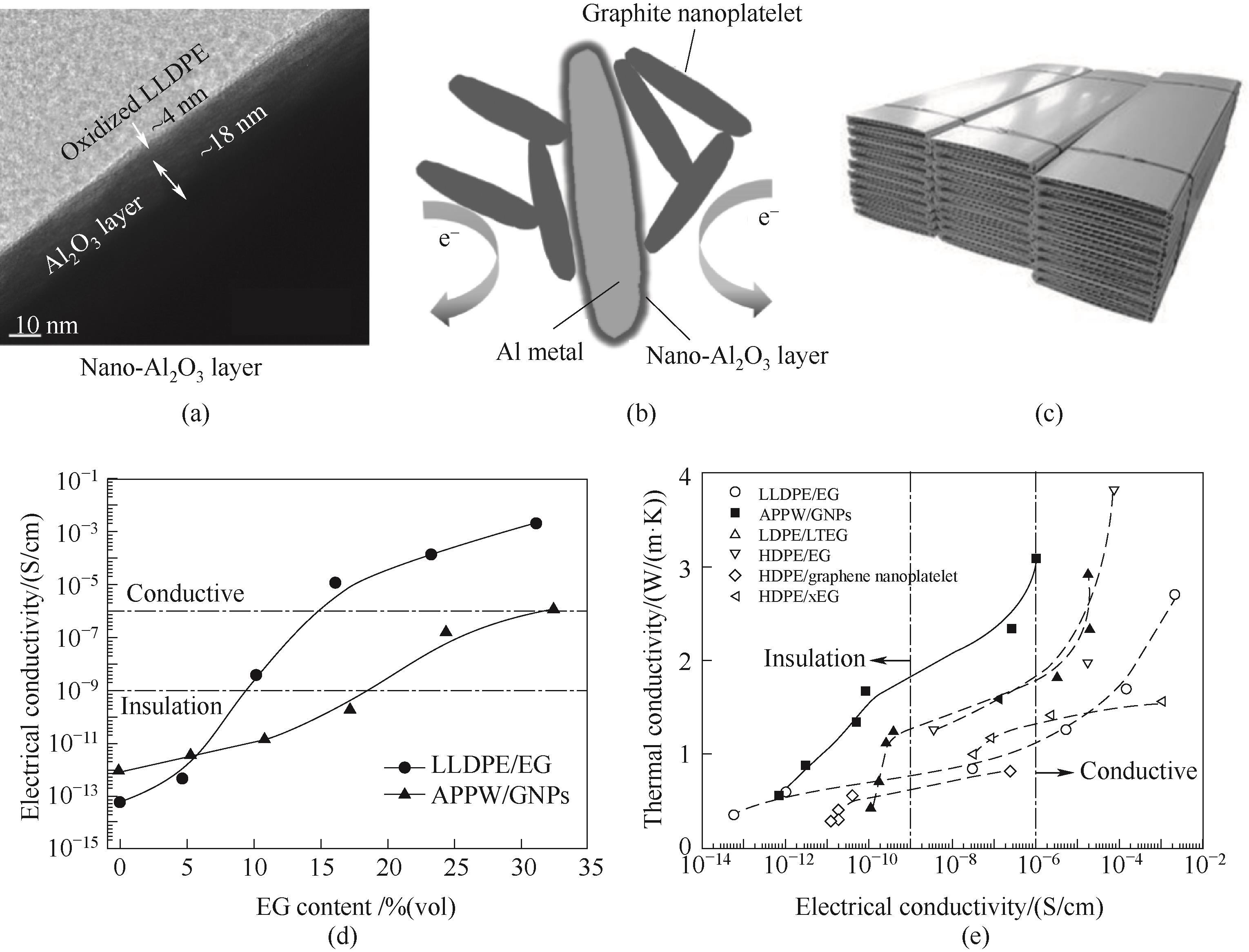

图9 废弃铝塑导热材料中铝箔透射电镜 (a),导热绝缘机理示意图(b),制备的工业散热板(c),电导率与可膨胀石墨含量的关系(d),热导率与电导率的关系(e)[40]

Fig.9 TEM of Al in APPW thermal conductive material (a), mechanism of thermal conductivity (b), prepared industrial cooling plates (c), relation between conductivity and expandable graphite loading (d) and relation between thermal conductivity and conductivity (e) [40]

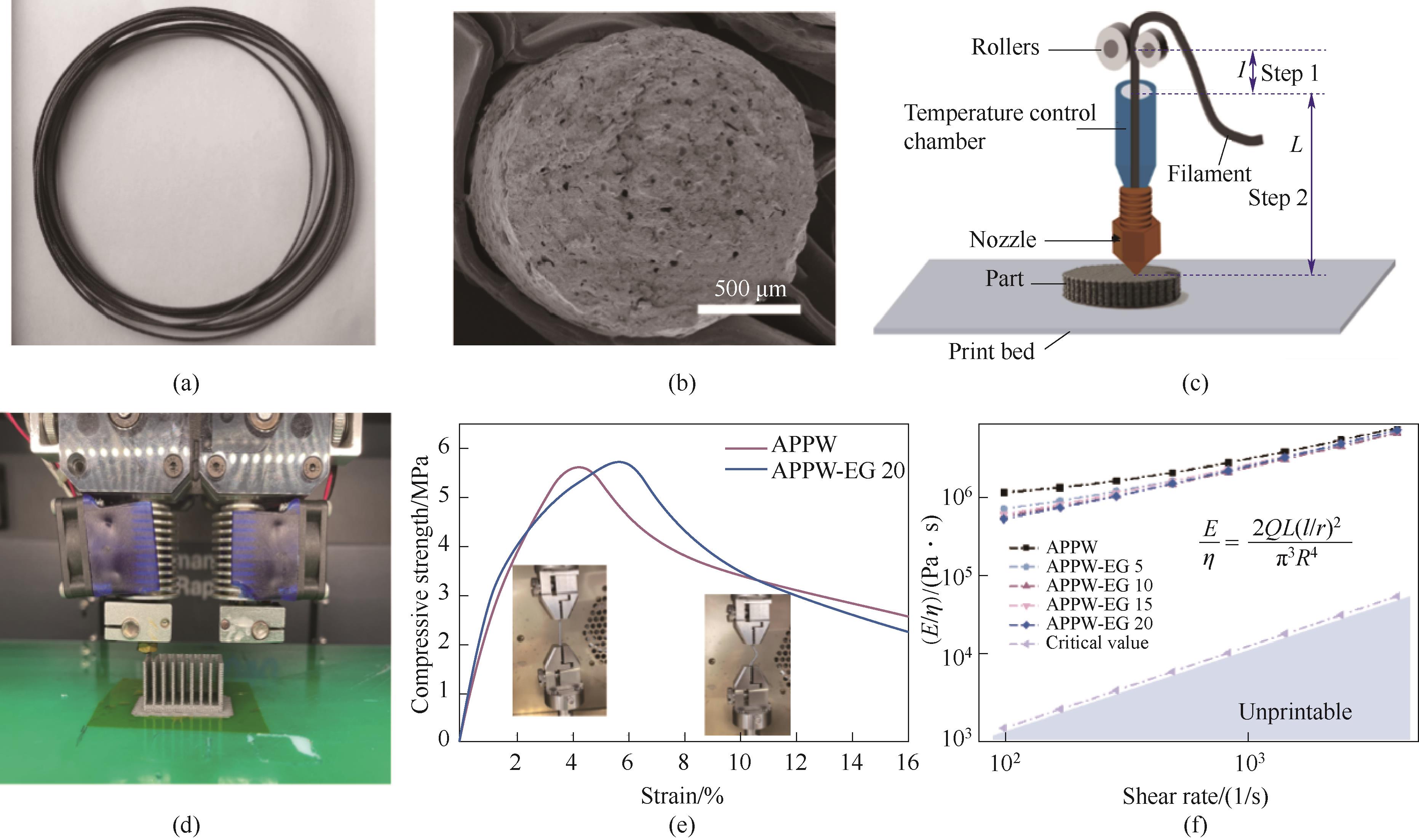

图10 铝塑复合包装为基体制备的3D可打印丝条数码照片(a),可打印丝条截面SEM图 (b),3D打印过程示意图(c),3D打印过程数码照片(d),压缩强度与应变的关系(e),E/η与剪切速率的关系(f)[41]

Fig.10 Photos of APPW filaments for 3D printing (a), SEM image of APPW filaments (b), schematic diagram of 3D printing process (c), photos of 3D printing process (d), relation between compressive strength and strain (e) and relation between E/η and shear rate (f) [41]

图11 废弃铝塑复合包装制备的3D打印散热器(a),热导率与填料含量关系[(b)、(c)],导热机理示意图(d),复合材料散热效果对比(e)[41]

Fig.11 3D printed radiators from APPW (a), relation between thermal conductivity and filler loading [(b),(c)], schematic diagram of thermal conductive mechanism (d) and comparison of heat dissipation effect of composites (e) [41]

| 1 | 中国包装联合会. 2021年全国包装行业运行概况[EB/OL]. [2022-02-22]. . |

| China Packaging Federation. 2021 operation overview of national packaging industry[EB/OL]. [2022-02-22]. . | |

| 2 | 蓝敏怡, 李会茹, 胡立新, 等. 塑料食品包装材料的环境污染综述[J]. 生态毒理学报, 2021, 16(5): 186-210. |

| Lan M Y, Li H R, Hu L X, et al. A review of the environmental pollution of food plastic packaging materials[J]. Asian Journal of Ecotoxicology, 2021, 16(5): 186-210. | |

| 3 | Creton C. Molecular stitches for enhanced recycling of packaging[J]. Science, 2017, 355(6327): 797-798. |

| 4 | 马占峰, 姜宛君, 杨森. 中国塑料加工工业(2019)[J]. 中国塑料, 2020, 34(5): 102-106. |

| Ma Z F, Jiang W J, Yang S. China plastics industry (2019)[J]. China Plastics, 2020, 34(5): 102-106. | |

| 5 | 祝爱萍, 麦伟明, 林锡康. 几种食品包装用塑料膜阻透性能比较[J]. 包装工程, 2018, 39(1): 74-78. |

| Zhu A P, Mai W M, Lin X K. Comparison on the barrier properties of several plastic films for food packaging[J]. Packaging Engineering, 2018, 39(1): 74-78. | |

| 6 | Garcia J M, Robertson M L. The future of plastics recycling[J]. Science, 2017, 358(6365): 870-872. |

| 7 | 叶聪贤, 钱庆荣, 曹长林, 等. 碳中和目标下利乐包的高值化回收利用[J]. 再生资源与循环经济, 2022, 15(2): 34-38. |

| Ye C X, Qian Q R, Cao C L, et al. High-value recycling of Tetra Pak with the goal of carbon neutrality[J]. Recyclable Resources and Circular Economy, 2022, 15(2): 34-38. | |

| 8 | 余绍火, 邵双喜, 段景宽, 等. 废塑料基复合材料粉体分离及回收技术(续)[J]. 资源再生, 2010(8): 42-43. |

| Yu S H, Shao S X, Duan J K, et al. Separating and recycling technology of scraps of plastic-base composite[J]. Resource Recycling, 2010(8): 42-43. | |

| 9 | Xie M H, Bai W N, Bai L, et al. Life cycle assessment of the recycling of Al-PE (a laminated foil made from polyethylene and aluminum foil) composite packaging waste[J]. Journal of Cleaner Production, 2016, 112: 4430-4434. |

| 10 | Samorì C, Cespi D, Blair P, et al. Application of switchable hydrophilicity solvents for recycling multilayer packaging materials[J]. Green Chemistry, 2017, 19(7): 1714-1720. |

| 11 | 张冀飞, 闫大海, 李丽, 等. 分离剂甲酸溶液浓度和温度对于铝塑湿法分离的影响研究[J]. 环境工程学报, 2010, 4(3): 665-670. |

| Zhang J F, Yan D H, Li L, et al. Research on the effect of separation reagent concentration and reaction temperature on Al-PE wet separation technics[J]. Chinese Journal of Environmental Engineering, 2010, 4(3): 665-670. | |

| 12 | 张海舰, 吴韬, 冯嘉宁, 等. 废弃铝塑包装材料高效回收方法的研究[J]. 塑料工业, 2014, 42(7): 114-117. |

| Zhang H J, Wu T, Feng J N, et al. Recovery methods of waste aluminum-plastic packaging materials[J]. China Plastics Industry, 2014, 42(7): 114-117. | |

| 13 | 张志红, 刘玉婷, 魏守端, 等. 药用铝塑包装材料分离回收研究[J]. 昌吉学院学报, 2011(2): 95-98. |

| Zhang Z H, Liu Y T, Wei S D, et al. Study on separation and recovery of aluminum-plastic packaging materials for medicine [J]. Journal of Changji University, 2011(2): 95-98. | |

| 14 | Yousef S, Eimontas J, Striūgas N, et al. Pyrolysis kinetic behavior and TG-FTIR-GC-MS analysis of metallised food packaging plastics[J]. Fuel, 2020, 282: 118737. |

| 15 | 宋薇, 岳东北, 刘建国, 等. 铝塑包装废物热解过程能量平衡分析[J]. 环境工程学报, 2012, 6(1): 307-310. |

| Song W, Yue D B, Liu J G, et al. Energy balance analysis on the pyrolysis process of aluminum-plastic package waste[J]. Chinese Journal of Environmental Engineering, 2012, 6(1): 307-310. | |

| 16 | Chu M Y, Tu W L, Yang S Q, et al. Sustainable chemical upcycling of waste polyolefins by heterogeneous catalysis[J]. SusMat, 2022, 2(2): 161-185. |

| 17 | 余绍火, 邵双喜, 段景宽, 等. 废塑料基复合材料粉体分离及回收技术[J]. 宁波工程学院学报, 2010, 22(2): 40-45. |

| Yu S H, Shao S X, Duan J K, et al. Separating and recycling technology of scraps of plastic-base composite[J]. Journal of Ningbo University of Technology, 2010, 22(2): 40-45. | |

| 18 | Favaro S L, Pereira A G B, Fernandes J R, et al. Outstanding impact resistance of post-consumer HDPE/multilayer packaging composites[J]. Materials Sciences and Applications, 2017, 8(1): 15-25. |

| 19 | Ragaert K, Delva L, Geem K V. Mechanical and chemical recycling of solid plastic waste[J]. Waste Management, 2017, 69: 24-58. |

| 20 | Schyns Z O G, Shaver M P. Mechanical recycling of packaging plastics: a review[J]. Macromolecular Rapid Communications, 2021, 42(3): e2000415. |

| 21 | 王琪, 卢灿辉, 夏和生. 高分子力化学研究进展[J]. 高分子通报, 2013(9): 35-49. |

| Wang Q, Lu C H, Xia H S. Research progress in polymer mechanochemistry[J]. Polymer Bulletin, 2013(9): 35-49. | |

| 22 | Yang S Q, Zhong F, Wang M, et al. Recycling of automotive shredder residue by solid state shear milling technology[J]. Journal of Industrial and Engineering Chemistry, 2018, 57: 143-153. |

| 23 | 张新星, 张伟, 卢灿辉. 力化学技术在聚合物加工中的应用进展[J]. 高分子材料科学与工程, 2013, 29(7): 183-186. |

| Zhang X X, Zhang W, Lu C H. Application advances of mechanochemical technology in polymer processing[J]. Polymer Materials Science & Engineering, 2013, 29(7): 183-186. | |

| 24 | 卢灿辉, 王琪. 聚合物固体粉碎过程中力化学效应的应用[J]. 高分子材料科学与工程, 2001, 17(5): 11-15. |

| Lu C H, Wang Q. Application of mechanochemical effects of polymer solids during pulverization[J]. Polymeric Materials Science & Cngineering, 2001, 17(5): 11-15. | |

| 25 | Wang Q, Xu X. A pan-milling type of equipment and its application in developing polymer materials[J]. Chemical Research in Chinese Universities, 1997(7): 1197-1201. |

| 26 | Xu X, Wang Q, Kong X, et al. Pan mill type equipment designed for polymer stress reactions: theoretical analysis of structure and milling process of equipment[J]. Plastics, Rubber and Composites Processing and Applications, 1996, 25: 152-158. |

| 27 | Liu P J, Chen W H, Bai S B. Influence of solid-state shear milling on structure and mechanical properties of polypropylene/polyethylene blends[J]. Polymer-Plastics Technology and Engineering, 2018, 57(7): 682-689. |

| 28 | Liu Y, Li J, Wang Q. Pan-milling to prepare ultrafine high-density polyethylene powder with sodium chloride serving as grinding aid[J]. Journal of Applied Polymer Science, 2007, 105(6): 3426-3431. |

| 29 | Lu C H, Wang Q. Preparation of ultrafine polypropylene/iron composite powders through pan-milling[J]. Journal of Materials Processing Technology, 2004, 145(3): 336-344. |

| 30 | Chen Z, Liu C S, Wang Q. Solid-phase preparation of ultra-fine PA6 powder through pan-milling[J]. Polymer Engineering & Science, 2001, 41(7): 1187-1195. |

| 31 | Zhang X X, Lu C H, Liang M. Preparation of rubber composites from ground tire rubber reinforced with waste-tire fiber through mechanical milling[J]. Journal of Applied Polymer Science, 2007, 103(6): 4087-4094. |

| 32 | Liu Q, He P, Yang S Q, et al. Recycling and reuse of waste artificial turf via solid-state shear milling technology[J]. RSC Advances, 2017, 7(85): 54117-54127. |

| 33 | Yang S Q, Jiang J, Duan W F, et al. Production of sustainable wood-plastic composites from the nonmetals in waste printed circuit boards: excellent physical performance achieved by solid-state shear milling[J]. Composites Science and Technology, 2020, 200: 108411. |

| 34 | Yang S Q, Bai S B, Wang Q. Preparation of fine fiberglass-resin powders from waste printed circuit boards by different milling methods for reinforcing polypropylene composites[J]. Journal of Applied Polymer Science, 2015, 132(35): 42494. |

| 35 | Yang S Q, Jiang J, Wang Q. The novel application of nonmetals from waste printed circuit board in high-performance thermal management materials[J]. Composites Part A: Applied Science and Manufacturing, 2020, 139: 106096. |

| 36 | 郭杰. 破碎-分选废弃电路板中非金属粉的资源化利用研究[D]. 上海: 上海交通大学, 2011. |

| Guo J. Study on reutilization of nonmetals reclamed from crushing-separating waste printed circuit boards[D]. Shanghai: Shanghai Jiao Tong University, 2011. | |

| 37 | Wu H J, Liang M, Lu C H. Morphological and structural development of recycled crosslinked polyethylene during solid-state mechanochemical milling[J]. Journal of Applied Polymer Science, 2011, 122(1): 257-264. |

| 38 | Sun F S, Guo J, Li Y J, et al. Preparation of high-performance polyethylene tubes under the coexistence of silicone cross-linked polyethylene and rotation extrusion[J]. Royal Society Open Science, 2019, 6(5): 182095. |

| 39 | Murthy K. Grinding studies of mango ginger: mathematical modelling of particle size distribution and energy consumption[J]. American Journal of Food Science & Technology, 2013, 4: 70-76. |

| 40 | Yang S Q, Bai S B, Duan W F, et al. Production of value-added composites from aluminum–plastic package waste via solid-state shear milling process[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(3): 4282-4293. |

| 41 | Wei B J, Yang S Q, Wang Q. Green recycling of aluminum plastic packaging waste by solid-state shear milling and 3D printing for thermal conductive composites[J]. Polymers for Advanced Technologies, 2021, 32(6): 2576-2587. |

| [1] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [2] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| [3] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [4] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [5] | 崔张宁, 胡紫璇, 吴雷, 周军, 叶干, 刘田田, 张秋利, 宋永辉. 可降解纤维素基材料的耐水性能研究进展[J]. 化工学报, 2023, 74(6): 2296-2307. |

| [6] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| [7] | 代佳琳, 毕唯东, 雍玉梅, 陈文强, 莫晗旸, 孙兵, 杨超. 热物性对混合型CPCMs固液相变特性影响模拟研究[J]. 化工学报, 2023, 74(5): 1914-1927. |

| [8] | 陈韶云, 徐东, 陈龙, 张禹, 张远方, 尤庆亮, 胡成龙, 陈建. 单层聚苯胺微球阵列结构的制备及其吸附性能[J]. 化工学报, 2023, 74(5): 2228-2238. |

| [9] | 刘瑞琪, 周栖桐, 张悦, 贺莹, 高静, 马丽. 基于金纳米颗粒修饰二氧化硅纳米花的生物传感器构建及应用[J]. 化工学报, 2023, 74(3): 1247-1259. |

| [10] | 徐东, 田杜, 陈龙, 张禹, 尤庆亮, 胡成龙, 陈韶云, 陈建. 聚苯胺/二氧化锰/聚吡咯复合纳米球的制备及其电化学储能性[J]. 化工学报, 2023, 74(3): 1379-1389. |

| [11] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [12] | 徐振和, 李泓江, 高雨, 礼峥, 张含烟, 徐宝彤, 丁茯, 孙亚光. In2O3/Ag:ZnIn2S4“Type Ⅱ”型异质结构材料的制备及可见光催化性能[J]. 化工学报, 2022, 73(8): 3625-3635. |

| [13] | 钟磊, 邱学青, 张文礼. 木质素衍生炭在碱金属离子电池负极中的研究进展[J]. 化工学报, 2022, 73(8): 3369-3380. |

| [14] | 张鑫, 许蕊, 路馨语, 牛永安. SiO2@BiOCl-Bi24O31Cl10核壳微球的合成及光催化[J]. 化工学报, 2022, 73(8): 3636-3646. |

| [15] | 顾仁杰, 张加威, 靳雪阳, 文利雄. 微撞击流反应器制备镍钴复合氢氧化物超级电容器材料及其性能研究[J]. 化工学报, 2022, 73(8): 3749-3757. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号