化工学报 ›› 2023, Vol. 74 ›› Issue (7): 3079-3092.DOI: 10.11949/0438-1157.20230381

收稿日期:2023-04-18

修回日期:2023-06-23

出版日期:2023-07-05

发布日期:2023-08-31

通讯作者:

罗英武

作者简介:张澳(1999—),男,硕士研究生,aozhang@zju.edu.cn

基金资助:Received:2023-04-18

Revised:2023-06-23

Online:2023-07-05

Published:2023-08-31

Contact:

Yingwu LUO

摘要:

丙烯酸酯压敏胶广泛应用在电子器件的装配中。随着可折叠屏手机等柔性电子器件发展,传统压敏胶因无法平衡低模量、高弹性以及高剥离强度而难以满足柔性电子器件对反复动态变形的需求。以苯乙烯、丙烯酸异辛酯为单体,采用RAFT乳液聚合设计制备了聚苯乙烯-b-聚丙烯酸异辛酯-b-聚苯乙烯(SEHAS)和聚苯乙烯-b-聚丙烯酸异辛酯(SEHA)嵌段聚合物,研究两种嵌段共聚物共混体系的力学性能、黏弹性和黏结性能。发现当共混物中SEHA的含量从0(质量)提高到75%(质量)时,玻璃化温度仍为-68℃,保持不变,剪切储能模量从27 kPa下降至15 kPa,剥离强度从8.1 N/25 mm提升到10.3 N/25 mm,应变回复率仍然保持在95%以上。研究表明SEHAS/SEHA共组装是一种简便降低模量同时维持较好的交联网络完整性并提高黏弹性的新方法,能够更好地平衡压敏胶高柔性、大变形后的回弹性和良好界面黏合性之间的关系。

中图分类号:

张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092.

Ao ZHANG, Yingwu LUO. Low modulus, high elasticity and high peel adhesion acrylate pressure sensitive adhesives[J]. CIESC Journal, 2023, 74(7): 3079-3092.

| Type | Stage | Mn,design① | Mn,exp | PDI | |

|---|---|---|---|---|---|

| SEHAS | 1 | 96.9 | 15 | 17.4 | 1.27 |

| 2 | 97.1 | 195 | 201.6 | 2.08 | |

| 3 | 95.5 | 210 | 217.1 | 2.10 | |

| SEHA | 1 | 96.8 | 5 | 6.3 | 1.64 |

| 2 | 97.6 | 125 | 124.0 | 2.74 |

表1 嵌段共聚物的链结构

Table 1 Molecular structure of the block copolymers

| Type | Stage | Mn,design① | Mn,exp | PDI | |

|---|---|---|---|---|---|

| SEHAS | 1 | 96.9 | 15 | 17.4 | 1.27 |

| 2 | 97.1 | 195 | 201.6 | 2.08 | |

| 3 | 95.5 | 210 | 217.1 | 2.10 | |

| SEHA | 1 | 96.8 | 5 | 6.3 | 1.64 |

| 2 | 97.6 | 125 | 124.0 | 2.74 |

图15 200%、300%和400%拉伸应变下不同比例SEHAS/SEHA共混物的应力和应变随时间的变化

Fig.15 Stress and strain related with time of SEHAS/SEHA with different blending ratios under a strain of 200%, 300% and 400%

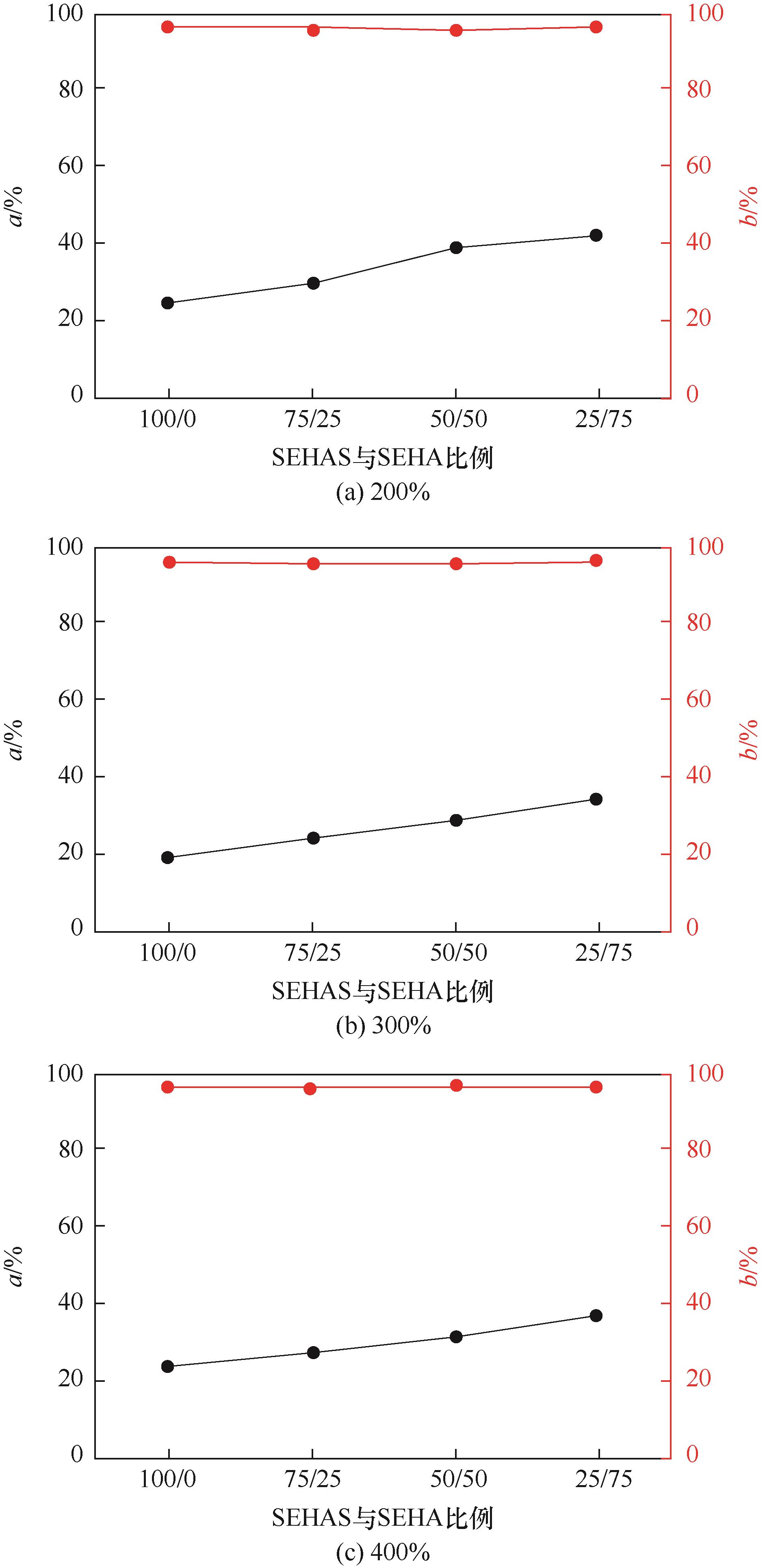

图16 200%、300%和400%拉伸应变下不同比例SEHAS/SEHA共混物的应力松弛率和应变回复率

Fig.16 Stress relaxation ratio and strain recovery ratio of SEHAS/SEHA with different blending ratios under a strain of 200%, 300% and 400%

图17 400%拉伸应变下不同比例SEHAS/SEHA共混物的应力松弛拟合

Fig.17 Experimental (dot) and fitting results (solid line) with KWW equation of stress relaxation behavior of SEHAS/SEHA with different blending ratios under a strain 400%

| SEHAS/SEHA比例 | ||||

|---|---|---|---|---|

| 100∶0 | 0.033 | 0.095 | 3.21 | 0.35 |

| 75∶25 | 0.034 | 0.082 | 2.20 | 0.32 |

| 50∶50 | 0.045 | 0.061 | 2.45 | 0.34 |

| 25∶75 | 0.022 | 0.036 | 0.84 | 0.34 |

表2 400%拉伸应变下不同比例SEHAS/SEHA共混物的拟合参数

Table 2 Fitting parameters of SEHAS/SEHA with different blending ratios under a strain of 400%

| SEHAS/SEHA比例 | ||||

|---|---|---|---|---|

| 100∶0 | 0.033 | 0.095 | 3.21 | 0.35 |

| 75∶25 | 0.034 | 0.082 | 2.20 | 0.32 |

| 50∶50 | 0.045 | 0.061 | 2.45 | 0.34 |

| 25∶75 | 0.022 | 0.036 | 0.84 | 0.34 |

| 品牌/参数 | 膜厚/μm | 断裂 伸长率/% | 玻璃化 温度/°C | 剪切储能模量 (1 rad/s)/kPa | 损耗因子 (1 rad/s) | 应力 松弛率/% | 应变 回复率/% | 剥离强度/ (N/25 mm) |

|---|---|---|---|---|---|---|---|---|

| SEHAS∶SEHA=100∶0 | 25 | 1000 | -68 | 27 | 0.21 | 约20 | >95 | 8.1 |

| SEHAS∶SEHA=25∶75 | 25 | 700 | -68 | 15 | 0.30 | 约40 | >95 | 10.3 |

| 3M CEF3501 | 25 | 598 | -42 | 30 | 0.33 | — | — | 8.5 |

| AA改性[ | 100 | 约410 | -54 | 27 | — | 约48 | >95 | 约13.8① |

| 丙烯酸酯弹性体改性[ | 75 | — | -40 | — | — | 约50 | 约75 | 约12.0① |

| 交联密度调控[ | 50 | — | -31 | — | — | 约71 | 约71 | 约10.0① |

表3 本文设计制备的压敏胶与文献报道的可折叠压敏胶综合性能对比

Table 3 The property and performance comparison of the foldable pressure sensitive adhesive between the current work and the literature

| 品牌/参数 | 膜厚/μm | 断裂 伸长率/% | 玻璃化 温度/°C | 剪切储能模量 (1 rad/s)/kPa | 损耗因子 (1 rad/s) | 应力 松弛率/% | 应变 回复率/% | 剥离强度/ (N/25 mm) |

|---|---|---|---|---|---|---|---|---|

| SEHAS∶SEHA=100∶0 | 25 | 1000 | -68 | 27 | 0.21 | 约20 | >95 | 8.1 |

| SEHAS∶SEHA=25∶75 | 25 | 700 | -68 | 15 | 0.30 | 约40 | >95 | 10.3 |

| 3M CEF3501 | 25 | 598 | -42 | 30 | 0.33 | — | — | 8.5 |

| AA改性[ | 100 | 约410 | -54 | 27 | — | 约48 | >95 | 约13.8① |

| 丙烯酸酯弹性体改性[ | 75 | — | -40 | — | — | 约50 | 约75 | 约12.0① |

| 交联密度调控[ | 50 | — | -31 | — | — | 约71 | 约71 | 约10.0① |

| 1 | Wang C, Hwang D, Yu Z B, et al. User-interactive electronic skin for instantaneous pressure visualization[J]. Nature Materials, 2013, 12(10): 899-904. |

| 2 | Park J, Heo S, Park K, et al. Research on flexible display at Ulsan National Institute of Science and Technology[J]. NPJ Flexible Electronics, 2017, 1: 9. |

| 3 | Rogers J A, Someya T, Huang Y G. Materials and mechanics for stretchable electronics[J]. Science, 2010, 327(5973): 1603-1607. |

| 4 | Lim D, Baek M J, Kim H S, et al. Carboxyethyl acrylate incorporated optically clear adhesives with outstanding adhesion strength and immediate strain recoverability for stretchable electronics[J]. Chemical Engineering Journal, 2022, 437: 135390. |

| 5 | Zhang P, Zhou W Y, He Y F, et al. Stretchable heterogeneous polymer networks of high adhesion and low hysteresis[J]. ACS Applied Materials & Interfaces, 2022, 14(43): 49264-49273. |

| 6 | Kim S, An J, Son S R, et al. Fabrication of highly elastic and optically transparent adhesive films for flexible displays using multifunctional photocrosslinker[J]. Molecular Crystals and Liquid Crystals, 2022, 740(1): 28-34. |

| 7 | Bartkowiak M, Czech Z, Mozelewska K, et al. Influence of thermal reactive crosslinking agents on the tack, peel adhesion, and shear strength of acrylic pressure-sensitive adhesives[J]. Polymer Testing, 2020, 90: 106603. |

| 8 | Baek S S, Jang S J, Hwang S H. The effect of crosslinker type on adhesion properties of transparent acrylic pressure sensitive adhesives for optical applications[J]. Elastomers and Composites, 2014, 49(3): 199-203. |

| 9 | Zhang X W, Ding Y T, Zhang G L, et al. Preparation and rheological studies on the solvent based acrylic pressure sensitive adhesives with different crosslinking density[J]. International Journal of Adhesion and Adhesives, 2011, 31(7): 760-766. |

| 10 | Lee J H, Park J, Myung M H, et al. Stretchable and recoverable acrylate-based pressure sensitive adhesives with high adhesion performance, optical clarity, and metal corrosion resistance[J]. Chemical Engineering Journal, 2021, 406: 126800. |

| 11 | Lee S H, You R, Yoon Y I, et al. Preparation and characterization of acrylic pressure-sensitive adhesives based on UV and heat curing systems[J]. International Journal of Adhesion and Adhesives, 2017, 75: 190-195. |

| 12 | Czech Z, Kabatc J, Kowalczyk A, et al. Application of selected 2-methylbenzothiazoles AS cationic photoreactive crosslinkers for pressure-sensitive adhesives based on acrylics[J]. International Journal of Adhesion and Adhesives, 2015, 58: 1-6. |

| 13 | Kim J S, Kim H J, Kim Y D. Flexibility properties of pressure-sensitive adhesive with different pattern of crosslinking density for electronic displays[J]. Journal of Materials Research and Technology, 2021, 15: 1408-1415. |

| 14 | Back J H, Baek D, Sim K B, et al. Optimization of recovery and relaxation of acrylic pressure-sensitive adhesives by using UV patterning for flexible displays[J]. Industrial & Engineering Chemistry Research, 2019, 58(10): 4331-4340. |

| 15 | Mao J, Li T F, Luo Y W. Significantly improved electromechanical performance of dielectric elastomers via alkyl side-chain engineering[J]. Journal of Materials Chemistry C, 2017, 5(27): 6834-6841. |

| 16 | Lee J H, Lee T H, Shim K S, et al. Effect of crosslinking density on adhesion performance and flexibility properties of acrylic pressure sensitive adhesives for flexible display applications[J]. International Journal of Adhesion and Adhesives, 2017, 74: 137-143. |

| 17 | Lee J H, Lee T H, Shim K S, et al. Molecular weight and crosslinking on the adhesion performance and flexibility of acrylic PSAs[J]. Journal of Adhesion Science and Technology, 2016, 30(21): 2316-2328. |

| 18 | Lee J H, Shim G S, Kim H J, et al. Adhesion performance and recovery of acrylic PSA with acrylic elastomer (AE) blends via thermal crosslinking for application in flexible displays[J]. Polymers, 2019, 11(12): 1959. |

| 19 | Bartkowiak M, Czech Z, Kim H J, et al. Photoreactive UV-crosslinkable acrylic pressure-sensitive adhesives (PSA) containing multifunctional photoinitiators[J]. Polymers, 2021, 13(24): 4413. |

| 20 | Chen Z Q, Xiao Y H, Fang J W, et al. Ultrasoft-yet-strong pentablock copolymer as dielectric elastomer highly responsive to low voltages[J]. Chemical Engineering Journal, 2021, 405: 126634. |

| 21 | 徐菘. RAFT乳液聚合可控制备SBAS新型水性压敏胶[D]. 杭州: 浙江大学, 2015. |

| Xu S. Development of novel water-based high performance pressure-sensitive adhesive of SBAS via RAFT emulsion polymerization[D]. Hangzhou: Zhejiang University, 2015. | |

| 22 | Ferguson C J, Hughes R J, Nguyen D, et al. Ab initio emulsion polymerization by RAFT-controlled self-assembly[J]. Macromolecules, 2005, 38(6): 2191-2204. |

| 23 | Wang X G, Luo Y W, Li B G, et al. Ab initio batch emulsion RAFT polymerization of styrene mediated by poly(acrylic acid-b-styrene) trithiocarbonate[J]. Macromolecules, 2009, 42(17): 6414-6421. |

| 24 | Ma Z P, Xie Y H, Mao J E, et al. Thermoplastic dielectric elastomer of triblock copolymer with high electromechanical performance[J]. Macromolecular Rapid Communications, 2017, 38(16): 1700268. |

| 25 | Wu L F, Cochran E W, Lodge T P, et al. Consequences of block number on the order-disorder transition and viscoelastic properties of linear (AB) n multiblock copolymers[J]. Macromolecules, 2004, 37(9): 3360-3368. |

| 26 | Guo Y L, Gao X A, Luo Y W. Suppressing the long-chain branching in the synthesis of poly(styrene-b-butyl acrylate-b-styrene) in RAFT emulsion polymerization by tuning the interfacial properties[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2015, 53(12): 1464-1473. |

| 27 | Hadjichristidis N, Pispas S, Floudas G. Block Copolymers: Synthetic Strategies, Physical Properties, and Applications[M]. Hoboken, NJ: Wiley, 2003. |

| 28 | Swann J M G, Topham P D. Design and application of nanoscale actuators using block-copolymers[J]. Polymers, 2010, 2(4): 454-469. |

| 29 | Fang Y, Xia J. Highly stretchable, soft, and clear viscoelastic film with good recoverability for flexible display[J]. ACS Applied Materials & Interfaces, 2022, 14(33): 38398-38408. |

| 30 | 高扬. 纳米BaTiO3增强丙烯酸酯嵌段共聚物介电弹性体机电性能[D]. 杭州: 浙江大学, 2021. |

| Gao Y. Mechanical and electrical properties of acrylate block copolymer dielectric elastomer reinforced by nano BaTiO3 [D]. Hangzhou: Zhejiang University, 2021. | |

| 31 | 冒杰. 介电弹性体新材料与纤维状驱动器的设计与可控制备[D]. 杭州: 浙江大学, 2020. |

| Mao J. Design and controllable preparation of dielectric elastomer materials and fibrous actuators[D]. Hangzhou: Zhejiang University, 2020. | |

| 32 | Roos A, Creton C. Effect of the presence of diblock copolymer on the nonlinear elastic and viscoelastic properties of elastomeric triblock copolymers[J]. Macromolecules, 2005, 38(18): 7807-7818. |

| 33 | Ha M H, Choi J K, Park B M, et al. Highly flexible cover window using ultra-thin glass for foldable displays[J]. Journal of Mechanical Science and Technology, 2021, 35(2): 661-668. |

| 34 | Tong J D, Jerôme R. Dependence of the ultimate tensile strength of thermoplastic elastomers of the triblock type on the molecular weight between chain entanglements of the central block[J]. Macromolecules, 2000, 33(5): 1479-1481. |

| 35 | Sakaguchi Y, Kosaka N, Hori N, et al. Rheological analysis of the adhesion surface with a scanning probe microscope (SPM)[J]. International Journal of Adhesion and Adhesives, 2011, 31(1): 1-8. |

| 36 | Fujita M, Takemura A, Ono H, et al. Effects of miscibility and viscoelasticity on shear creep resistance of natural-rubber-based pressure-sensitive adhesives[J]. Journal of Applied Polymer Science, 2000, 75(12): 1535-1545. |

| 37 | Fujita M, Kajiyama M, Takemura A, et al. Effects of miscibility on probe tack of natural-rubber-based pressure-sensitive adhesives[J]. Journal of Applied Polymer Science, 1998, 70(4): 771-776. |

| [1] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [2] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [3] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [4] | 崔张宁, 胡紫璇, 吴雷, 周军, 叶干, 刘田田, 张秋利, 宋永辉. 可降解纤维素基材料的耐水性能研究进展[J]. 化工学报, 2023, 74(6): 2296-2307. |

| [5] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| [6] | 代佳琳, 毕唯东, 雍玉梅, 陈文强, 莫晗旸, 孙兵, 杨超. 热物性对混合型CPCMs固液相变特性影响模拟研究[J]. 化工学报, 2023, 74(5): 1914-1927. |

| [7] | 陈韶云, 徐东, 陈龙, 张禹, 张远方, 尤庆亮, 胡成龙, 陈建. 单层聚苯胺微球阵列结构的制备及其吸附性能[J]. 化工学报, 2023, 74(5): 2228-2238. |

| [8] | 刘瑞琪, 周栖桐, 张悦, 贺莹, 高静, 马丽. 基于金纳米颗粒修饰二氧化硅纳米花的生物传感器构建及应用[J]. 化工学报, 2023, 74(3): 1247-1259. |

| [9] | 徐东, 田杜, 陈龙, 张禹, 尤庆亮, 胡成龙, 陈韶云, 陈建. 聚苯胺/二氧化锰/聚吡咯复合纳米球的制备及其电化学储能性[J]. 化工学报, 2023, 74(3): 1379-1389. |

| [10] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [11] | 徐振和, 李泓江, 高雨, 礼峥, 张含烟, 徐宝彤, 丁茯, 孙亚光. In2O3/Ag:ZnIn2S4“Type Ⅱ”型异质结构材料的制备及可见光催化性能[J]. 化工学报, 2022, 73(8): 3625-3635. |

| [12] | 杨双桥, 韦宝杰, 徐大伟, 李莉, 王琪. 铝塑复合包装的应用及废弃物回收利用新技术[J]. 化工学报, 2022, 73(8): 3326-3337. |

| [13] | 钟磊, 邱学青, 张文礼. 木质素衍生炭在碱金属离子电池负极中的研究进展[J]. 化工学报, 2022, 73(8): 3369-3380. |

| [14] | 张鑫, 许蕊, 路馨语, 牛永安. SiO2@BiOCl-Bi24O31Cl10核壳微球的合成及光催化[J]. 化工学报, 2022, 73(8): 3636-3646. |

| [15] | 顾仁杰, 张加威, 靳雪阳, 文利雄. 微撞击流反应器制备镍钴复合氢氧化物超级电容器材料及其性能研究[J]. 化工学报, 2022, 73(8): 3749-3757. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号