化工学报 ›› 2023, Vol. 74 ›› Issue (9): 3821-3830.DOI: 10.11949/0438-1157.20230455

范孝雄1,2( ), 郝丽芳1(

), 郝丽芳1( ), 范垂钢1, 李松庚1(

), 范垂钢1, 李松庚1( )

)

收稿日期:2023-05-09

修回日期:2023-08-31

出版日期:2023-09-25

发布日期:2023-11-20

通讯作者:

郝丽芳,李松庚

作者简介:范孝雄(1998—),男,硕士研究生,fanxiaoxiong20@mails.ucas.ac.cn

基金资助:

Xiaoxiong FAN1,2( ), Lifang HAO1(

), Lifang HAO1( ), Chuigang FAN1, Songgeng LI1(

), Chuigang FAN1, Songgeng LI1( )

)

Received:2023-05-09

Revised:2023-08-31

Online:2023-09-25

Published:2023-11-20

Contact:

Lifang HAO, Songgeng LI

摘要:

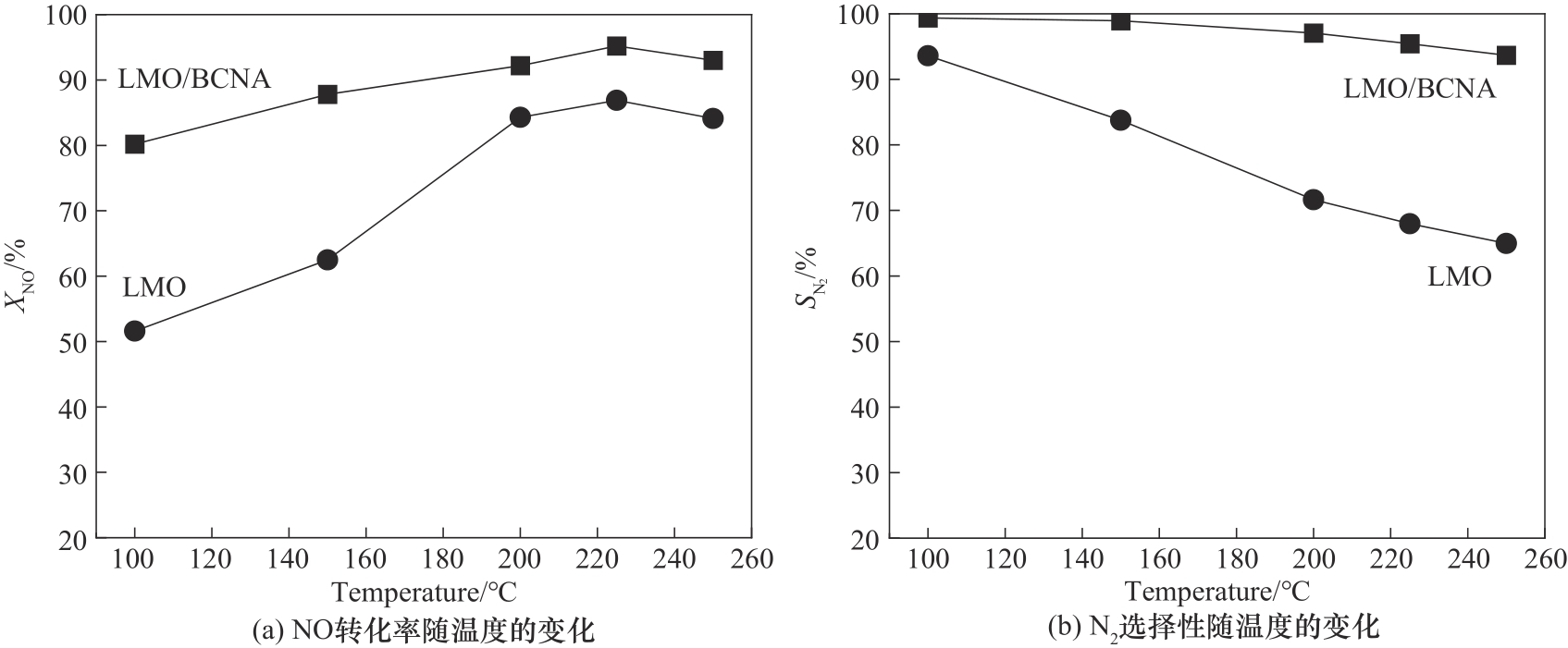

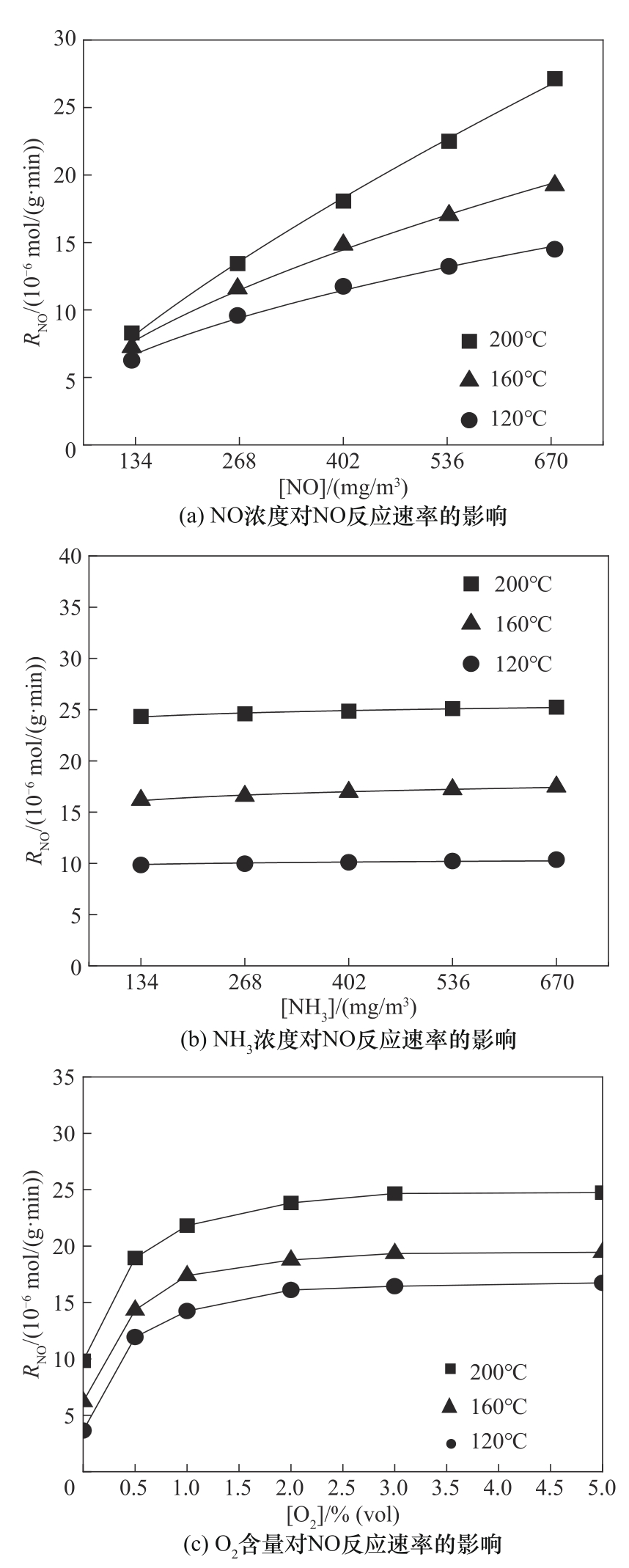

以La-Mn钙钛矿氧化物为活性组分,生物炭为载体,利用浸渍法制备负载型脱硝催化剂LMO/BCNA。利用固定床反应装置考察了催化剂的催化活性以及耐硫耐水性能,100~250℃范围内,NO转化率>80%,N2选择性>90%,225℃时NO转化率最高,为95.8%,对应的N2选择性为95.4%。与氧化物相比,负载型催化剂的催化活性大幅提升,同时也扩宽了工作温度区间;生物炭载体的引入,减弱了催化剂对H2O、SO2的吸附,增强了耐硫耐水性能。应用稳态动力学方法构建催化反应动力学模型,在实验条件范围且O2含量为5%时,催化NH3-SCR反应过程中NO、O2、NH3的反应级数分别为0.66、0、0,并得到LMO/BCNA催化的反应活化能为25.52 kJ/mol,低于商用钒钨钛催化剂的化学反应活化能(40~94 kJ/mol)。

中图分类号:

范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830.

Xiaoxiong FAN, Lifang HAO, Chuigang FAN, Songgeng LI. Study on the catalytic denitrification performance of low-temperature NH3-SCR over LaMnO3/biochar catalyst[J]. CIESC Journal, 2023, 74(9): 3821-3830.

图4 100~250℃催化剂的催化脱硝活性[GHSV=16000 h-1; [NO]=[NH3]=670 mg/m3; [O2]=5%(vol); N2 as balance; a total flow rate of 800 ml/min]

Fig.4 NO conversion and N2 selectivity for LMO and LMO/BCNA at 100—250℃

图5 催化剂的耐硫耐水性能[225℃; GHSV=16000 h-1; [NO]=[NH3]=670 mg/m3; [O2]=5%(vol); 10% H2O (when used); 134 mg/m3 SO2 (when used); N2 as balance; a total flow rate of 800 ml/min]

Fig.5 H2O and SO2 resistance performance of catalysts

图7 气体反应物浓度对NO反应速率(RNO)的影响(Particle size of 0.18—0.25 mm; GHSV 232000 h-1; N2 as balance; a total flow rate of 2.9 L/min)

Fig. 7 Dependence of NO conversion rate on NO (a), NH3 (b) and O2 (c) concentration at 120, 160, 200℃

| 催化剂质量W/g | NO转化率/% | ||

|---|---|---|---|

| 120℃ | 160℃ | 200℃ | |

| 0.5 | 4.4 | 7.6 | 12.1 |

| 0.6 | 5.0 | 9.2 | 15.4 |

| 0.8 | 6.1 | 12.6 | 19.7 |

| 0.9 | 7.2 | 15.3 | 24.9 |

表1 不同质量催化剂在120、160、200℃条件下的NO转化率(XNO)

Table 1 NO conversion (XNO) over catalyst at 120, 160, 200℃

| 催化剂质量W/g | NO转化率/% | ||

|---|---|---|---|

| 120℃ | 160℃ | 200℃ | |

| 0.5 | 4.4 | 7.6 | 12.1 |

| 0.6 | 5.0 | 9.2 | 15.4 |

| 0.8 | 6.1 | 12.6 | 19.7 |

| 0.9 | 7.2 | 15.3 | 24.9 |

| 27 | Chen S Y, Chen P, Li Y W, et al. Catalytic Reaction Kinetics[M]. Beijing: Chemical Industry Press, 2007. |

| 28 | Ma Z R, Wu X D, Härelind H, et al. NH3-SCR reaction mechanisms of NbO x /Ce0.75Zr0.25O2 catalyst: DRIFTS and kinetics studies[J]. Journal of Molecular Catalysis A: Chemical, 2016, 423: 172-180. |

| 29 | Qi G, Yang R T. Performance and kinetics study for low-temperature SCR of NO with NH3 over MnO x -CeO2 catalyst[J]. Journal of Catalysis, 2003, 217(2): 434-441. |

| 30 | Hu X L, Qu W Y, Chen J X, et al. Speeding up low-temperature SCR with reactants-coupling dual catalytic sites[J]. Chemical Engineering Journal, 2022, 440: 135832. |

| 31 | Amiridis M D, Solar J P. Selective catalytic reduction of nitric oxide by ammonia over V2O5/TiO2, V2O5/TiO2/SiO2, and V2O5-WO3/TiO2 catalysts: effect of vanadia content on the activation energy[J]. Industrial & Engineering Chemistry Research, 1996, 35: 978-981. |

| 1 | 环境保护部, 国家质量监督检验检疫总局. 火电厂大气污染物排放标准: [S]. 北京: 中国环境科学出版社, 2012. |

| Ministry of Environmental Protection of the People’s Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Emission standard of air pollutants for thermal power plants: [S]. Beijing: China Environmental Science Press, 2012. | |

| 2 | 环境保护部, 国家质量监督检验检疫总局. 轻型汽车污染物排放限值及测量方法: [S]. 北京: 中国环境科学出版社, 2020. |

| Ministry of Environmental Protection of the People’s Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Limits and measurement methods for emissions from light-duty vehicles(): GB 18352.6—2016[S]. Beijing: China Environmental Science Press, 2020. | |

| 3 | Kobayashi M, Miyoshi K. WO3-TiO2 monolithic catalysts for high temperature SCR of NO by NH3: influence of preparation method on structural and physico-chemical properties, activity and durability[J]. Applied Catalysis B: Environmental, 2007, 72(3/4): 253-261. |

| 4 | Liu Z M, Zhang S X, Li J H, et al. Novel V2O5-CeO2/TiO2 catalyst with low vanadium loading for the selective catalytic reduction of NO x by NH3 [J]. Applied Catalysis B: Environmental, 2014, 158/159: 11-19. |

| 5 | Han L P, Cai S X, Gao M, et al. Selective catalytic reduction of NO x with NH3 by using novel catalysts: state of the art and future prospects[J]. Chemical Reviews, 2019, 119(19): 10916-10976. |

| 6 | 李俊华, 杨恂, 常化振, 等. 烟气催化脱硝关键技术研发及应用[M]. 北京: 科学出版社, 2015. |

| Li J H, Yang X, Chang H Z, et al. Developmet and Application of Key Technologies for Selective Catalytic Reduction of NO x from Flue Gas[M]. Beijing: Science Press, 2015. | |

| 7 | Zhu H Y, Zhang P F, Dai S. Recent advances of lanthanum-based perovskite oxides for catalysis[J]. ACS Catalysis, 2015, 5(11): 6370-6385. |

| 8 | Kim Y K, Hao L F, Park J I, et al. Catalytic activity and activation mechanism of potassium carbonate supported on perovskite oxide for coal char combustion[J]. Fuel, 2012, 94: 516-522. |

| 9 | Royer S, Duprez D, Can F, et al. Perovskites as substitutes of noble metals for heterogeneous catalysis: dream or reality[J]. Chemical Reviews, 2014, 114(20): 10292-10368. |

| 10 | Jabłońska M, Palkovits R. Perovskite-based catalysts for the control of nitrogen oxide emissions from diesel engines[J]. Catalysis Science & Technology, 2019, 9(9): 2057-2077. |

| 11 | 拓凯, 张朋, 王利, 等. 钙钛矿催化剂用于氨选择性还原氮氧化物的研究进展[J]. 华中农业大学学报, 2020, 39(5): 26-34. |

| Tuo K, Zhang P, Wang L, et al. Perovskite catalysts for selective catalytic reduction of NO x with NH3 [J]. Journal of Huazhong Agriculture University, 2020, 39(5): 26-34. | |

| 12 | Tang C J, Zhang H L, Dong L. Ceria-based catalysts for low-temperature selective catalytic reduction of NO with NH3 [J]. Catalysis Science & Technology, 2016, 6(5): 1248-1264. |

| 13 | Zhang R D, Yang W, Luo N, et al. Low-temperature NH3-SCR of NO by lanthanum manganite perovskites: effect of A-/B-site substitution and TiO2/CeO2 support[J]. Applied Catalysis B: Environmental, 2014, 146: 94-104. |

| 14 | Zhang Z K, Zhu Z Y, Shen B X, et al. Insights into biochar and hydrochar production and applications: a review[J]. Energy, 2019, 171: 581-598. |

| 15 | Fan X X, Hao L F, Gu X Y, et al. Low-temperature selective catalytic reduction of NO with NH3 over a biochar-supported perovskite oxide catalyst[J]. Energy & Fuels, 2023, 37(10): 7339-7352. |

| 16 | 刘怀平, 尹海滨, 熊尚超, 等. 水泥炉窑中低温催化脱硝技术中试性能[J]. 中国环境科学, 2021, 41(7): 3169-3175. |

| Liu H P, Yin H B, Xiong S C, et al. A pilot scale study of low-temperature De-NO x in cement furnace[J]. China Environmental Science, 2021, 41(7): 3169-3175. | |

| 17 | Valdés-Solís T, Marbán G, Fuertes A B. Kinetics and mechanism of low-temperature SCR of NO x with NH3 over vanadium oxide supported on carbon-ceramic cellular monoliths[J]. Industrial & Engineering Chemistry Research, 2004, 43(10): 2349-2355. |

| 18 | Xing J Y, Wang C B, Huang Y L, et al. A comprehensive exploration about the effects of O2, SO2 and NO on As2O3 adsorption over Cu/γ-Al2O3 SCR catalyst: a DFT study[J]. Chemical Engineering Science, 2022, 248: 117260. |

| 19 | Millan R, Cnudde P, Van Speybroeck V, et al. Mobility and reactivity of Cu+ species in Cu-CHA catalysts under NH3-SCR-NO x reaction conditions: insights from AIMD simulations[J]. JACS Au, 2021, 1(10): 1778-1787. |

| 20 | Yao X J, Wang Z, Yu S H, et al. Acid pretreatment effect on the physicochemical property and catalytic performance of CeO2 for NH3-SCR[J]. Applied Catalysis A: General, 2017, 542: 282-288. |

| 21 | Zhang N Q, Li L C, Guo Y Z, et al. A MnO2-based catalyst with H2O resistance for NH3-SCR: study of catalytic activity and reactants-H2O competitive adsorption[J]. Applied Catalysis B: Environmental, 2020, 270: 118860. |

| 22 | Kang T H, Youn S, Kim D H. Improved catalytic performance and resistance to SO2 over V2O5-WO3/TiO2 catalyst physically mixed with Fe2O3 for low-temperature NH3-SCR[J]. Catalysis Today, 2021, 376: 95-103. |

| 23 | Wang Y Z, Yi W, Yu J E, et al. Novel methods for assessing the SO2 poisoning effect and thermal regeneration possibility of MO x -WO3/TiO2 (M=Fe, Mn, Cu, and V) catalysts for NH3-SCR[J]. Environmental Science & Technology, 2020, 54(19): 12612-12620. |

| 24 | Wang C Z, Gao F Y, Ko S, et al. Structural control for inhibiting SO2 adsorption in porous MnCe nanowire aerogel catalysts for low-temperature NH3-SCR[J]. Chemical Engineering Journal, 2022, 434: 134729. |

| 25 | Gray M, Johnson M G, Dragila M I, et al. Water uptake in biochars: the roles of porosity and hydrophobicity[J]. Biomass and Bioenergy, 2014, 61: 196-205. |

| 26 | Shu Y, Zhang F, Wang H C. Manganese-cerium mixed oxides supported on rice husk based activated carbon with high sulfur tolerance for low-temperature selective catalytic reduction of nitrogen oxides with ammonia[J]. RSC Advances, 2019, 9(41): 23964-23972. |

| 27 | 陈诵英, 陈平, 李永旺, 等. 催化反应动力学[M]. 北京: 化学工业出版社, 2007. |

| [1] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [2] | 姜家豪, 黄笑乐, 任纪云, 朱正荣, 邓磊, 车得福. 生物炭吸附溶液中Pb2+的定性及定量研究[J]. 化工学报, 2023, 74(2): 830-842. |

| [3] | 赵希强, 张健, 孙爽, 王文龙, 毛岩鹏, 孙静, 刘景龙, 宋占龙. 生物质炭改性微球去除化工废水中无机磷的性能研究[J]. 化工学报, 2022, 73(5): 2158-2173. |

| [4] | 陈冠益, 童图军, 李瑞, 王燕杉, 颜蓓蓓, 李宁, 侯立安. 热解时间对污泥生物炭活化过硫酸盐的影响研究[J]. 化工学报, 2022, 73(5): 2111-2119. |

| [5] | 李文怀, 周嵬. 高氧离子电导钙钛矿的影响因素分析和设计策略[J]. 化工学报, 2022, 73(4): 1455-1471. |

| [6] | 秦坤, 李佳乐, 王章鸿, 张会岩. 富Ca香菇菌渣基生物炭对含磷废水处理性能的研究[J]. 化工学报, 2022, 73(11): 5263-5274. |

| [7] | 李泽严, 樊星, 李坚. 非热等离子体强化TiO2催化尿素分解副产物水解性能的研究[J]. 化工学报, 2021, 72(9): 4698-4707. |

| [8] | 邱爽, 肖永厚, 刘建辉, 贺高红. 一步法制备高活性NH3-SCR催化剂Cu-SAPO-34:Si含量的影响[J]. 化工学报, 2021, 72(5): 2578-2585. |

| [9] | 杨林, 孟小谜, 姚露, 赖雨果, 蒋文举. 天然矿物共混活性焦联合低温脱硫脱硝[J]. 化工学报, 2021, 72(4): 2241-2248. |

| [10] | 卿梦霞, 张鑫, 刘亮, 张巍, 王乐乐, 苏胜, 孔凡海, 向军. 燃煤烟气脱硝副产物硫酸氢铵/硫酸铵沉积与分解特性研究[J]. 化工学报, 2021, 72(2): 1132-1141. |

| [11] | 史玉婷, 皇甫林, 李长明, 王月, 高士秋, 伞晓广, 韩振南, 余剑. V2O5-MoO3/TiO2催化滤袋的制备及中试应用[J]. 化工学报, 2021, 72(11): 5598-5606. |

| [12] | 王玉,余广炜,江汝清,林佳佳,汪印. 粒径对餐厨沼渣热解制备生物炭中磷和重金属的影响[J]. 化工学报, 2021, 72(10): 5344-5353. |

| [13] | 周鑫, 邱鸣慧, 罗平. 陶瓷膜接触器化学吸收氮氧化物的传质过程与阻力分析[J]. 化工学报, 2020, 71(8): 3652-3660. |

| [14] | 刘涛, 张书廷. Ba、Co共掺MnOx复合氧化物低温选择性催化还原NO研究[J]. 化工学报, 2020, 71(7): 3106-3113. |

| [15] | 莫官海, 谢水波, 曾涛涛, 刘迎九, 蔡萍莉. 污泥基生物炭处理酸性含U(Ⅵ)废水的效能与机理[J]. 化工学报, 2020, 71(5): 2352-2362. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号