化工学报 ›› 2023, Vol. 74 ›› Issue (12): 5048-5060.DOI: 10.11949/0438-1157.20231063

• 过程安全 • 上一篇

王燕( ), 杨帅帅, 张国涛, 徐子晖, 毛文哲, 纪文涛(

), 杨帅帅, 张国涛, 徐子晖, 毛文哲, 纪文涛( )

)

收稿日期:2023-10-13

修回日期:2023-11-23

出版日期:2023-12-25

发布日期:2024-02-19

通讯作者:

纪文涛

作者简介:王燕(1982—),女,博士,教授,yanwang@ hpu.edu.cn

基金资助:

Yan WANG( ), Shuaishuai YANG, Guotao ZHANG, Zihui XU, Wenzhe MAO, Wentao JI(

), Shuaishuai YANG, Guotao ZHANG, Zihui XU, Wenzhe MAO, Wentao JI( )

)

Received:2023-10-13

Revised:2023-11-23

Online:2023-12-25

Published:2024-02-19

Contact:

Wentao JI

摘要:

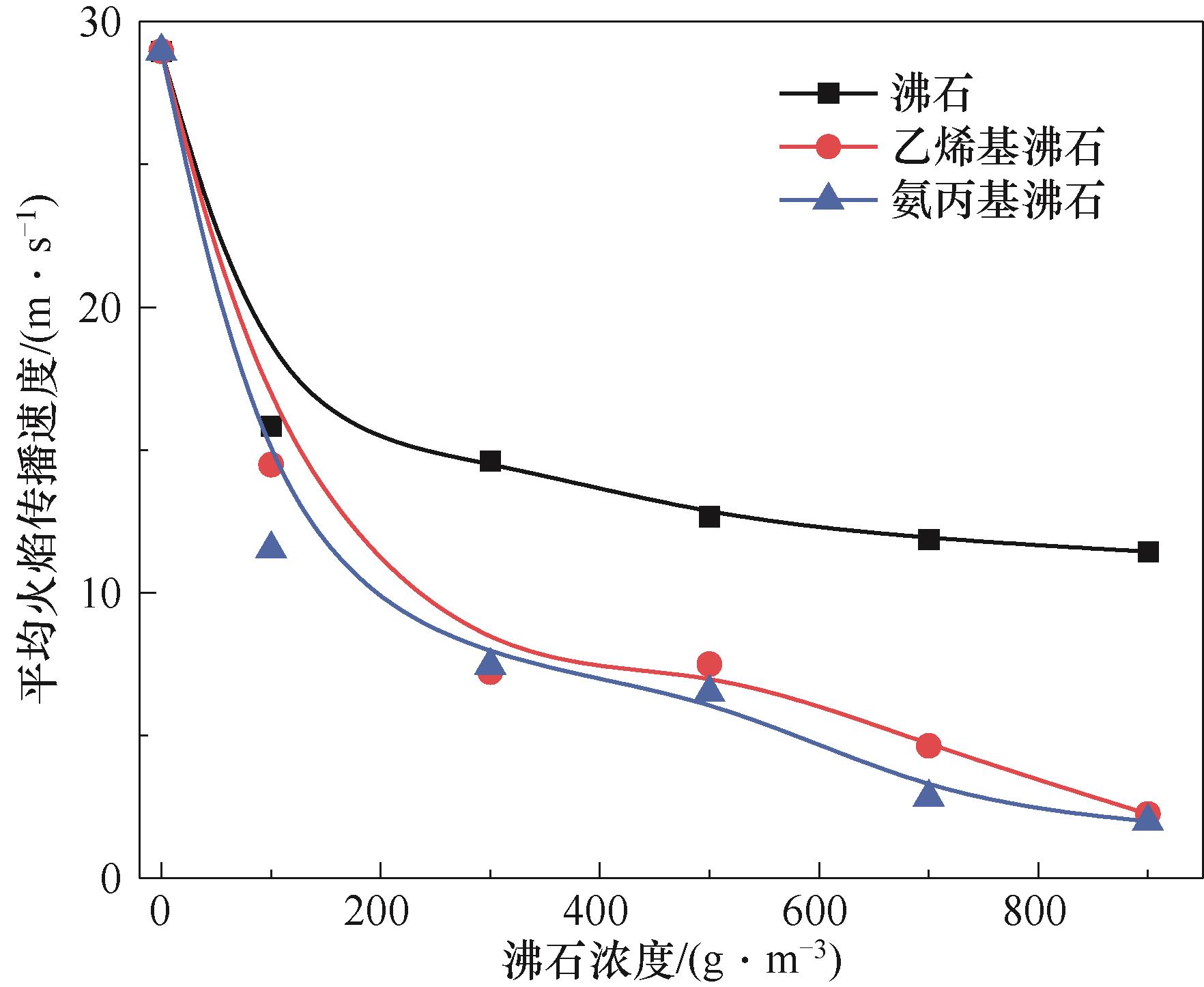

为研发抑制性能优异且廉价环保的新型乙烯抑爆材料,以沸石为基材,根据乙烯爆炸基元反应,选取氨丙基三甲氧基硅烷和乙烯基三甲氧基硅烷两种硅烷偶联剂对沸石进行表面改性,并采用20 L球形爆炸装置及5 L管道爆炸装置研究了改性后沸石对乙烯爆炸超压和火焰传播抑制性能。实验结果表明:采用水解法可将硅烷偶联剂接枝在沸石表面,成功制得氨丙基沸石和乙烯基沸石。相同条件下,浓度为1500 g·m-3的沸石、氨丙基沸石、乙烯基沸石可使浓度为6.5%(体积分数)的乙烯爆炸压力分别降低31.40%、42.05%、43.43%,爆炸压力上升速率分别降低63.36%、91.22%、92.40%。浓度为900 g·m-3的沸石、氨丙基沸石、乙烯基沸石均可显著降低浓度为6.5%的乙烯爆炸火焰亮度和火焰结构连续性,并使火焰平均传播速度分别降低60.46%、92.23%、93.16%。相比之下,改性沸石对乙烯爆炸超压和火焰的抑制作用更为显著,即改性沸石具有更为优异的乙烯爆炸抑制性能,且乙烯基沸石抑制性能优于氨丙基沸石。结合沸石及改性沸石热解特性及乙烯爆炸基元反应,从物理和化学两个方面分析了改性沸石对乙烯爆炸的抑制机理。

中图分类号:

王燕, 杨帅帅, 张国涛, 徐子晖, 毛文哲, 纪文涛. 改性沸石抑制乙烯爆炸性能及机理研究[J]. 化工学报, 2023, 74(12): 5048-5060.

Yan WANG, Shuaishuai YANG, Guotao ZHANG, Zihui XU, Wenzhe MAO, Wentao JI. Explosion suppression characteristics and mechanism of ethylene by modified zeolite[J]. CIESC Journal, 2023, 74(12): 5048-5060.

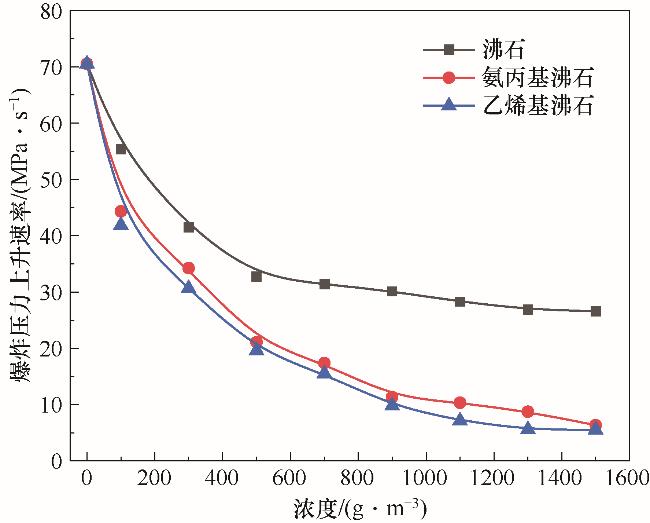

图10 不同浓度沸石、改性沸石对乙烯爆炸压力上升速率抑制规律

Fig.10 The explosion pressure rise rate of ethylene inhibition law of different concentrations of zeolite, modified zeolite

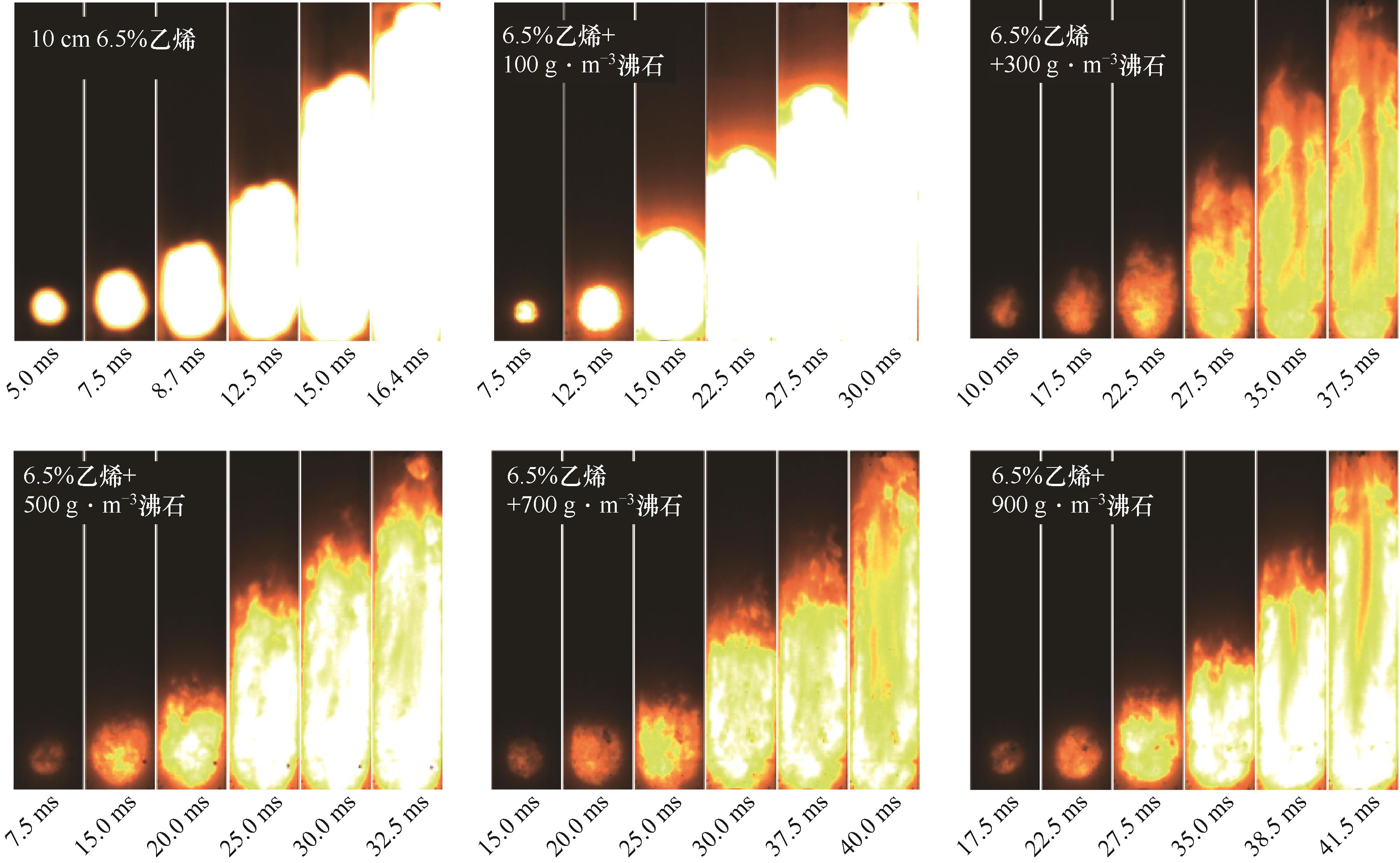

图11 不同浓度沸石作用下乙烯爆炸火焰结构变化规律

Fig.11 The variation patterns of ethylene explosion flame structure under the influence of zeolite at different concentrations

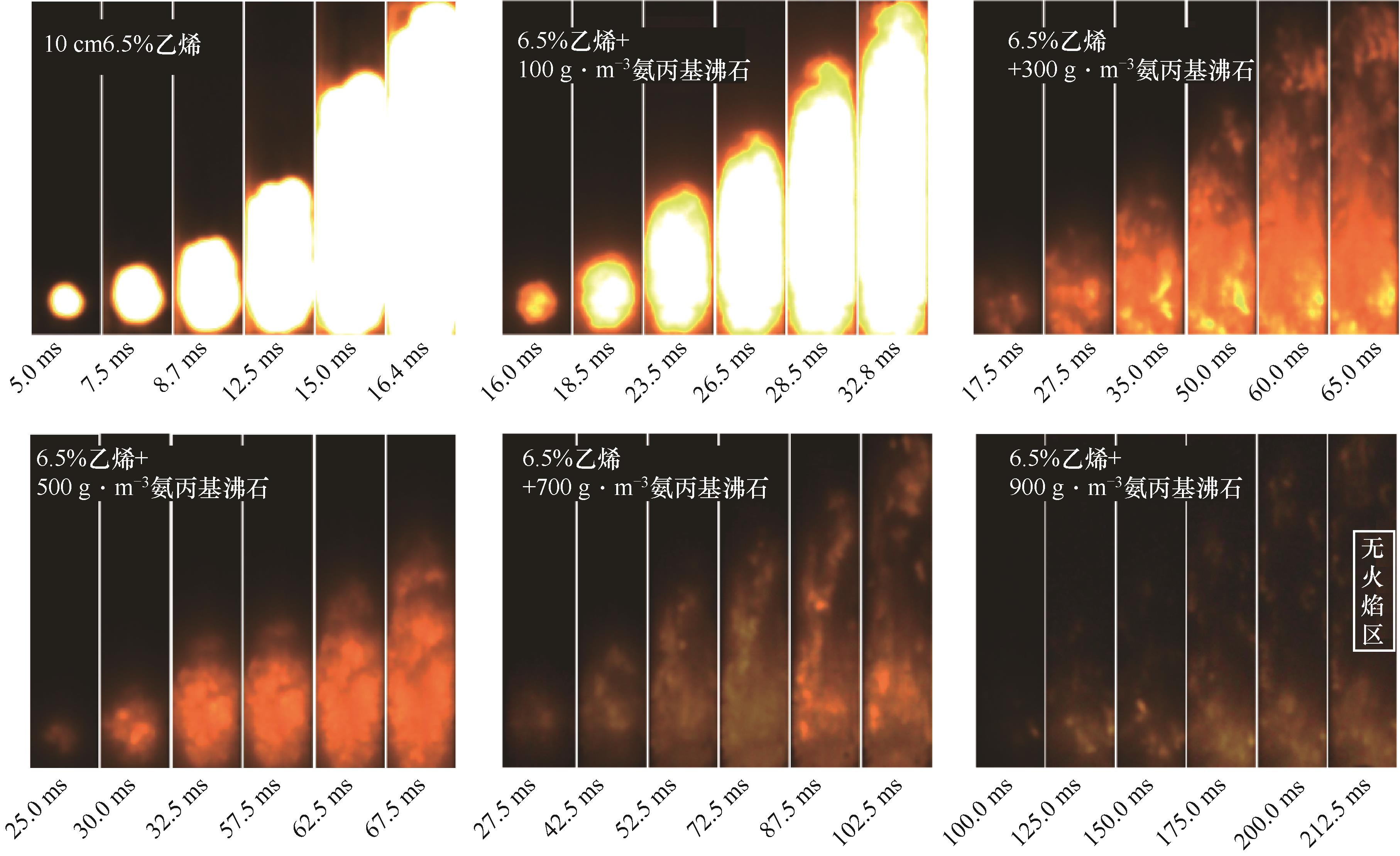

图12 不同浓度氨丙基沸石作用下乙烯爆炸火焰结构变化规律

Fig.12 The variation patterns of ethylene explosion flame structure under the influence of aminopropyl zeolite at different concentrations

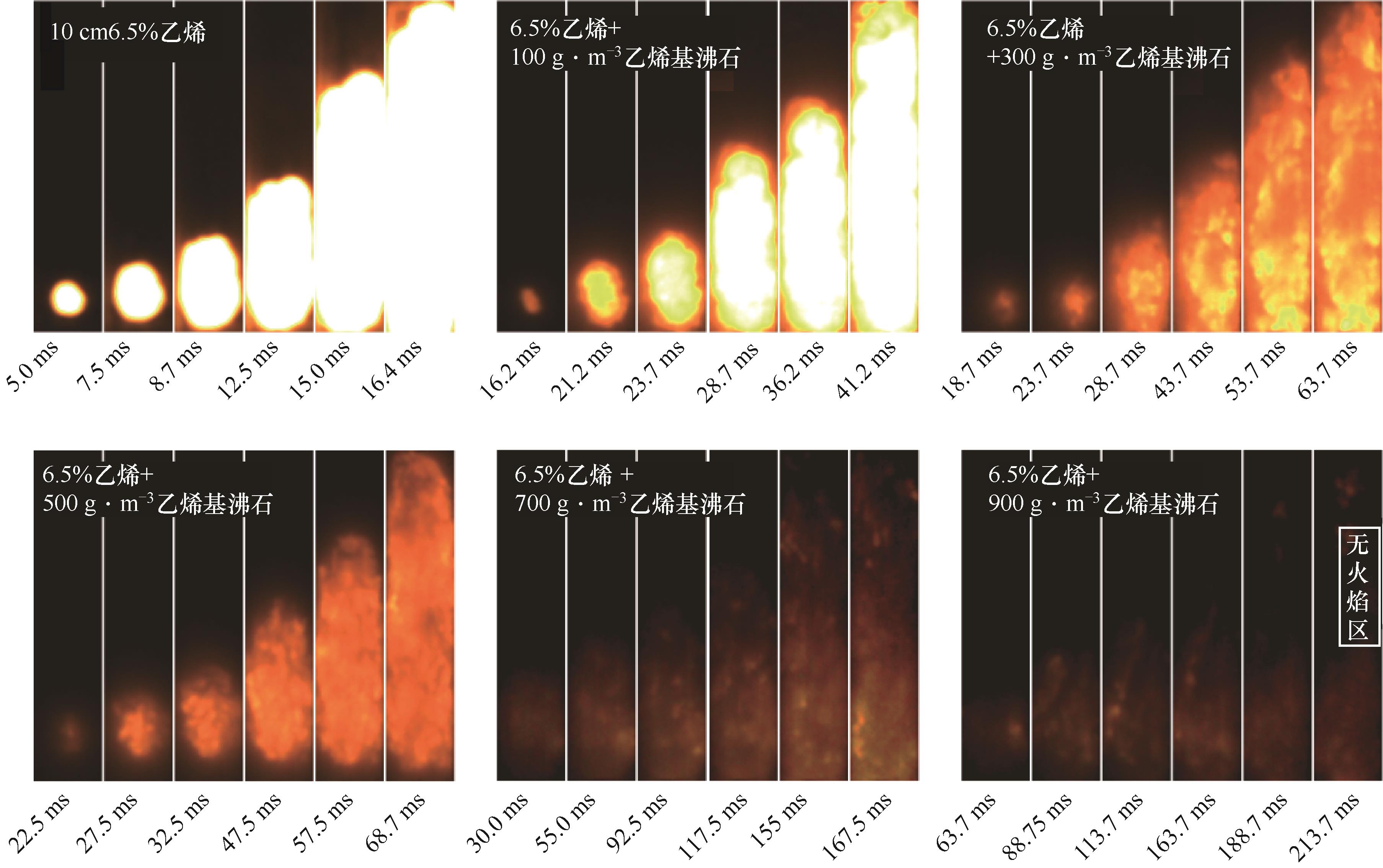

图13 不同浓度乙烯基沸石作用下乙烯爆炸火焰结构变化规律

Fig.13 The variation patterns of ethylene explosion flame structure under the influence of vinyl zeolite at different concentrations

图16 沸石、氨丙基沸石、乙烯基沸石对乙烯爆炸平均火焰传播速度的影响

Fig.16 Influence of zeolite, aminopropyl zeolite and vinyl zeolite on the average fcame propagaion velocity of ethylene explosion

| 33 | Zhang Y S, Pan Z C, Yang J J, et al. Study on the suppression mechanism of (NH4)2CO3 and SiC for polyethylene deflagration based on flame propagation and experimental analysis[J]. Powder Technology, 2022, 399: 117193. |

| 1 | 罗振敏, 刘璐, 苏彬, 等. 惰性气体影响乙烯爆炸极限参数及动力学特性[J]. 化工进展, 2022, 41(9): 4653-4661. |

| Luo Z M, Liu L, Su B, et al. Effect of inert gas on ethylene explosion limit parameters and kinetic characteristics[J]. Chemical Industry and Engineering Progress, 2022, 41(9): 4653-4661. | |

| 2 | Wang L, Gao J C, Pan R M, et al. Effect and mechanism analysis of wires explosion-proof material on ethylene-air explosion[J]. Journal of Loss Prevention in the Process Industries, 2022, 80: 104881. |

| 3 | Zhao T L, Chen X K, Cheng F M, et al. Study on the synergistic inhibition mechanism of multicomponent powders on methane explosions[J]. Powder Technology, 2023, 418: 118326. |

| 4 | Zhang S L, Bi M S, Jiang H P, et al. Suppression effect of inert gases on aluminum dust explosion[J]. Powder Technology, 2021, 388: 90-99. |

| 5 | Feng X, Ren J J, Pu M Z, et al. Suppression effect of ultra-fine water mist on methane-coal dust hybrid explosion[J]. Powder Technology, 2022, 406: 117590. |

| 6 | Jiang H P, Bi M S, Peng Q K, et al. Suppression of pulverized biomass dust explosion by NaHCO3 and NH4H2PO4 [J]. Renewable Energy, 2020, 147: 2046-2055. |

| 7 | Song Y F, Zhang Q. The quantitative studies on gas explosion suppression by an inert rock dust deposit[J]. Journal of Hazardous Materials, 2018, 353: 62-69. |

| 8 | Dounia O, Vermorel O, Poinsot T. Theoretical analysis and simulation of methane/air flame inhibition by sodium bicarbonate particles[J]. Combustion and Flame, 2018, 193: 313-326. |

| 9 | Zhao Q, Chen X F, Yang M J, et al. Suppression characteristics and mechanisms of ABC powder on methane/coal dust compound deflagration[J]. Fuel, 2021, 298: 120831. |

| 10 | Liu J Q, Meng X B, Yan K, et al. Study on the effect and mechanism of Ca(H2PO4)2 and CaCO3 powders on inhibiting the explosion of titanium powder[J]. Powder Technology, 2022, 395: 158-167. |

| 11 | Lu K L, Chen X K, Luo Z M, et al. The inhibiting effects of sodium carbonate on coal dust deflagration based on thermal methods[J]. Fuel, 2022, 315: 123122. |

| 12 | Zhao Q, Chen X F, Dai H M, et al. Inhibition of diammonium phosphate on the wheat dust explosion[J]. Powder Technology, 2020, 367: 751-761. |

| 13 | Wei X R, Zhang Y S, Wu G G, et al. Study on explosion suppression of coal dust with different particle size by shell powder and NaHCO3 [J]. Fuel, 2021, 306: 121709. |

| 14 | Wang Y, Yang J J, He J, et al. Inhibition effect of KHCO3 and KH2PO4 on ethylene explosion[J]. ACS Omega, 2023, 8(8): 7566-7574. |

| 15 | 王燕, 李忠, 张一民, 等. 不同磷酸氢盐作用下的乙烯抑爆特性及机制[J]. 中国安全科学学报, 2022, 32(5): 48-54. |

| Wang Y, Li Z, Zhang Y M, et al. Suppression characteristics and mechanism of different hydrogen phosphates on ethylene explosion[J]. China Safety Science Journal, 2022, 32(5): 48-54. | |

| 16 | Jiang H P, Bi M S, Li B, et al. Inhibition evaluation of ABC powder in aluminum dust explosion[J]. Journal of Hazardous Materials, 2019, 361: 273-282. |

| 17 | 余明高, 贺涛, 李海涛, 等. 改性高岭土抑爆剂对瓦斯煤尘复合爆炸压力的影响[J]. 煤炭学报, 2022, 47(1): 348-359. |

| Yu M G, He T, Li H T, et al. Influence of modified kaoline inhibitor on the explosion suppression pressure of the methane-coal dust mixture[J]. Journal of China Coal Society, 2022, 47(1): 348-359. | |

| 18 | Wei Q X, Zhang Y S, Chen K, et al. Preparation and performance of novel APP/NaY-Fe suppressant for coal dust explosion[J]. Journal of Loss Prevention in the Process Industries, 2021, 69: 104374. |

| 19 | Zhang J, Tang X L, Yi H H, et al. Synthesis, characterization and application of Fe-zeolite: a review[J]. Applied Catalysis A: General, 2022, 630: 118467. |

| 20 | Liu A H, Lu X E, Zhou X Y, et al. Experimental investigation on suppression of methane explosion using KHCO3/zeolite composite powder[J]. Powder Technology, 2023, 415: 118157. |

| 21 | Dai H M, Liang G Q, Yin H P, et al. Experimental investigation on the inhibition of coal dust explosion by the composite inhibitor of carbamide and zeolite[J]. Fuel, 2022, 308: 121981. |

| 22 | Chen J S, Chen K, Shi W X, et al. The preparation of novel core-shell suppressor and its suppression mechanism on coal dust explosion flame[J]. Fuel, 2022, 313: 122997. |

| 23 | Jiang H P, Bi M S, Zhang T J, et al. A novel reactive P-containing composite with an ordered porous structure for suppressing nano-Al dust explosions[J]. Chemical Engineering Journal, 2021, 416: 129156. |

| 24 | Li Y, Chen X F, Yuan B H, et al. Synthesis of a novel prolonged action inhibitor with lotus leaf-like appearance and its suppression on methane/hydrogen/air explosion[J]. Fuel, 2022, 329: 125401. |

| 25 | Wang Z, Meng X B, Yan K, et al. Study on the inhibition of Al-Mg alloy dust explosion by modified Mg(OH)2 [J]. Powder Technology, 2021, 384: 284-296. |

| 26 | Beall W G, Duraia M E, El-Tantawy F, et al. Rapid fabrication of nanostructured magnesium hydroxide and hydromagnesite via microwave-assisted technique[J]. Powder Technology, 2013, 234: 26-31. |

| 27 | Thakur K M, Gupta K R, Thakur K V. Surface modification of cellulose using silane coupling agent[J]. Carbohydrate Polymers, 2014, 111: 849-855. |

| 28 | Cheng G J, Tong B, Tang Z F, et al. Surface functionalization of coal powder with different coupling agents for potential applications in organic materials[J]. Applied Surface Science, 2014, 313: 954-960. |

| 29 | Lan S J, Li L J, Xu D F, et al. Surface modification of magnesium hydroxide using vinyltriethoxysilane by dry process[J]. Applied Surface Science, 2016, 382: 56-62. |

| 30 | Nkhahleng L, Thollwana A M, Richard M M. Polyacrylonitrile ultrafiltration membranes incorporating graphene oxide fillers modified with zeolitic imidazolate framework-8 and 3-aminopropyltriethoxysilane for dye and salt removal in real textile wastewater[J]. Journal of Environmental Chemical Engineering, 2023, 11(5): 110883. |

| 31 | Ni X M, Kuang K Q, Yang D L, et al. A new type of fire suppressant powder of NaHCO3/zeolite nanocomposites with core-shell structure[J]. Fire Safety Journal, 2009, 44(7): 968-975. |

| 32 | Wang Q H, Sun Y L, Jiang J C, et al. Inhibiting effects of gas-particle mixtures containing CO2, Mg(OH)2 particles, and NH4H2PO4 particles on methane explosion in a 20-L closed vessel[J]. Journal of Loss Prevention in the Process Industries, 2020, 64: 104082. |

| [1] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [2] | 刘晓洋, 喻健良, 侯玉洁, 闫兴清, 张振华, 吕先舒. 螺旋微通道对掺氢甲烷爆轰传播的影响[J]. 化工学报, 2023, 74(7): 3139-3148. |

| [3] | 何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247. |

| [4] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| [5] | 贠程, 王倩琳, 陈锋, 张鑫, 窦站, 颜廷俊. 基于社团结构的化工过程风险演化路径深度挖掘[J]. 化工学报, 2023, 74(4): 1639-1650. |

| [6] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [7] | 肖忠良, 尹碧露, 宋刘斌, 匡尹杰, 赵亭亭, 刘成, 袁荣耀. 废旧锂离子电池回收工艺研究进展及其安全风险分析[J]. 化工学报, 2023, 74(4): 1446-1456. |

| [8] | 武子超, 汪志雷, 李荣业, 李可昕, 华敏, 潘旭海, 王三明, 蒋军成. 点火方式对欠膨胀氢气射流爆炸超压影响规律研究[J]. 化工学报, 2023, 74(3): 1409-1418. |

| [9] | 杜江龙, 杨雯棋, 黄凯, 练成, 刘洪来. 复合相变材料/空冷复合式锂离子电池模块散热性能[J]. 化工学报, 2023, 74(2): 674-689. |

| [10] | 邓均锐, 李泽宇, 陈嘉衍. 面向动力电池热安全的准被动式热移出系统[J]. 化工学报, 2023, 74(11): 4679-4687. |

| [11] | 邵翔宇, 蒋敏, 杨晓静, 蒲亮, 雷刚, 高建良. 低温氢气爆炸实验腔体预冷过程研究[J]. 化工学报, 2023, 74(10): 4343-4351. |

| [12] | 江丙友, 丁大伟, 苏明清, 鲁昆仑. 聚磷酸铵对聚乙烯粉尘爆炸特性及热解动力学影响研究[J]. 化工学报, 2023, 74(10): 4352-4366. |

| [13] | 熊昊, 梁潇予, 张晨曦, 白浩隆, 范晓宇, 魏飞. 重质油直接制化工品:多级逆流下行催化裂解技术[J]. 化工学报, 2023, 74(1): 86-104. |

| [14] | 杨克, 王辰升, 纪虹, 郑凯, 邢志祥, 毕海普, 蒋军成. 聚多巴胺包覆混合粉体抑制甲烷爆炸的实验研究[J]. 化工学报, 2022, 73(9): 4245-4254. |

| [15] | 廖珊珊, 张少刚, 陶骏骏, 刘家豪, 汪金辉. 竖直射流火撞击障碍管道数值模拟分析[J]. 化工学报, 2022, 73(9): 4226-4234. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号