化工学报 ›› 2023, Vol. 74 ›› Issue (5): 2239-2247.DOI: 10.11949/0438-1157.20221688

• 材料化学工程与纳米技术 • 上一篇

收稿日期:2022-12-31

修回日期:2023-03-14

出版日期:2023-05-05

发布日期:2023-06-29

通讯作者:

曾婧

作者简介:何汉兵(1980—),男,博士,副教授,hehanbinghhb@csu.edu.cn

基金资助:

Hanbing HE1( ), Zhen LIU1, Yong CHEN1, Xiaofeng WANG2, Jing ZENG1(

), Zhen LIU1, Yong CHEN1, Xiaofeng WANG2, Jing ZENG1( )

)

Received:2022-12-31

Revised:2023-03-14

Online:2023-05-05

Published:2023-06-29

Contact:

Jing ZENG

摘要:

制备可适用于直写成型程序的、具有较高固相含量的浆料是提升直写成型产品质量的关键,但现有研究在浆料调控的普适规律方面仍有所欠缺。采用水热法合成了一系列尺寸可控的锰氧化物粉末,并将其用于直写成型电极,采用XRD、SEM、BET表征并分析了不同颗粒尺度对固相含量选取的规律,采用稳态流动测试了相关浆料的流变行为。结果表明,通过调节水热反应温度,锰氧化物颗粒直径呈梯度变化,1.06~1.64 μm颗粒的适配固相含量随颗粒比表面积的下降而上升,46.46~91.36 μm颗粒的适配固相含量随颗粒直径的上升而下降。采用该规律所配浆料进行直写成型,挤出流畅、体积收缩小、产品机械强度高。

中图分类号:

何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247.

Hanbing HE, Zhen LIU, Yong CHEN, Xiaofeng WANG, Jing ZENG. Synthesis and slurry control of manganese oxide powder for direct ink writing electrode[J]. CIESC Journal, 2023, 74(5): 2239-2247.

| 水热反应 温度/℃ | 颗粒直径/μm | 比表面积/ (m²·g-1) | 可打印区间 (固相质量分数)/% |

|---|---|---|---|

| 100 | 1.64 | 33.0418 | 20~25 |

| 110 | 1.52 | 30.7876 | 20~25 |

| 120 | 1.39 | 28.4776 | 25~30 |

| 130 | 1.24 | 24.1953 | 25~30 |

| 140 | 1.06 | 17.2011 | 25~35 |

| 150 | 46.46 | 9.7487 | 25~30 |

| 160 | 67.63 | 6.4359 | 30~35 |

| 170 | 87.32 | 2.6529 | 25~30 |

| 180 | 91.36 | 2.2817 | 25~30 |

表1 不同水热反应温度下锰氧化物颗粒的直径、比表面积、可打印区间

Table 1 Diameter, specific surface area and printable range of manganese oxide particles under different hydrothermal reaction temperatures

| 水热反应 温度/℃ | 颗粒直径/μm | 比表面积/ (m²·g-1) | 可打印区间 (固相质量分数)/% |

|---|---|---|---|

| 100 | 1.64 | 33.0418 | 20~25 |

| 110 | 1.52 | 30.7876 | 20~25 |

| 120 | 1.39 | 28.4776 | 25~30 |

| 130 | 1.24 | 24.1953 | 25~30 |

| 140 | 1.06 | 17.2011 | 25~35 |

| 150 | 46.46 | 9.7487 | 25~30 |

| 160 | 67.63 | 6.4359 | 30~35 |

| 170 | 87.32 | 2.6529 | 25~30 |

| 180 | 91.36 | 2.2817 | 25~30 |

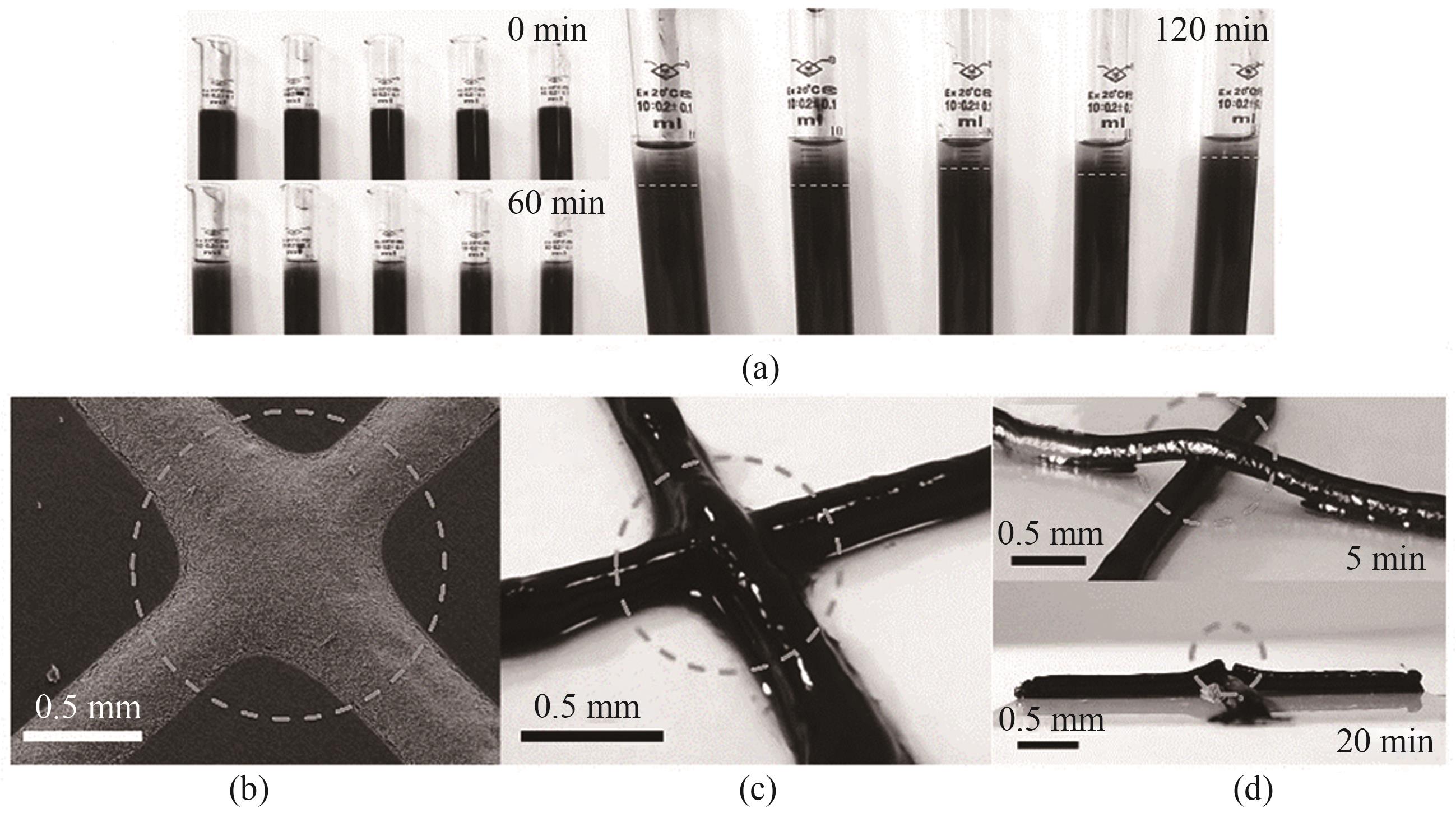

图3 添加不同增稠剂(从左至右依次为PEG-600、PEG-1000、CMC、HEMC、PVDF)的浆料沉降性测试(a);Mn100浆料在固相质量分数为15% (b)、20% (c)、25% (d)时预打印情况

Fig.3 Slurry sedimentation test with different thickeners: PEG-600,PEG-1000,CMC,HEMC,PVDF (from left to right) (a); Preprinting of Mn100 slurry at different solid mass fractions: 15% (b); 20% (c); 25% (d)

图5 打印过程示意图:浆料中颗粒的几种分布方式[(a)~(c)];以Mn100 28%浆料制备的DIW电极干燥前(d)、干燥后(e)的数字显微镜图像

Fig.5 Schematic diagram of the printing process: several distribution modes of particles in the slurry [(a)—(c)]; digital microscope image of direct writing formed electrode prepared with Mn100 28% slurry before drying (d) and after drying (e)

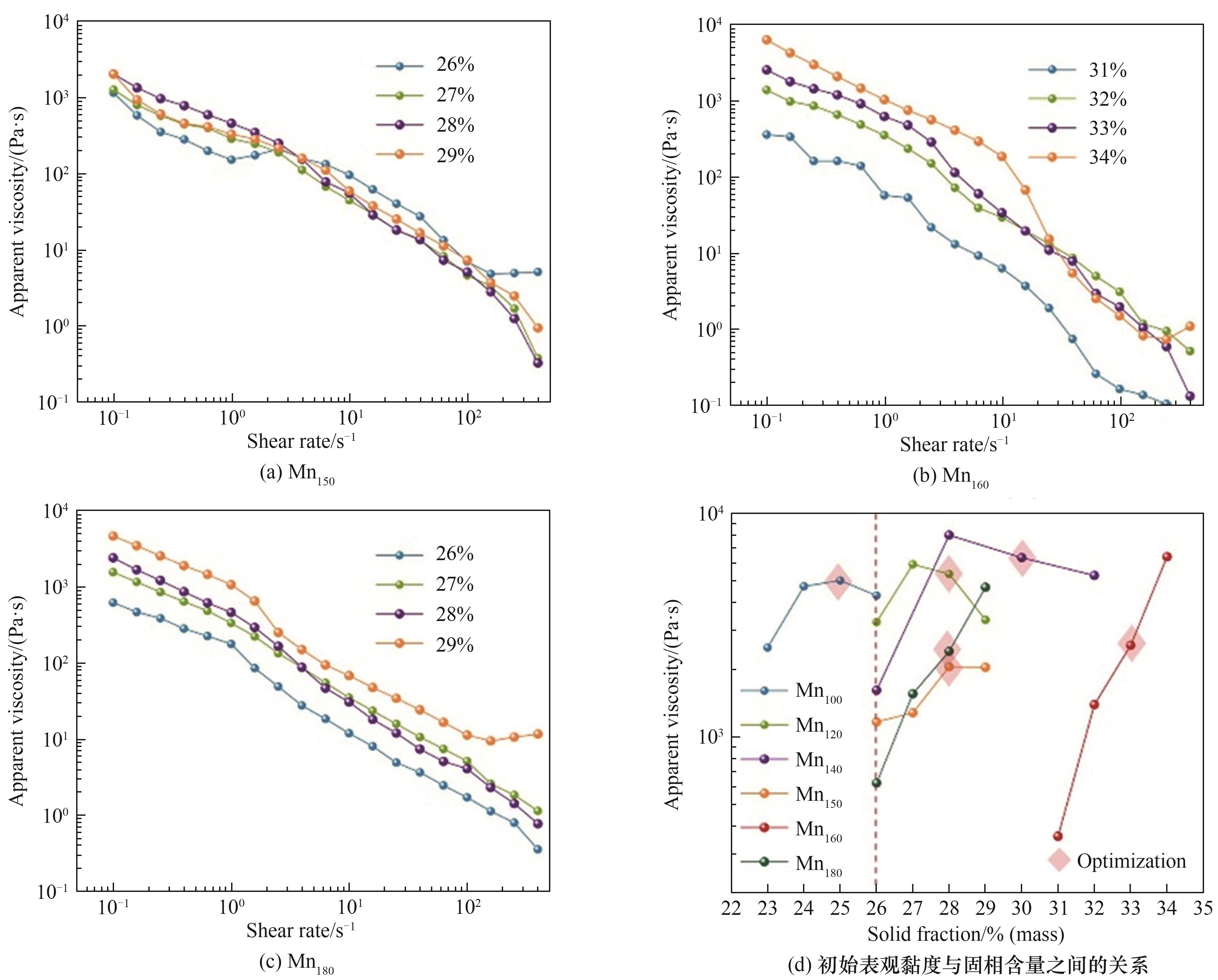

图6 不同粉体所配浆料的表观黏度与剪切速率的函数图像及各浆料初始表观黏度与固相含量之间的关系

Fig.6 Function image of apparent viscosity and shear rate of slurry prepared by different powders and relationship between initial apparent viscosity and solid content of each slurry

| 1 | Wei M, Zhang F, Wang W, et al. 3D direct writing fabrication of electrodes for electrochemical storage devices[J]. Journal of Power Sources, 2017, 354: 134-147. |

| 2 | Goodenough J B. Electrochemical energy storage in a sustainable modern society[J]. Energy & Environmental Science, 2014, 7(1): 14-18. |

| 3 | Whittingham M S. Lithium batteries and cathode materials[J]. Chemical Reviews, 2004, 104(10): 4271-4301. |

| 4 | Zhong C, Liu B, Ding J, et al. Decoupling electrolytes towards stable and high-energy rechargeable aqueous zinc-manganese dioxide batteries[J]. Nature Energy, 2020, 5(6): 440-449. |

| 5 | Ji J, Wan H Z, Zhang B, et al. Co2+/3+/4+-regulated electron state of Mn-O for superb aqueous zinc-manganese oxide batteries[J]. Advanced Energy Materials, 2021, 11(6): 2003203. |

| 6 | Tagliaferri S, Panagiotopoulos A, Mattevi C. Direct ink writing of energy materials[J]. Materials Advances, 2021, 2(2): 540-563. |

| 7 | Wu K, Huang J H, Yi J, et al. Recent advances in polymer electrolytes for zinc ion batteries: mechanisms, properties, and perspectives[J]. Advanced Energy Materials, 2020, 10(12): 1903977. |

| 8 | Luo Z X, Zeng J, Liu Z, et al. Carbon-coated hydrated vanadium dioxide for high-performance aqueous zinc-ion batteries[J]. Journal of Alloys and Compounds, 2022, 906: 164388. |

| 9 | Wei T S, Ahn B Y, Grotto J, et al. 3D printing of customized Li-ion batteries with thick electrodes[J]. Advanced Materials, 2018, 30(16): 1703027. |

| 10 | Chang P, Mei H, Zhou S X, et al. 3D printed electrochemical energy storage devices[J]. Journal of Materials Chemistry A, 2019, 7(9): 4230-4258. |

| 11 | Amato D N, Amato D V, Sandoz M, et al. Programmable porous polymers via direct bubble writing with surfactant-free inks[J]. ACS Applied Materials & Interfaces, 2020, 12(37): 42048-42055. |

| 12 | Tian X C, Wang T, Ma H, et al. A universal strategy towards 3D printable nanomaterial inks for superior cellular high-loading battery electrodes[J]. Journal of Materials Chemistry A, 2021, 9(29): 16086-16092. |

| 13 | 李文利, 周宏志, 刘卫卫, 等. 光固化3D打印陶瓷浆料及流变性研究进展[J]. 材料工程, 2022, 50(7): 40-50. |

| Li W L, Zhou H Z, Liu W W, et al. Research progress in ceramic slurries and rheology viaphotopolymerization-based 3D printing[J]. Journal of Materials Engineering, 2022, 50(7): 40-50. | |

| 14 | Bae C J, Ramachandran A, Halloran J W. Quantifying particle segregation in sequential layers fabricated by additive manufacturing[J]. Journal of the European Ceramic Society, 2018, 38(11): 4082-4088. |

| 15 | Bae C J, Halloran J W. Concentrated suspension-based additive manufacturing-viscosity, packing density, and segregation[J]. Journal of the European Ceramic Society, 2019, 39(14): 4299-4306. |

| 16 | Zakeri S, Vippola M, Levänen E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography[J]. Additive Manufacturing, 2020, 35: 101177. |

| 17 | Dou R, Tang W Z, Hu K X, et al. Ceramic paste for space stereolithography 3D printing technology in microgravity environment[J]. Journal of the European Ceramic Society, 2022, 42(9): 3968-3975. |

| 18 | Praveen S, Santhoshkumar P, Joe Y C, et al. 3D-printed architecture of Li-ion batteries and its applications to smart wearable electronic devices[J]. Applied Materials Today, 2020, 20: 100688. |

| 19 | Wang J W, Sun Q, Gao X J, et al. Toward high areal energy and power density electrode for Li-ion batteries via optimized 3D printing approach[J]. ACS Applied Materials & Interfaces, 2018, 10(46): 39794-39801. |

| 20 | Shen C L, Wang T, Xu X, et al. 3D printed cellular cathodes with hierarchical pores and high mass loading for Li-SeS2 battery[J]. Electrochimica Acta, 2020, 349: 136331. |

| 21 | Janssen R, Scheppokat S, Claussen N. Tailor-made ceramic-based components—advantages by reactive processing and advanced shaping techniques[J]. Journal of the European Ceramic Society, 2008, 28(7): 1369-1379. |

| 22 | Zhang Y N, Liu Y P, Liu Z H, et al. MnO2 cathode materials with the improved stability via nitrogen doping for aqueous zinc-ion batteries[J]. Journal of Energy Chemistry, 2022, 64: 23-32. |

| 23 | Cao X W, Xu Y T, Yang B, et al. In-situ Co-precipitated α-MnO2@2-methylimidazole cathode material for high performance zinc ion batteries[J]. Journal of Alloys and Compounds, 2022, 896: 162785. |

| 24 | Wang X, Li Y D. Synthesis and formation mechanism of manganese dioxide nanowires/nanorods[J]. Chemistry, 2003, 9(1): 300-306. |

| 25 | 左文婧, 屈银虎, 祁攀虎, 等. 3D打印锂离子电池正极的制备及性能[J]. 工程科学学报, 2020, 42(3): 358-364. |

| Zuo W J, Qu Y H, Qi P H, et al. Preparation and performance of 3D-printed positive electrode for lithium-ion battery[J]. Chinese Journal of Engineering, 2020, 42(3): 358-364. | |

| 26 | 王一博, 赵九蓬. 3D打印柔性可穿戴锂离子电池[J]. 材料工程, 2018, 46(3): 13-21. |

| Wang Y B, Zhao J P. 3D printing of flexible electrodes towards wearable lithium ion battery[J]. Journal of Materials Engineering, 2018, 46(3): 13-21. | |

| 27 | Friedrich L, Begley M. Printing direction dependent microstructures in direct ink writing[J]. Additive Manufacturing, 2020, 34: 101192. |

| 28 | Sydney Gladman A, Matsumoto E A, Nuzzo R G, et al. Biomimetic 4D printing[J]. Nature Materials, 2016, 15(4): 413-418. |

| 29 | Kou T Y, Wang S W, Shi R P, et al. Water splitting: periodic porous 3D electrodes mitigate gas bubble traffic during alkaline water electrolysis at high current densities[J]. Advanced Energy Materials, 2020, 10(46): 2070189. |

| 30 | Bu X M, Mao Z Y, Bu Y, et al. Remarkable gas bubble transport driven by capillary pressure in 3D printing-enabled anisotropic structures for efficient hydrogen evolution electrocatalysts[J]. Applied Catalysis B: Environmental, 2023, 320: 121995. |

| 31 | Smith P T, Basu A, Saha A, et al. Chemical modification and printability of shear-thinning hydrogel inks for direct-write 3D printing[J]. Polymer, 2018, 152: 42-50. |

| 32 | Wilt J K, Gilmer D, Kim S, et al. Direct ink writing techniques for in situ gelation and solidification[J]. MRS Communications, 2021, 11(2): 106-121. |

| [1] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [2] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [3] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [4] | 饶纤纤, 杜淼, 单国荣, 潘鹏举. 不同金属盐破乳对丁基橡胶硫化行为的影响[J]. 化工学报, 2023, 74(2): 756-765. |

| [5] | 仇鹏, 韩洋, 许建良, 王辅臣, 代正华. 用于预测气流床煤气化的EDC模型参数研究[J]. 化工学报, 2023, 74(1): 428-437. |

| [6] | 王燕, 何佳, 杨晶晶, 林晨迪, 纪文涛. 草酸盐和碳酸氢盐抑制聚乙烯粉尘爆炸特性[J]. 化工学报, 2022, 73(9): 4207-4216. |

| [7] | 杨克, 王辰升, 纪虹, 郑凯, 邢志祥, 毕海普, 蒋军成. 聚多巴胺包覆混合粉体抑制甲烷爆炸的实验研究[J]. 化工学报, 2022, 73(9): 4245-4254. |

| [8] | 姚翰林, 辛忠. 液相沉淀反应在管式微通道反应器中的流动行为研究[J]. 化工学报, 2022, 73(8): 3518-3528. |

| [9] | 陆遥, 董杰, 孙大为, 谢乐天, 卢家勇, 杜晓宁. 织构PNN-PZT陶瓷的光固化成型制备及其电学性能研究[J]. 化工学报, 2022, 73(8): 3768-3775. |

| [10] | 葛世轶, 杨遥, 黄正梁, 孙婧元, 王靖岱, 阳永荣. 基于静电分选解析聚乙烯颗粒生长与形貌演变[J]. 化工学报, 2022, 73(4): 1585-1596. |

| [11] | 尚慧俊, 黎亨利, 刘家义, 潘锋, 杜占, 孙林兵. Co对WO3-Co3O4预还原的影响及其产物碳化性能[J]. 化工学报, 2022, 73(12): 5592-5604. |

| [12] | 向茂乔, 耿玉琦, 朱庆山. 氮化硅粉体制备技术及粉体质量研究进展[J]. 化工学报, 2022, 73(1): 73-84. |

| [13] | 聂璇宇, 陈祯, 朱春英, 付涛涛, 高习群, 马友光. T型微通道内浆料体系中气泡的生成动力学[J]. 化工学报, 2022, 73(1): 204-212. |

| [14] | 纪文涛, 李璐, 李忠, 何佳, 杨晶晶, 王燕. 聚磷酸铵抑制PMMA粉尘爆炸特性研究[J]. 化工学报, 2022, 73(1): 461-469. |

| [15] | 陆海峰, 曹嘉琨, 郭晓镭, 刘海峰. 基于颗粒间相互作用的细颗粒粉体料仓下料过程分析[J]. 化工学报, 2021, 72(8): 4047-4054. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号