化工学报 ›› 2024, Vol. 75 ›› Issue (5): 1939-1950.DOI: 10.11949/0438-1157.20231182

收稿日期:2023-11-15

修回日期:2024-03-12

出版日期:2024-05-25

发布日期:2024-06-25

通讯作者:

杨明磊,钱锋

作者简介:赵光耀(1993—),男,博士研究生,1029149158@qq.com

基金资助:

Guangyao ZHAO1( ), Minglei YANG1,2(

), Minglei YANG1,2( ), Feng QIAN1(

), Feng QIAN1( )

)

Received:2023-11-15

Revised:2024-03-12

Online:2024-05-25

Published:2024-06-25

Contact:

Minglei YANG, Feng QIAN

摘要:

在随机重构法的采样过程中,每个结构特征需要的采样数量是不相等且变化的。为了将拉丁超立方采样用于降低随机重构模型的方差,基于随机重构法采样过程的特征和拉丁超立方采样原理,提出了适用于随机重构法的新型拉丁超立方采样方法,探究了在多种分子数量设定情况下应用该方法对随机重构模型的方差和精度的影响。结果表明,应用该方法能够显著降低随机重构模型的方差,提高模型的精度,在分子数量为1000~50000范围内,新模型的标准差相较传统模型降低了71.36%~74.53%,目标函数值降低了1.69%~13.82%。综合模型精度和模拟过程的运算开销,选择4000~6000作为新模型最优的分子数量设定。

中图分类号:

赵光耀, 杨明磊, 钱锋. 基于降方差采样策略的随机重构法[J]. 化工学报, 2024, 75(5): 1939-1950.

Guangyao ZHAO, Minglei YANG, Feng QIAN. Variance reduction sampling strategy-based stochastic reconstruction method[J]. CIESC Journal, 2024, 75(5): 1939-1950.

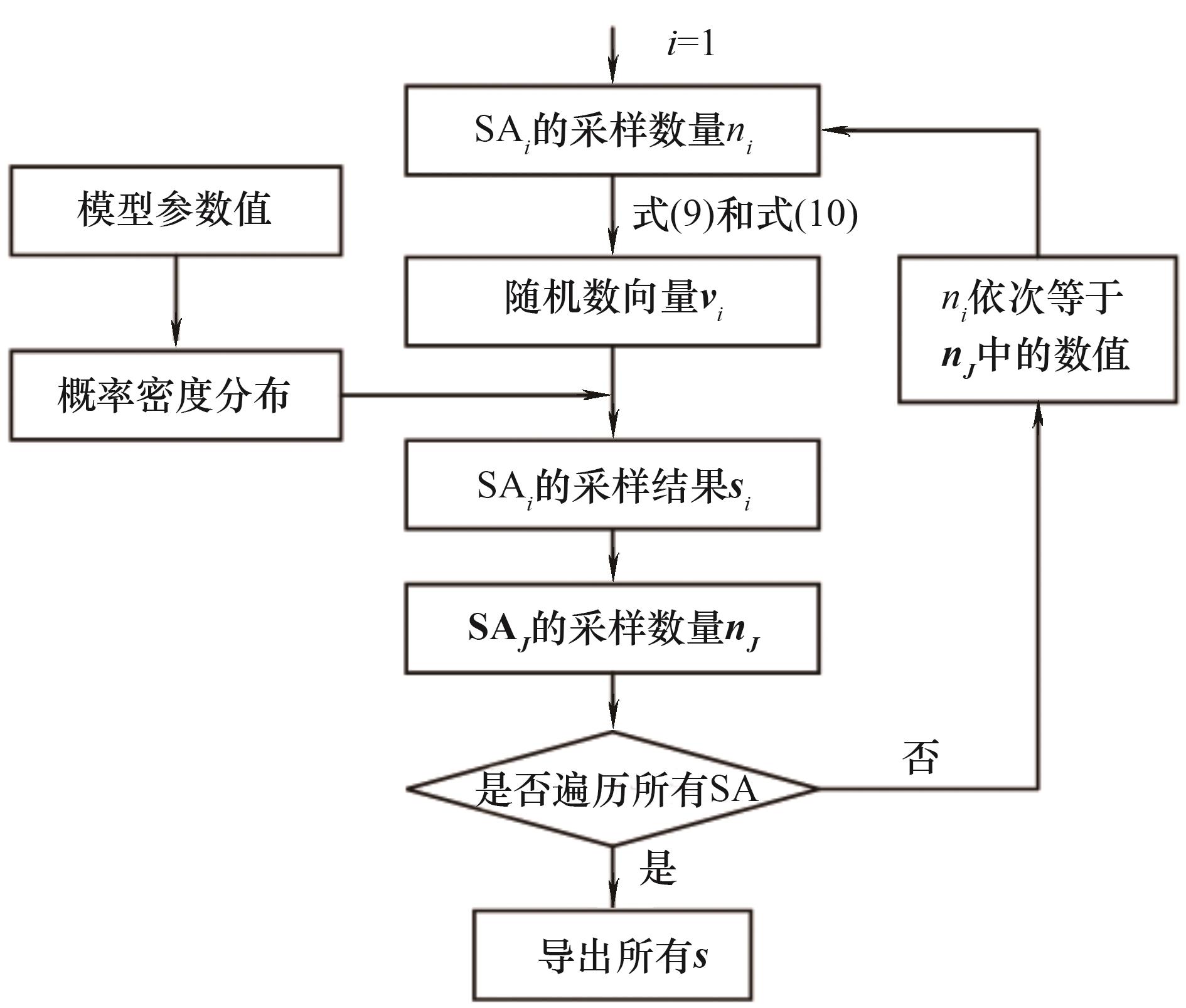

图2 结合新型拉丁超立方采样生成虚拟混合物中结构特征数值的流程示意图

Fig.2 Diagram for generation process of values of structural attributes in pseduo mixtures with novel Latin hypercube sampling

| 性 质 | 实验值 | 性 质 | 实验值 | 性 质 | 实验值 |

|---|---|---|---|---|---|

| 密度/(g/cm3) | 0.9127 | 硫元素组成/10-6 | 模拟蒸馏/K | ||

| 碳元素/%(质量分数) | 85.68 | 四氢苯并噻吩 | 566 | 初馏点 | 482 |

| 氢元素/%(质量分数) | 12.38 | 苯并噻吩 | 7681 | 5% | 605 |

| 硫元素/%(质量分数) | 2.24 | 四氢二苯并噻吩 | 853 | 10% | 637 |

| 氮元素/10-6 | 456 | 二苯并噻吩 | 7141 | 20% | 670 |

| 氢碳比(摩尔比) | 1.72 | 四氢苯并萘噻吩 | 1269 | 30% | 693 |

| SARA组成/%(质量分数) | 苯并萘噻吩 | 3393 | 40% | 710 | |

| 饱和烃 | 64.2 | 二苯并萘噻吩 | 1507 | 50% | 725 |

| 芳烃 | 35.8 | 13C核磁/%(质量分数) | 60% | 739 | |

| 同系物组成/%(质量分数) | 脂肪烃 CH3 | 14.5 | 70% | 753 | |

| 烷烃 | 22.1 | 脂肪烃 CH2 | 52.5 | 80% | 768 |

| 环烷烃 | 42.0 | 脂肪烃 CH | 16.2 | 90% | 785 |

| 单环芳烃 | 6.1 | 芳烃 CH | 9.7 | 95% | 797 |

| 双环芳烃 | 12.5 | 芳烃取代位 C | 6.3 | 终馏点 | 827 |

| 三环芳烃 | 10.4 | 芳烃桥位 C | 0.8 | ||

| 四环芳烃 | 6.2 | ||||

| 五环芳烃 | 0.7 |

表1 蜡油样本的宏观性质

Table 1 Properties of VGO sample

| 性 质 | 实验值 | 性 质 | 实验值 | 性 质 | 实验值 |

|---|---|---|---|---|---|

| 密度/(g/cm3) | 0.9127 | 硫元素组成/10-6 | 模拟蒸馏/K | ||

| 碳元素/%(质量分数) | 85.68 | 四氢苯并噻吩 | 566 | 初馏点 | 482 |

| 氢元素/%(质量分数) | 12.38 | 苯并噻吩 | 7681 | 5% | 605 |

| 硫元素/%(质量分数) | 2.24 | 四氢二苯并噻吩 | 853 | 10% | 637 |

| 氮元素/10-6 | 456 | 二苯并噻吩 | 7141 | 20% | 670 |

| 氢碳比(摩尔比) | 1.72 | 四氢苯并萘噻吩 | 1269 | 30% | 693 |

| SARA组成/%(质量分数) | 苯并萘噻吩 | 3393 | 40% | 710 | |

| 饱和烃 | 64.2 | 二苯并萘噻吩 | 1507 | 50% | 725 |

| 芳烃 | 35.8 | 13C核磁/%(质量分数) | 60% | 739 | |

| 同系物组成/%(质量分数) | 脂肪烃 CH3 | 14.5 | 70% | 753 | |

| 烷烃 | 22.1 | 脂肪烃 CH2 | 52.5 | 80% | 768 |

| 环烷烃 | 42.0 | 脂肪烃 CH | 16.2 | 90% | 785 |

| 单环芳烃 | 6.1 | 芳烃 CH | 9.7 | 95% | 797 |

| 双环芳烃 | 12.5 | 芳烃取代位 C | 6.3 | 终馏点 | 827 |

| 三环芳烃 | 10.4 | 芳烃桥位 C | 0.8 | ||

| 四环芳烃 | 6.2 | ||||

| 五环芳烃 | 0.7 |

| 序数 | 结构特征 | 缩写 | 分布类型 | 数值 范围 | 参数 | 采样数量 |

|---|---|---|---|---|---|---|

| 1 | 分子类型 | SA1 | 直方图分布 | 1,2或3 | x1, x2 | n1 |

| 2 | 链烷烃上是否 存在侧链 | SA2 | 直方图分布 | 0或1 | x3 | n2 |

| 3 | 链烷烃上侧链的 数量 | SA3 | 直方图分布 | 1,2或3 | x4, x5 | n3 |

| 4 | 链烷烃的长度 | SA4 | 伽马分布 | 10~40 | x6, x7 | n4 |

| 5 | 脂肪环数量 | SA5 | 伽马分布 | 1~6 | x8, x9 | n5 |

| 6 | 苯环数量 | SA6 | 伽马分布 | 1~5 | x10, x11 | n6 |

| 7 | 芳烃中脂肪环数量 | SA7 | 直方图分布 | 0,1或2 | x12, x13 | n7 |

| 8 | 噻吩环数量 | SA8 | 直方图分布 | 0或1 | x14 | n8 |

| 9 | 吡咯环数量 | SA9 | 直方图分布 | 0或1 | x15 | n9 |

| 10 | 吡啶环数量 | SA10 | 直方图分布 | 0或1 | x16 | n10 |

| 11 | 环状结构上侧链的数量 | SA11 | 直方图分布 | 1,2,3或 4 | x17, x18, x19 | n11 |

| 12 | 环状结构上侧链的长度 | SA12 | 伽马分布 | 1~29 | x20, x21 | n12 |

表2 结构特征的设定

Table 2 Setting of structural attributes

| 序数 | 结构特征 | 缩写 | 分布类型 | 数值 范围 | 参数 | 采样数量 |

|---|---|---|---|---|---|---|

| 1 | 分子类型 | SA1 | 直方图分布 | 1,2或3 | x1, x2 | n1 |

| 2 | 链烷烃上是否 存在侧链 | SA2 | 直方图分布 | 0或1 | x3 | n2 |

| 3 | 链烷烃上侧链的 数量 | SA3 | 直方图分布 | 1,2或3 | x4, x5 | n3 |

| 4 | 链烷烃的长度 | SA4 | 伽马分布 | 10~40 | x6, x7 | n4 |

| 5 | 脂肪环数量 | SA5 | 伽马分布 | 1~6 | x8, x9 | n5 |

| 6 | 苯环数量 | SA6 | 伽马分布 | 1~5 | x10, x11 | n6 |

| 7 | 芳烃中脂肪环数量 | SA7 | 直方图分布 | 0,1或2 | x12, x13 | n7 |

| 8 | 噻吩环数量 | SA8 | 直方图分布 | 0或1 | x14 | n8 |

| 9 | 吡咯环数量 | SA9 | 直方图分布 | 0或1 | x15 | n9 |

| 10 | 吡啶环数量 | SA10 | 直方图分布 | 0或1 | x16 | n10 |

| 11 | 环状结构上侧链的数量 | SA11 | 直方图分布 | 1,2,3或 4 | x17, x18, x19 | n11 |

| 12 | 环状结构上侧链的长度 | SA12 | 伽马分布 | 1~29 | x20, x21 | n12 |

| 参数 | 下限 | 上限 | 递增约束 | 参数 | 下限 | 上限 | 递增约束 |

|---|---|---|---|---|---|---|---|

| x1, x2 | 0 | 1 | x1< x2 | x10 | 0 | 20 | |

| x3, x14, x15, x16 | 0 | 1 | x11 | 0 | 6 | ||

| x4, x5 | 0 | 1 | x4< x5 | x12, x13 | 0 | 1 | x12< x13 |

| x6 | 1 | 20 | x17, x18, x19 | 0 | 1 | x17< x18< x19 | |

| x7 | 9 | 41 | x20 | 1 | 20 | ||

| x8 | 0 | 20 | x21 | 0 | 30 | ||

| x9 | 0 | 7 |

表3 模型参数的边界和直方图分布中参数的约束

Table 3 Boundaries for parameters and constraints for parameters in histogram distributions

| 参数 | 下限 | 上限 | 递增约束 | 参数 | 下限 | 上限 | 递增约束 |

|---|---|---|---|---|---|---|---|

| x1, x2 | 0 | 1 | x1< x2 | x10 | 0 | 20 | |

| x3, x14, x15, x16 | 0 | 1 | x11 | 0 | 6 | ||

| x4, x5 | 0 | 1 | x4< x5 | x12, x13 | 0 | 1 | x12< x13 |

| x6 | 1 | 20 | x17, x18, x19 | 0 | 1 | x17< x18< x19 | |

| x7 | 9 | 41 | x20 | 1 | 20 | ||

| x8 | 0 | 20 | x21 | 0 | 30 | ||

| x9 | 0 | 7 |

| 分子序数 | SA1 | SA2 | SA3 | SA4 |

|---|---|---|---|---|

| 1 | s1,1 | — | — | — |

| 2 | s2,1 | s1,2 | s1,3 | s1,4 |

| 3 | s3,1 | s2,2 | — | s2,4 |

| 4 | s4,1 | — | — | — |

| 5 | s5,1 | s3,2 | s2,3 | s3,4 |

| 6 | s6,1 | s4,2 | — | s4,4 |

| ︙ | ︙ | ︙ | ︙ | ︙ |

| k2 | ︙ | ︙ | ||

| ︙ | ︙ | ︙ | — | ︙ |

| k1 | — | |||

| ︙ | ︙ | — | — | — |

| n | — | — | — |

表4 链烷烃分子中结构特征值的匹配过程

Table 4 Alignment of structural attribute values in paraffins

| 分子序数 | SA1 | SA2 | SA3 | SA4 |

|---|---|---|---|---|

| 1 | s1,1 | — | — | — |

| 2 | s2,1 | s1,2 | s1,3 | s1,4 |

| 3 | s3,1 | s2,2 | — | s2,4 |

| 4 | s4,1 | — | — | — |

| 5 | s5,1 | s3,2 | s2,3 | s3,4 |

| 6 | s6,1 | s4,2 | — | s4,4 |

| ︙ | ︙ | ︙ | ︙ | ︙ |

| k2 | ︙ | ︙ | ||

| ︙ | ︙ | ︙ | — | ︙ |

| k1 | — | |||

| ︙ | ︙ | — | — | — |

| n | — | — | — |

| 工况 | 分子数量 | 工况 | 分子数量 | 工况 | 分子数量 |

|---|---|---|---|---|---|

| 1 | 1000 | 6 | 6000 | 11 | 20000 |

| 2 | 2000 | 7 | 7000 | 12 | 30000 |

| 3 | 3000 | 8 | 8000 | 13 | 40000 |

| 4 | 4000 | 9 | 9000 | 14 | 50000 |

| 5 | 5000 | 10 | 10000 |

表5 在不同工况中采用的分子数量

Table 5 Number of molecules in different cases

| 工况 | 分子数量 | 工况 | 分子数量 | 工况 | 分子数量 |

|---|---|---|---|---|---|

| 1 | 1000 | 6 | 6000 | 11 | 20000 |

| 2 | 2000 | 7 | 7000 | 12 | 30000 |

| 3 | 3000 | 8 | 8000 | 13 | 40000 |

| 4 | 4000 | 9 | 9000 | 14 | 50000 |

| 5 | 5000 | 10 | 10000 |

| 性 质 | 实验值 | 文献[ | 传统模型 | 本模型 |

|---|---|---|---|---|

| 密度/(g/cm3) | 0.9127 | 0.9170 | 0.9269 | 0.9292 |

| 碳元素/%(质量分数) | 85.68 | 85.40 | 85.54 | 85.51 |

| 氢元素/%(质量分数) | 12.38 | 12.30 | 12.30 | 12.18 |

| 硫元素/%(质量分数) | 2.24 | 2.24 | 2.12 | 2.26 |

| 氮元素/10-6 | 456 | 608 | 458 | 448 |

| 氢碳比(摩尔比) | 1.72 | 1.72 | 1.72 | 1.71 |

| SARA组成/%(质量分数) | ||||

| 饱和烃 | 64.2 | 64.1 | 63.6 | 63.8 |

| 芳烃 | 35.8 | 35.9 | 36.4 | 36.2 |

| 同系物组成/%(质量分数) | ||||

| 烷烃 | 22.1 | 21.3 | 23.2 | 21.9 |

| 环烷烃 | 42.0 | 42.8 | 39.9 | 41.9 |

| 单环芳烃 | 6.1 | 6.2 | 6.2 | 5.4 |

| 双环芳烃 | 12.5 | 13.2 | 11.5 | 11.9 |

| 三环芳烃 | 10.4 | 9.8 | 10.2 | 10.3 |

| 四环芳烃 | 6.2 | 5.0 | 5.9 | 5.7 |

| 五环芳烃 | 0.7 | 1.8 | 3.0 | 3.0 |

| 硫元素组成/10-6 | ||||

| 四氢苯并噻吩 | 566 | 577 | 555 | 491 |

| 苯并噻吩 | 7681 | 7772 | 8194 | 8469 |

| 四氢二苯并噻吩 | 853 | 904 | 853 | 981 |

| 二苯并噻吩 | 7141 | 7061 | 5916 | 6628 |

| 四氢苯并萘噻吩 | 1269 | 1126 | 845 | 1023 |

| 苯并萘噻吩 | 3393 | 3391 | 3300 | 3478 |

| 二苯并萘噻吩 | 1507 | 1592 | 1538 | 1514 |

| 13C核磁/%(质量分数) | ||||

| 脂肪烃 CH3 | 14.5 | 13.0 | 14.6 | 14.2 |

| 脂肪烃 CH2 | 52.5 | 54.3 | 56.0 | 55.9 |

| 脂肪烃 CH | 16.2 | 15.9 | 15.7 | 16.0 |

| 芳烃 CH | 9.7 | 8.0 | 5.4 | 5.2 |

| 芳烃取代位 C | 6.3 | 4.3 | 4.0 | 4.3 |

| 芳烃桥位 C | 0.8 | 4.4 | 4.3 | 4.4 |

表6 宏观性质计算值和实验值的对比

Table 6 Comparison of bulk properties between estimation and experiment

| 性 质 | 实验值 | 文献[ | 传统模型 | 本模型 |

|---|---|---|---|---|

| 密度/(g/cm3) | 0.9127 | 0.9170 | 0.9269 | 0.9292 |

| 碳元素/%(质量分数) | 85.68 | 85.40 | 85.54 | 85.51 |

| 氢元素/%(质量分数) | 12.38 | 12.30 | 12.30 | 12.18 |

| 硫元素/%(质量分数) | 2.24 | 2.24 | 2.12 | 2.26 |

| 氮元素/10-6 | 456 | 608 | 458 | 448 |

| 氢碳比(摩尔比) | 1.72 | 1.72 | 1.72 | 1.71 |

| SARA组成/%(质量分数) | ||||

| 饱和烃 | 64.2 | 64.1 | 63.6 | 63.8 |

| 芳烃 | 35.8 | 35.9 | 36.4 | 36.2 |

| 同系物组成/%(质量分数) | ||||

| 烷烃 | 22.1 | 21.3 | 23.2 | 21.9 |

| 环烷烃 | 42.0 | 42.8 | 39.9 | 41.9 |

| 单环芳烃 | 6.1 | 6.2 | 6.2 | 5.4 |

| 双环芳烃 | 12.5 | 13.2 | 11.5 | 11.9 |

| 三环芳烃 | 10.4 | 9.8 | 10.2 | 10.3 |

| 四环芳烃 | 6.2 | 5.0 | 5.9 | 5.7 |

| 五环芳烃 | 0.7 | 1.8 | 3.0 | 3.0 |

| 硫元素组成/10-6 | ||||

| 四氢苯并噻吩 | 566 | 577 | 555 | 491 |

| 苯并噻吩 | 7681 | 7772 | 8194 | 8469 |

| 四氢二苯并噻吩 | 853 | 904 | 853 | 981 |

| 二苯并噻吩 | 7141 | 7061 | 5916 | 6628 |

| 四氢苯并萘噻吩 | 1269 | 1126 | 845 | 1023 |

| 苯并萘噻吩 | 3393 | 3391 | 3300 | 3478 |

| 二苯并萘噻吩 | 1507 | 1592 | 1538 | 1514 |

| 13C核磁/%(质量分数) | ||||

| 脂肪烃 CH3 | 14.5 | 13.0 | 14.6 | 14.2 |

| 脂肪烃 CH2 | 52.5 | 54.3 | 56.0 | 55.9 |

| 脂肪烃 CH | 16.2 | 15.9 | 15.7 | 16.0 |

| 芳烃 CH | 9.7 | 8.0 | 5.4 | 5.2 |

| 芳烃取代位 C | 6.3 | 4.3 | 4.0 | 4.3 |

| 芳烃桥位 C | 0.8 | 4.4 | 4.3 | 4.4 |

| 1 | Ren Y, Liao Z, Sun J, et al. Molecular reconstruction: recent progress toward composition modeling of petroleum fractions[J]. Chemical Engineering Journal, 2019, 357: 761-775. |

| 2 | Chen Z, Wang Y, Li Y, et al. Explicit molecule-based reaction network simplification: theory and application on catalytic reforming[J]. Chemical Engineering Science, 2023, 277: 118833. |

| 3 | Zhang Y, Zhou Z, Zhang X, et al. Molecular characterization of heavy olefins in slurry-phase hydrocracking products using high-resolution mass spectrometry[J]. Energy & Fuels, 2023, 37(16): 11743-11753. |

| 4 | Chen Z, Wang G, Zhao S, et al. A molecular kinetic model for heavy gas oil catalytic pyrolysis to light olefins[J]. AIChE Journal, 2023, 69(8): e18116. |

| 5 | Guan D, Cai G, Zhang L. Dual-objective optimization for petroleum molecular reconstruction based on property and composition similarities[J]. AIChE Journal, 2023, 69(8): e18108. |

| 6 | Bi K, Qiu T. Novel naphtha molecular reconstruction process using a self-adaptive cloud model and hybrid genetic algorithm-particle swarm optimization algorithm[J]. Industrial & Engineering Chemistry Research, 2019, 58(36): 16753-16760. |

| 7 | Chen J, Fang Z, Qiu T. Molecular reconstruction model based on structure oriented lumping and group contribution methods[J]. Chinese Journal of Chemical Engineering, 2018, 26(8): 1677-1683. |

| 8 | Quann R J, Jaffe S B. Structure-oriented lumping: describing the chemistry of complex hydrocarbon mixtures[J]. Industrial & Engineering Chemistry Research, 1992, 31(11): 2483-2497. |

| 9 | Jaffe S B, Freund H, Olmstead W N. Extension of structure-oriented lumping to vacuum residua[J]. Industrial & Engineering Chemistry Research, 2005, 44(26): 9840-9852. |

| 10 | Quann R J, Jaffe S B. Additions and corrections: structure-oriented lumping: describing the chemistry of complex hydrocarbon mixtures[J]. Industrial & Engineering Chemistry Research, 1993, 32(8): 1800. |

| 11 | Ye L, Liu J, Xing B, et al. Molecular-level reaction network in delayed coking process based on structure-oriented lumping[J]. Chemical Engineering Science, 2021, 246: 116981. |

| 12 | Qin X, Ye L, Murad A, et al. Reaction network and molecular distribution of sulfides in gasoline and diesel of FCC process[J]. Fuel, 2022, 319: 123567. |

| 13 | Trauth D M, Stark S M, Petti T F, et al. Representation of the molecular structure of petroleum resid through characterization and Monte Carlo modeling[J]. Energy & Fuels, 1994, 8(3): 576-580. |

| 14 | Agarwal P, Sahasrabudhe M, Khandalkar S, et al. Molecular-level kinetic modeling of a real vacuum gas oil hydroprocessing refinery system[J]. Energy & Fuels, 2019, 33(10): 10143-10158. |

| 15 | Aye M M S, Zhang N. A novel methodology in transforming bulk properties of refining streams into molecular information[J]. Chemical Engineering Science, 2005, 60(23): 6702-6717. |

| 16 | Gomez Prado J, Zhang N, Theodoropoulos C. Characterisation of heavy petroleum fractions using modified molecular-type homologous series (MTHS) representation[J]. Energy, 2008, 33(6): 974-987. |

| 17 | Wu Y. Molecular management for refining operations[D]. Manchester: University of Manchester, 2010. |

| 18 | Liu L. Molecular characterisation and modelling for refining processes[D]. Manchester: University of Manchester, 2015. |

| 19 | Ren Y, Liao Z, Sun J, et al. Molecular reconstruction of naphtha via limited bulk properties: methods and comparisons[J]. Industrial & Engineering Chemistry Research, 2019, 58(40): 18742-18755. |

| 20 | Hudebine D, Verstraete J J. Molecular reconstruction of LCO gasoils from overall petroleum analyses[J]. Chemical Engineering Science, 2004, 59(22-23): 4755-4763. |

| 21 | Van Geem K M, Hudebine D, Reyniers M F, et al. Molecular reconstruction of naphtha steam cracking feedstocks based on commercial indices[J]. Computers & Chemical Engineering 2007, 31(9): 1020-1034. |

| 22 | Verstraete J J, Schnongs P, Dulot H, et al. Molecular reconstruction of heavy petroleum residue fractions[J]. Chemical Engineering Science, 2010, 65(1): 304-312. |

| 23 | Van Geem K M, Reyniers M F, Marin G B. Challenges of modeling steam cracking of heavy feedstocks[J]. Oil & Gas Science and Technology-Rev. IFP, 2008, 63(1): 79-94. |

| 24 | Klein M T, Neurock M, Nigam A, et al. In Monte Carlo modeling of complex reaction systems: an asphaltene example[M]//Sapre E A M. Chemical Reactions in Complex Mixtures. New York: Van Nostrand Reinhold, 1991: 126-142. |

| 25 | Neurock M, Nigam A, Trauth D, et al. Molecular representation of complex hydrocarbon feedstocks through efficient characterization and stochastic algorithms[J]. Chemical Engineering Science, 1994, 49(24): 4153-4177. |

| 26 | Petti T F, Trauth D M, Stark S M, et al. CPU issues in the representation of the molecular structure of petroleum resid through characterization, reaction, and monte carlo modeling[J]. Energy & Fuels, 1994, 8(3): 570-585. |

| 27 | Campbell D M, Klein M T. Construction of a molecular representation of a complex feedstock by Monte Carlo and quadrature methods[J]. Applied Catalysis A: General, 1997, 160(1): 41-54. |

| 28 | Campbell D M, Klein M T. Structural attribute reaction model for heavy hydrocarbons[J]. American Chemical Society, Division of Petroleum Chemistry, Preprints, 1997, 42(2): 300-302. |

| 29 | Horton S R, Zhang L, Hou Z, et al. Molecular-level kinetic modeling of resid pyrolysis[J]. Industrial & Engineering Chemistry Research, 2015, 54(16): 4226-4235. |

| 30 | Zhang L, Hou Z, Horton S R, et al. Molecular representation of petroleum vacuum resid[J]. Energy & Fuels, 2014, 28(3): 1736-1749. |

| 31 | Alvarez-Majmutov A, Chen J W, Gieleciak R. Molecular-level modeling and simulation of vacuum gas oil hydrocracking[J]. Energy & Fuels, 2016, 30(1): 138-148. |

| 32 | Deniz C U, Yasar M, Klein M T. A new extended structural parameter set for stochastic molecular reconstruction: application to asphaltenes[J]. Energy & Fuels, 2017, 31(8): 7919-7931. |

| 33 | Deniz C U, Yasar M, Klein M T. Stochastic reconstruction of complex heavy oil molecules using an artificial neural network[J]. Energy & Fuels, 2017, 31(11): 11932-11938. |

| 34 | Deniz C U, Yasar S H O, Yasar M, et al. Effect of boiling point and density prediction methods on stochastic reconstruction[J]. Energy & Fuels, 2018, 32(3): 3344-3355. |

| 35 | Gani R, Nielsen B, Fredenslund A. A group contribution approach to computer-aided molecular design[J]. AIChE Journal, 1991, 37(9): 1318-1332. |

| 36 | Marrero J, Gani R. Group-contribution based estimation of pure component properties[J]. Fluid Phase Equilibria, 2001, 183: 183-208. |

| 37 | Hukkerikar A S, Sarup B, Ten Kate A, et al. Group-contribution+ (GC+) based estimation of properties of pure components: improved property estimation and uncertainty analysis[J]. Fluid Phase Equilibria, 2012, 321: 25-43. |

| 38 | Yen L C, Woods S S. A generalized equation for computer calculation of liquid densities[J]. AIChE Journal, 1966, 12(1): 95-99. |

| 39 | Haktanır M, Karahan S, Yaşar M. Structurally explicit composition model of petroleum vacuum residue[J]. Fuel, 2021, 300: 120977. |

| 40 | Glazov N, Dik P, Zagoruiko A. Effect of experimental data accuracy on stochastic reconstruction of complex hydrocarbon mixture[J]. Catalysis Today, 2021, 378: 202-210. |

| 41 | Horton S R, Mohr R J, Zhang Y, et al. Molecular-level kinetic modeling of biomass gasification[J]. Energy & Fuels, 2016, 30(3): 1647-1661. |

| 42 | Horton S R, Klein M T. Reaction and catalyst families in the modeling of coal and biomass hydroprocessing kinetics[J]. Energy & Fuels, 2014, 28(1): 37-40. |

| 43 | Dufour R, Labeau P E, Henneaux P, et al. Stochastic optimization for reactive power planning problems[C]//2016 IEEE International Energy Conference (ENERGYCON). IEEE, 2016: 1-6. |

| 44 | Henderson S G, Nelson B L. Handbooks in Operations Research and Management Science: Simulation[M]. Amsterdam: Elsevier, 2006. |

| 45 | Amaran S, Sahinidis N, Sharda B, et al. Simulation optimization: a review of algorithms and applications[J]. Annals of Operations Research, 2016, 240: 351-380. |

| 46 | Rubinstein R Y, Kroese D P. Simulation and the Monte Carlo Method[M]. MYSE: John Wiley & Sons, 2016. |

| 47 | Loh W L. On Latin hypercube sampling[J]. The Annals of Statistics, 1996, 24(5): 2058-2080. |

| 48 | Alvarez Majmutov A, Gieleciak R, Chen J W. Deriving the molecular composition of vacuum distillates by integrating statistical modeling and detailed hydrocarbon characterization[J]. Energy & Fuels, 2015, 29(12): 7931-7940. |

| 49 | Das S, Suganthan P N. Differential evolution: a survey of the state-of-the-art[J]. IEEE Transactions on Evolutionary Computation, 2011, 15(1): 4-31. |

| 50 | Chen B, Zeng W, Lin Y, et al. An enhanced differential evolution based algorithm with simulated annealing for solving multiobjective optimization problems[J]. Journal of Applied Mathematics, 2014:1-13. |

| 51 | Ali M Z, Awad N H, Suganthan P N. Multi-population differential evolution with balanced ensemble of mutation strategies for large-scale global optimization[J]. Applied Soft Computing, 2015, 33: 304-327. |

| [1] | 王金山, 王世学, 朱禹. 冷却表面温差对高温质子交换膜燃料电池性能的影响[J]. 化工学报, 2024, 75(5): 2026-2035. |

| [2] | 李怡菲, 董新宇, 王为术, 刘璐, 赵一璠. 微肋板表面干冰升华喷雾冷却传热数值模拟[J]. 化工学报, 2024, 75(5): 1830-1842. |

| [3] | 刘帆, 张芫通, 陶成, 胡成玉, 杨小平, 魏进家. 歧管式射流微通道液冷散热性能[J]. 化工学报, 2024, 75(5): 1777-1786. |

| [4] | 李娟, 曹耀文, 朱章钰, 石雷, 李佳. 仿生正形尾鳍结构微通道流动与传热特性数值研究及结构优化[J]. 化工学报, 2024, 75(5): 1802-1815. |

| [5] | 秦晗淞, 李国梁, 闫昊, 冯翔, 刘熠斌, 陈小博, 杨朝合. 多级孔ZSM-5分子筛中油酸甲酯催化裂解吸附和扩散行为模拟研究[J]. 化工学报, 2024, 75(5): 1870-1881. |

| [6] | 李静, 张方芳, 王帅帅, 徐建华, 张朋远. 凹腔结构对正丁烷部分预混火焰可燃极限的影响[J]. 化工学报, 2024, 75(5): 2081-2090. |

| [7] | 谢磊, 徐永生, 林梅. 不同截面肋柱-软尾结构单相流动传热比较[J]. 化工学报, 2024, 75(5): 1787-1801. |

| [8] | 王文雅, 张玮, 楼小玲, 钟若菲, 陈冰冰, 贠军贤. 纳米纤维素嵌合型晶胶微球的多微管成形与模拟[J]. 化工学报, 2024, 75(5): 2060-2071. |

| [9] | 周康, 王建新, 于海, 魏朝良, 范丰奇, 车昕昊, 张磊. 基于分子动力学模拟的矿物基础油泡沫破裂性能研究[J]. 化工学报, 2024, 75(4): 1668-1678. |

| [10] | 刘东飞, 张帆, 刘铮, 卢滇楠. 机器学习势及其在分子模拟中的应用综述[J]. 化工学报, 2024, 75(4): 1241-1255. |

| [11] | 张政, 汪妩琼, 张雅静, 王康军, 吉远辉. 理论计算在药物制剂设计中的研究进展[J]. 化工学报, 2024, 75(4): 1429-1438. |

| [12] | 吉笑盈, 郑园, 李晓鹏, 杨振, 张维, 邱诗蕊, 张倩颖, 罗沧海, 孙东鹏, 陈东, 李东亮. 微流控可控制备液滴、颗粒和胶囊及其应用[J]. 化工学报, 2024, 75(4): 1455-1468. |

| [13] | 文一如, 付佳, 刘大欢. 基于机器学习的MOFs材料研究进展:能源气体吸附分离[J]. 化工学报, 2024, 75(4): 1370-1381. |

| [14] | 曾玉娇, 肖炘, 杨刚, 张意博, 郑光明, 李防, 汪凤玲. 基于机理与数据混合驱动的湿法磷酸生产过程代理建模与优化[J]. 化工学报, 2024, 75(3): 936-944. |

| [15] | 谭耀文, 姜攀星, 杜青, 余婉秋, 温小飞, 詹志刚. 工作电压对PEMFC膜电极衰退影响模拟研究[J]. 化工学报, 2024, 75(3): 974-986. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号