化工学报 ›› 2024, Vol. 75 ›› Issue (11): 3923-3934.DOI: 10.11949/0438-1157.20240533

收稿日期:2024-05-20

修回日期:2024-07-15

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

巨晓洁

作者简介:巨晓洁(1980—),女,博士,教授,juxiaojie@scu.edu.cn

基金资助:

Xiaojie JU( ), Mingwei HE, Youqiang XIA, Wei WANG, Liangyin CHU

), Mingwei HE, Youqiang XIA, Wei WANG, Liangyin CHU

Received:2024-05-20

Revised:2024-07-15

Online:2024-11-25

Published:2024-12-26

Contact:

Xiaojie JU

摘要:

异形微纤维因其多样化的结构和功能被广泛应用于仿生材料、药物控释和生物医学等诸多领域。微流控技术作为一种新型的微纳材料制备技术,通过调节通道结构、流体物性和流动条件,可以实现多种异形微纤维的可控制备。综述了近年基于微流控技术制备面向医药、化工和环境等重要领域的异形微纤维的研究进展。介绍了通过设计微流控装置的通道结构实现可控制备实心、中空、纺锤状和螺旋状等异形微纤维的诸多策略,探讨了基于异形微纤维的微观结构实现其功能多样化的重要思路,展望了微流控技术在可控构建新型异形微纤维方面的发展趋势,以期通过加强流动机制和成型机理的研究为制备高仿生性的异形微纤维提供重要参考。

中图分类号:

巨晓洁, 何明炜, 夏有强, 汪伟, 褚良银. 微流控技术可控制备异形微纤维的研究进展[J]. 化工学报, 2024, 75(11): 3923-3934.

Xiaojie JU, Mingwei HE, Youqiang XIA, Wei WANG, Liangyin CHU. Research progress on controllable fabrication of anisotropic microfibers by microfluidics[J]. CIESC Journal, 2024, 75(11): 3923-3934.

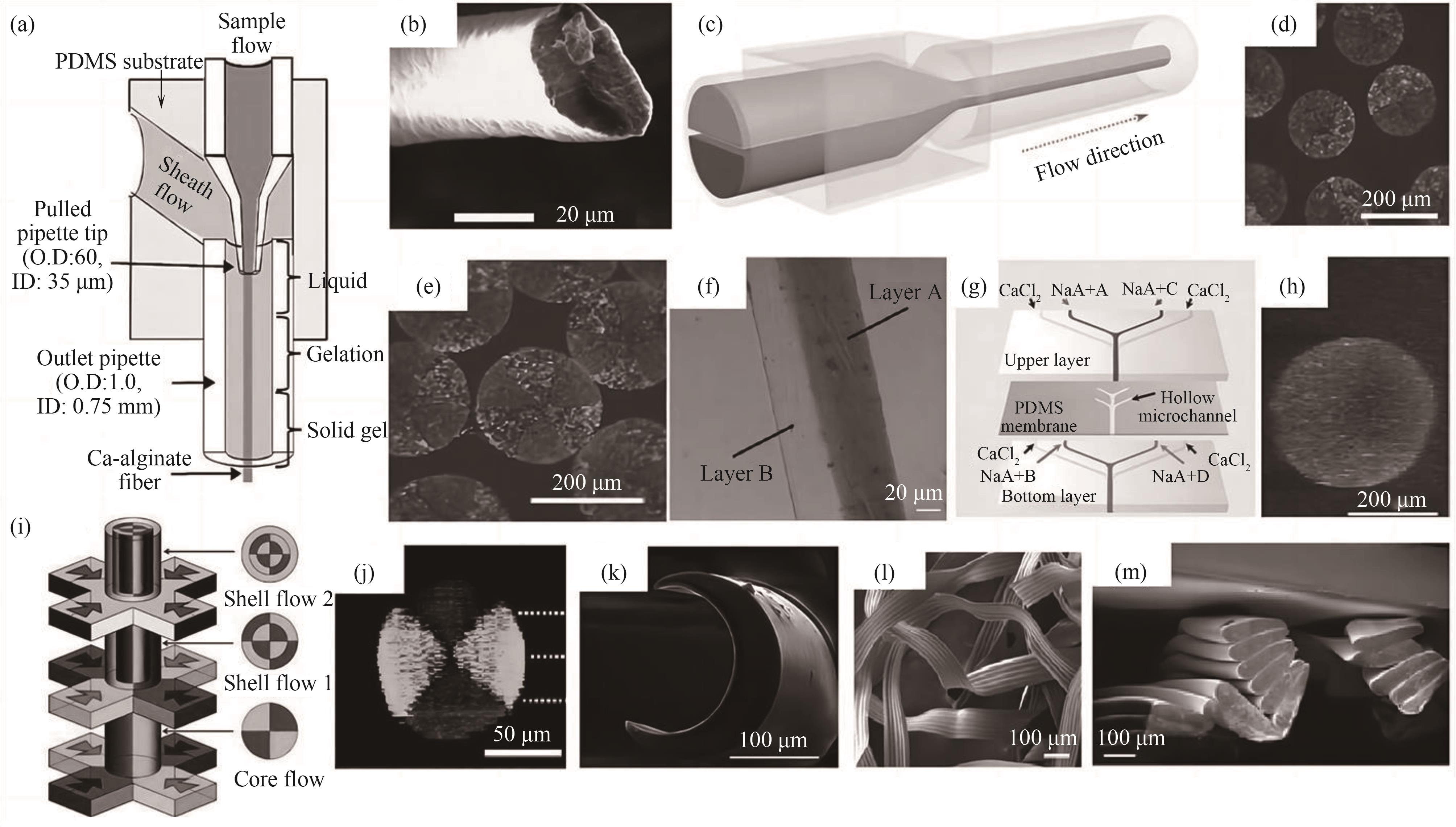

图1 微流控制备实心微纤维:(a)同轴毛细管微流控装置制备CaAlg微纤维的示意图[31];(b)PCL微纤维[32];(c)以双锥形管为内相微通道的同轴毛细管微流控装置的示意图[35];具有Janus双室(d)和六室(e)的CaAlg微纤维[35];(f)Janus双室型微纤维[36];三明治微芯片的示意图(g)和具有双室的CaAlg微纤维(h)[37];三维微流控芯片的示意图(i)和具有四室的CaAlg微纤维(j)[38];(k)具有非圆形横截面的微纤维[39];(l)扁平状聚丙烯酸酯微纤维[40];(m)带有沟槽的扁平状CaAlg微纤维[8]

Fig.1 Microfluidic fabrication of solid microfibers: (a) Illustration of a coaxial capillary microfluidic device for the fabrication of CaAlg microfibers[31]; (b) PCL microfibers[32]; (c) Illustration of a coaxial capillary microfluidic device with a double conical tube as an internal phase microchannel[35]; CaAlg microfibers with Janus-compartments (d) and six-compartments (e)[35]; (f) Janus bicompartmental microfibers[36]; Illustration of a “sandwich-like” microchip (g) and CaAlg microfibers with two-compartments (h)[37]; Illustration of a three-dimensional microfluidic chip (i) and CaAlg microfibers with four-compartments (j)[38]; (k) Microfibers with noncircular cross-section[39]; (l) Polymerized acrylate flat microfibers[40]; (m) Flat CaAlg microfibers with grooves[8]

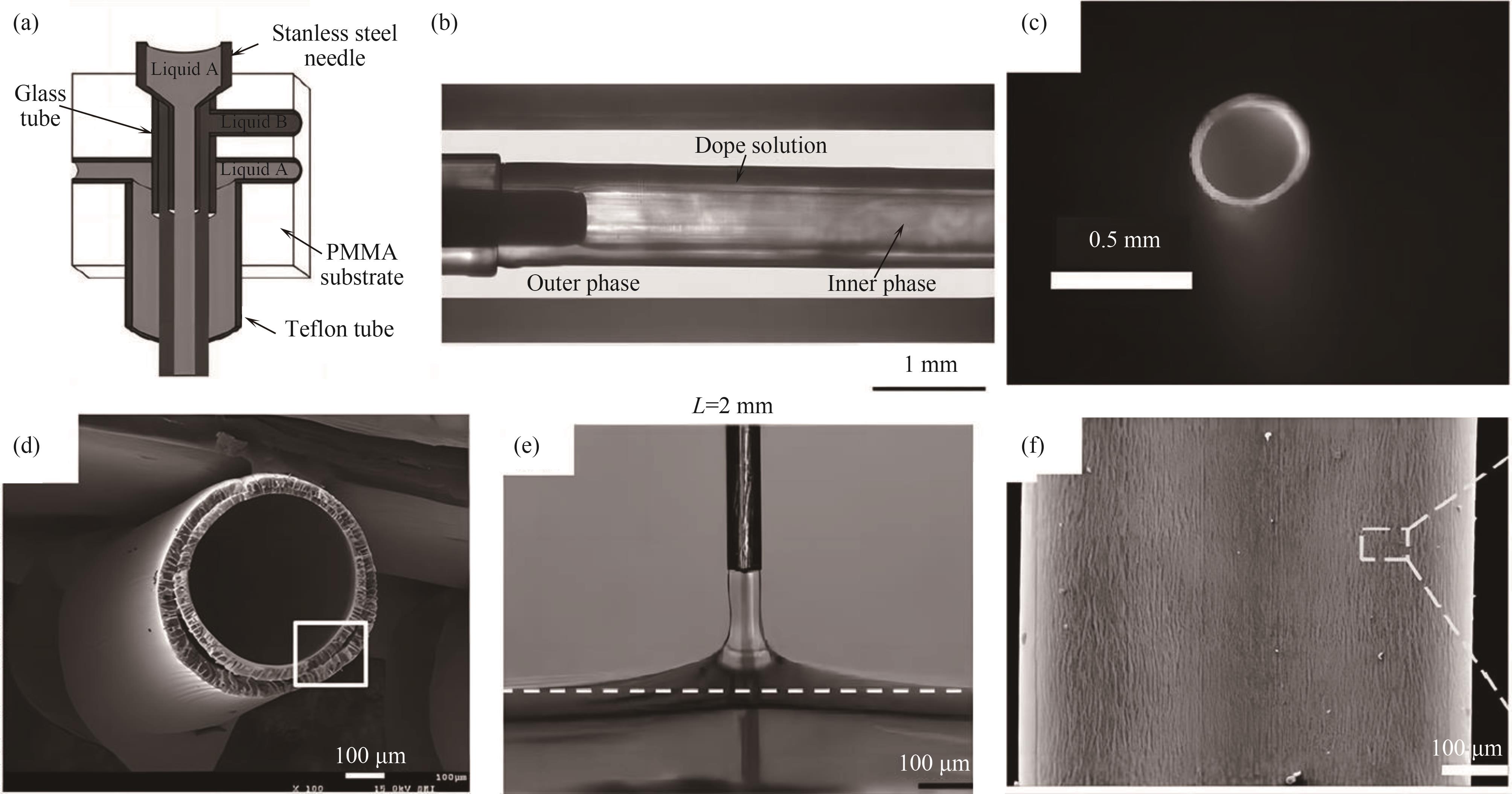

图2 微流控制备单通道中空微纤维:(a),(b)制备中空CaAlg微纤维的微流控装置[43];(c)PAN中空微纤维[41];(d)PES中空微纤维[22];(e)油相隔离层中射流[45];(f)包埋有K+响应性纳米颗粒的PLGA中空微纤维[13]

Fig.2 Microfluidic fabrication of single-channel hollow microfibers: (a),(b) The microfluidic device to fabricate hollow PES microfibers[43]; (c) PAN hollow microfibers[41]; (d) PES hollow microfibers[22]; (e) The jet flow in the oil-phase isolation layer[45]; (f) PLGA hollow microfibers embedded with K+-responsive nanoparticles[13]

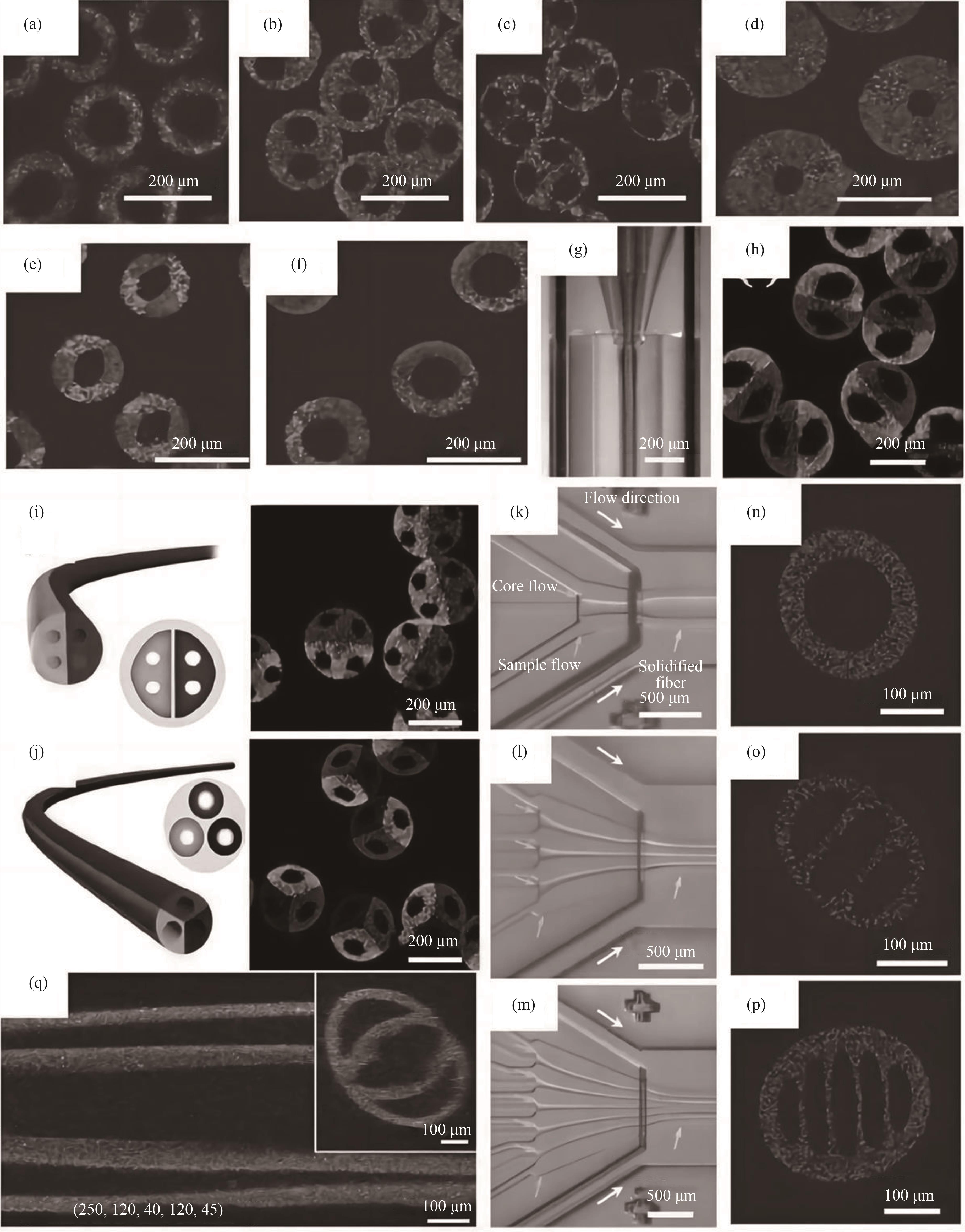

图3 微流控制备多层、多通道、多组分中空微纤维:(a)~(c)具有多个通道的CaAlg中空微纤维[35];(d)~(f)具有多室壳层的CaAlg中空微纤维[35];θ形毛细管微通道装置(g)及所制备Janus中空微纤维(h)[46];具有Janus双室四通道(i)及三室三通道(j)的微纤维[46];微流控制备具有1[(k), (n)]、3[(l), (o)]和5[(m), (p)]个中空通道的CaAlg微纤维[47];(q)多通道多组分CaAlg微纤维[48]

Fig.3 Microfluidic fabrication of multilayer, multichannel, multicomponent hollow microfibers: (a)—(c) CaAlg hollow microfibers with multichannels[35]; (d)—(f) CaAlg hollow microfibers with multicompartmental shell layers[35]; θ-type capillary microchannel device (g) and the prepared Janus-hollow microfibers (h)[46]; The Janus-hollow microfibers with four-channels (i) and three-compartment-hollow microfibers with three-channels (j)[46]; CaAlg microfibers with one [(k), (n)], three [(l), (o)] and five [(m), (p)] hollows[47]; (q) Multi-component CaAlg microfibers with multi-hollow structure[48]

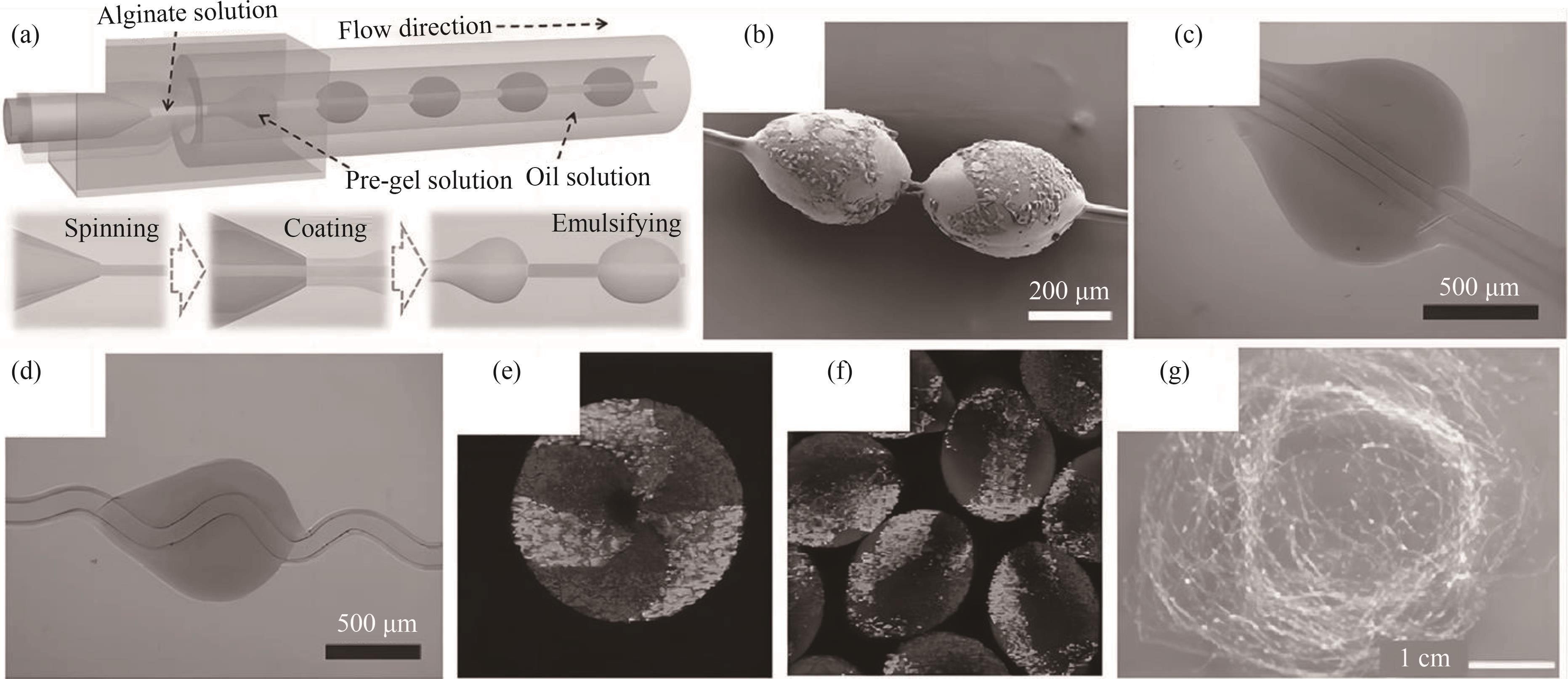

图4 微流控制备纺锤状微纤维:(a),(b)微流控制备纺锤状微纤维[49];带有内嵌Janus通道(c)和螺旋通道(d)的纺锤状微纤维[51];(e),(f)“佛珠”纺锤状微纤维[52];(g)纺锤状CaAlg微纤维[54]

Fig.4 Microfluidic fabrication of spindle-shaped microfibers: (a), (b) Microfluidic fabrication of spindle-shaped microfibers[49]; Spindle-shaped microfibers with embedded Janus channels (c) and helical channels (d)[51]; (e), (f) The “Buddha beads” spindle-shaped microfibers[52]; (g) CaAlg spindle microfibers[54]

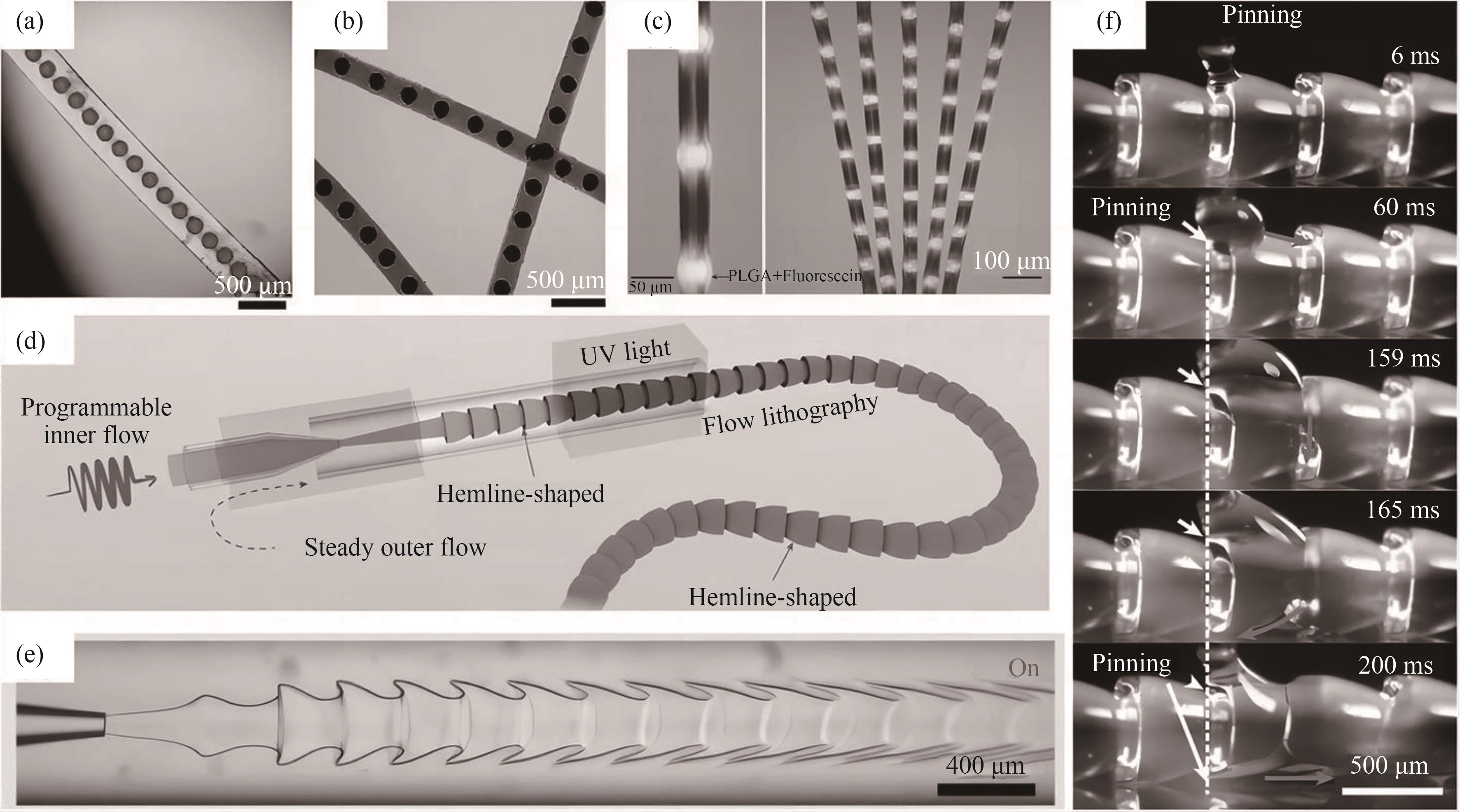

图5 微流控类似“纺锤状”微纤维:(a),(b)“豆荚状”微纤维[29];(c)“竹节状”微纤维[60];(d)~(f)“下摆形”微纤维[3]

Fig.5 Microfluidic fabrication of “spindle-like” shaped microfibers: (a),(b) The “peapod-like” microfibers[29]; (c) The “bamboo-like” microfibers[60]; (d)—(f) The “hemline-shaped” microfibers[3]

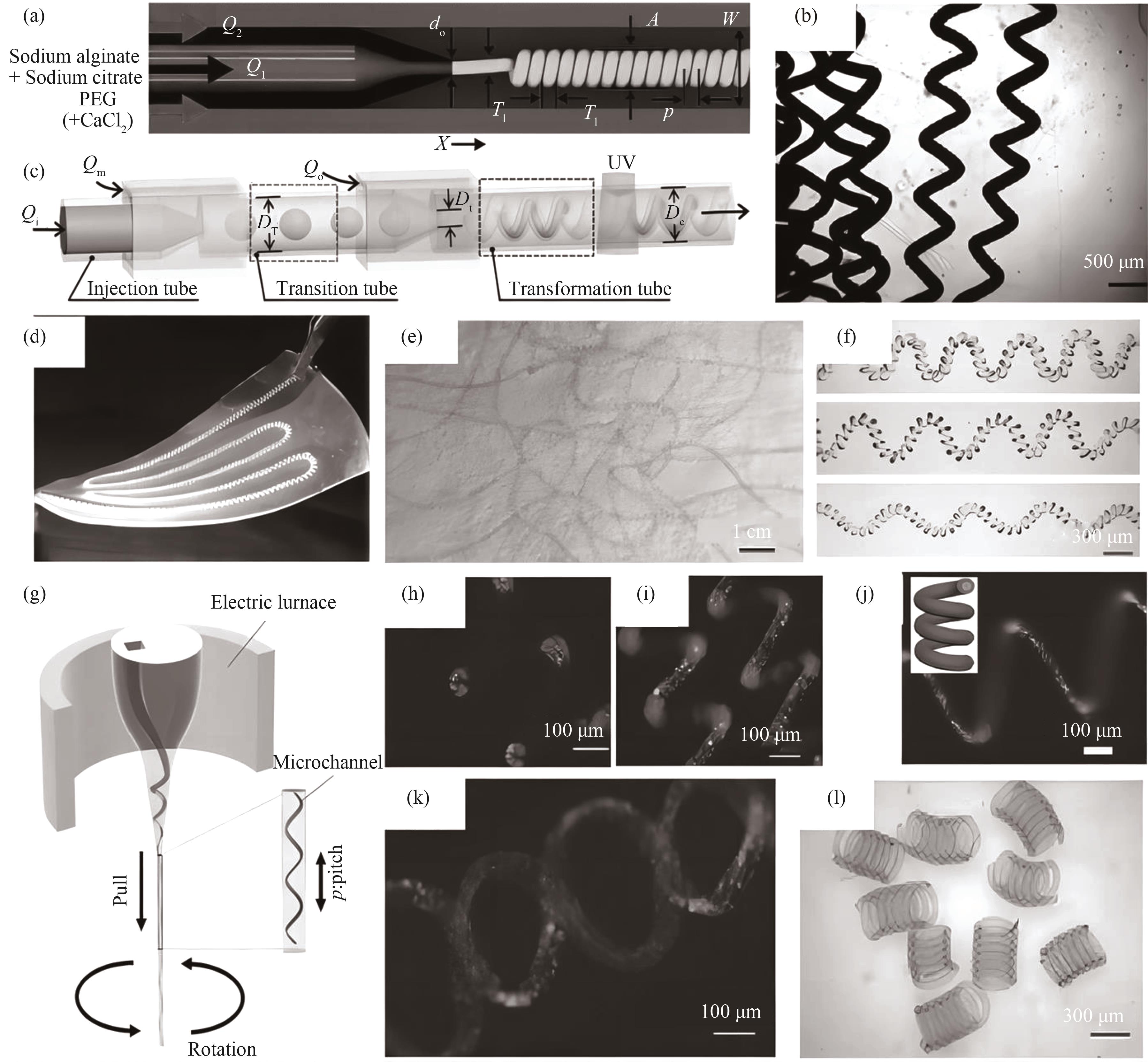

图6 微流控制备螺旋微纤维:(a)微流控装置可控制备螺旋微纤维的示意图[64];(b)CaAlg螺旋微纤维[65];(c)微流控可控制备螺旋微纤维的示意图[67];(d)嵌入螺旋微纤维的柔性聚合物薄膜[63];(e),(f)PUU3-12螺旋微纤维及其超螺旋微纤维[69];(g)mini-rTDP系统的示意图[71];具有三组分(h)、Janus结构(i)、多层结构(j)及双螺旋型(k)的CaAlg微纤维[16];(l)螺旋微电机[72]

Fig.6 Microfluidics fabrication of helical microfibers: (a) Illustration of microfluidic device for controllable fabrication of helical microfibers[64]; (b) CaAlg helical microfibers[65]; (c) Illustration of microfluidic device for controllable fabrication of helical microfibers[67]; (d) Flexible polymer film embedded in the helical microfibers[63]; (e),(f) PUU3-12 helical microfibers and their super helical microfibers[69]; (g) Illustration of the mini-rTDP system[71]; CaAlg microfibers with three-component (h), Janus structure (i), multilayered structure (j) and double-helical type (k)[16]; (l) Helical micromotors[72]

| 43 | Lan W J, Li S W, Xu J H, et al. Controllable synthesis of microscale titania fibers and tubes using co-laminar micro-flows[J]. Chemical Engineering Journal, 2012, 181: 828-833. |

| 44 | Meng Z J, Wang W, Xie R, et al. Microfluidic generation of hollow Ca-alginate microfibers[J]. Lab on a Chip, 2016, 16(14): 2673-2681. |

| 45 | 谭昕玥, 巨晓洁, 谢锐, 等. 具有油相隔离层的微流控法可控制备中空微纤维[J]. 高分子材料科学与工程, 2022, 38(3): 1-9, 17. |

| Tan X Y, Ju X J, Xie R, et al. Controllable preparation of hollow microfibers by microfluidic with oil phase as isolatoin layer[J]. Polymer Materials Science & Engineering, 2022, 38(3): 1-9, 17. | |

| 46 | Cheng Y, Yu Y R, Fu F F, et al. Controlled fabrication of bioactive microfibers for creating tissue constructs using microfluidic techniques[J]. ACS Applied Materials & Interfaces, 2016, 8(2): 1080-1086. |

| 47 | Yu Y, Wei W B, Wang Y Q, et al. Simple spinning of heterogeneous hollow microfibers on chip[J]. Advanced Materials, 2016, 28(31): 6649-6655. |

| 48 | Li W, Yao K, Tian L L, et al. 3D printing of heterogeneous microfibers with multi-hollow structure via microfluidic spinning[J]. Journal of Tissue Engineering and Regenerative Medicine, 2022, 16(10): 913-922. |

| 49 | Shang L R, Fu F F, Cheng Y, et al. Bioinspired multifunctional spindle-knotted microfibers from microfluidics[J]. Small, 2017, 13(4): 1600286. |

| 50 | Shang L R, Wang Y T, Yu Y R, et al. Bio-inspired stimuli-responsive graphene oxide fibers from microfluidics[J]. Journal of Materials Chemistry A, 2017, 5(29): 15026-15030. |

| 51 | Xie R X, Xu P D, Liu Y P, et al. Necklace-like microfibers with variable knots and perfusable channels fabricated by an oil-free microfluidic spinning process[J]. Advanced Materials, 2018, 30(14): 1705082. |

| 52 | Wang J, Zou M H, Sun L Y, et al. Microfluidic generation of Buddha beads-like microcarriers for cell culture[J]. Science China Materials, 2017, 60(9): 857-865. |

| 53 | Ji X B, Guo S, Zeng C F, et al. Continuous generation of alginate microfibers with spindle-knots by using a simple microfluidic device[J]. RSC Advances, 2015, 5(4): 2517-2522. |

| 54 | Liu Y F, Yang N, Li X, et al. Water harvesting of bioinspired microfibers with rough spindle-knots from microfluidics[J]. Small, 2020, 16(9): 1901819. |

| 55 | Kang E, Jeong G S, Choi Y Y, et al. Digitally tunable physicochemical coding of material composition and topography in continuous microfibres[J]. Nature Materials, 2011, 10(11): 877-883. |

| 56 | Peng Q F, Shao H L, Hu X C, et al. The development of fibers that mimic the core-sheath and spindle-knot morphology of artificial silk using microfluidic devices[J]. Macromolecular Materials and Engineering, 2017, 302(10): 1700102. |

| 57 | Tian Y, Zhu P G, Tang X, et al. Large-scale water collection of bioinspired cavity-microfibers[J]. Nature Communications, 2017, 8(1): 1080. |

| 58 | Tian Y, Wang J C, Wang L Q. Microfluidic fabrication of bioinspired cavity-microfibers for 3D scaffolds[J]. ACS Applied Materials & Interfaces, 2018, 10(35): 29219-29226. |

| 59 | 张秀, 谢锐, 汪伟, 等. 豆荚结构聚乙烯醇缩丁醛/氧化铝复合相变纤维的制备及性能[J]. 化工进展, 2019, 38(2): 993-999. |

| Zhang X, Xie R, Wang W, et al. Preparation and properties of polyvinyl butyral/Al2O3 composite phase change microfibers with peapod-like structure[J]. Chemical Industry and Engineering Progress, 2019, 38(2): 993-999. | |

| 60 | Yu Y, Wen H, Ma J Y, et al. Flexible fabrication of biomimetic bamboo-like hybrid microfibers[J]. Advanced Materials, 2014, 26(16) :2494-2499. |

| 61 | Jia L L, Han F X, Yang H L, et al. Microfluidic fabrication of biomimetic helical hydrogel microfibers for blood-vessel-on-a-chip applications[J]. Advanced Healthcare Materials, 2019, 8(13): 1900435. |

| 62 | Tang M J, Wang W, Li Z L, et al. Controllable microfluidic fabrication of magnetic hybrid microswimmers with hollow helical structures[J]. Industrial & Engineering Chemistry Research, 2018, 57(29): 9430-9438. |

| 63 | Yu Y R, Guo J H, Sun L Y, et al. Microfluidic generation of microsprings with ionic liquid encapsulation for flexible electronics[J]. Research, 2019, 2019: 6906275. |

| 64 | Tottori S, Takeuchi S. Formation of liquid rope coils in a coaxial microfluidic device[J]. RSC Advances, 2015, 5(42): 33691-33695. |

| 65 | Ma W J, Liu D, Ling S D, et al. High-throughput and controllable fabrication of helical microfibers by hydrodynamically focusing flow[J]. ACS Applied Materials & Interfaces, 2021, 13(49): 59392-59399. |

| 66 | Wang W, He X H, Zhang M J, et al. Controllable microfluidic fabrication of microstructured materials from nonspherical particles to helices[J]. Macromolecular Rapid Communications, 2017, 38(23): 1700429. |

| 67 | Cai Q W, Ju X J, Zhang S Y, et al. Controllable fabrication of functional microhelices with droplet microfluidics[J]. ACS Applied Materials & Interfaces, 2019, 11(49): 46241-46250. |

| 68 | 朱爱娣. 单乳液微流控制备核-壳/Janus微球及螺旋型微纤维[D]. 苏州: 苏州大学, 2016. |

| Zhu A D. Preparation of core-shell /Janus microspheres and spiral microfibers by single emulsion microfluidic control[D]. Suzhou: Soochow University, 2016. | |

| 69 | Yang H L, Guo M Y. Bioinspired polymeric helical and superhelical microfibers via microfluidic spinning[J]. Macromolecular Rapid Communications, 2019, 40(12): 1900111. |

| 70 | 杨慧丽. 微流控制备聚合物螺旋、超螺旋微纤维及螺旋管研究[D]. 苏州: 苏州大学, 2019. |

| Yang H L. Study on preparation of polymer spiral, super-spiral microfiber and spiral tube by microfluidic control[D]. Suzhou: Soochow University, 2019. | |

| 71 | Kato S, Carlson D W, Shen A Q, et al. Twisted fiber microfluidics: a cutting-edge approach to 3D spiral devices[J]. Microsystems & Nanoengineering, 2024, 10: 14. |

| 72 | Yu Y R, Shang L R, Gao W, et al. Microfluidic lithography of bioinspired helical micromotors[J]. Angewandte Chemie International Edition, 2017, 56(40): 12127-12131. |

| 1 | Bai H, Sun R Z, Ju J, et al. Large-scale fabrication of bioinspired fibers for directional water collection[J]. Small, 2011, 7(24): 3429-3433. |

| 2 | Feng S L, Hou Y P, Xue Y, et al. Photo-controlled water gathering on bio-inspired fibers[J]. Soft Matter, 2013, 9(39): 9294-9297. |

| 3 | Yang C Y, Yu Y R, Shang L R, et al. Flexible hemline-shaped microfibers for liquid transport[J]. Nature Chemical Engineering, 2024, 1: 87-96. |

| 4 | Hwang C M, Khademhosseini A, Park Y, et al. Microfluidic chip-based fabrication of PLGA microfiber scaffolds for tissue engineering[J]. Langmuir, 2008, 24(13): 6845-6851. |

| 5 | Li Z R, Zhang X C, Ouyang J, et al. Ca2+-supplying black phosphorus-based scaffolds fabricated with microfluidic technology for osteogenesis[J]. Bioactive Materials, 2021, 6(11): 4053-4064. |

| 6 | Filippi M, Buchner T, Yasa O, et al. Microfluidic tissue engineering and bio-actuation[J]. Advanced Materials, 2022, 34(23): 2108427. |

| 7 | Moutos F T, Freed L E, Guilak F. A biomimetic three-dimensional woven composite scaffold for functional tissue engineering of cartilage[J]. Nature Materials, 2007, 6(2): 162-167. |

| 8 | Kang E, Choi Y Y, Chae S K, et al. Microfluidic spinning of flat alginate fibers with grooves for cell-aligning scaffolds[J]. Advanced Materials, 2012, 24(31): 4271-4277. |

| 9 | Jiao J, Wang F, Huang J J, et al. Microfluidic hollow fiber with improved stiffness repairs peripheral nerve injury through non-invasive electromagnetic induction and controlled release of NGF[J]. Chemical Engineering Journal, 2021, 426: 131826. |

| 10 | Aykar S S, Alimoradi N, Taghavimehr M, et al. Microfluidic seeding of cells on the inner surface of alginate hollow microfibers[J]. Advanced Healthcare Materials, 2022, 11(11): 2102701. |

| 11 | Illath K, Kar S, Gupta P, et al. Microfluidic nanomaterials: from synthesis to biomedical applications[J]. Biomaterials, 2022, 280: 121247. |

| 12 | Lin Y S, Huang K S, Yang C H, et al. Microfluidic synthesis of microfibers for magnetic-responsive controlled drug release and cell culture[J]. PLoS One, 2012, 7(3): e33184. |

| 13 | Jiang M Y, Ju X J, Deng K, et al. The microfluidic synthesis of composite hollow microfibers for K+-responsive controlled release based on a host-guest system[J]. Journal of Materials Chemistry B, 2016, 4(22): 3925-3935. |

| 14 | Cho S, Shim T S, Yang S M. High-throughput optofluidic platforms for mosaicked microfibers toward multiplex analysis of biomolecules[J]. Lab on a Chip, 2012, 12(19): 3676-3679. |

| 15 | Park S, Guo Y Y, Jia X T, et al. One-step optogenetics with multifunctional flexible polymer fibers[J]. Nature Neuroscience, 2017, 20(4): 612-619. |

| 16 | Yu Y R, Fu F F, Shang L R, et al. Bioinspired helical microfibers from microfluidics[J]. Advanced Materials, 2017, 29(18): 1605765. |

| 17 | Guo J H, Yu Y R, Cai L J, et al. Microfluidics for flexible electronics[J]. Materials Today, 2021, 44: 105-135. |

| 18 | Wen G Q, Xie R, Liang W G, et al. Microfluidic fabrication and thermal characteristics of core-shell phase change microfibers with high paraffin content[J]. Applied Thermal Engineering, 2015, 87: 471-480. |

| 19 | Zhao Y, Cao X Y, Jiang L. Bio-mimic multichannel microtubes by a facile method[J]. Journal of the American Chemical Society, 2007, 129(4): 764-765. |

| 20 | 姚子琪, 马东明, 雷文龙, 等. 熔体静电纺丝直写技术在组织工程中的应用进展[J]. 化工进展, 2019, 38(8): 3756-3762. |

| Yao Z Q, Ma D M, Lei W L, et al. Progress in melt electrospinning direct writing technology in tissue engineering[J]. Chemical Industry and Engineering Progress, 2019, 38(8): 3756-3762. | |

| 21 | Hu M, Deng R S, Schumacher K M, et al. Hydrodynamic spinning of hydrogel fibers[J]. Biomaterials, 2010, 31(5): 863-869. |

| 22 | Deng K, Liu Z, Luo F, et al. Controllable fabrication of polyethersulfone hollow fiber membranes with a facile double co-axial microfluidic device[J]. Journal of Membrane Science, 2017, 526: 9-17. |

| 23 | Lyu H L, Liu J R, Qiu S, et al. Carbon composite spun fibers with in situ formed multicomponent nanoparticles for a lithium-ion battery anode with enhanced performance[J]. Journal of Materials Chemistry A, 2016, 4(25): 9881-9889. |

| 24 | Hufenus R, Reifler F A, Maniura-Weber K, et al. Biodegradable bicomponent fibers from renewable sources: melt-spinning of poly(lactic acid) and poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)][J]. Macromolecular Materials and Engineering, 2012, 297(1): 75-84. |

| 25 | Pinto T V, Fernandes D M, Guedes A, et al. Photochromic polypropylene fibers based on UV-responsive silica@phosphomolybdate nanoparticles through melt spinning technology[J]. Chemical Engineering Journal, 2018, 350: 856-866. |

| 26 | Nunes J K, Tsai S S H, Wan J, et al. Dripping and jetting in microfluidic multiphase flows applied to particle and fiber synthesis[J]. Journal of Physics D: Applied Physics, 2013, 46(11): 114002. |

| 27 | 何淑兰, 尹玉姬, 张敏, 等. 组织工程用海藻酸盐水凝胶的研究进展[J]. 化工进展, 2004,23 (11): 1174-1178. |

| He S L, Yin Y J, Zhang M, et al. Research advances on sodium alginate hydrogels for tissue engineering[J]. Chemical Industry and Engineering Progress, 2004, 23(11): 1174-1178. | |

| 28 | Choi C H, Yi H, Hwang S, et al. Microfluidic fabrication of complex-shaped microfibers by liquid template-aided multiphase microflow[J]. Lab on a Chip, 2011, 11(8): 1477-1483. |

| 29 | He X H, Wang W, Deng K, et al. Microfluidic fabrication of chitosan microfibers with controllable internals from tubular to peapod-like structures[J]. RSC Advances, 2015, 5(2): 928-936. |

| 30 | Du X Y, Li Q, Wu G, et al. Multifunctional micro/nanoscale fibers based on microfluidic spinning technology[J]. Advanced Materials, 2019, 31(52): 1903733. |

| 31 | Shin S J, Park J Y, Lee J Y, et al. "On the fly" continuous generation of alginate fibers using a microfluidic device[J]. Langmuir, 2007, 23(17): 9104-9108. |

| 32 | Sharifi F, Kurteshi D, Hashemi N. Designing highly structured polycaprolactone fibers using microfluidics[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 61: 530-540. |

| 33 | Xiao Y, Yang C J, Guo B L, et al. Bioinspired strong and tough organic-inorganic hybrid fibers[J]. Small Structures, 2023, 4(10): 2300080. |

| 34 | Xiao Y, Yang C J, Zhai X W, et al. Bioinspired tough and strong fibers with hierarchical core-shell structure[J]. Advanced Materials Interfaces, 2023, 10(2): 2201962. |

| 35 | Cheng Y, Zheng F Y, Lu J, et al. Bioinspired multicompartmental microfibers from microfluidics[J]. Advanced Materials, 2014, 26(30): 5184-5190. |

| 36 | Zhou M L, Gong J H, Ma J H. Continuous fabrication of near-infrared light responsive bilayer hydrogel fibers based on microfluidic spinning[J]. e-Polymers, 2019, 19(1): 215-224. |

| 37 | Yao K, Li W, Li K Y, et al. Simple fabrication of multicomponent heterogeneous fibers for cell co-culture via microfluidic spinning[J]. Macromolecular Bioscience, 2020, 20(3): 1900395. |

| 38 | Yoon D H, Kobayashi K, Tanaka D, et al. Simple microfluidic formation of highly heterogeneous microfibers using a combination of sheath units[J]. Lab on a Chip, 2017, 17(8): 1481-1486. |

| 39 | Lan W J, Du Y J, Guo X Q, et al. Flexible microfluidic fabrication of anisotropic polymer microfibers[J]. Industrial & Engineering Chemistry Research, 2018, 57(1): 212-219. |

| 40 | Thangawng A L, Howell P B, Spillmann C M, et al. UV polymerization of hydrodynamically shaped fibers[J]. Lab on a Chip, 2011, 11(6): 1157-1160. |

| 41 | Lan W J, Li S W, Lu Y C, et al. Controllable preparation of microscale tubes with multiphase co-laminar flow in a double co-axial microdevice[J]. Lab on a Chip, 2009, 9(22): 3282-3288. |

| 42 | Lan W J, Li S W, Xu J H, et al. Preparation and carbon dioxide separation performance of a hollow fiber supported ionic liquid membrane[J]. Industrial & Engineering Chemistry Research, 2013, 52(20): 6770-6777. |

| [1] | 肖扬可, 常印龙, 李平, 王文俊, 李伯耿, 刘平伟. 动态化学交联聚烯烃类弹性体研究进展[J]. 化工学报, 2024, 75(4): 1394-1413. |

| [2] | 刘恺轩, 姜沁源, 汪菲, 李润, 朱平, 王康康, 臧永路, 赵彦龙, 张如范. 高密度超长碳纳米管的可控制备:进展与展望[J]. 化工学报, 2024, 75(4): 1355-1369. |

| [3] | 丁相斐, 丘晓琳, 朱喜成, 张佳伟, 陈锦华. pH响应性气体渗透CNC/PBAT复合膜的制备与性能[J]. 化工学报, 2024, 75(3): 1040-1051. |

| [4] | 张少博, 方莉, 高雪焘, 程文婷. 碱式硫酸镁晶须的可控制备及不同离子的影响机制[J]. 化工学报, 2021, 72(6): 3031-3040. |

| [5] | 苏瑶瑶, 李平凡, 汪伟, 巨晓洁, 谢锐, 刘壮, 褚良银. 微流控液滴模板法可控构建功能微颗粒材料[J]. 化工学报, 2021, 72(1): 42-60. |

| [6] | 刘鑫, 冯平丽, 侯文烁, 王振华, 孙克宁. 锂硫电池中间层的研究进展[J]. 化工学报, 2020, 71(9): 4031-4045. |

| [7] | 杨鑫宇, 吴杰, 张建庭, 吴纯鑫, 赵德明. 功能化磁性纳米复合材料Fe3O4-mPD/SP吸附Cr(Ⅵ)研究[J]. 化工学报, 2020, 71(3): 1060-1071. |

| [8] | 邓晓霞, 龚磊, 刘小棒, 邓东顺. 咪唑类三元低共熔溶剂捕集低压SO2的实验研究[J]. 化工学报, 2020, 71(1): 368-375. |

| [9] | 肖俏欣, 林文俊, 李浩然, 王从敏. 含醚阴离子功能化离子液体高效捕集SO2[J]. 化工学报, 2020, 71(1): 361-367. |

| [10] | 刘亚敏, 彭蕾, 苏凤英, 王湘湘, 黄艺真, 林在春, 喻晓静, 裴义山. 多孔胺基化氧化石墨烯基材料对CO2的吸附性能研究[J]. 化工学报, 2019, 70(5): 2016-2024. |

| [11] | 何凯武, 唐思扬, 刘长军, 岳海荣, 梁斌. 有机胺功能化介孔固体吸附剂吸附分离CO2性能研究[J]. 化工学报, 2018, 69(9): 3887-3895. |

| [12] | 柳璐, 张文, 王宇新. 石墨相氮化碳的可控制备及其在能源催化中的应用[J]. 化工学报, 2018, 69(11): 4577-4591. |

| [13] | 胡甜甜, 赵地顺, 武宇, 张拴力, 扈士海, 翟建华. 醚基功能化离子液体催化合成乙酸正丁酯[J]. 化工学报, 2017, 68(1): 136-145. |

| [14] | 赵红, 徐晓敏, 徐建鸿, 王涛, 骆广生. 微流控制备壳聚糖功能材料研究进展[J]. 化工学报, 2016, 67(2): 373-378. |

| [15] | 陈凯宏, 梅柯, 李浩然, 王从敏. 肉桂酸型离子液体的合成及其二氧化碳吸收[J]. 化工学报, 2016, 67(2): 623-626. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号