化工学报 ›› 2025, Vol. 76 ›› Issue (2): 564-575.DOI: 10.11949/0438-1157.20241048

• 流体力学与传递现象 • 上一篇

谢楠楠1( ), 陈和2, 叶光华1(

), 陈和2, 叶光华1( ), 束忠明1, 傅送保2(

), 束忠明1, 傅送保2( ), 周兴贵1

), 周兴贵1

收稿日期:2024-09-23

修回日期:2024-10-25

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

叶光华,傅送保

作者简介:谢楠楠(1999—),男,硕士研究生,Y30220141@mail.ecust.edu.cn

基金资助:

Nannan XIE1( ), He CHEN2, Guanghua YE1(

), He CHEN2, Guanghua YE1( ), Zhongming SHU1, Songbao FU2(

), Zhongming SHU1, Songbao FU2( ), Xinggui ZHOU1

), Xinggui ZHOU1

Received:2024-09-23

Revised:2024-10-25

Online:2025-03-25

Published:2025-03-10

Contact:

Guanghua YE, Songbao FU

摘要:

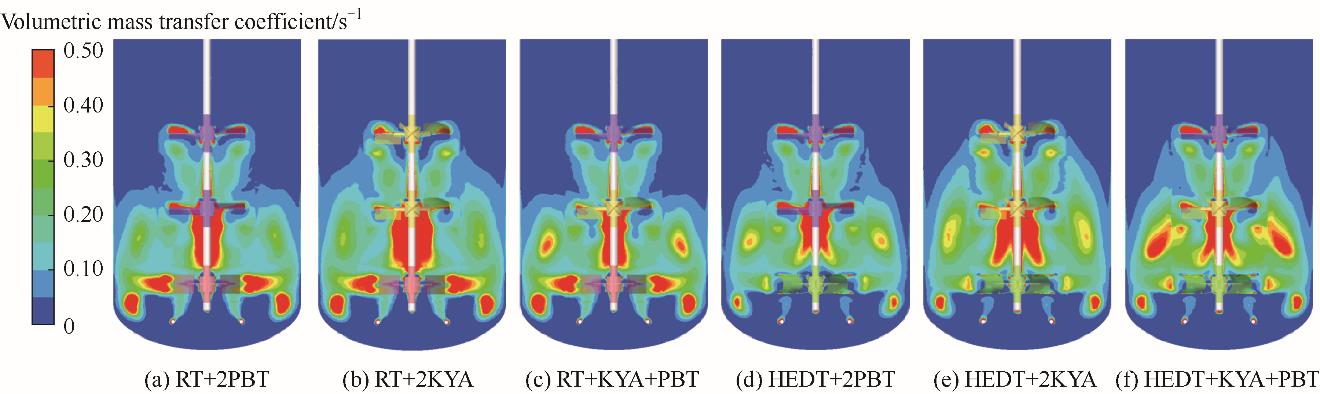

桨叶是气液搅拌釜最重要的部件之一,其结构和组合形式会显著影响气液分散和传质性能。结合冷模实验和CFD-PBM数值模拟,获取了气液搅拌釜多层桨叶之间的相互作用关系,以及较优的桨叶组合形式。研究结果表明,径向桨作为底桨对气相分散和气泡破碎影响最大,中层轴流桨对底桨的剪切应力影响较小,而顶层轴流桨产生的轴向汇流会减弱中层桨的剪切应力。多层桨的排列组合方式会影响各个桨叶的功率消耗,其中顶层桨对中层桨的功耗影响最显著。HEDT作为底层桨功耗低且气相分散效果好,KYA作为中层桨能强化轴向汇流、减小局部涡流以及进一步破碎气泡,PBT作为顶层桨功耗低且能扩大循环流结构。因此,HEDT+KYA+PBT桨叶组合能平衡功率消耗、气相滞留和气液传质,具有最高的单位功耗气含率和平均容积传质系数,是较优的桨叶组合。研究结果可以为气液搅拌反应釜多层桨叶的设计和优化提供理论指导。

中图分类号:

谢楠楠, 陈和, 叶光华, 束忠明, 傅送保, 周兴贵. 气液搅拌釜多层桨叶相互作用及组合优化[J]. 化工学报, 2025, 76(2): 564-575.

Nannan XIE, He CHEN, Guanghua YE, Zhongming SHU, Songbao FU, Xinggui ZHOU. Interaction of multiple impellers for gas-liquid stirred tank and optimization of their combinations[J]. CIESC Journal, 2025, 76(2): 564-575.

| T/mm | H/T | C0/T | C1/T | C2/T | C3/T | D1~3/T | d/T | W/T | P0/T | P/T | E/T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 500 | 1.4 | 0.15 | 0.1 | 0.5 | 0.9 | 0.4 | 0.36 | 0.1 | 0.3 | 0.2 | 0.05 |

表1 气液搅拌釜结构参数

Table 1 Structural parameters of gas-liquid stirred tank

| T/mm | H/T | C0/T | C1/T | C2/T | C3/T | D1~3/T | d/T | W/T | P0/T | P/T | E/T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 500 | 1.4 | 0.15 | 0.1 | 0.5 | 0.9 | 0.4 | 0.36 | 0.1 | 0.3 | 0.2 | 0.05 |

图11 容积传质系数分布云图(模拟中采用的转速为400 r/min)

Fig.11 Contours of volumetric mass transfer coefficient distribution (rotation speed is 400 r/min in the simulations)

| 1 | Visscher F, van der Schaaf J, Nijhuis T A, et al. Rotating reactors—a review[J]. Chemical Engineering Research and Design, 2013, 91(10): 1923-1940. |

| 2 | Jegatheeswaran S, Kazemzadeh A, Ein-Mozaffari F. Enhanced aeration efficiency in non-Newtonian fluids using coaxial mixers: high-solidity ratio central impeller with an anchor[J]. Chemical Engineering Journal, 2019, 378: 122081. |

| 3 | Montante G, Paglianti A. Gas hold-up distribution and mixing time in gas-liquid stirred tanks[J]. Chemical Engineering Journal, 2015, 279: 648-658. |

| 4 | Martín M, Montes F J, Galán M A. Bubbling process in stirred tank reactors(Ⅱ): Agitator effect on the mass transfer rates[J]. Chemical Engineering Science, 2008, 63(12): 3223-3234. |

| 5 | Liu B Q, Xiao Q, Sun N, et al. Effect of gas distributor on gas-liquid dispersion and mass transfer characteristics in stirred tank[J]. Chemical Engineering Research and Design, 2019, 145: 314-322. |

| 6 | Zhu Y W, Yu J C, Ma X, et al. Blade configuration optimization of the axial flow impeller applied in a tall stirred tank[J]. Industrial & Engineering Chemistry Research, 2023, 62(35): 14047-14060. |

| 7 | Alfaro-Ayala J A, Ayala-Ramírez V, Gallegos-Muñoz A, et al. Optimal location of axial impellers in a stirred tank applying evolutionary programing and CFD[J]. Chemical Engineering Research and Design, 2015, 100: 203-211. |

| 8 | Bao Y Y, Wang B J, Lin M L, et al. Influence of impeller diameter on overall gas dispersion properties in a sparged multi-impeller stirred tank[J]. Chinese Journal of Chemical Engineering, 2015, 23(6): 890-896. |

| 9 | Arjunwadkar S J, Saravanan K, Pandit A B, et al. Optimizing the impeller combination for maximum hold-up with minimum power consumption[J]. Biochemical Engineering Journal, 1998, 1(1): 25-30. |

| 10 | Xia J Y, Wang Y H, Zhang S L, et al. Fluid dynamics investigation of variant impeller combinations by simulation and fermentation experiment[J]. Biochemical Engineering Journal, 2009, 43(3): 252-260. |

| 11 | Zhang J J, Gao Z M, Cai Y T, et al. Power consumption and mass transfer in a gas-liquid-solid stirred tank reactor with various triple-impeller combinations[J]. Chemical Engineering Science, 2017, 170: 464-475. |

| 12 | You S T, Raman A A A, Raja Shazrin Shah Raja Ehsan Shah, et al. Multiple-impeller stirred vessel studies[J]. Reviews in Chemical Engineering, 2014, 30(3): 323-336. |

| 13 | Kang Z M, Feng L F, Wang J J. Optimization of a gas-liquid dual-impeller sirred tank based on deep learning with a small data set from CFD simulation[J]. Industrial & Engineering Chemistry Research, 2024, 63(1): 843-855. |

| 14 | Zheng Z Y, Sun D D, Li J, et al. Improving oxygen transfer efficiency by developing a novel energy-saving impeller[J]. Chemical Engineering Research and Design, 2018, 130: 199-207. |

| 15 | Zhao X Z, Fan H A, Lin G B, et al. Multi-objective optimization of radially stirred tank based on CFD and machine learning[J]. AIChE Journal, 2024, 70(3): e18324. |

| 16 | Jia Z T, Zhang S F, Guo M K, et al. Experimental and numerical investigation of the characteristics of novel disc turbines in aerated stirred tanks[J]. Industrial & Engineering Chemistry Research, 2023, 62(25): 9886-9900. |

| 17 | Zhang Y H, Yang C, Mao Z S. Large eddy simulation of the gas-liquid flow in a stirred tank[J]. AIChE Journal, 2008, 54(8): 1963-1974. |

| 18 | Cooke M, Heggs P J. Advantages of the hollow (concave) turbine for multi-phase agitation under intense operating conditions[J]. Chemical Engineering Science, 2005, 60(20): 5529-5543. |

| 19 | Yang S F, Li X Y, Deng G, et al. Application of KHX impeller in a low-shear stirred bioreactor[J]. Chinese Journal of Chemical Engineering, 2014, 22(10): 1072-1077. |

| 20 | Ankamma Rao D, Sivashanmugam P. Experimental and CFD simulation studies on power consumption in mixing using energy saving turbine agitator[J]. Journal of Industrial and Engineering Chemistry, 2010, 16(1): 157-161. |

| 21 | Xu C Z, Liu X, Gu X. Computational studies of airlift and stirred airlift bioreactors with non-Newtonian fluid: a comparison of hydrodynamics and gas-liquid mass transfer[J]. Journal of Environmental Chemical Engineering, 2023, 11(5): 110800. |

| 22 | Zhang J J, Gao Z M, Cai Y T, et al. Mass transfer in gas-liquid stirred reactor with various triple-impeller combinations[J]. Chinese Journal of Chemical Engineering, 2016, 24(6): 703-710. |

| 23 | Xie M H, Xia J Y, Zhou Z, et al. Flow pattern, mixing, gas hold-up and mass transfer coefficient of triple-impeller configurations in stirred tank bioreactors[J]. Industrial & Engineering Chemistry Research, 2014, 53(14): 5941-5953. |

| 24 | Chen H, Zhang X B, Luo Z H. A CFD-PBM coupled method to optimize a pilot-scale stirred bioreactor[J]. Industrial & Engineering Chemistry Research, 2022, 61(23): 8302-8312. |

| 25 | Lane G L, Schwarz M P, Evans G M. Numerical modelling of gas-liquid flow in stirred tanks[J]. Chemical Engineering Science, 2005, 60(8/9): 2203-2214. |

| 26 | Khopkar A R, Kasat G R, Pandit A B, et al. CFD simulation of mixing in tall gas-liquid stirred vessel: role of local flow patterns[J]. Chemical Engineering Science, 2006, 61(9): 2921-2929. |

| 27 | Scargiali F, D'Orazio A, Grisafi F, et al. Modelling and simulation of gas-liquid hydrodynamics in mechanically stirred tanks[J]. Chemical Engineering Research and Design, 2007, 85(5): 637-646. |

| 28 | Pukkella A K, Vysyaraju R, Tammishetti V, et al. Improved mixing of solid suspensions in stirred tanks with interface baffles: CFD simulation and experimental validation[J]. Chemical Engineering Journal, 2019, 358: 621-633. |

| 29 | Wang T F, Wang J F, Jin Y. A CFD-PBM coupled model for gas-liquid flows[J]. AIChE Journal, 2006, 52(1): 125-140. |

| 30 | Gu D Y, Wen L, Xu H, et al. Study on hydrodynamics characteristics in a gas-liquid stirred tank with a self-similarity impeller based on CFD-PBM coupled model[J]. Journal of the Taiwan Institute of Chemical Engineers, 2023, 143: 104688. |

| 31 | Li S, Yang R Q, Wang C L, et al. CFD-PBM simulation on bubble size distribution in a gas-liquid-solid flow three-phase flow stirred tank[J]. ACS Omega, 2022, 7(2): 1934-1942. |

| 32 | Ramkrishna D. Theory and Applications to Particulate Systems in Engineering[M]. San Diego: Academic Press, 2000. |

| 33 | Luo H, Svendsen H F. Modeling and simulation of binary approach by energy conservation analysis [J]. Chemical Engineering Communications, 1996, 145(1): 145-153. |

| 34 | Green D W, Southard M Z. Perry's Chemical Engineers' Handbook[M]. 9th ed. New York: McGraw Hill, 2018. |

| 35 | Jamshidian R, Scully J, van den Akker. Two-fluid simulations of an aerated lab-scale bioreactor[J]. Chemical Engineering Research and Design, 2023, 196: 254-275. |

| 36 | Dhanasekharan K M, Sanyal J, Jain A, et al. A generalized approach to model oxygen transfer in bioreactors using population balances and computational fluid dynamics[J].Chemical Engineering Science, 2005, 60(1): 213-218. |

| 37 | 张志斌, 戴干策, 陈敏恒. 气液搅拌反应器功率消耗的研究[J]. 化学反应工程与工艺, 1985, 1(S1): 38-46. |

| Zhang Z B, Dai G C, Chen M H. Study on power consumption of gas-liquid stirred reactor[J]. Chemical Reaction Engineering and Technology, 1985, 1(S1): 38-46. |

| [1] | 李雨诗, 陈源, 李运堂, 彭旭东, 王冰清, 李孝禄. 新型柔性坝箔片端面气膜密封变形协调分析及性能智能优化[J]. 化工学报, 2025, 76(1): 324-334. |

| [2] | 任超, 王凯, 韩洁, 阳春华. 事件-时间触发的慢时变工业过程动态调度方法[J]. 化工学报, 2025, 76(1): 256-265. |

| [3] | 李海东, 张奇琪, 杨路, AKRAM Naeem, 常承林, 莫文龙, 申威峰. 采用智能进化算法的管壳式换热器详细设计[J]. 化工学报, 2025, 76(1): 241-255. |

| [4] | 黄娜, 蒋云龙, 王东涵, 吴明婷, 蒋雪莉, 钟豫. 通道振动频率对超临界正癸烷裂解流动换热影响的数值研究[J]. 化工学报, 2025, 76(1): 173-183. |

| [5] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [6] | 杨晔, 卢建刚. 基于融合Transformer的门尼系数预测建模研究[J]. 化工学报, 2025, 76(1): 266-282. |

| [7] | 张俊杰, 陈源, 李运堂, 李孝禄, 王冰清, 彭旭东. 超椭圆织构浮动坝箔片端面气膜密封动态性能分析与优化[J]. 化工学报, 2025, 76(1): 296-310. |

| [8] | 李彦, 郭红利, 苏国庆, 张建文. 加氢装置空冷器气液两相流动与冲刷腐蚀问题[J]. 化工学报, 2025, 76(1): 141-150. |

| [9] | 郭骐瑞, 任丽媛, 陈康, 黄翔宇, 马卫华, 肖乐勤, 周伟良. 用于HTPB推进剂浆料的静态混合管数值模拟[J]. 化工学报, 2024, 75(S1): 206-216. |

| [10] | 蒲黎明, 汪贵, 郑春来, 王科, 向腾龙, 王治红. 混合制冷级联天然气液化工艺优化及分析[J]. 化工学报, 2024, 75(S1): 267-275. |

| [11] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [12] | 王军锋, 张俊杰, 张伟, 王家乐, 双舒炎, 张亚栋. 液相放电等离子体分解甲醇制氢:电极配置的优化[J]. 化工学报, 2024, 75(9): 3277-3286. |

| [13] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [14] | 李倩, 张蓉民, 林子杰, 战琪, 蔡伟华. 基于机器学习的印刷电路板式换热器流动换热预测与仿真[J]. 化工学报, 2024, 75(8): 2852-2864. |

| [15] | 曹佳蕾, 孙立岩, 曾德望, 尹凡, 高子翔, 肖睿. 双流化床化学链制氢反应器的数值模拟[J]. 化工学报, 2024, 75(8): 2865-2874. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号